Heat treatment method of iron-based nanometer amorphous magnetic core material

A heat treatment method and nano-amorphous technology, which are applied in the field of heat treatment of iron-based nano-amorphous magnetic core materials, can solve the problems of grain refinement of magnetic cores, reduced efficiency, and are not conducive to the normal operation of equipment, so as to reduce hysteresis loss. , the effect of slow temperature rise process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

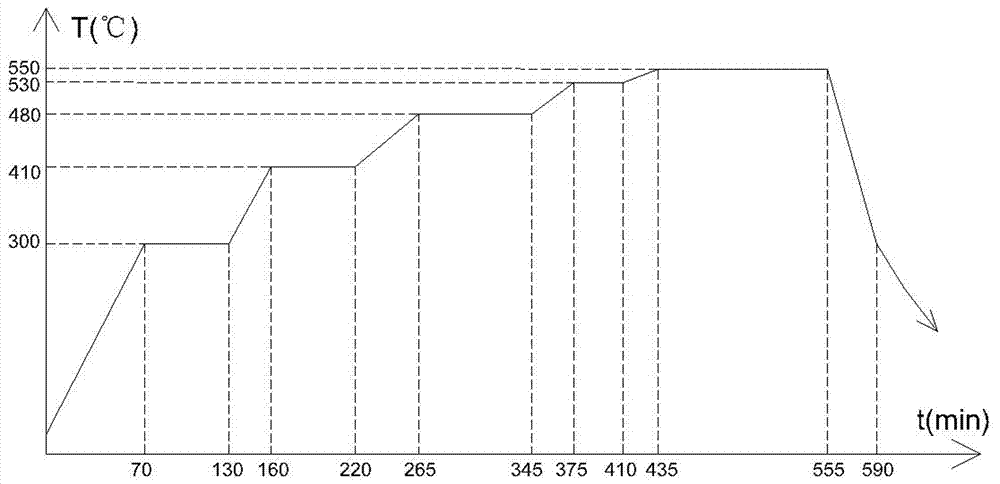

[0026] Embodiment 1: the heat treatment method of iron-based nano-amorphous magnetic core material, comprises the following steps:

[0027] Step 1: Put the iron-based nano-amorphous magnetic core material into a vacuum chamber, heat-treat the iron-based nano-amorphous magnetic core material, and keep the vacuum chamber filled with nitrogen during the heat treatment process;

[0028] Step 2: uniformly heat the iron-based nano-amorphous magnetic core material placed in the vacuum chamber from room temperature for 70 minutes until its temperature reaches 300°C, and keep it at a constant temperature for 60 minutes;

[0029] Step 3: After completing Step 2, continue to heat the iron-based nano-amorphous magnetic core material for 30 minutes to 410°C, and keep the temperature constant for 60 minutes;

[0030] Step 4: After completing Step 3, continue to heat the iron-based nano-amorphous magnetic core material for 45 minutes to 480°C, and keep the temperature constant for 80 minutes...

Embodiment 2

[0034] Embodiment 2: the heat treatment method of iron-based nano-amorphous magnetic core material, comprises the following steps:

[0035] Step 1: Put the iron-based nano-amorphous magnetic core material into a vacuum chamber, heat-treat the iron-based nano-amorphous magnetic core material, and keep the vacuum chamber filled with hydrogen during the heat treatment process;

[0036] Step 2: uniformly heat the iron-based nano-amorphous magnetic core material placed in the vacuum chamber from room temperature for 60 minutes until its temperature reaches 290°C, and keep it at a constant temperature for 50 minutes;

[0037] Step 3: After completing Step 2, continue to heat the iron-based nano-amorphous magnetic core material for 25 minutes to 420°C, and keep the temperature constant for 70 minutes;

[0038] Step 4: After completing Step 3, continue to heat the iron-based nano-amorphous magnetic core material for 40 minutes to 470°C, and keep the temperature constant for 85 minutes...

Embodiment 3

[0042] Embodiment 3: the heat treatment method of iron-based nano-amorphous magnetic core material, comprises the following steps:

[0043] Step 1: Put the iron-based nano-amorphous magnetic core material into a vacuum chamber, heat-treat the iron-based nano-amorphous magnetic core material, and keep the vacuum chamber filled with hydrogen during the heat treatment process;

[0044] Step 2: uniformly heat the iron-based nano-amorphous magnetic core material placed in the vacuum chamber from room temperature for 65 minutes until its temperature reaches 310°C, and keep it at a constant temperature for 70 minutes;

[0045] Step 3: After completing Step 2, continue to heat the iron-based nano-amorphous magnetic core material for 35 minutes to 400°C, and keep the temperature constant for 65 minutes;

[0046] Step 4: After completing Step 3, continue to heat the iron-based nano-amorphous magnetic core material for 50 minutes to 490°C, and keep the temperature constant for 75 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com