Patents

Literature

89results about How to "Reduce injection molding costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

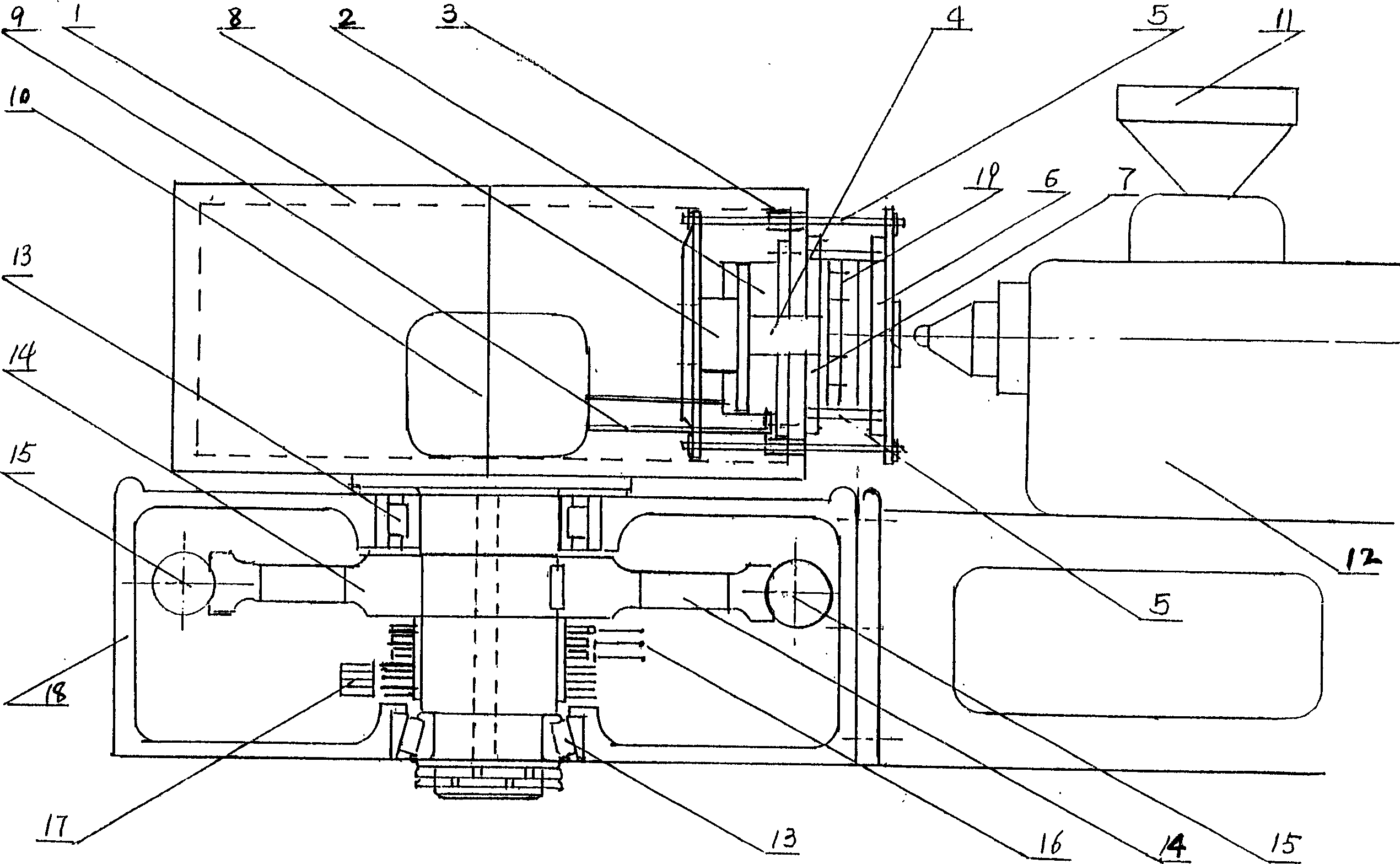

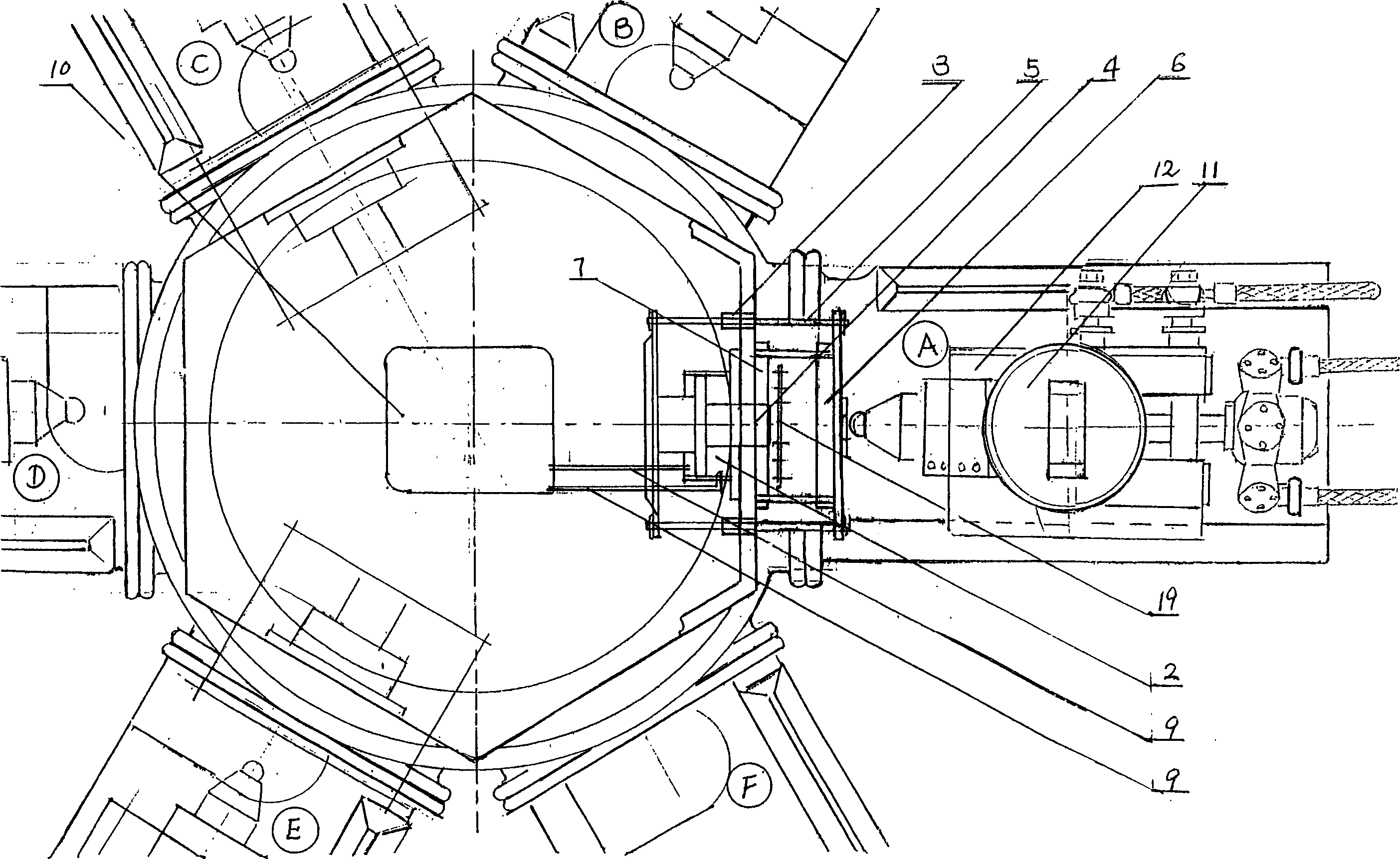

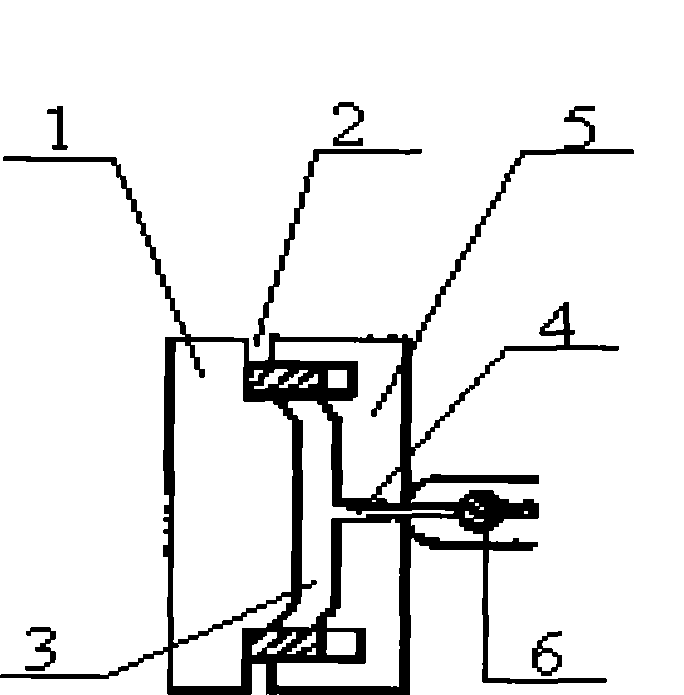

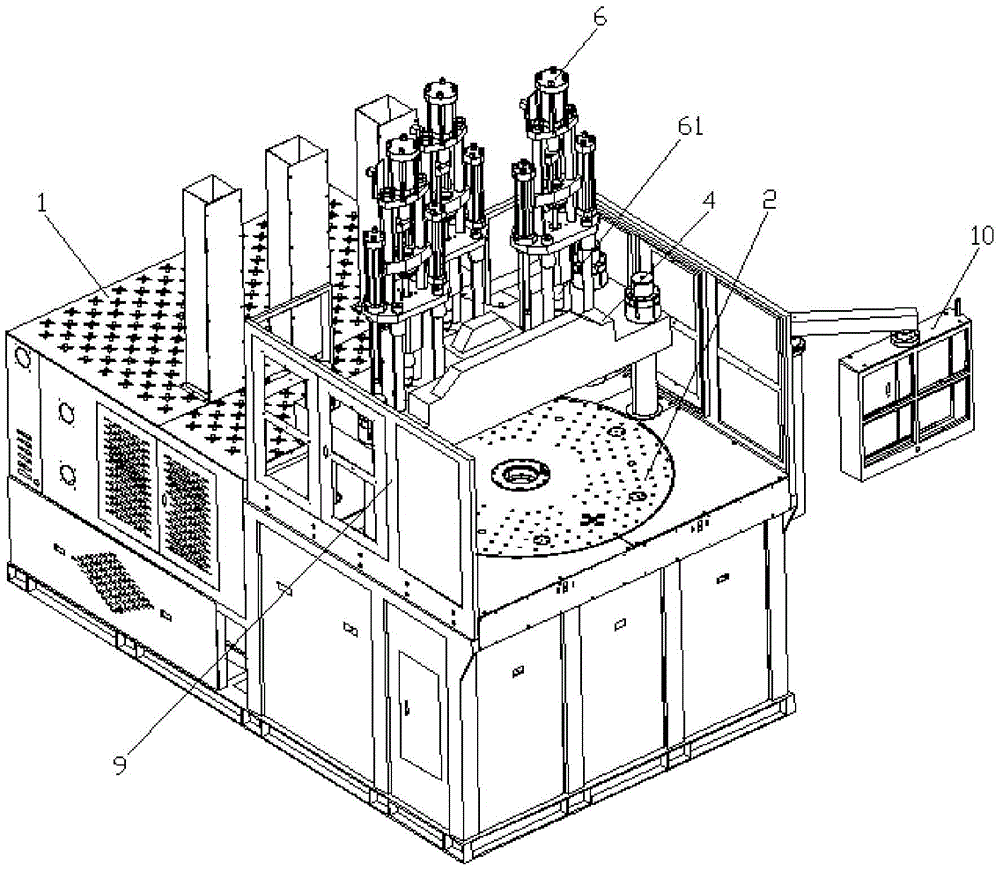

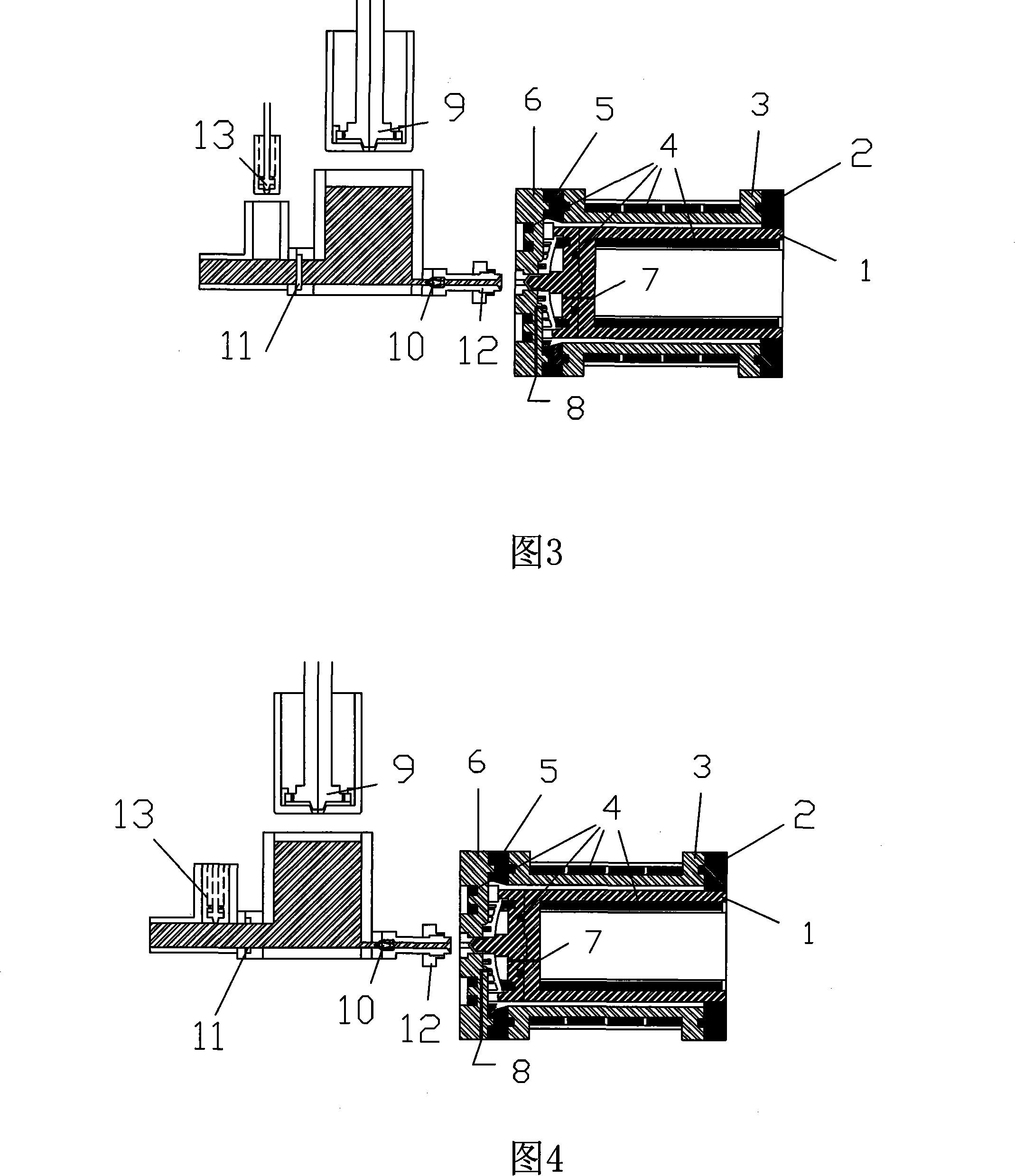

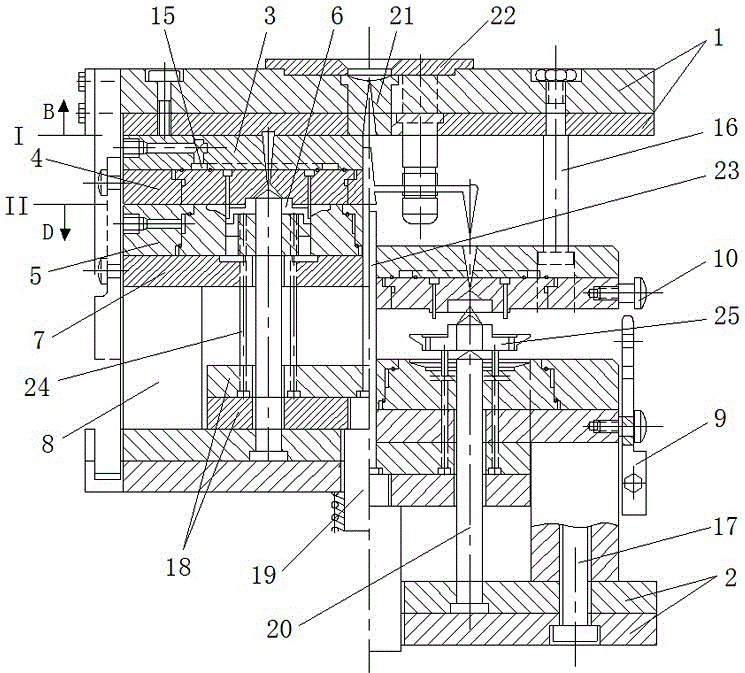

Multifunctional plastic jetting-molding machine

A multifunctional injection moulding machine is composed of a rotary bench with multiple work positions for moulds consisting upper and lower die plates and driven by motor via drive mechanism, and injection moulding unit, a mould closing unit, which is a pressure-holding high-pressure mould locking structure consisting of guide sleeve, beating rod, guide rod and upper and lower die plates, and a hydraulic system consisting of high-pressure cylinder and the booster installed in the center of said rotary bench.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

