Glue valve and method for controlling same

A technology of glue valve and control ground, applied in the direction of valve operation/release device, valve heating/cooling device, valve details, etc., which can solve problems such as multi-space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

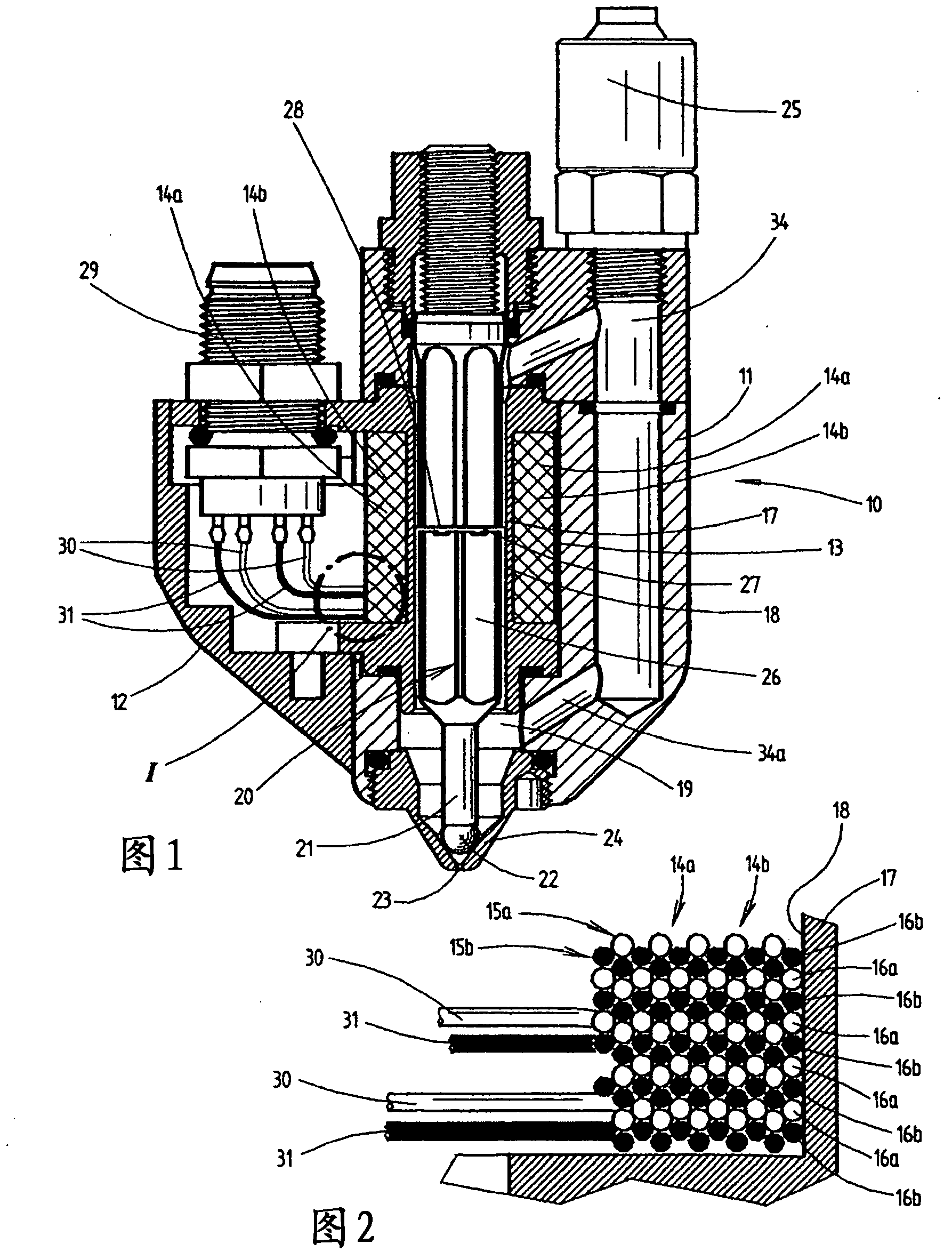

[0017] The glue valve 10 shown in the figures is preferably used to transfer smaller glue portions to the folded flaps of packaging, such as cigarette packs. The valve is designed for high cycle numbers.

