MnZn power ferrite material for reducing negative temperature loss and preparation method thereof

A ferrite material and power technology, which is applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc. reduce the loss and other issues to achieve the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

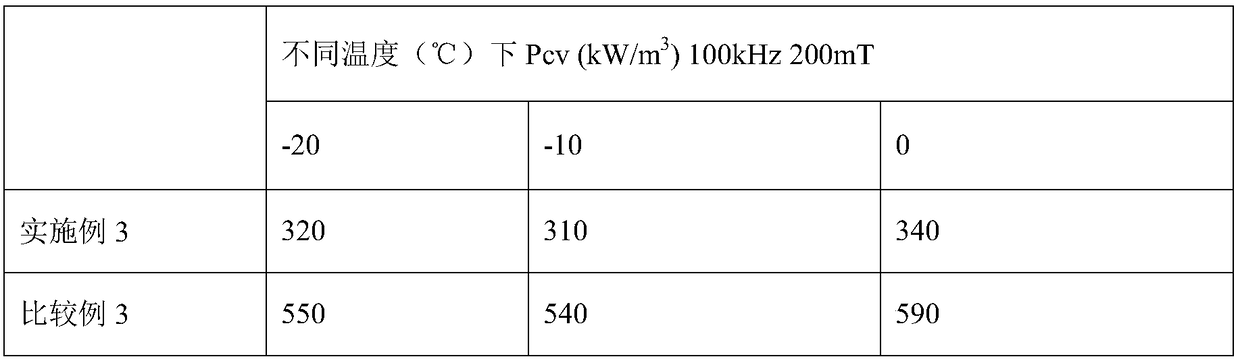

Examples

Embodiment 1

[0039] 52.6mol% Fe 2 o 3 And 10.2mol% of ZnO, the rest is the amount of MnO. Mix according to the ratio of ball water to 1:4:0.45, sand and crush in a sand mill for 1 hour, then spray and granulate, and put it into a rotary kiln for pre-calcination at 950°C. 0.04wt% CaCO 3 , 0.025wt% ZrO 2 and 0.35wt% Co 2 o 3 Add it to the calcined material, put the calcined material and additives into a sand mill, grind it for 160 minutes, then spray granulate, and press it into a standard ring under a certain pressure. Put the standard ring into a bell furnace for sintering, and the sintering temperature is 1300°C. Incubate for 5 hours with an oxygen content of 5%. Then cool under the protection of nitrogen. When the temperature drops to 1200°C, the oxygen content is controlled at 0.3%, and at 1150°C, the oxygen content is controlled at 0.95%, so that the MnZn power ferrite material with reduced negative temperature loss is obtained.

Embodiment 2

[0047] 52.7mol% Fe 2 o 3 And 9.7mol% of ZnO, the rest is the amount of MnO. Mix according to the ratio of ball water to 1:4:0.45, sand and crush in a sand mill for 1 hour, then spray and granulate, and put it into a rotary kiln for pre-calcination at 950°C. 0.06wt% CaCO 3 , 0.04wt% ZrO 2 and 0.4wt% Co 2 o 3 Add it to the calcined material, put the calcined material and additives into a sand mill, grind it for 160 minutes, then spray granulate, and press it into a standard ring under a certain pressure. Put the standard ring into a bell furnace for sintering, and the sintering temperature is 1300°C. Incubate for 5 hours with an oxygen content of 6%. Then cool under the protection of nitrogen. When the temperature drops to 1200°C, the oxygen content is controlled at 1.5%, and at 1150°C, the oxygen content is controlled at 0.1%, and then cooled to room temperature under the protection of nitrogen.

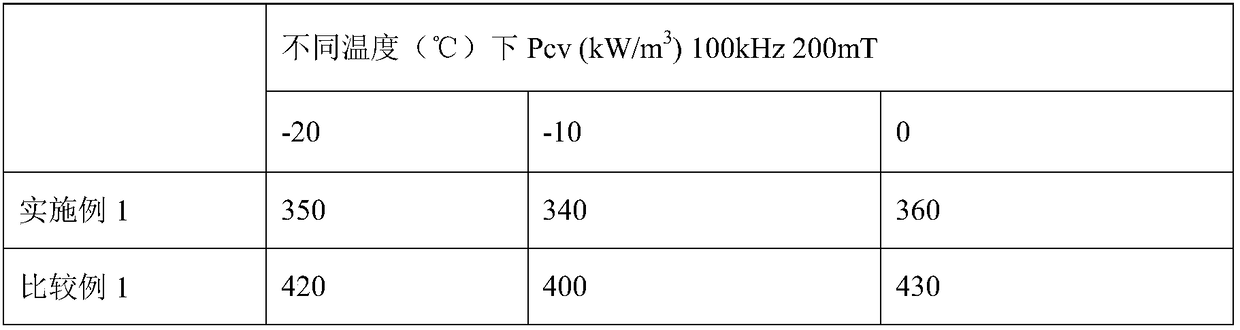

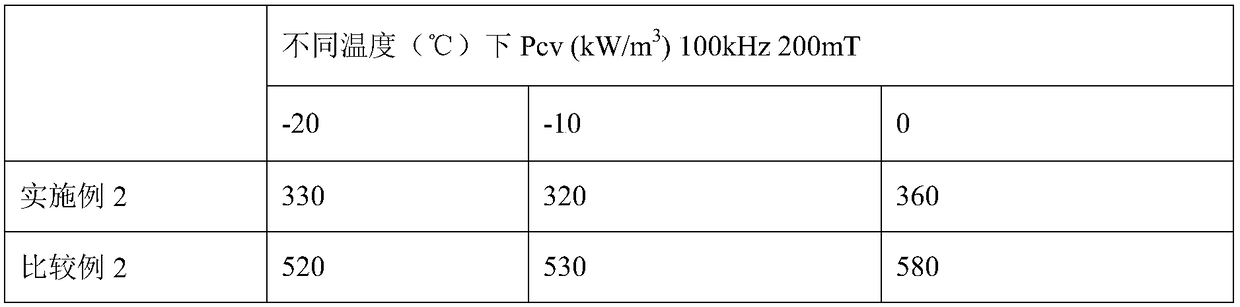

Embodiment 2 and comparative example 2

[0051] Table 2 embodiment 2 and comparative example 2 sample ring test results

[0052]

[0053] As can be seen from Table 2, in Comparative Example 2 Co 2 o 3 The amount is beyond the range of the present invention, resulting in relatively poor loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com