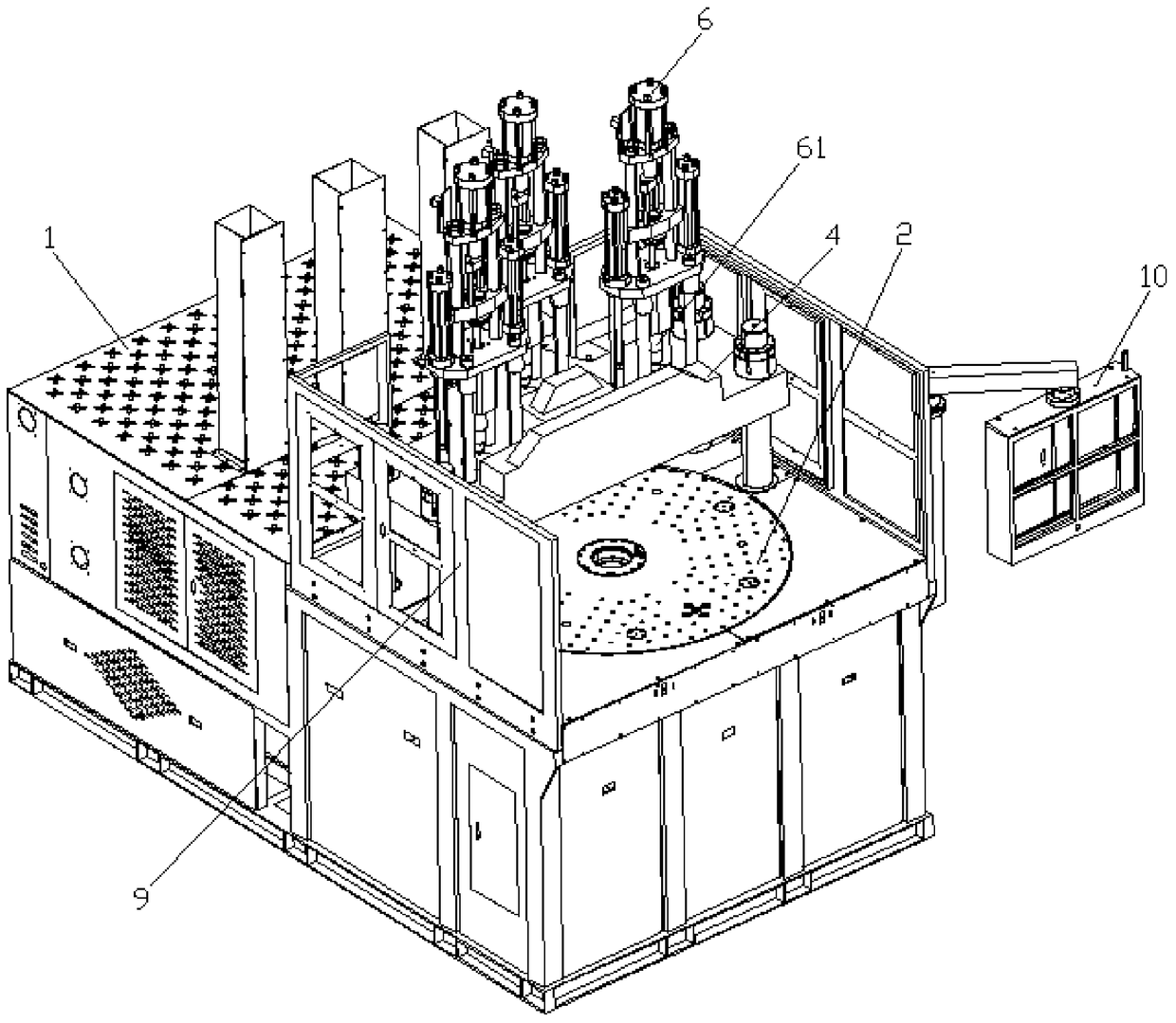

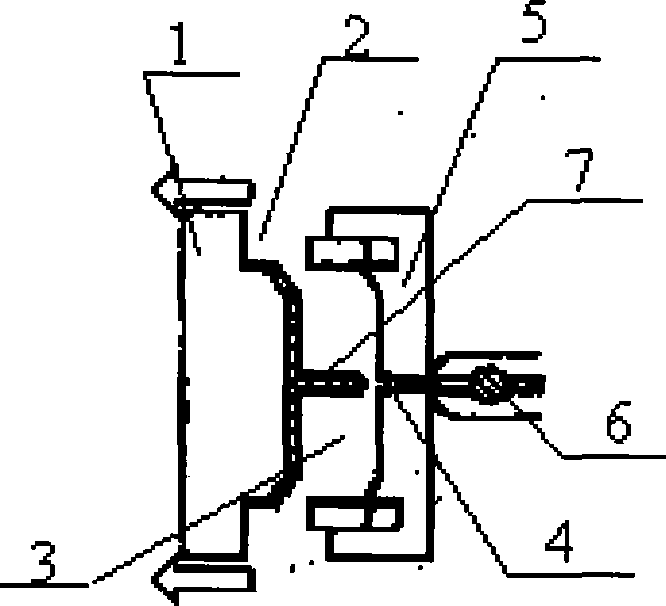

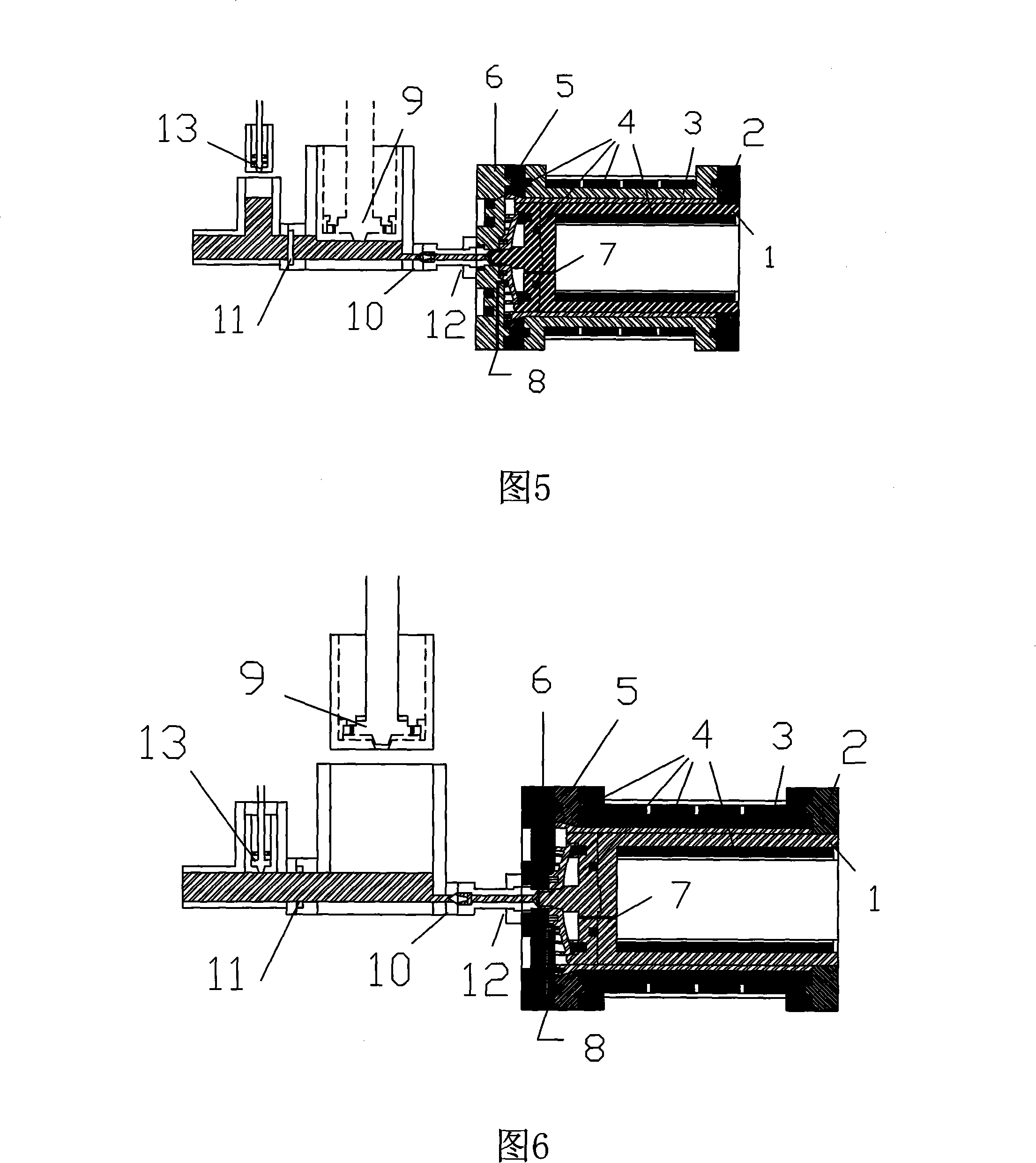

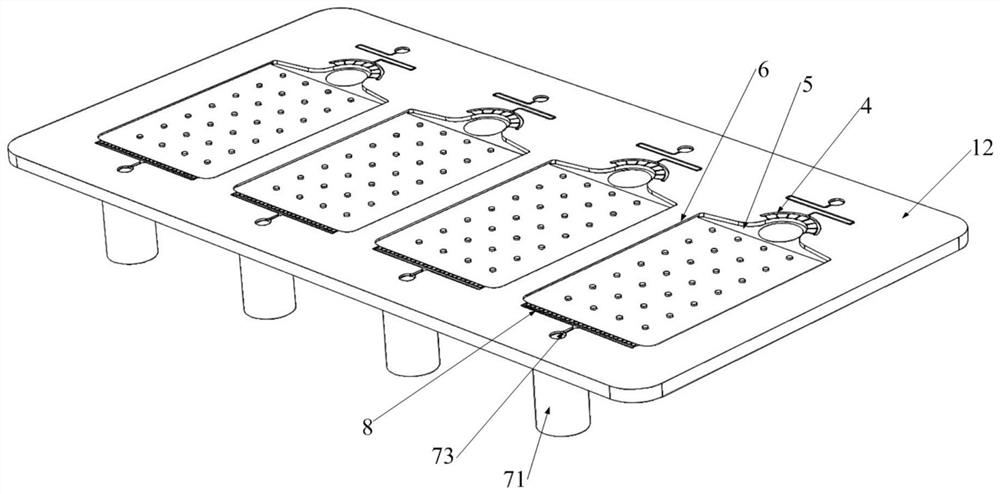

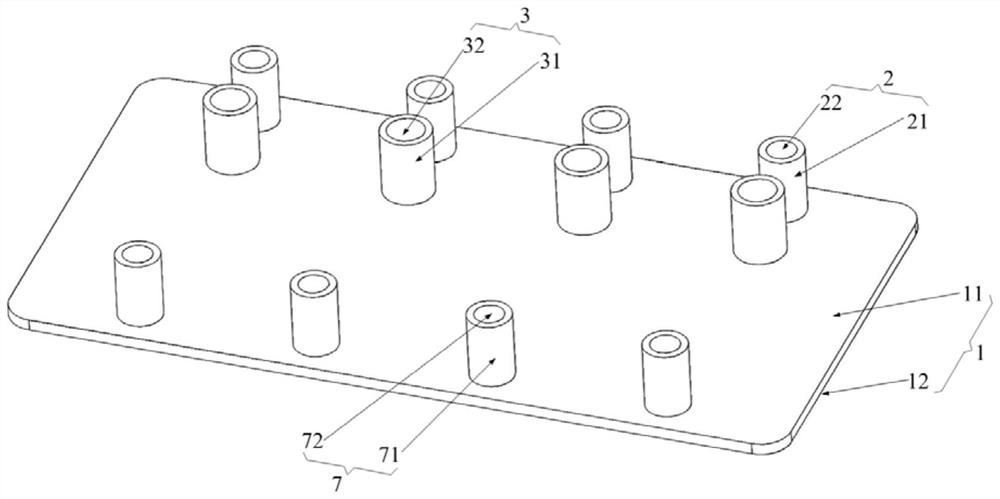

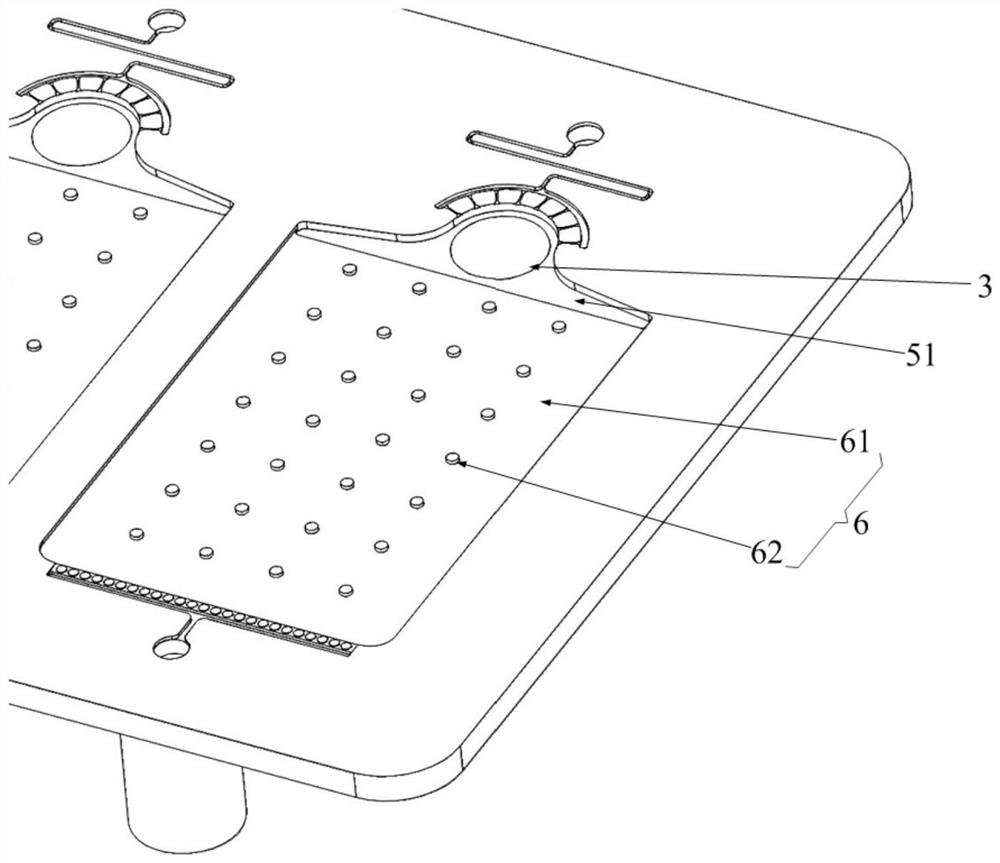

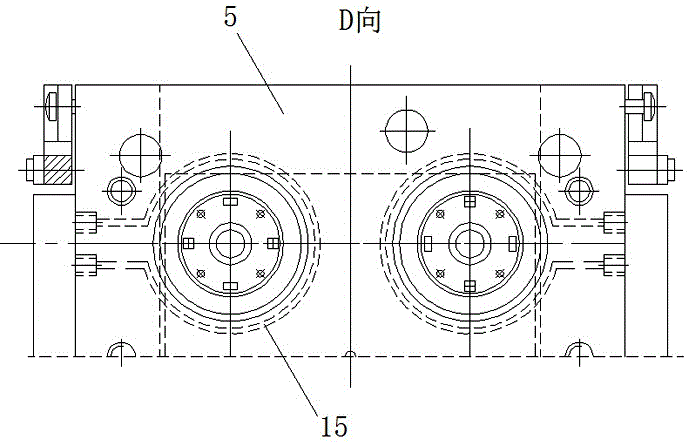

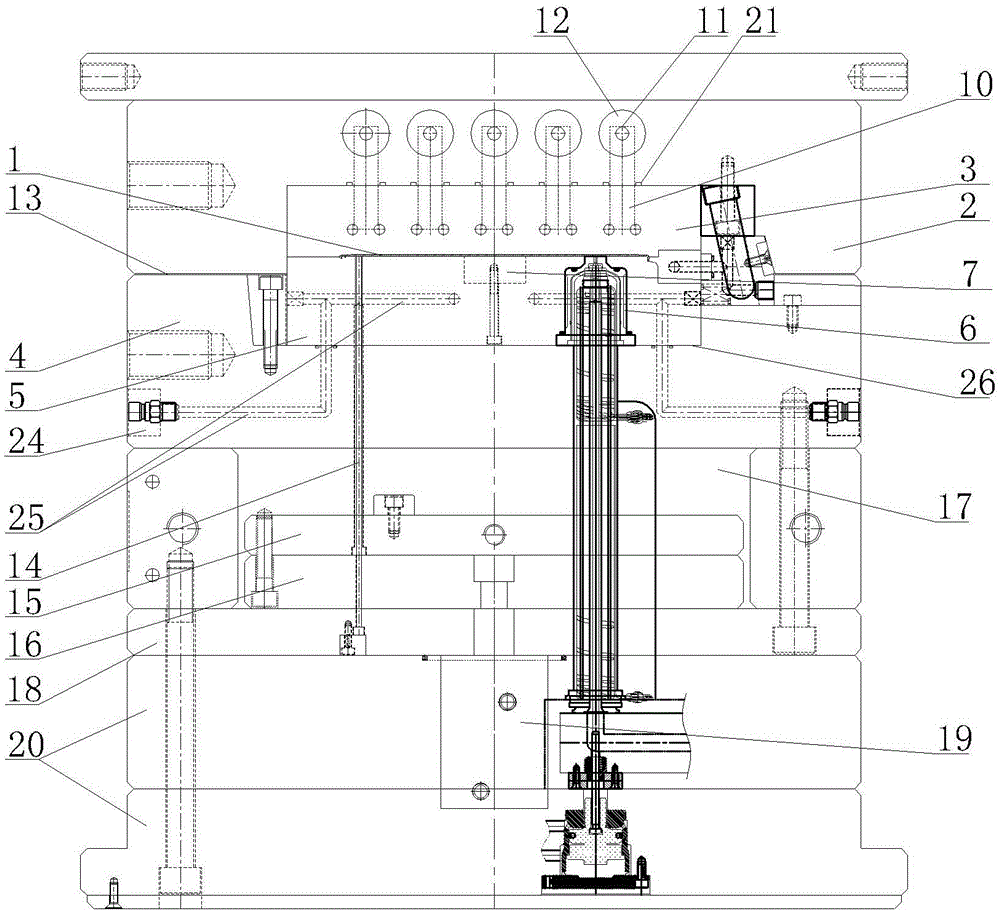

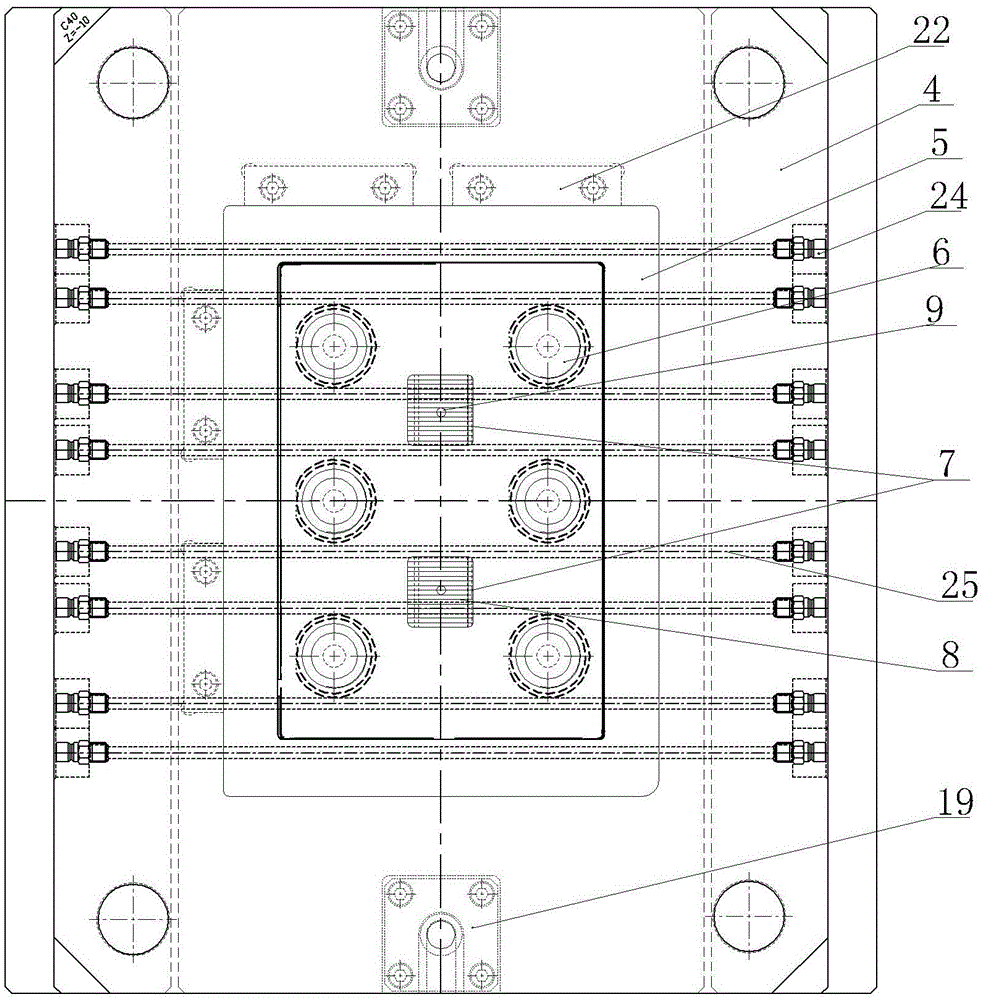

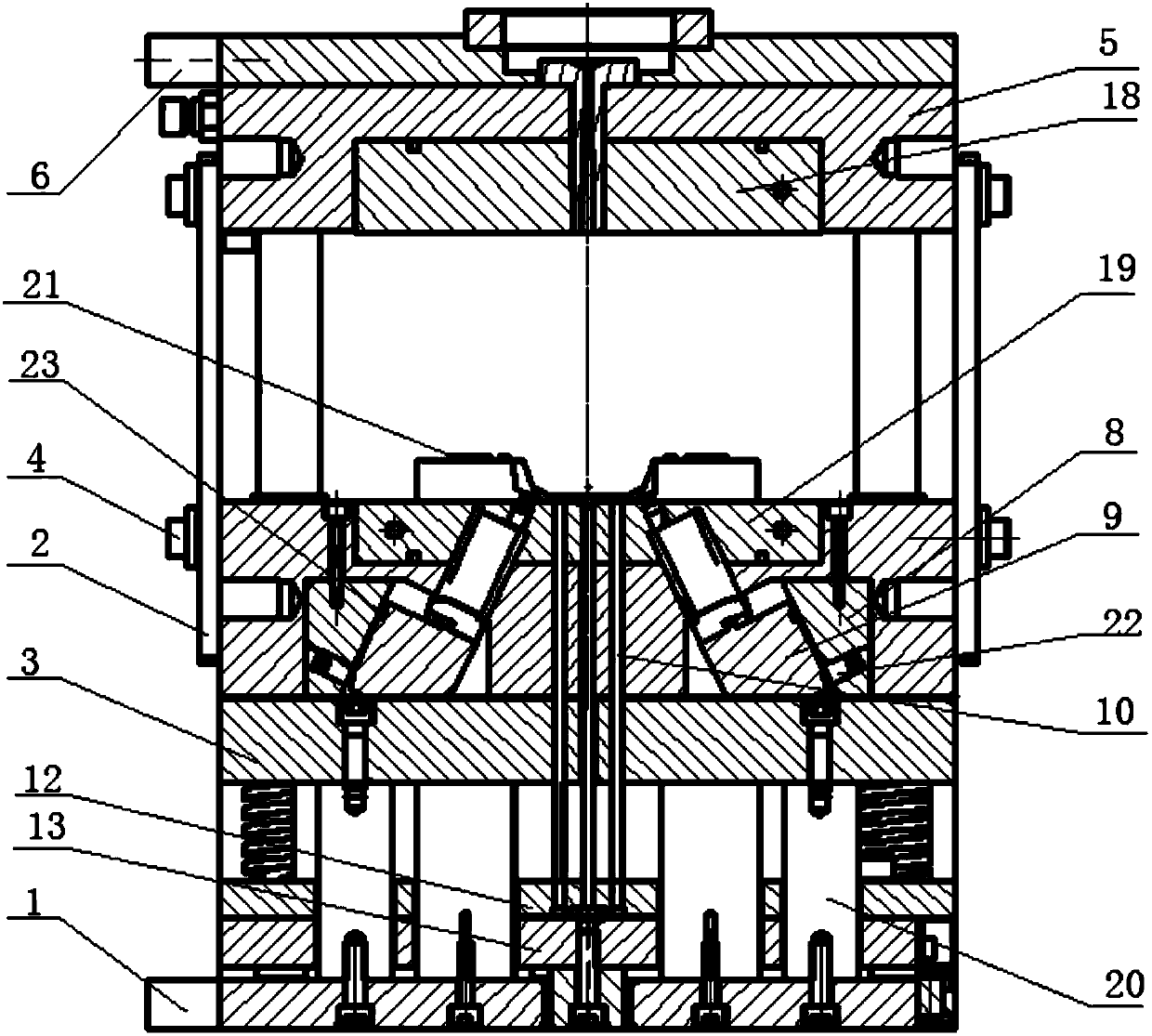

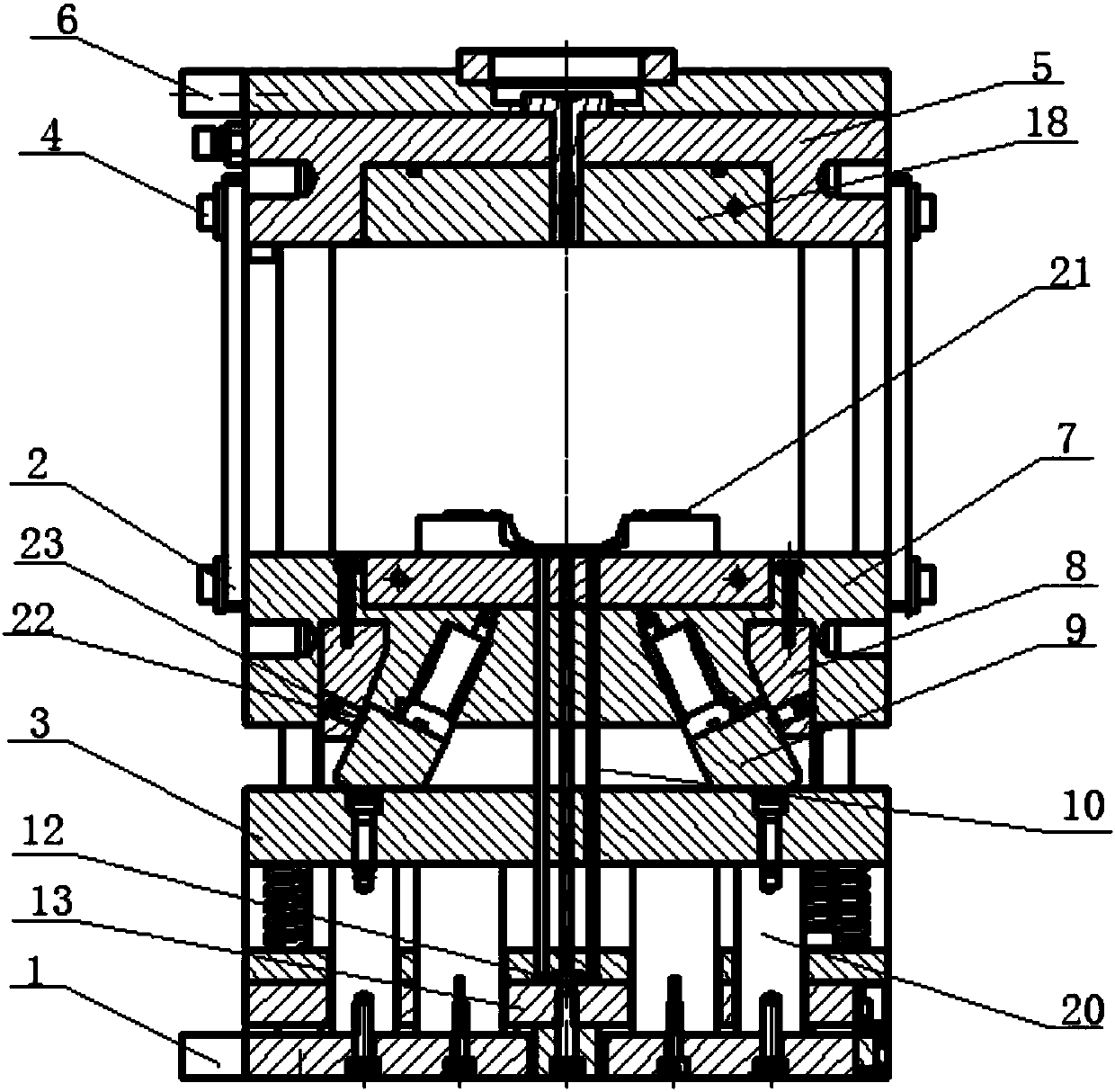

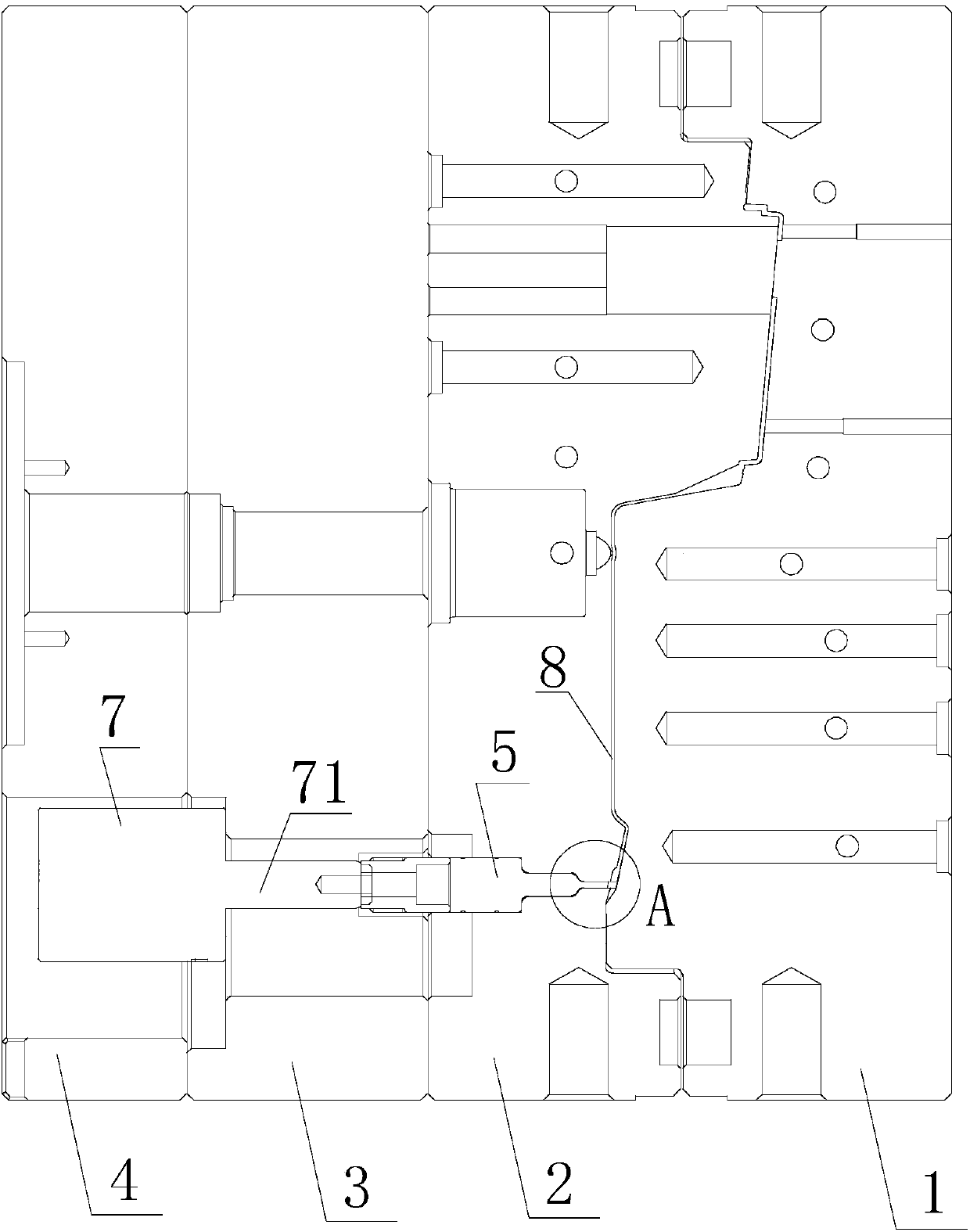

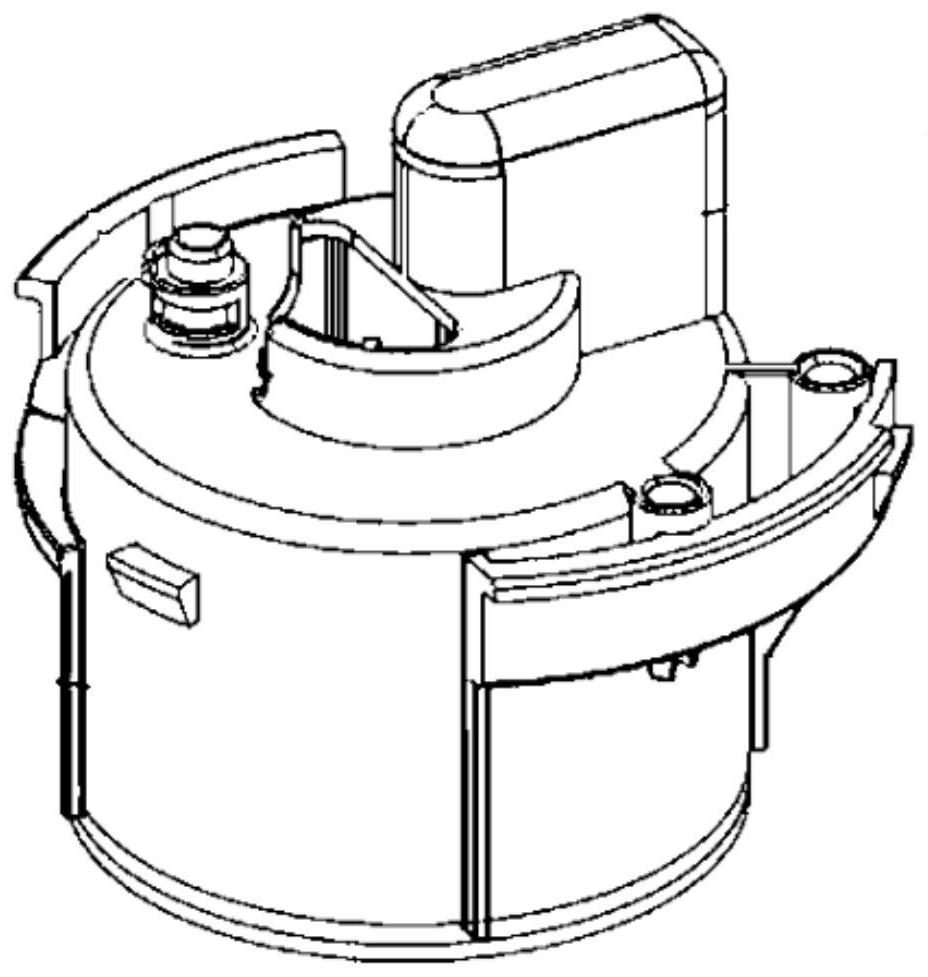

