Metal aluminum-zinc composite low-carbon aluminum carbon sliding plate and preparation method

A metal composite and metal aluminum technology, which is applied in metal processing equipment, casting equipment, manufacturing tools, etc., can solve the problems such as the decrease of the medium-temperature strength of the slide plate, the sliding surface is easy to rough, and the casting hole is not resistant to erosion, so as to improve the service life and improve the High-temperature mechanical properties, corrosion-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

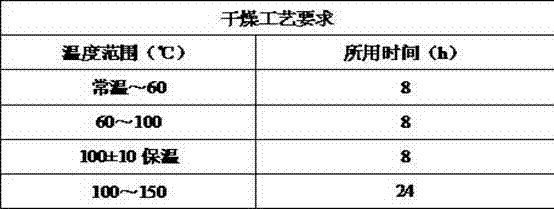

Image

Examples

Embodiment 1

[0031] A method for preparing metal-aluminum-zinc composite low-carbon aluminum-carbon sliding plate unfired bricks, the raw materials are composed of 25wt% white corundum, 36wt% dense corundum, 17wt% tabular corundum, 4.5wt% Al powder, Zn powder 0.5 wt%, activated alumina fine powder 10 wt%, graphite 1 wt%, carbon black 1 wt%, B 4 C 2 wt%, ZrB 2 2 wt%, CaB 6 1 wt%, plus 4~4.5 wt%.

[0032] 1) Firstly mix metal aluminum powder with a particle size of less than 0.044mm and a purity of more than 98.5% and metal zinc powder with a particle size of less than 0.040mm and a purity of more than 99.5%, and then mix fine corundum powder, activated alumina powder, graphite, carbon black, B 4 C. ZrB 2 and CaB 6 Mix evenly, then add the metal aluminum and zinc composite powder mixed in advance, and mix in a double-cone mixer to make a mixed powder;

[0033] 2) Take 3-0mm white corundum particles, 3-0mm dense corundum particles and 3-0mm plate-shaped corundum particles for stirrin...

Embodiment 2

[0038] A method for preparing metal-aluminum-zinc composite low-carbon aluminum-carbon sliding plate non-burning bricks. According to weight percentage, its raw materials are composed of white corundum 35wt%, dense corundum 29 wt%, tabular corundum 15 wt%, Al powder 14 wt%, Zn powder 1 wt%, activated alumina fine powder 3 wt%, graphite 2 wt%, B 4 C 1 wt%, plus 4~4.5 wt%.

[0039] 1) Firstly mix metal aluminum powder with a particle size of less than 0.044mm and a purity of more than 98.5% and metal zinc powder with a particle size of less than 0.040mm and a purity of more than 99.5%, and then mix corundum fine powder, activated alumina fine powder, graphite and B 4 C Mix evenly, then add the metal aluminum and zinc composite powder mixed in advance, and mix it into a mixed powder in a double-cone mixer;

[0040] 2) Take 3-0mm white corundum particles, 3-0mm dense corundum particles and 3-0mm plate-shaped corundum particles for stirring and mixing, and take another 4-4.5wt% res...

Embodiment 3

[0044] A method for preparing metal-aluminum-zinc composite low-carbon aluminum-carbon sliding plate non-fired bricks. According to weight percentage, its raw materials are composed of dense corundum 33 wt%, plate-shaped corundum 49wt%, Al powder 8 wt%, Zn powder 3 wt%, Activated alumina micropowder 5 wt%, B 4 C 1 wt%, ZrB 2 1 wt%, plus 4~4.5 wt%.

[0045] 1) Firstly mix metal aluminum powder with a particle size of less than 0.044mm and a purity of more than 98.5% and metal zinc powder with a particle size of less than 0.040mm and a purity of more than 99.5%, and then mix corundum fine powder, activated alumina fine powder, B 4 C and ZrB 2 Mix evenly, then add the metal aluminum and zinc composite powder mixed in advance, and mix in a double-cone mixer to make a mixed powder;

[0046] 2) Take 3-0mm white corundum particles, 3-0mm dense corundum particles and 3-0mm plate-shaped corundum particles for stirring and mixing, and take another 4-4.5wt% resin, first add 2 / 3 to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com