Inorganic binder used for metal soft magnetic powder core and metal soft magnetic powder core

An inorganic binder and metal soft magnetic technology, applied in the field of metal powder alloys, can solve the problems of being unsuitable for large-scale promotion and use, unsuitable for large-scale promotion, environmental damage, etc., and achieve stable performance, good high temperature resistance, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

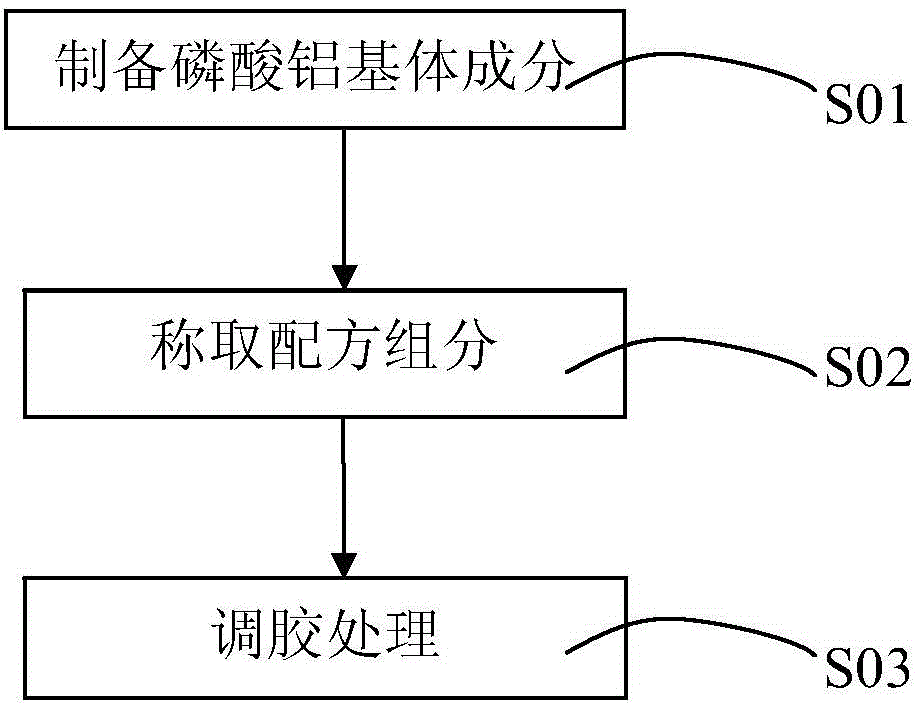

[0045] Correspondingly, an embodiment of the present invention provides a method for preparing an inorganic binder used in the preparation of metal soft magnetic powder cores, including the following steps, specifically as attached figure 1 Shown:

[0046] S01. Prepare aluminum phosphate matrix components;

[0047] S02. Weighing the formula components: Weighing each component according to the above-mentioned formula of the inorganic binder used for the preparation of the metal soft magnetic powder core;

[0048] S03. Glue adjustment treatment: Mix the above-mentioned components except the aggregate to obtain a pre-mixture, then add the aggregate into the pre-mixture, mix uniformly at 70-100°C, and cool.

[0049] Specifically, in the above step S01, the preparation method of the aluminum phosphate matrix component is: according to the weight ratio of 33:1, respectively measure phosphoric acid and aluminum hydroxide with a concentration of 85% by weight, and heat treatment to o...

Embodiment 1

[0077] An inorganic binder used for the preparation of metal soft magnetic powder cores, based on the total weight of the inorganic binder as 100%, the formula components and corresponding component contents included in it are shown in Example 1 in the following table 1, wherein The matrix is an aluminum phosphate matrix, the curing agent is zinc oxide, the aggregate is divided into aggregate I and aggregate II, the aggregate I is kaolin, the aggregate II is silica, and the aggregate II is silica. The additives are sodium phosphate, sodium tungstate and oxalic acid.