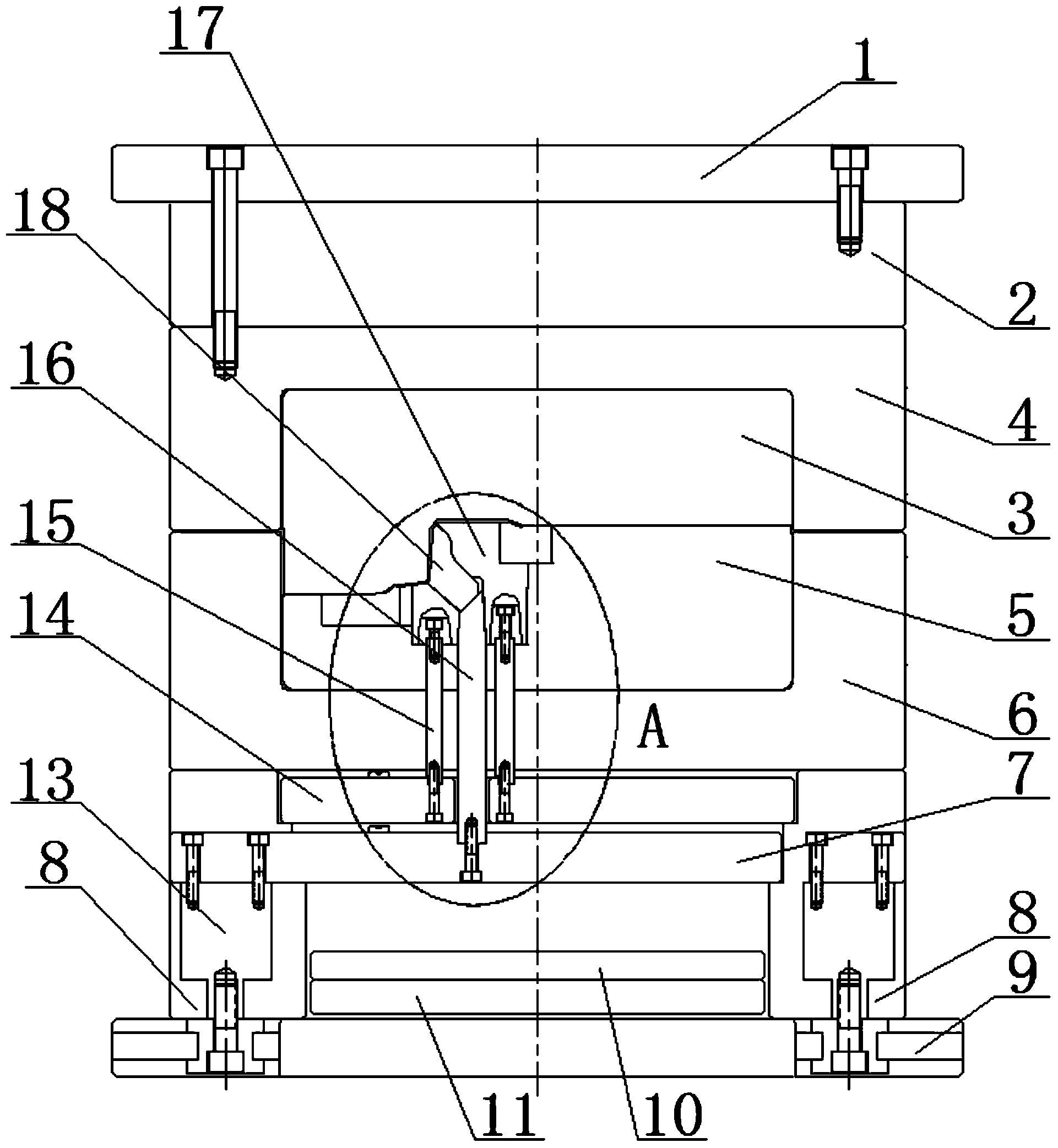

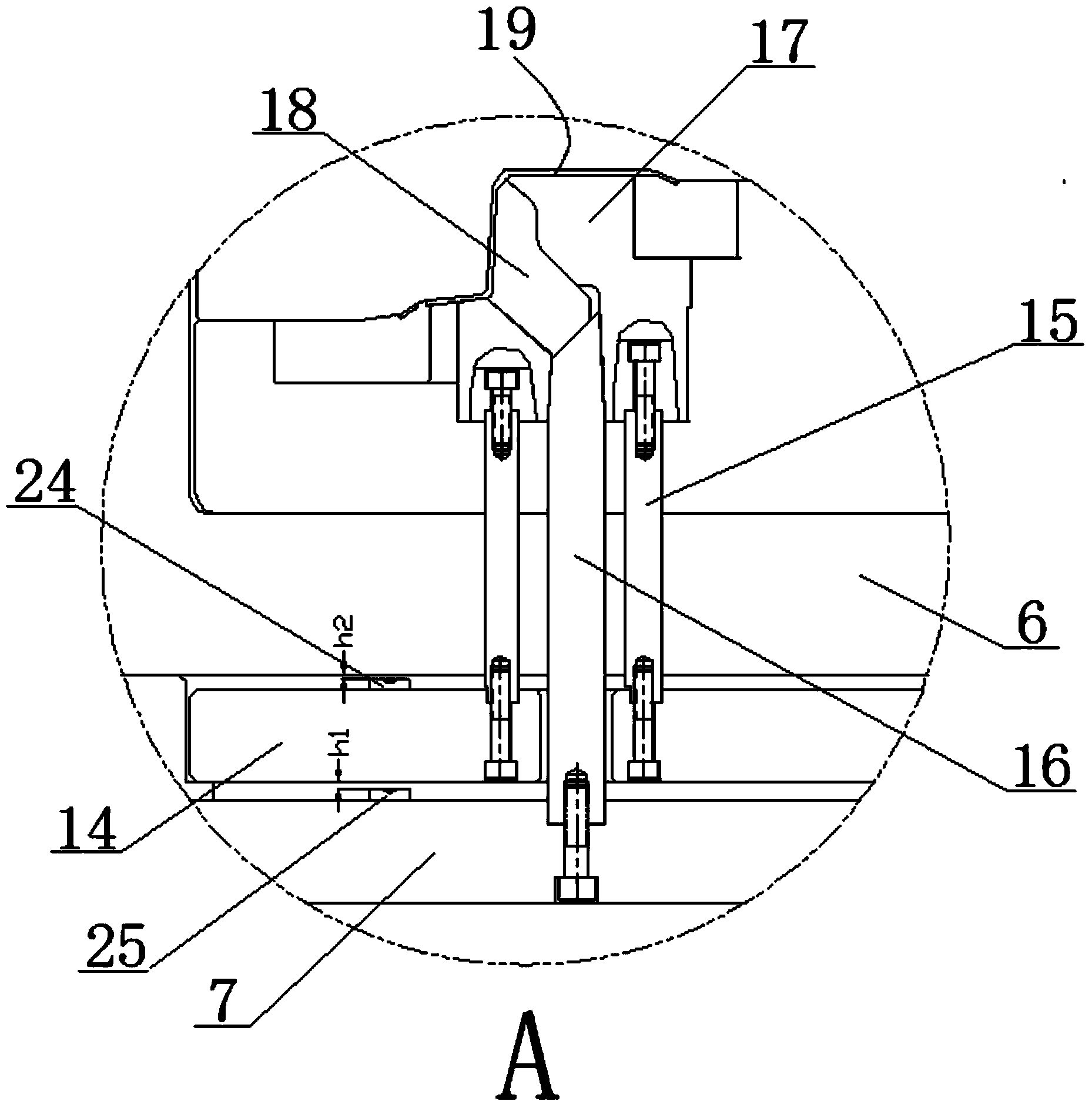

Multi-station injection molding machine

The invention discloses a multi-station injection molding machine which is suitable for the technical field of injection molding machines. The multi-station injection molding machine comprises a rack, a lower die plate arranged on the rack, a rotating mechanism for driving the lower die plate to rotate, an upper die plate located above the lower die plate, a lifting mechanism for driving the upper die plate to ascend and descend and multiple injection devices arranged above the upper die plate. The upper die plate is provided with multiple fixed die mounting positions. The lower die plate is provided with multiple movable die mounting positions corresponding to the fixed die mounting positions in rotation respectively. According to the multi-station injection molding machine, the injection devices are arranged above the upper die plate, products in different colors made of different materials can be obtained in an injection molding manner; and multiple movable dies can be mounted at the same time through the movable die mounting positions, and multiple processes can be conducted at the same time, so that the whole injection molding period is shortened, injection molding efficiency is improved, a great amount of time and manpower and a great number of material resources are saved, injection molding cost is lowered greatly, input cost is reduced, and the competitiveness of the products in the market can be improved.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

