Leakage disengaging deivce of earth leakage breaker

An earth leakage circuit breaker and trip device technology, applied in circuit breaker parts, circuits, switchgear and other directions, can solve the problems such as the difficulty of effectively utilizing the space for circuit breakers to store, and the difficulty in assembling the device as a whole in a compact manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

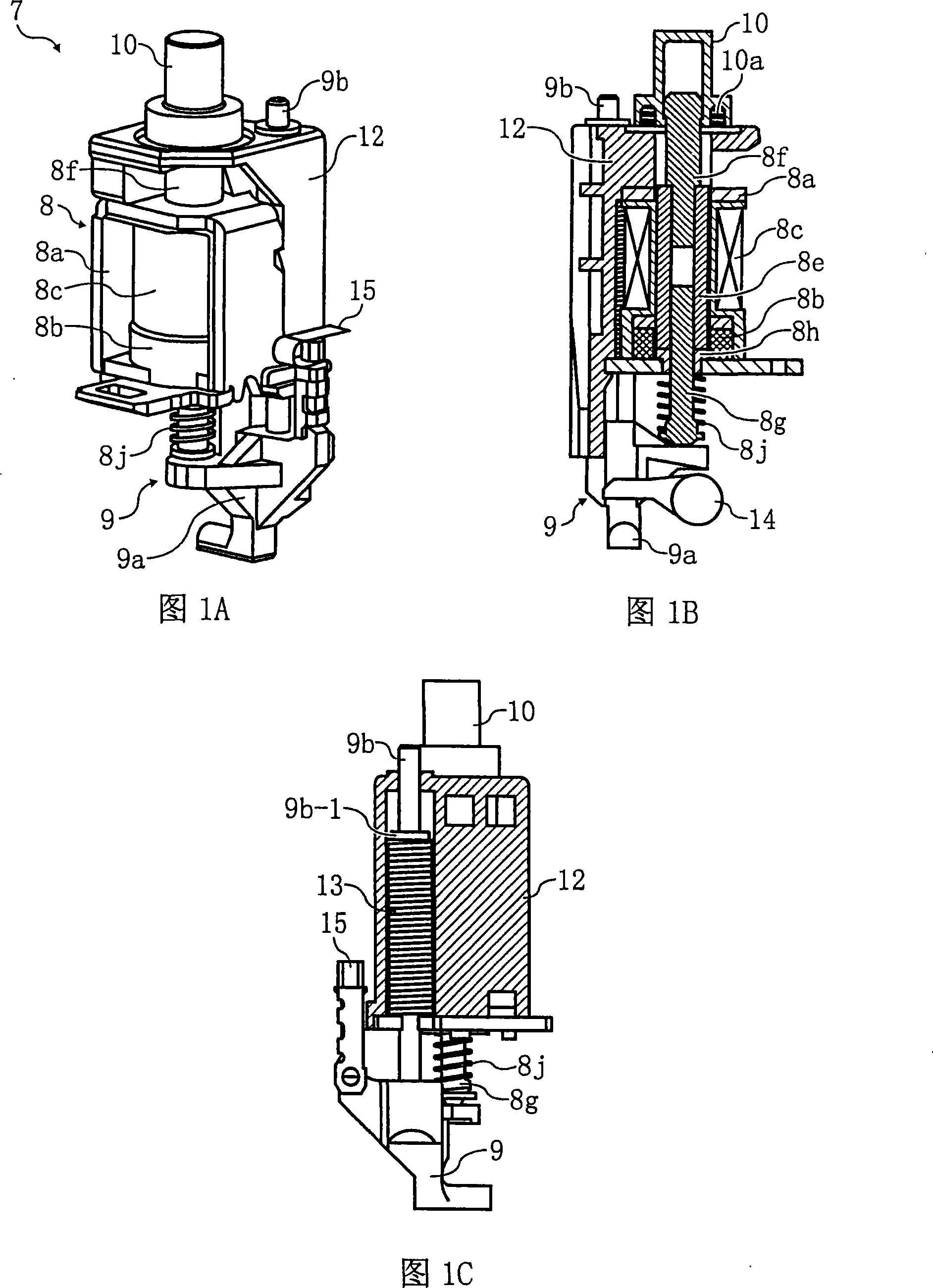

[0039] 1A to 1C and 2A to 2B to describe the structure and operation of the embodiment according to the technical solutions (1) to (3) of the present invention.

[0040] The leakage tripping device of the illustrated embodiment takes the leakage trip coil 8 as the core component, and assembles a trip actuator 9 and a pop-up type leakage display button 10 on it to form a unit structure, which is different from the prior art shown in FIG. 9 The structure is basically the same, however, in order to realize the miniaturization of the whole device, each part is connected and arranged as follows.