[0018] The glue valve 10 includes a valve housing 11 and a plug housing 12 fixed thereon.

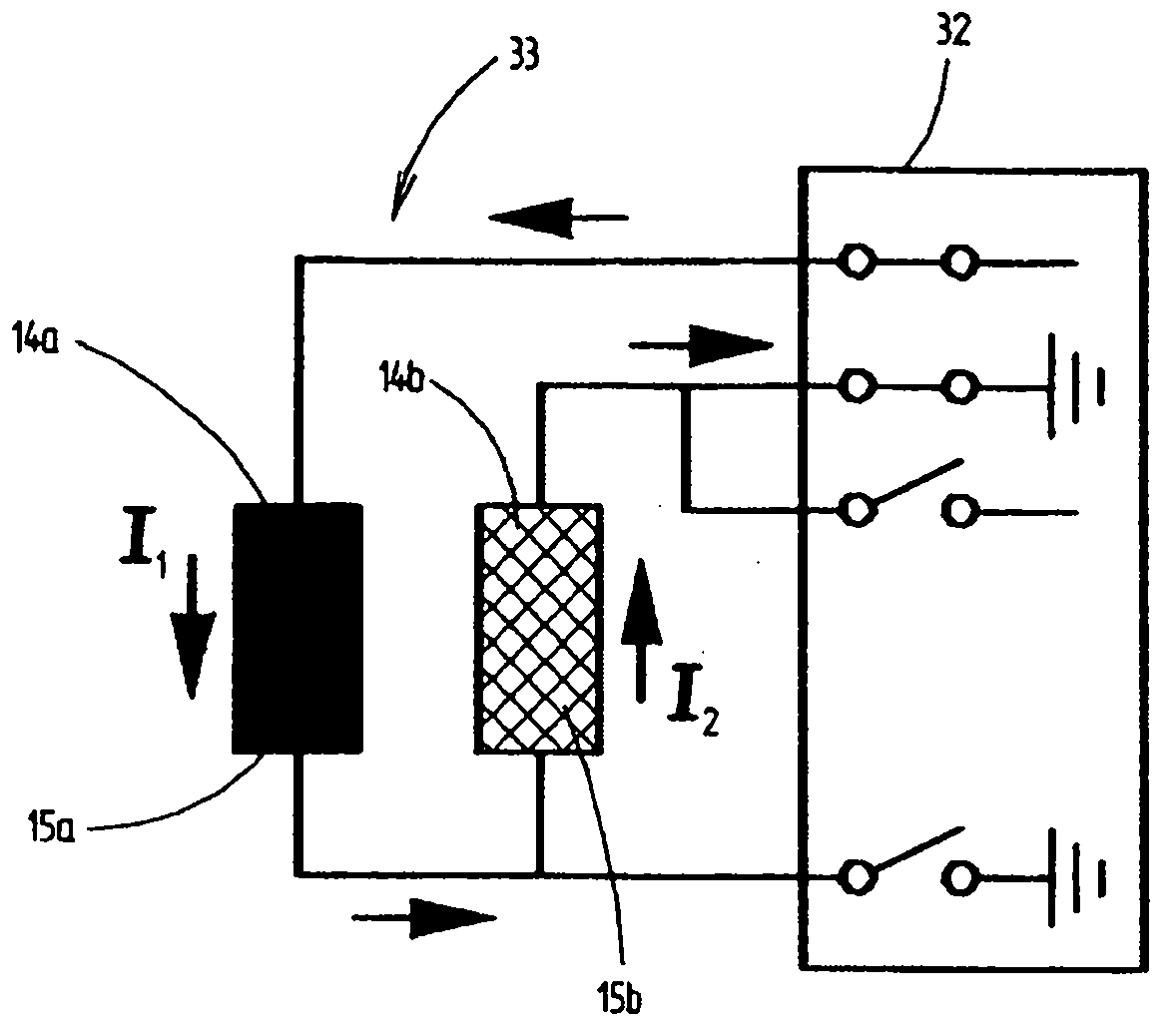

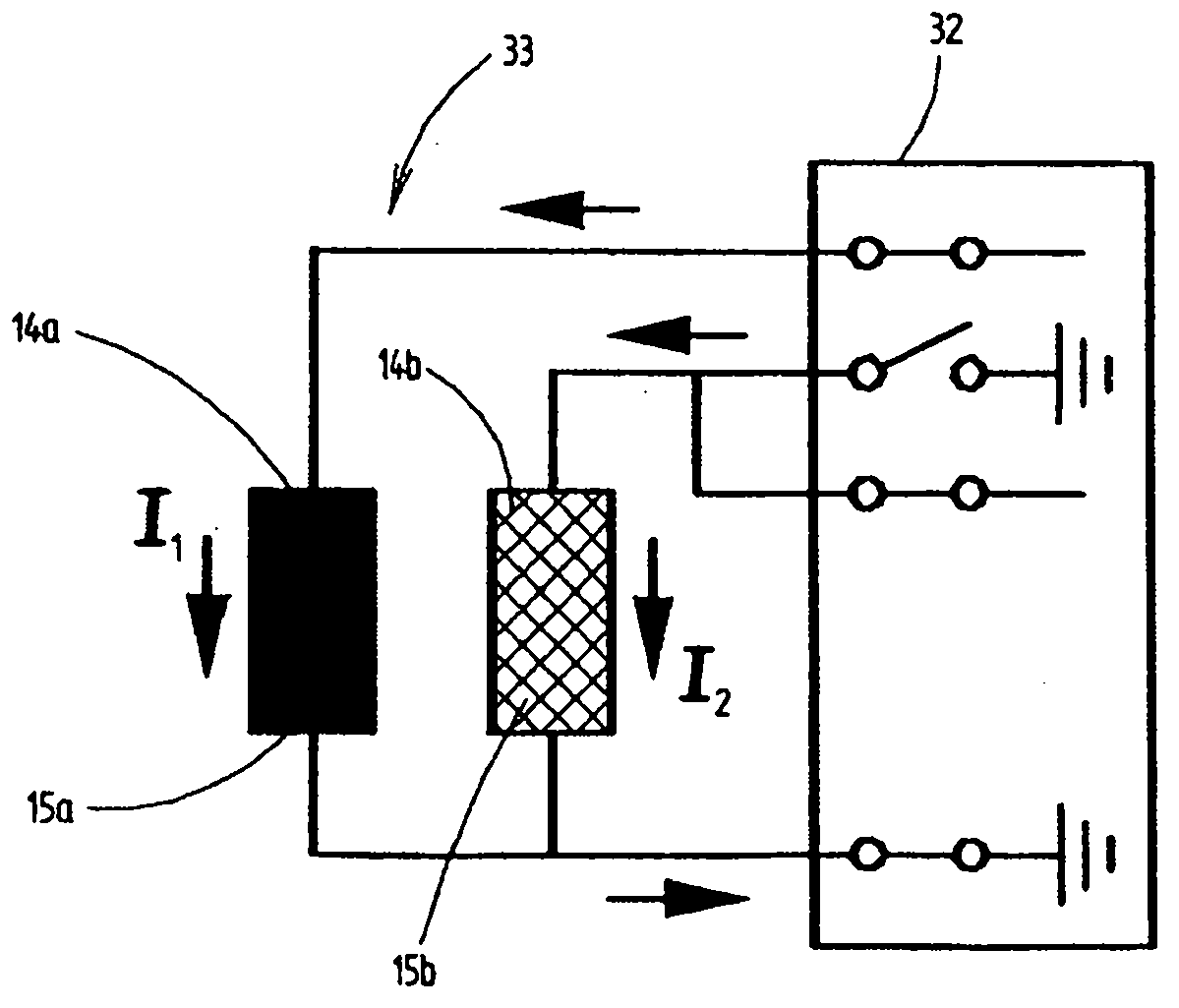

[0019] Inside the valve housing 11 , ie in the valve housing interior 13 , two electromagnets 14 a and 14 b are arranged. In principle, more than two electromagnets can also be used.

[0020] Each electromagnet 14a, 14b has a coil 15a, 15b comprising individual turns 16a, 16b.

[0021] In the present embodiment the coils 15a, 15b are wound on a coil former or coil body 17 . In this case, the coil body has a cylindrical surface 18 in the region of the windings of the coils 15a, 15b. Within the scope of the invention, such a coil body 17 can also be dispensed with, so that the coil is in this case designed without a support.

[0022] The coil body 17 is part of the valve chamber 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com