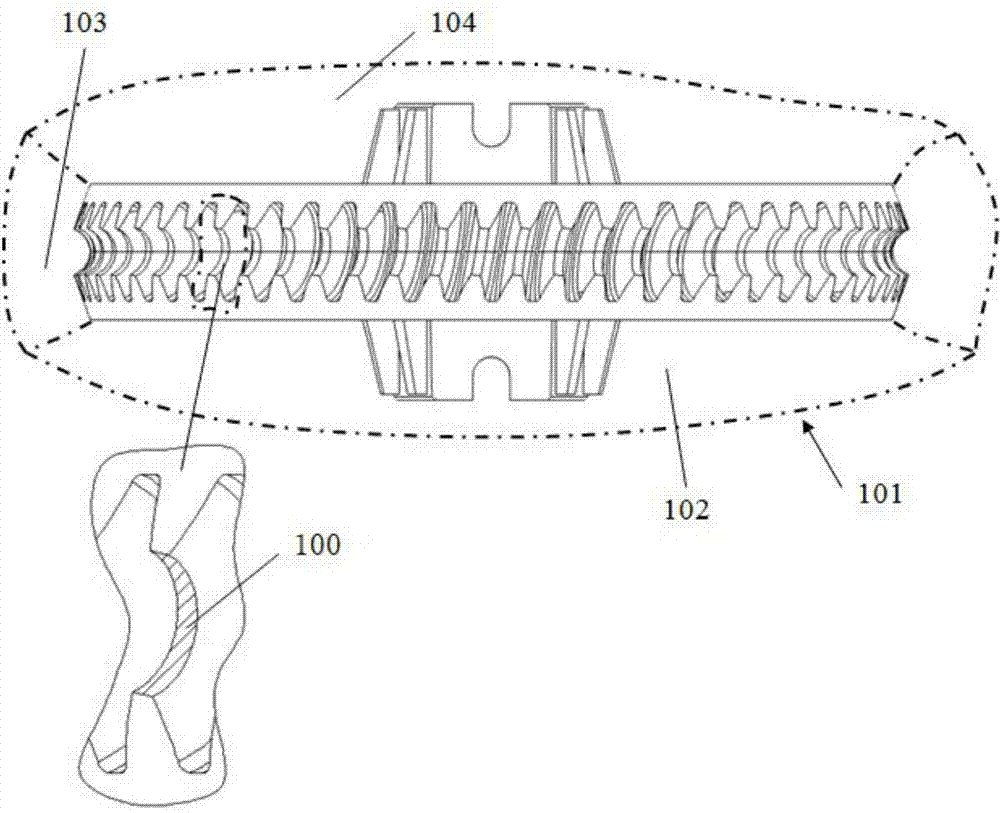

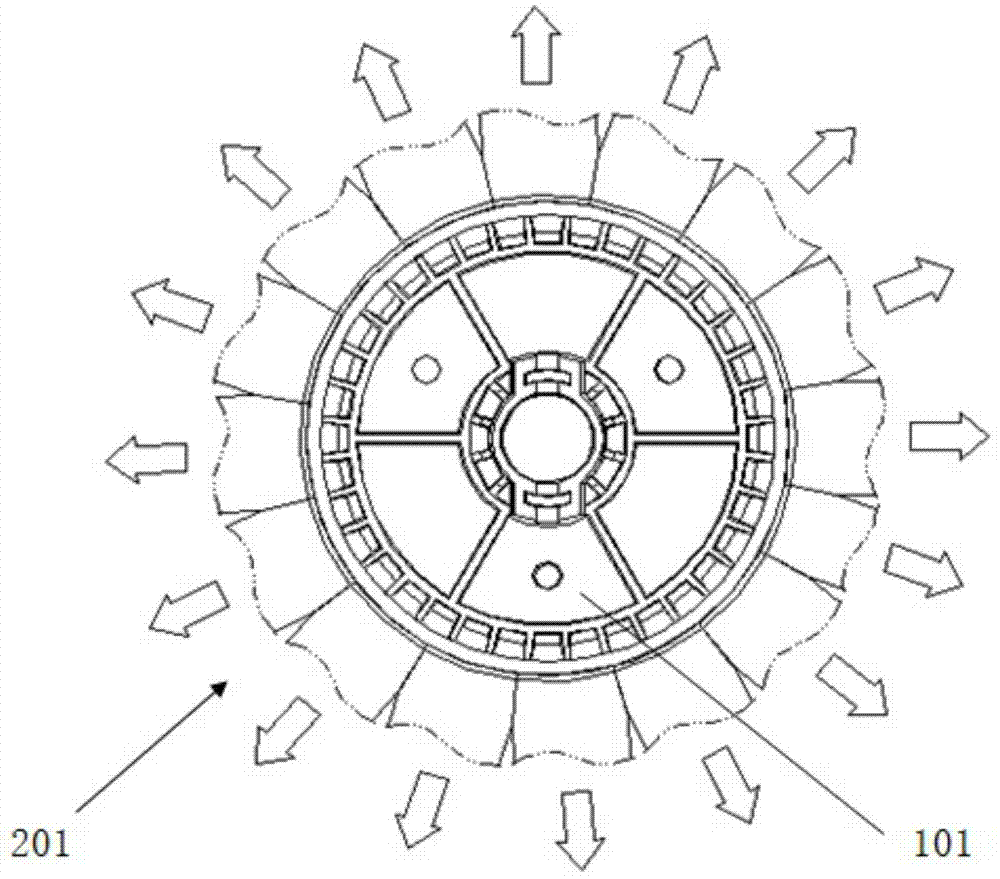

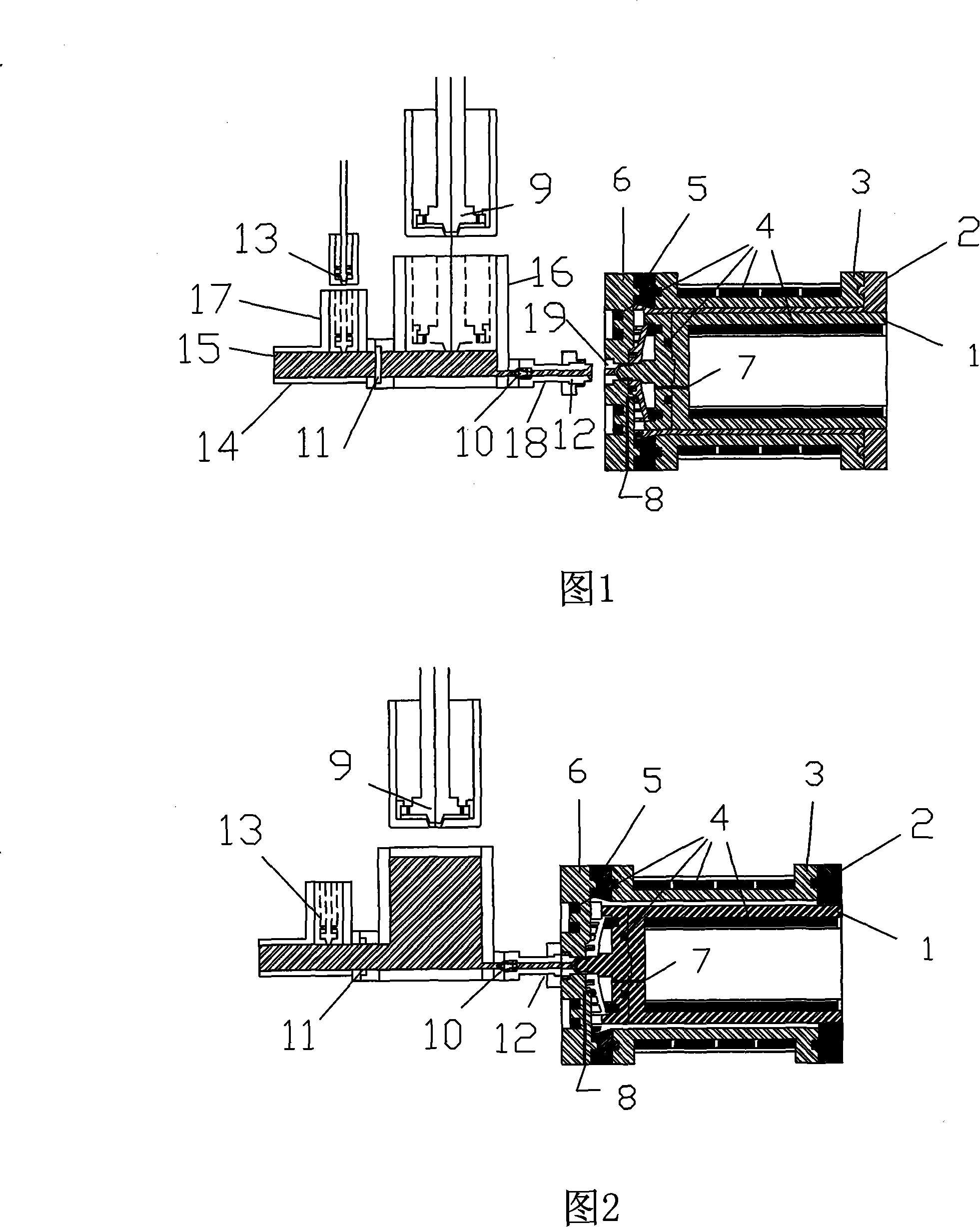

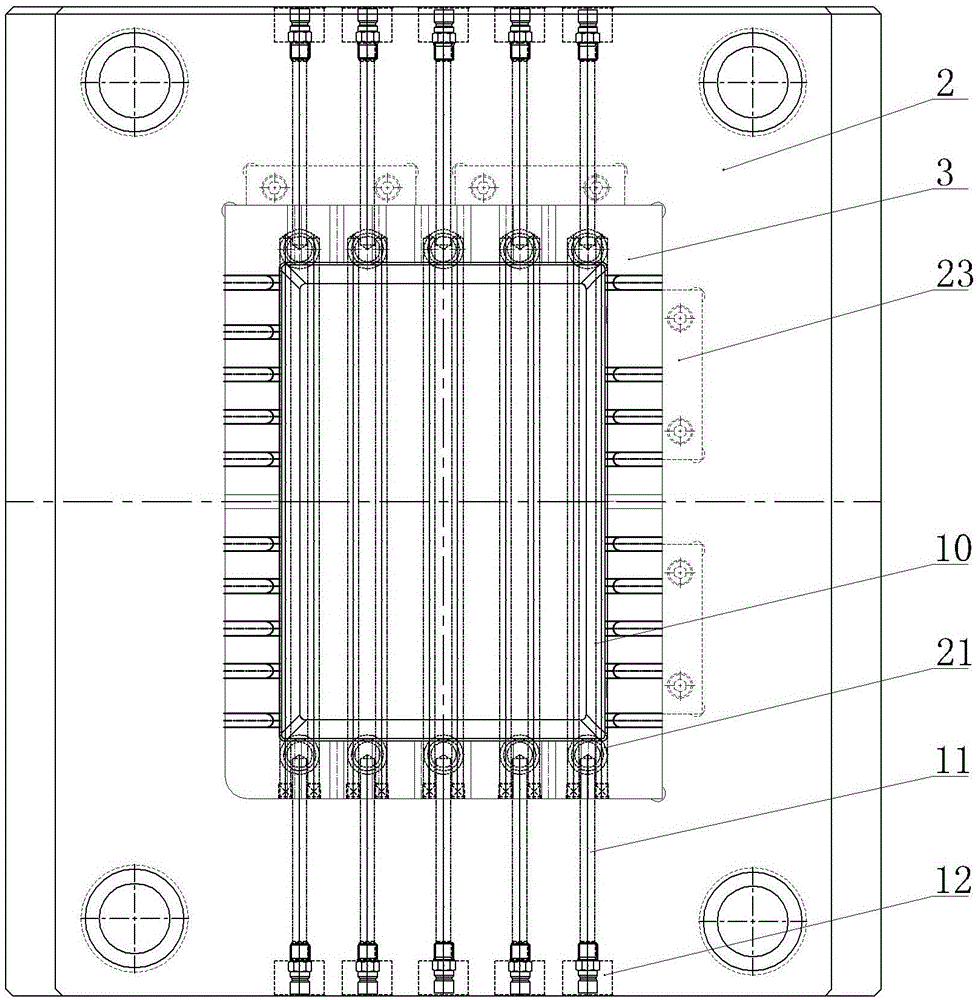

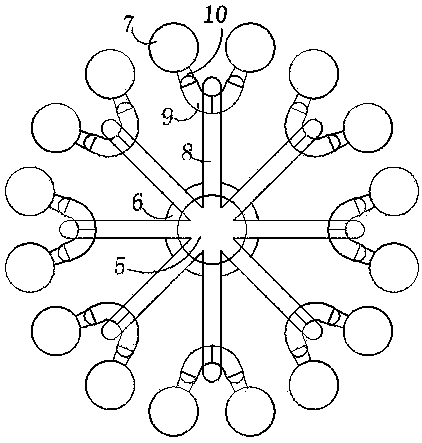

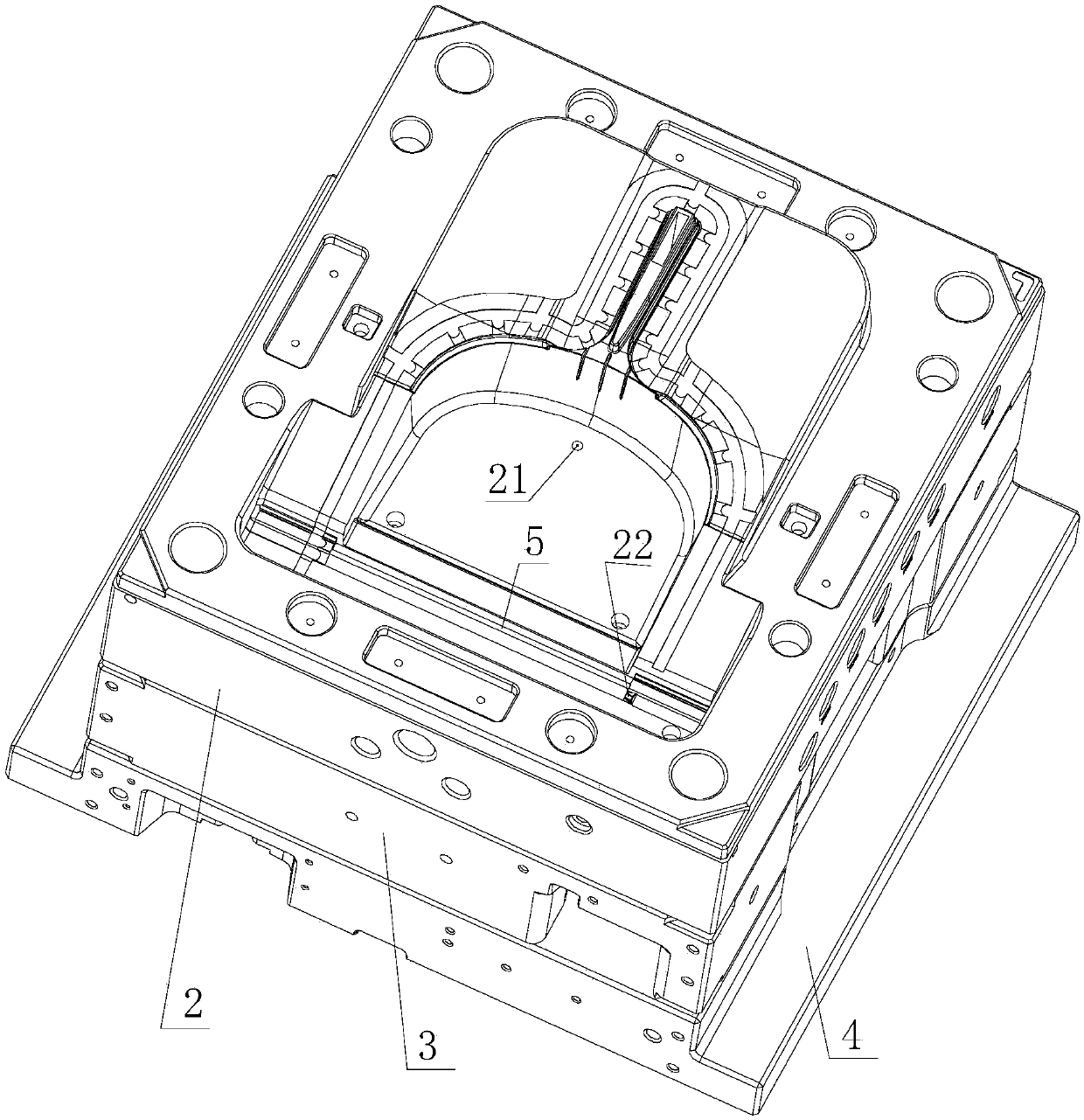

Injection molding method of plastic worm wheel and injection mold assembly

InactiveCN103522501ASimple structureVarious processing methodsGear wheelsEngineeringInjection molding machine

The invention provides an injection molding method of a plastic worm wheel and an injection mold assembly. The injection mold assembly comprises a fixed mold part and a movable mold part, and the movable mold part comprises a plurality of circumferentially-arranged lateral sliding mechanisms and an ejection mechanism. The end portions, close to a circle center, of the lateral sliding mechanisms are in a fan-shaped tooth shape, and the fan-shaped tooth end portions of the lateral sliding mechanisms, the front mold cavity of the fixed mold part and the rear mold cavity of the movable mold part form the mold cavity of a plastic worm wheel mold. In the demolding process, the lateral sliding mechanisms laterally slide to be separated from the plastic worm wheel, the ejection mechanism arranged on the movable mold part ejects out the plastic worm wheel, and the finished product of the plastic worm wheel is obtained. An injection mold is simple in structure, the machining method of the injection molding method of the injection mold is diversified, the precision of a mold part is easy to control, the machining period is short, cost is low, and above all, large-batch production can be achieved on an injection molding machine, product precision is high, and the size is stable.

Owner:SHENZHEN HISYM IND

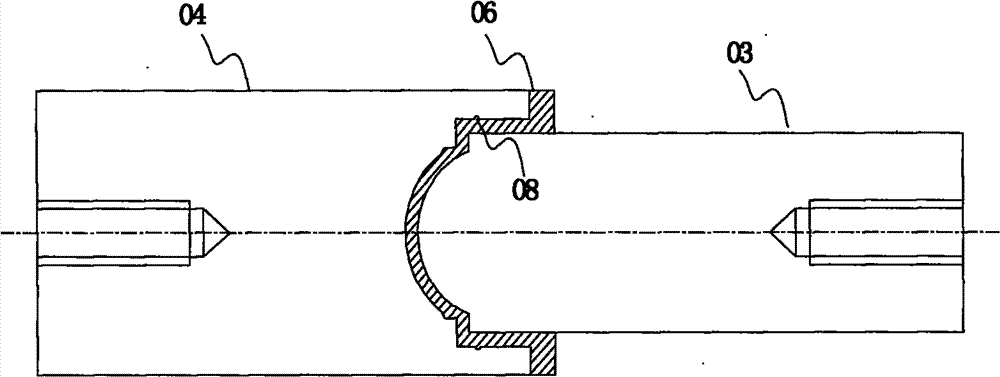

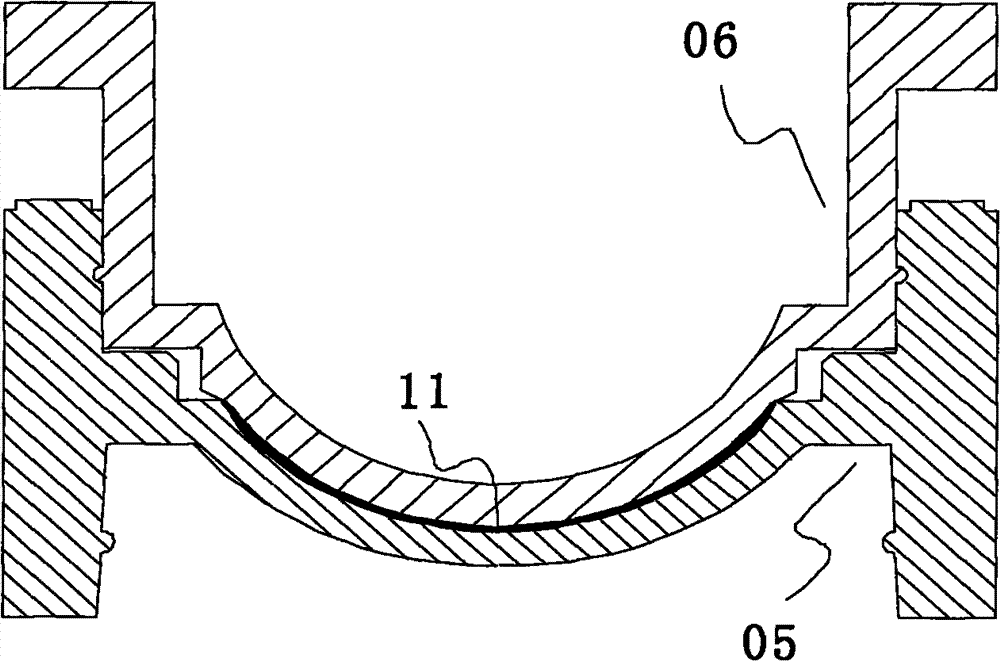

Low-cost manufacture method of high-quality diaphragm and filter plate

InactiveCN101417498AHigh molding densityExtended service lifeDomestic articlesThermoplasticMolten state

The invention relates to a manufacture method of a diaphragm or a filter plate, with low cost and high precision. When a larger die cavity space is left between an upper die and a lower die used for manufacturing the diaphragm or the filter plate, plastics in molten state in an infection machine charging barrel is quantitatively injected into the large die cavity formed by the upper die and the lower die of the die cavity under low pressure through the flow passage in the