[0041] First, the leakage tripping coil 8 is provided with a permanent magnet 8b, a demagnetizing coil 8c wound on a bobbin, and a movable iron core 8e and a fixed iron core inside a yoke 8a composed of an inverted U-shaped leg piece and a bottom piece. The magnetic holding type electromagnet 8h is arranged on the assembly base 12 so that the permanent magnet 8b is arranged on the lower s...

Embodiment 2

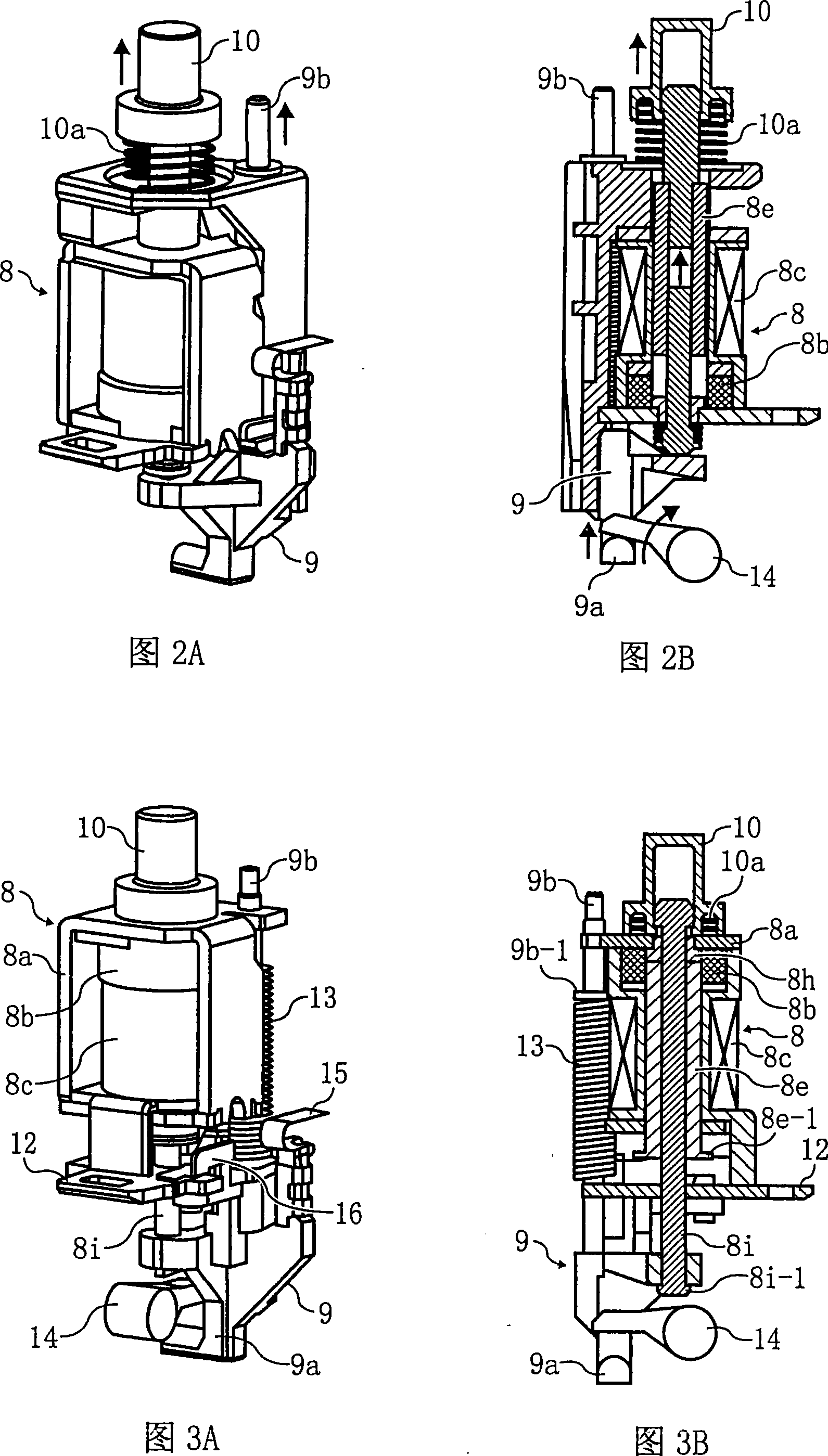

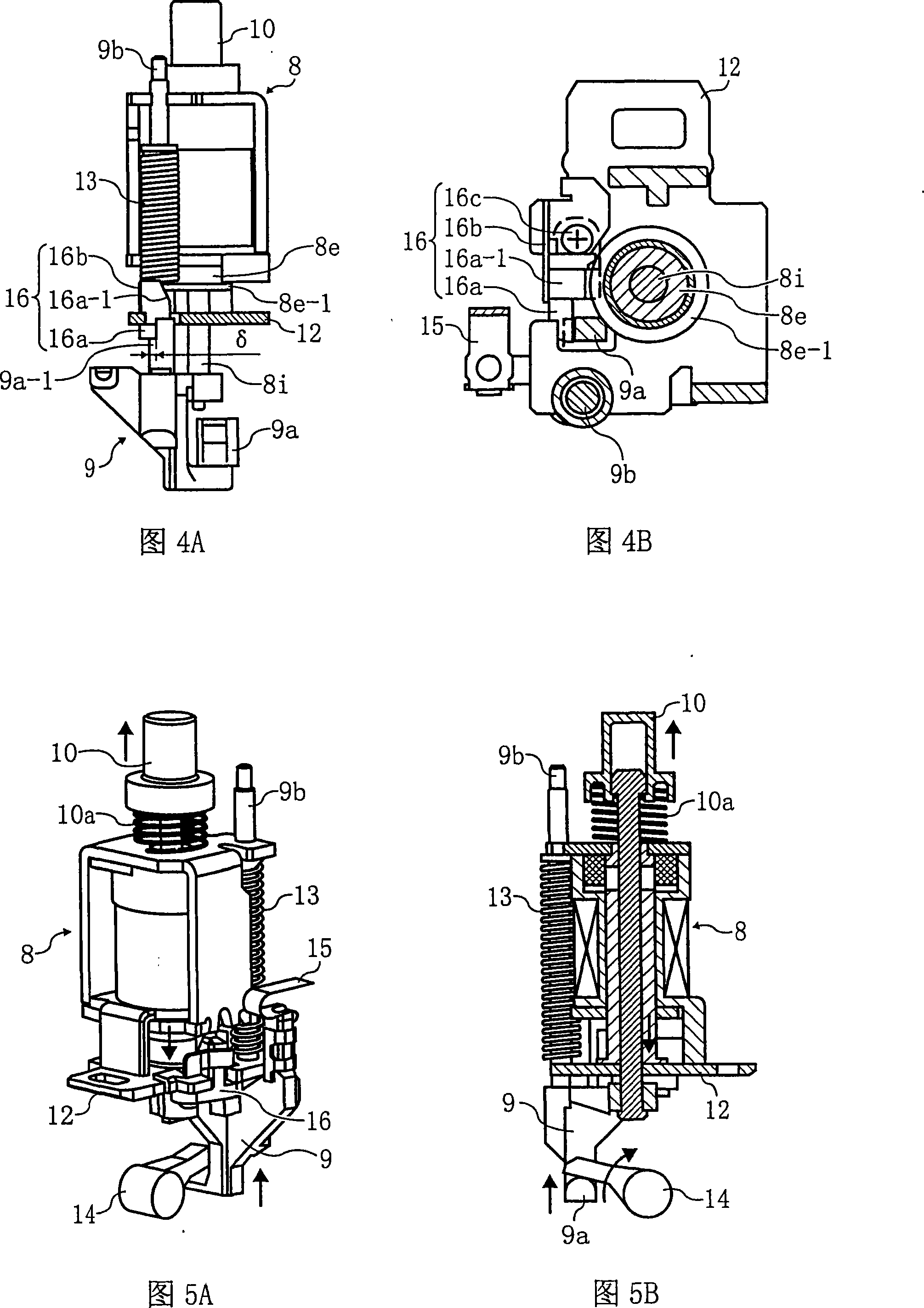

[0049] Next, an improved embodiment corresponding to technical solutions (4)-(5) of the present invention, which further develops the structure of the above-mentioned embodiment 1, will be described with reference to FIGS. 3A to 6B.

[0050] In this embodiment, the configuration of the leakage tripping coil 8, the tripping actuator 9, and the leakage display button 10 is the same as that of the above-mentioned embodiment 1, but the leakage tripping coil 8, and the connection between the leakage tripping coil 8 and the tripping actuator 9 The structure is different.

[0051] That is, on the yoke 8a, the permanent magnet 8b, the demagnetization coil 8c, the movable iron core 8e, and the trip coil 8 of the fixed iron core 8h are combined. - 1C) On the contrary, the permanent magnet 8b is arranged on the upper side of the demagnetization coil 8c and mounted on the assembly base 12 . In addition, a plunger shaft 8i made of a non-magnetic material is loosely fitted into a cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com