[0078] The preparation method of the inorganic binder used for the preparation of the metal soft magnetic powder core is:

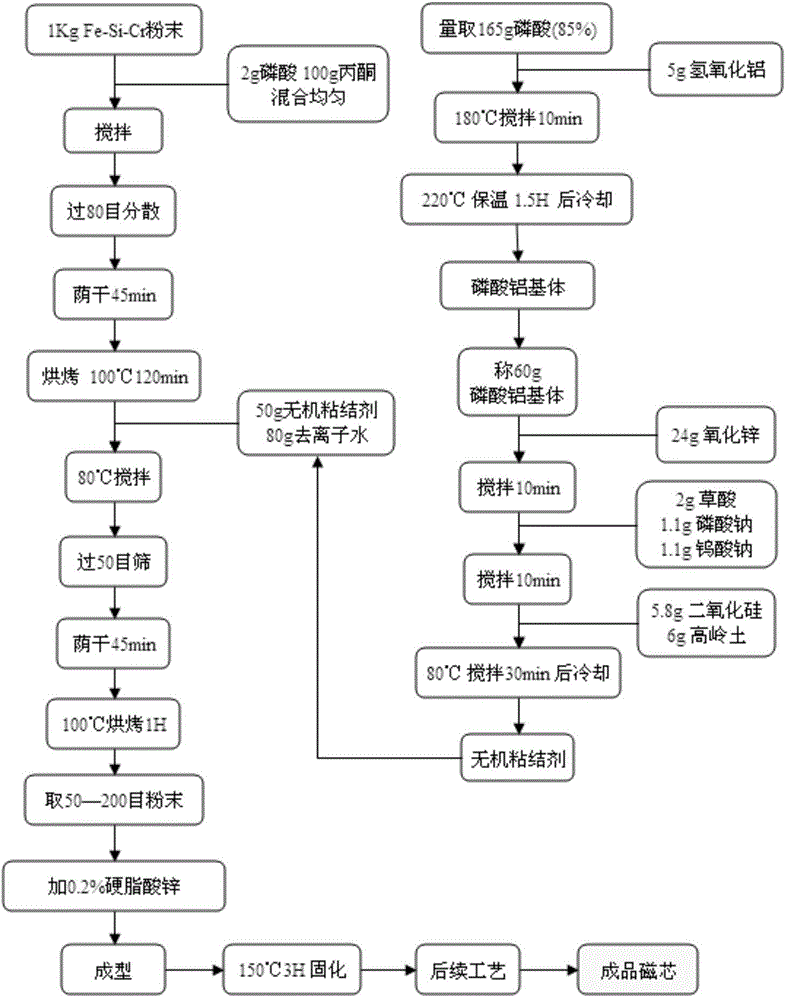

[0079] S11. Preparation of aluminum phosphate matrix components: Measure 165g of phosphoric acid (85%), add 5g of aluminum hydroxide, heat to 180°C and stir for 5-10min until the solution becomes a colorless, transparent viscous liquid, continue to heat up to 220°C, and keep for 1 -After ...

Embodiment 2

[0083] An inorganic binder used for the preparation of metal soft magnetic powder cores, based on the total weight of the inorganic binder as 100%, the formula components it includes and the content of the corresponding components are shown in Example 2 in the following table 1, wherein The matrix is an aluminum phosphate matrix, the curing agent is copper oxide, the aggregate is divided into aggregate I and aggregate II, the aggregate I is kaolin, the aggregate II is silica, and the aggregate II is silica. The additives are sodium phosphate, sodium tungstate and oxalic acid.

[0084] The preparation method of the inorganic binder used for the preparation of the metal soft magnetic powder core is:

[0085] S21. Preparation of aluminum phosphate matrix components: according to the ratio of 33:1 by weight, measure phosphoric acid and aluminum hydroxide with a concentration of 85% by weight respectively, heat treatment to obtain a colorless transparent viscous liquid, and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com