upper die or the lower die. Then, the periphery of the upper die and the lower die are treated with complete die-closing in closed state under the action of external force, and after the diaphragm or the filter plate in the die cavity is cooled down, the die is opened and the diaphragm or the filter plate is taken out. The method has the advantages that not only the plasticized plastics in the plastic diaphragm cavity are homogeneously extruded to every part of the cavity to be shaped, but also the low-pressure injection molding of the plastics diaphragm is realized and the demand for the mold locking tonnage of a press is reduced, therefore, resource waste and energy consumption are avoided. The method can be suitable not only for thermoplastics and thermosetting plastics, but also for plastic alloy, blending material, recycled thermoplastics, and the like, therefore, the regeneration and reutilization of the resources can be realized.

Owner:朱兴源

Multi-station injection molding machine

The invention discloses a multi-station injection molding machine which is suitable for the technical field of injection molding machines. The multi-station injection molding machine comprises a rack, a lower die plate arranged on the rack, a rotating mechanism for driving the lower die plate to rotate, an upper die plate located above the lower die plate, a lifting mechanism for driving the upper die plate to ascend and descend and multiple injection devices arranged above the upper die plate. The upper die plate is provided with multiple fixed die mounting positions. The lower die plate is provided with multiple movable die mounting positions corresponding to the fixed die mounting positions in rotation respectively. According to the multi-station injection molding machine, the injection devices are arranged above the upper die plate, products in different colors made of different materials can be obtained in an injection molding manner; and multiple movable dies can be mounted at the same time through the movable die mounting positions, and multiple processes can be conducted at the same time, so that the whole injection molding period is shortened, injection molding efficiency is improved, a great amount of time and manpower and a great number of material resources are saved, injection molding cost is lowered greatly, input cost is reduced, and the competitiveness of the products in the market can be improved.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

