Low-noise transformer core for inverter power supply

A technology of transformer iron core and inverter power supply, which is used in the manufacture of inductors/transformers/magnets, transformers/inductor cores, circuits, etc. Effects of residual magnetism, noise reduction, and eddy current loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

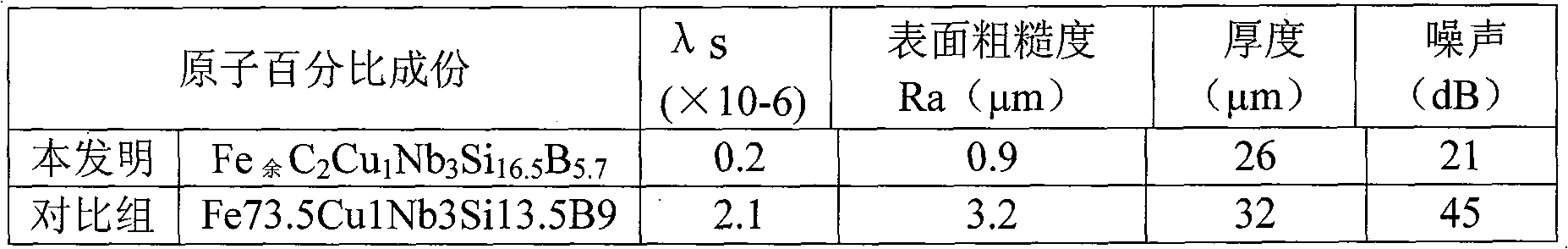

Examples

Embodiment 2

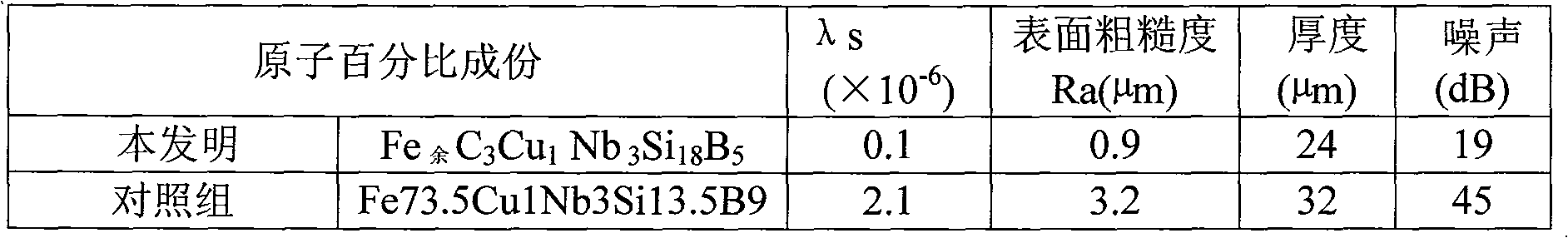

[0039] The ingredients are: Fe 余 C 3 Cu 1 Nb 3 Si 18 B 5 The alloy is made by the single roll method with a bandwidth of 30mm and a thickness of 24μm, and its λs is measured to be 0.1×10 -6 , wrapped into After adopting the same method as in Example 1 to operate the iron core, the measured noise is only 19dB. See comparison table.

[0040]

Embodiment 3

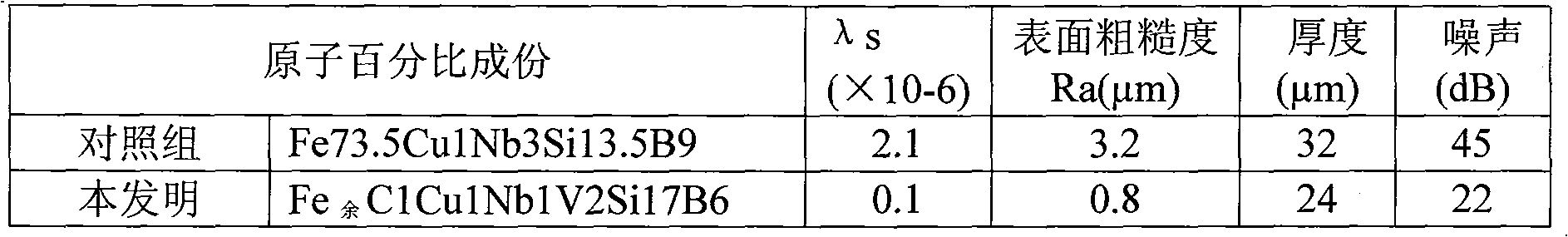

[0042] The ingredients are: Fe 余 C 1 Cu 1 Nb 1 V 2 Si 17 B 6 The alloy is made by the single roll method with a bandwidth of 30mm and a thickness of 24μm, and its λs is measured to be 0.1×10 -6 , wrapped into After the iron core is operated in the same way as in Example 1, its noise is measured to be only 22dB. See comparison table.

[0043]

Embodiment 4

[0045] This embodiment adopts the transformer manufactured by the same process as that of Embodiment 1. The difference from Embodiment 1 is that the transformer core made in this embodiment is not extruded; while the transformer core in Embodiment 1 is extruded. In order to illustrate the difference between the two types of transformer cores, the corresponding numerical values of the comparative examples are given at the same time, and the noise and core loss of the transformers are shown in the comparison table. It shows the influence of extrusion or non-extrusion on the performance of transformer iron core with the same composition alloy and the same heat treatment process.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com