Dynamic reactive compensation system based on magnetic control electric reactor

A magnetically controlled reactor and compensation system technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, AC network to reduce harmonics/ripples, etc., can solve frequent operation, transformer capacity limitation, occupation Large land area and other problems, to reduce line loss, adjust network voltage, improve the effect of use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below with reference to the accompanying drawings:

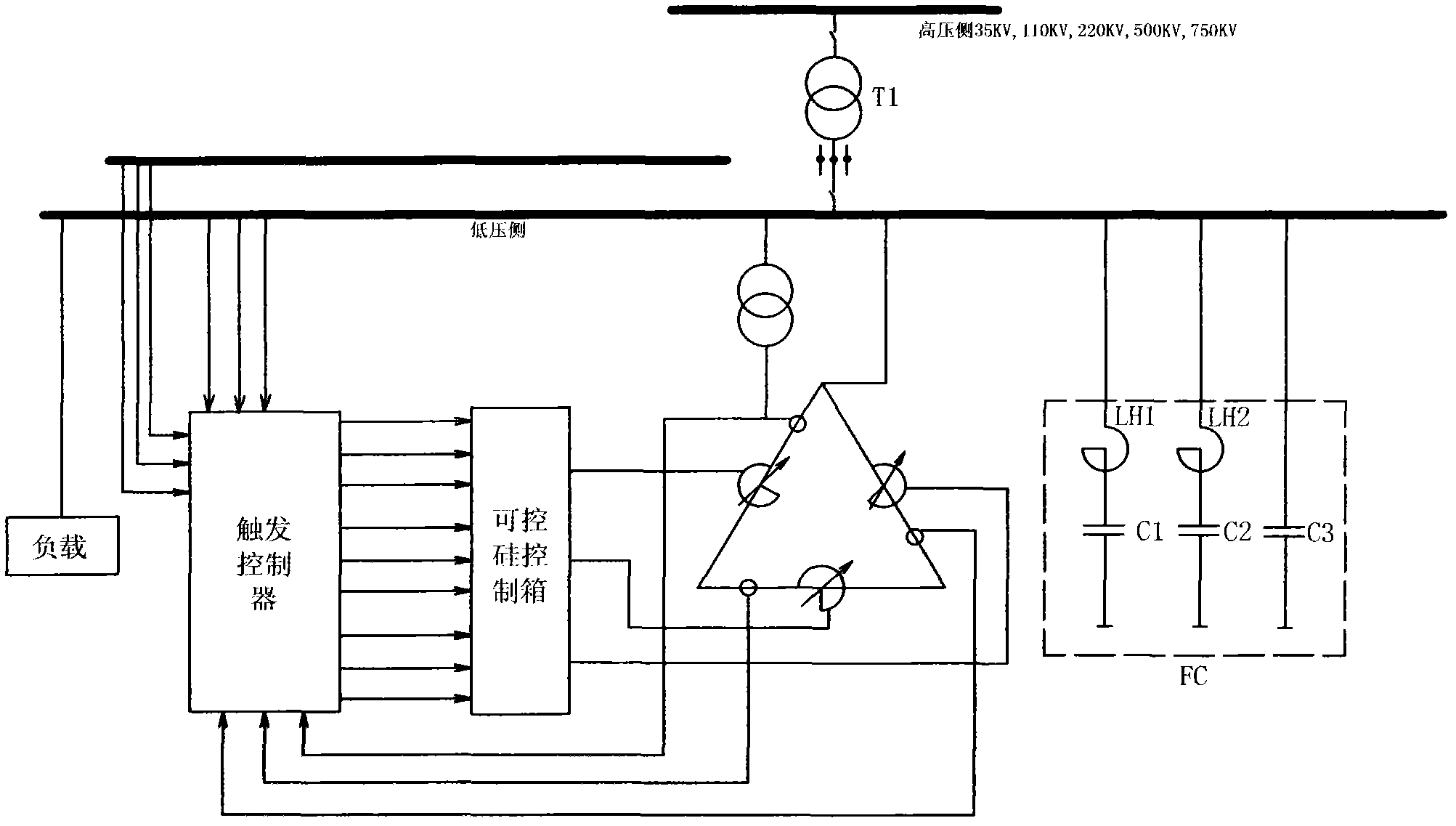

[0024] A dynamic reactive power compensation system based on a magnetron reactor, the system includes a passive filter FC for reactive power compensation and harmonic filtering and a magnetic Control reactor MCR;

[0025] The passive filter FC is provided with a filter reactor and a filter capacitor connected to the electrical equipment line; the passive filter FC includes a reactor LH1, LH2 and capacitors C1, C2, capacitor C3 arranged on the neutral line.

