Hydraulic forming machine set for moulding and solidifying biomass

A technology of solidification liquid and mold forming, which is applied in the direction of material forming presses, presses, manufacturing tools, etc. It can solve the problems of low density of forming blocks, poor combustion performance, short service life, etc., and achieve high calorific value and molding density. High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

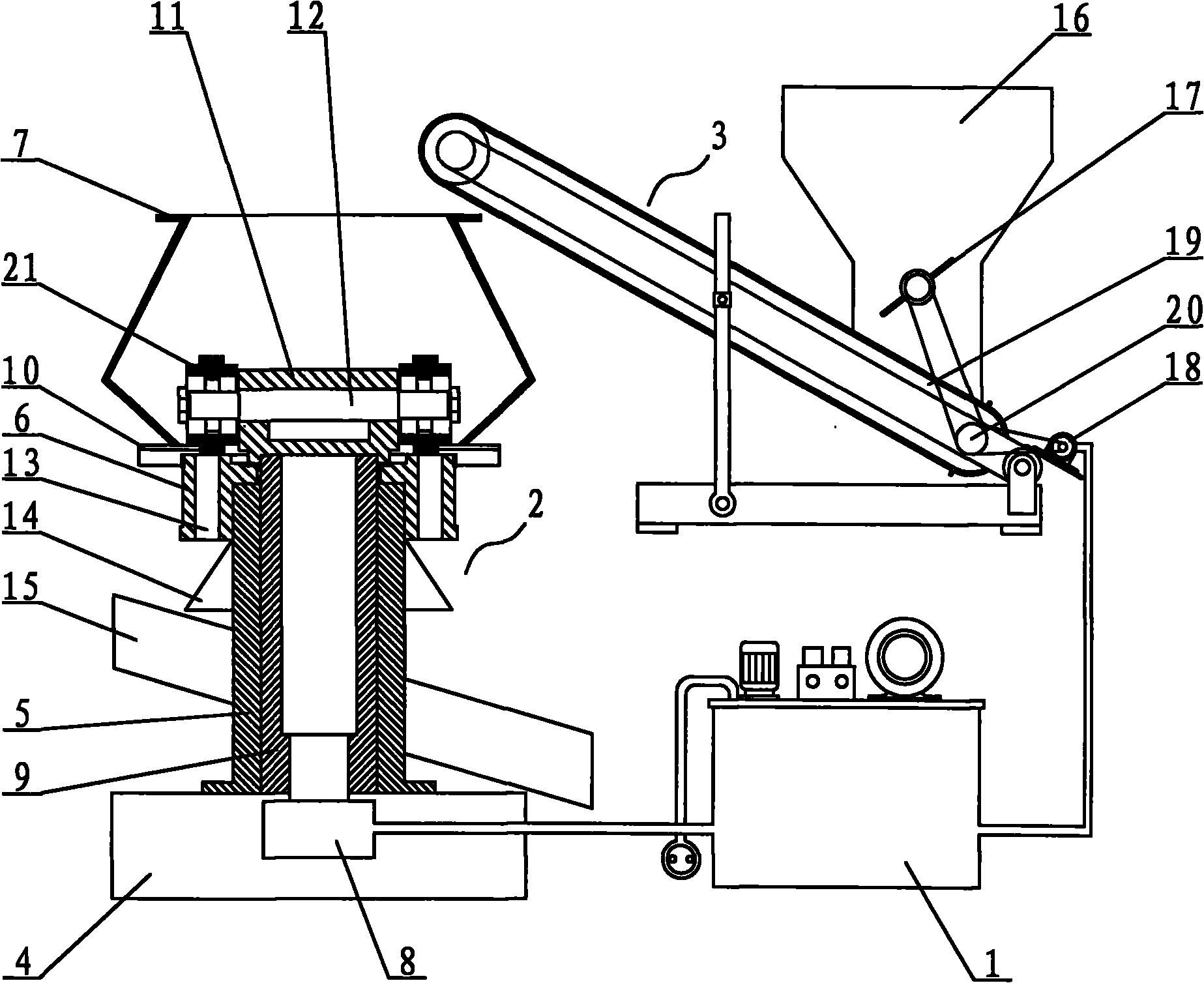

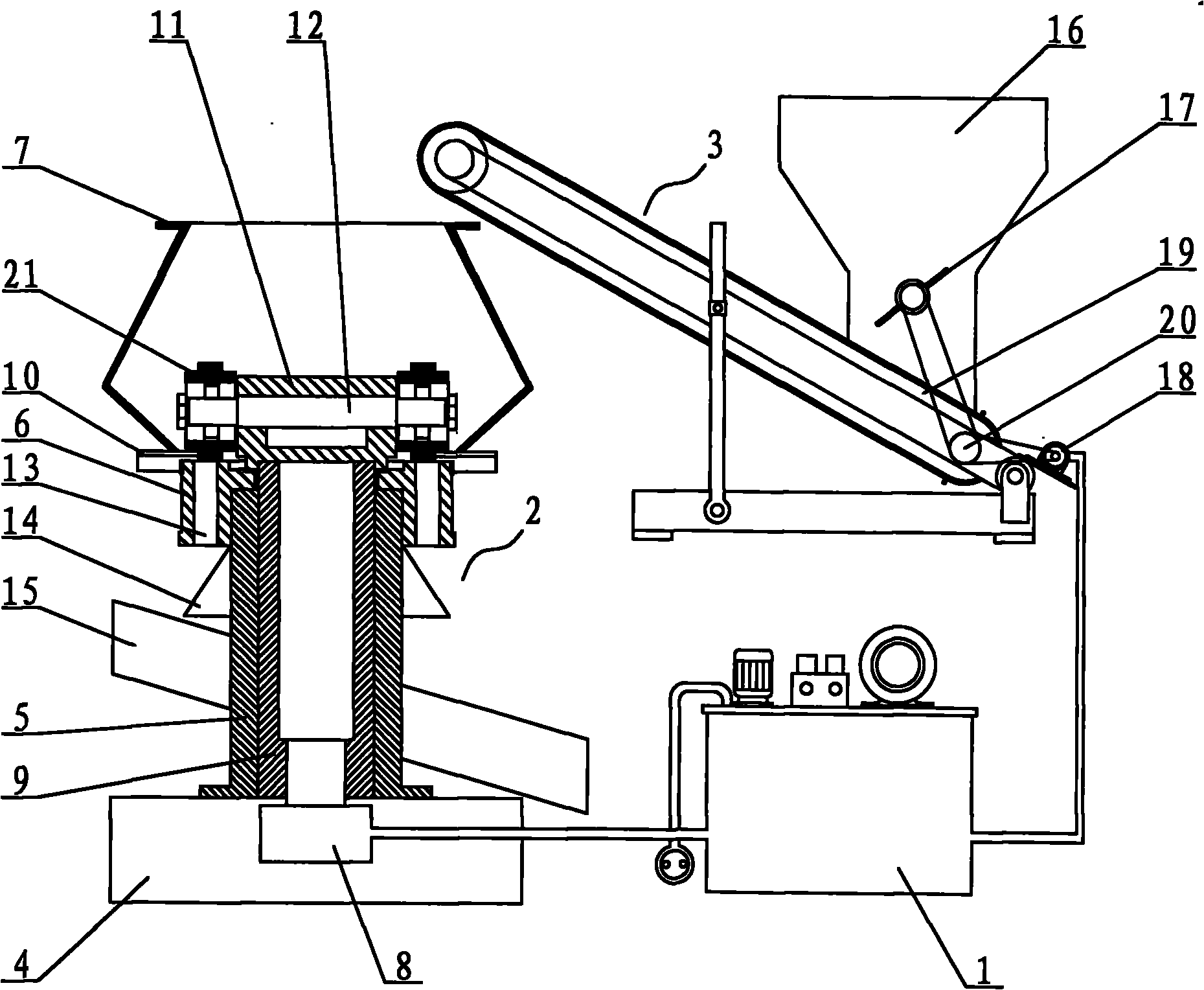

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

[0015] figure 1 The biomass solidification liquid molding unit shown mainly includes a molding machine 2, a feeding machine 3 and a hydraulic station 1 controlled by a control cabinet. The feeder 3 includes a hopper 16 and a conveyor belt 19, the hopper 16 is arranged above the conveyor belt 19, the hopper 16 is provided with a monolithic roller 17 for adjusting and feeding, the active rotating shaft 20 of the conveyor belt 19 is connected to the rotating shaft motor 18, The rotary shaft motor 18 is connected with the hydraulic station 1; the forming machine 2 includes a machine base 4, a support cylinder 5, a pressing plate 6 and an upper material cylinder 7, and a spindle motor 8 is arranged in the machine base 4, and the spindle motor 8 is connected with the hydraulic station 1, The supporting cylinder 5 is provided with a main shaft 9 vertically connected to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com