Low-cost manufacture method of high-quality diaphragm and filter plate

A manufacturing method and high-quality technology, applied in the direction of household components, household appliances, and other household appliances, can solve the problems of high clamping force of the press, high injection molding power, and high mold cost, so as to reduce injection molding costs and increase molding density. , stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

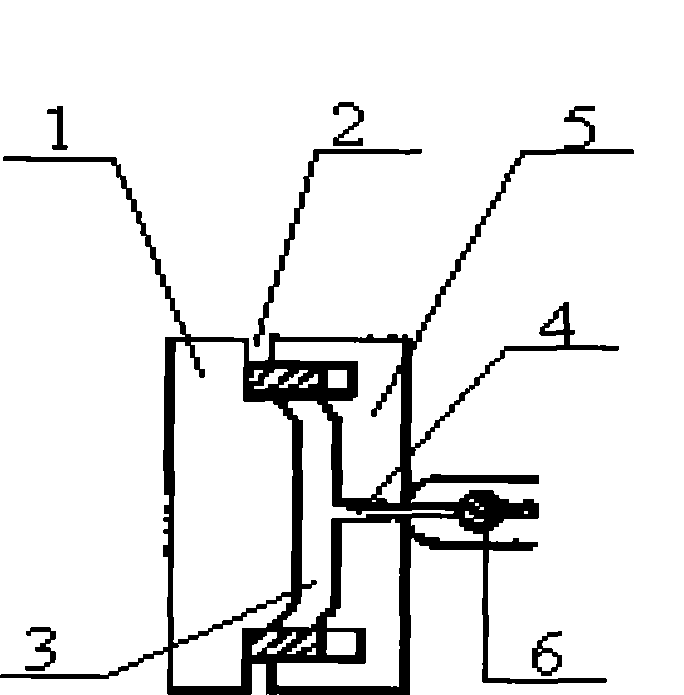

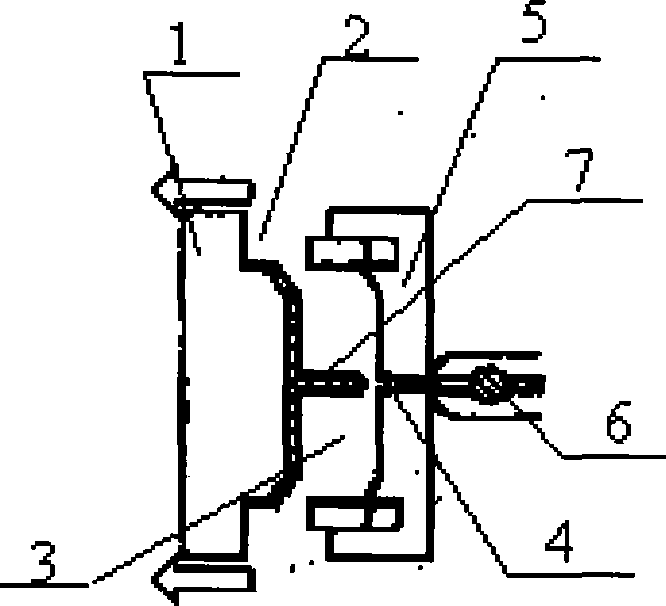

[0015] Embodiment 1: with reference to attached figure 1 and 2 . A low-pressure manufacturing method for high-quality diaphragms and filter plates, (1) There is a large gap 3 between the cavity of the lower die 1 and the cavity of the upper die 5 for manufacturing the diaphragm or filter plate, and the surroundings of the gap 3 can be in a closed state, That is to say, between the mold cavity of the lower mold 1 and the upper mold 2, depending on the thickness and size of the product, there is a gap of more than 6-16mm, and the distance around the distance forms a sealed (or not completely sealed) mold with the lower mold 1 and the upper mold 5. Cavity 3, under the situation that can not leak molten plastic body to outside mold frame; (2) then the plastics of molten state in injection molding machine cylinder 6 is quantitatively low pressure ( far lower than the conventional injection pressure of 70MPa) into the cavity 3 formed by the lower mold 1 and the upper mold 5 (the i...

Embodiment 2

[0019] Example 2: A low-cost manufacturing method for high-quality diaphragms and filter plates. Quantitative injection of molten plastic into the mold cavity between the lower mold and the upper mold leaves a large distance and the surrounding distance can be in a closed or nearly closed state. Using the upper and lower The parallel surface accuracy of the mold is used as the precision of controlling the parallelism and thickness of the product or as the control precision of the parallelism and depth of the filter chamber, and then the upper mold and the lower mold are completely closed under the action of external force, and the diaphragm in the mold cavity or After the filter plate is cooled, open the mold and take out the diaphragm or filter plate. When the compactness of the manufactured diaphragm or filter plate does not meet the requirements, the cavity can be repaired by constant pressure plastic repair or pressurized plastic repair, and the plastic repair device can us...

Embodiment 3

[0020]Embodiment 3: On the basis of embodiment 2, utilize the press machine itself and mold and the melted plastic of precise quantity, control the precision of product parallelism and thickness or the precision of the parallelism of filter chamber and depth, that is to say, by controlling The working accuracy of the hydraulic press, the accuracy of the mold itself and the amount of injection molding are used to control the accuracy of the parallelism and thickness of the product or the accuracy of the parallelism and depth of the filter chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com