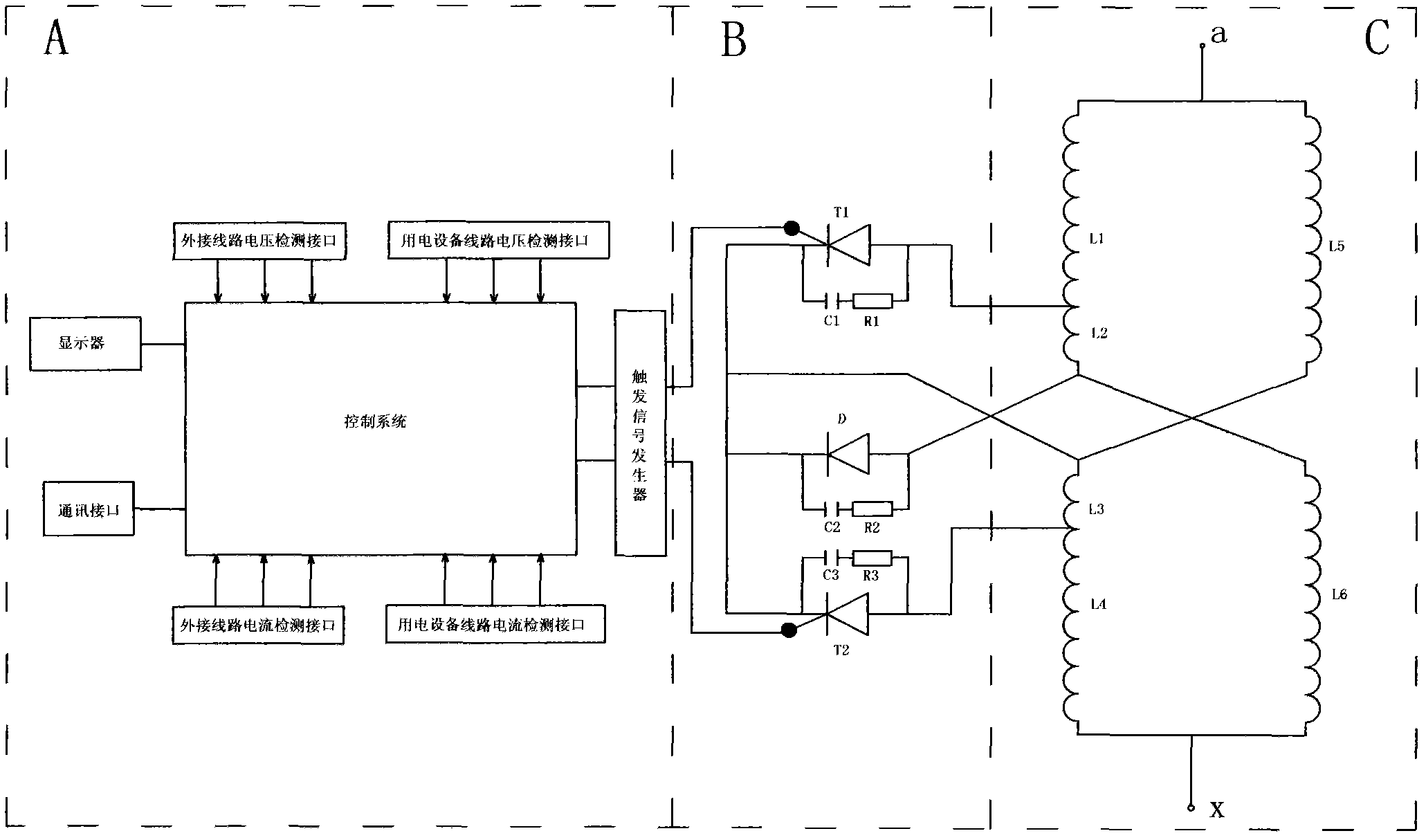

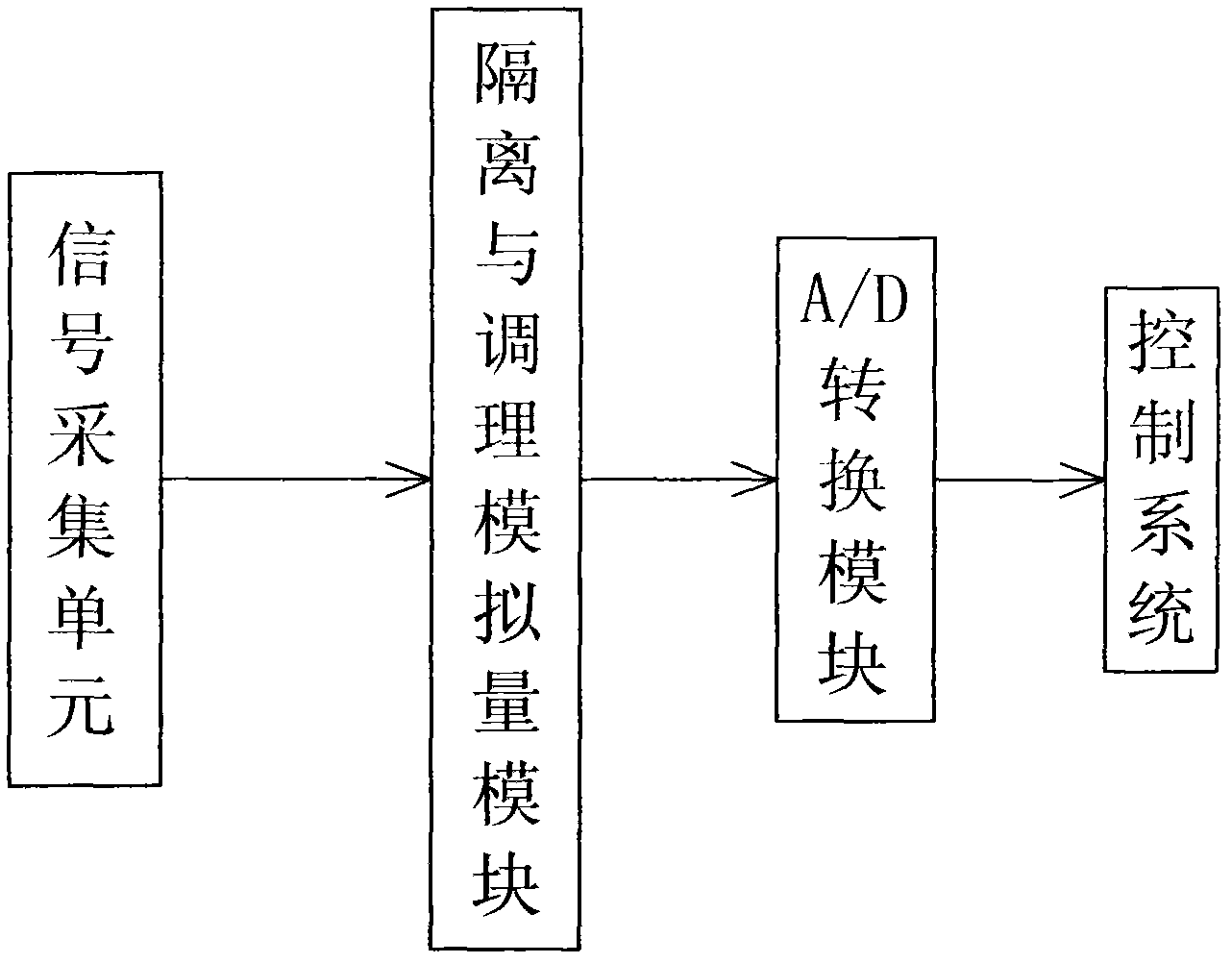

[0026] The magnetic control reactor MCR is a three-phase magnetic control reactor, including a reactor winding C, a rectifier thyristor controller B and a trigger controller A; each phase electric controller winding is composed of L1-L6, and the rectification is controllable Silicon controller B is composed of thyristor T1, T2, diode D, capacitors C1, C2, C3, resistors R1, R2, R3, trigger controller A is composed of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com