Method for preparing molybdenum target

A molybdenum target and molybdenum powder technology is applied in the field of thin film material preparation to achieve the effects of simple and low operation, improved safety and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

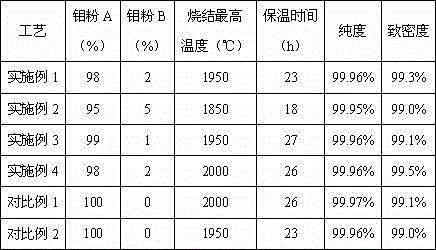

Embodiment 1

[0023] Purchase commercially available purity of 99.95%, average particle size of 2.8 μm micron molybdenum powder and purity of 99.9%, average particle size of 100nm nano-molybdenum powder, weighing 98kg micron molybdenum powder and 2kg nano-molybdenum powder, in the V-shaped mixer Mix in medium for 60 minutes; put the evenly mixed molybdenum powder into the rubber sheath, and use a cold isostatic press to form it under a pressure of 240MPa. The formed molybdenum billet is sintered in a vacuum sintering furnace: firstly, the temperature is raised to 800°C for 2 hours; then the temperature is raised from 800°C to 1200°C for 2 hours, and kept at 1200°C for 1 hour; and then the temperature is raised from 1200°C to 1400°C for 2 hours. ℃, and kept at 1400℃ for 4 hours; then heated from 1400℃ to the highest temperature of 1950℃ in 6 hours, and kept at the highest temperature for 23h. After sintering, it is hot rolled at 1400°C, vacuum heat treated at 900°C for 3 hours, and machined ...

Embodiment 2

[0025] Purchase commercially available micron molybdenum powder with a purity of 99.95% and an average particle size of 1 μm and a nanometer molybdenum powder with a purity of 99.9% and an average particle size of 50 nm. Weigh 95 kg of micron molybdenum powder and 5 kg of nanometer molybdenum powder in a V-type mixer. 60min; put the evenly mixed molybdenum powder into the rubber sheath, and use a cold isostatic press to form it under a pressure of 170MPa. The formed molybdenum billet is sintered in a vacuum sintering furnace: firstly, the temperature is raised to 800°C for 2 hours; then the temperature is raised from 800°C to 1200°C for 2 hours, and kept at 1200°C for 1 hour; and then the temperature is raised from 1200°C to 1400°C for 2 hours. ℃, and kept at 1400℃ for 4 hours; then heated from 1400℃ to the highest temperature of 1800℃ over 6 hours, and kept at the highest temperature for 35h. After sintering, it is hot rolled at 1450°C, vacuum heat treated at 1000°C for 5 hou...

Embodiment 3

[0027] Purchase commercially available micron molybdenum powder with a purity of 99.95% and an average particle size of 5 μm and a nanometer molybdenum powder with a purity of 99.9% and an average particle size of 200 nm. Weigh 99 kg of micron molybdenum powder and 1 kg of nanometer molybdenum powder in a V-type mixer. 60min; put the uniformly mixed molybdenum powder into the rubber sheath, and use a cold isostatic press to form it under a pressure of 250MPa; the formed molybdenum billet is sintered in a vacuum sintering furnace: firstly, the temperature is raised to 800°C for 2 hours; then Raise the temperature from 800°C to 1200°C in 2 hours, and keep it at 1200°C for 1 hour; then raise the temperature from 1200°C to 1400°C in 2 hours, and keep it at 1400°C for 4 hours; ℃, and kept at the highest temperature for 18h. After sintering, it is hot-rolled at 1300°C, vacuum heat-treated at 1100°C for 2 hours, and machined into a molybdenum target. The purity of the obtained molyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com