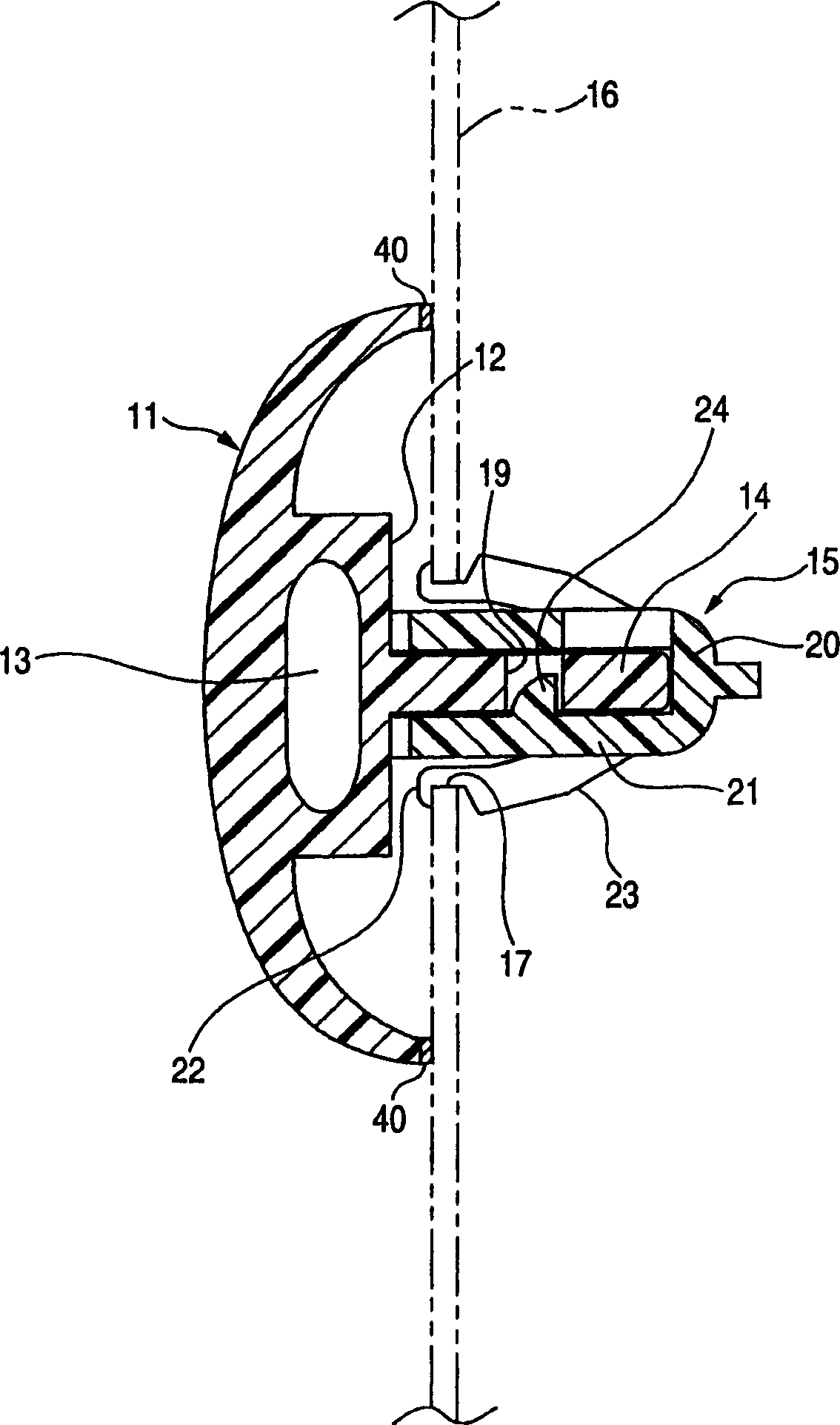

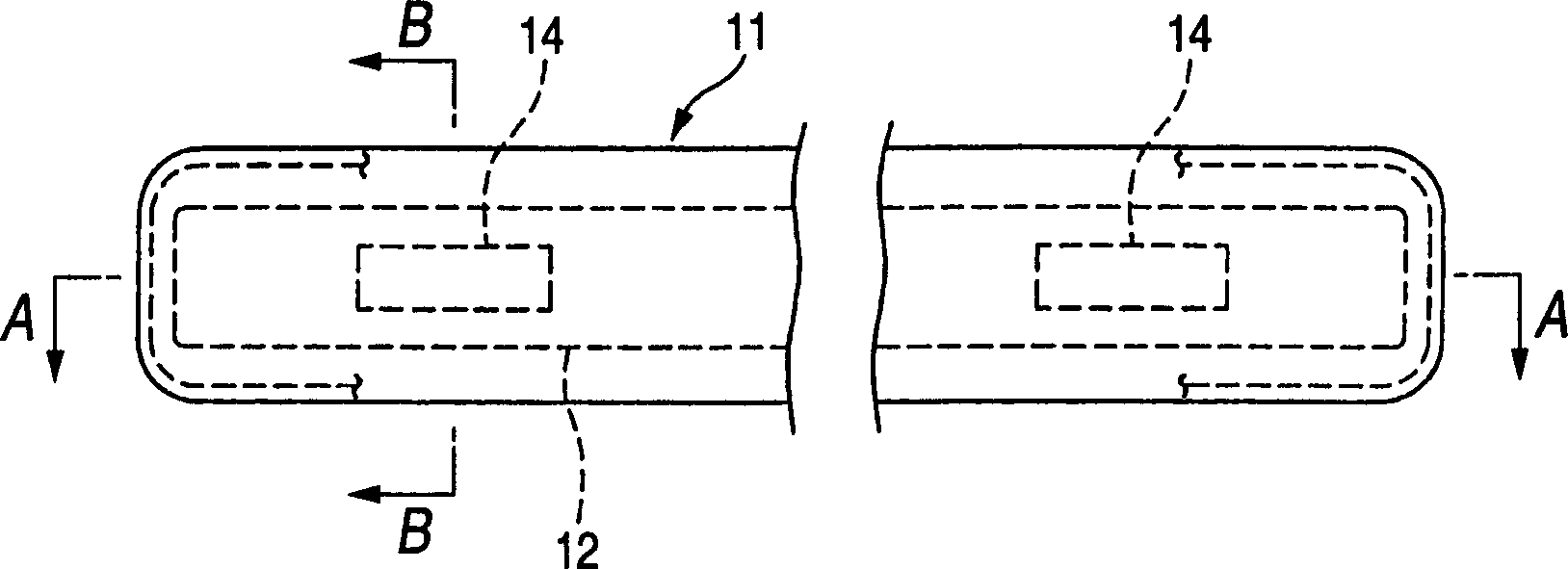

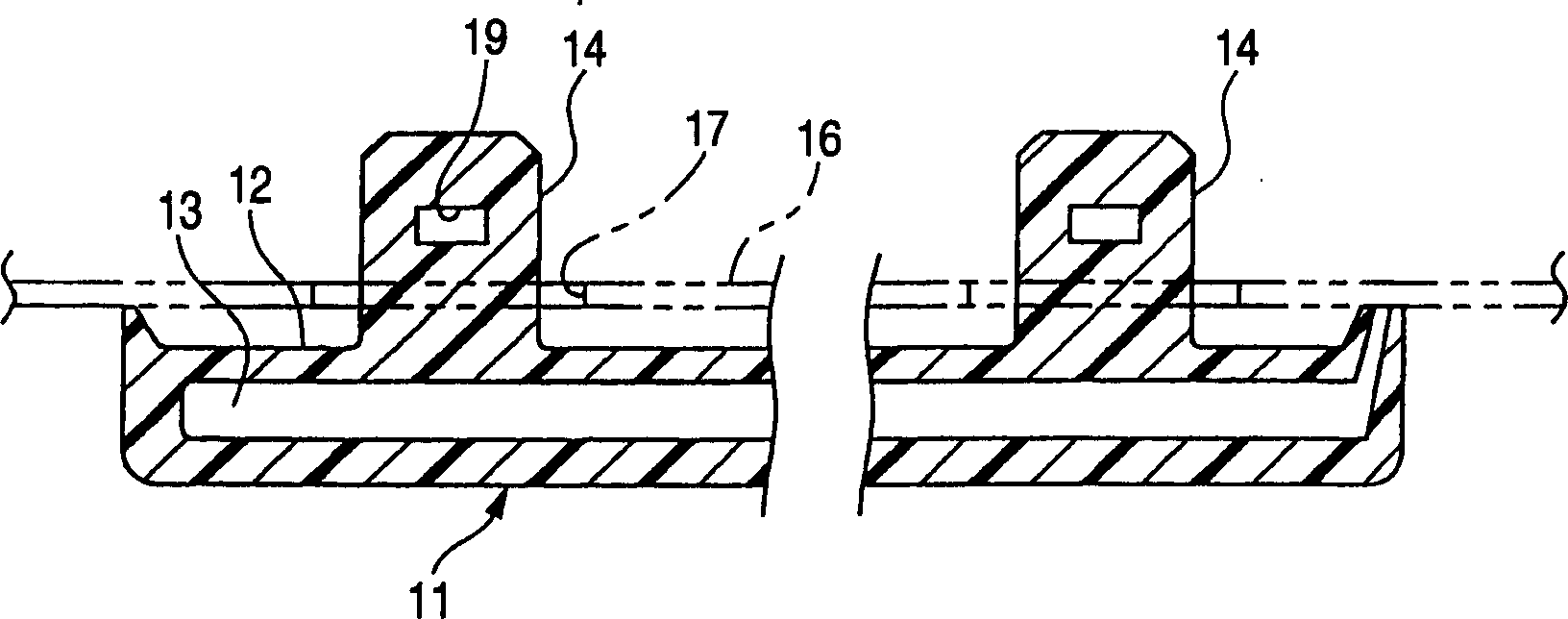

Molded product assembly and fastener

A molded product assembly includes a molded product being mountable to a body to be mounted having a mounting hole via a fastener. The molded product has a post projecting toward the mounting hole and disposed on a back surface of the molded product, at least a part of the post projecting through the mounting hole to a back surface side of the body to be mounted in mounting the molded product to the body to be mounted, and a holding portion disposed on the part of the post to hold the fastener. The fastener has a portion to be held that is held by the holding portion, and an elastic engagement leg being elastically deformable and having an engagement portion to be engaged with a peripheral edge of the mounting hole, the elastic engagement leg being located on the back surface side of the body to be mounted.

Owner:TOKAI KOGYO CO LTD

Unmanned aerial vehicle with night flight LED lamp

InactiveCN108015981ASolve the problems of difficult injection molding and low injection molding yieldGuarantee molding qualityAircraft componentsVehicle headlampsHot runnerShell molding

The invention provides an unmanned aerial vehicle with a night flight LED lamp. According to the unmanned aerial vehicle, a lamp holder of the LED lamp is manufactured by adopting a lamp holder injection mold, the mold structure of the injection mold adopts a two-plate mold hot runner twice parting structure, and a four-sprue subsurface type pouring mode is adopted; aiming at the machining problem, the machining difficulty can be lowered by adopting an insert splicing mode, and aiming at the problem that demolding is difficult, side core-pulling demolding mechanisms of different types are designed; and particularly aiming at demolding of a central inclined hole, the innovative design of three-time variable-direction driving of the inclined core-pulling demolding mechanisms is adopted, andtherefore the design difficulty of an inclined hole core-pulling mechanism can be lowered, the structural design size of the mold can be decreased, and the designing and manufacturing cost of the moldcan be effectively saved, the mechanism is simple and reliable, and the zero-defect automatic molding production of multi-type hole lamp holder products can be realized by using the simple mechanism.

Owner:王振环

Technics for manufacturing plastic products based on ejection principle and device thereof

The invention discloses a technique which manufactures a plastic product by integrating the injection principle and includes the steps of die-setting, material storage, connection, extrusion of material and filling, removal of shuttering and so on; the invention also discloses a device used for realizing the technique, which includes an extruder and a mold, the extruder has a feed passage, an extrusion storage vat and at least one reserve storage vat are arranged along the feed passage, an oil-pressure device is arranged in the extrusion storage vat and the reserve storage vat, a control valve is arranged between the extrusion storage vat and the reserve storage vat, a discharge pipe connecting with the mold is arranged on the storage vat, and the discharge pipe is provided with a valve; the molding charge for manufacturing ultra-heavy or complex article can be reduced and the injection molding cost can be lowered if the invention is adopted.

Owner:郑启修

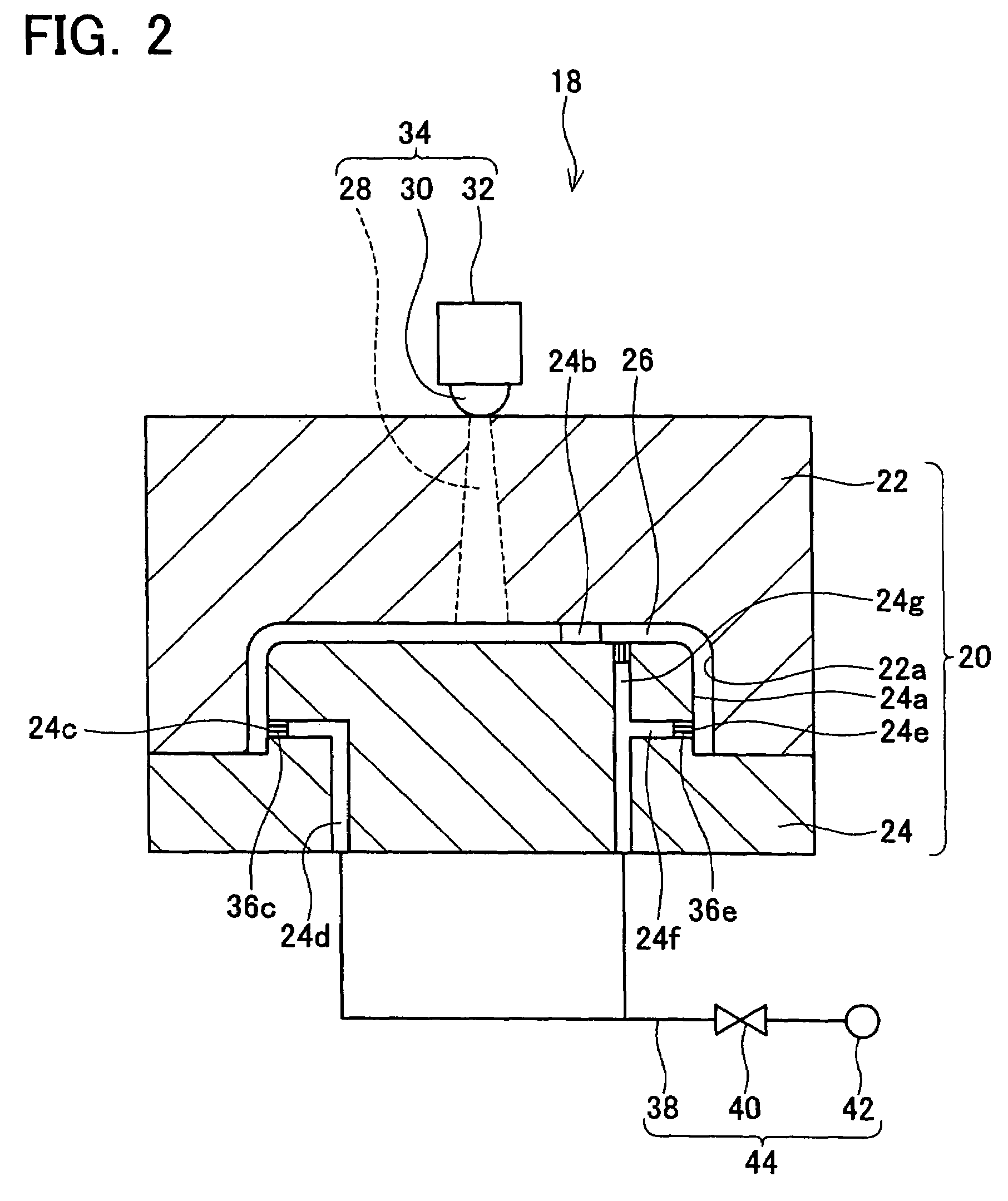

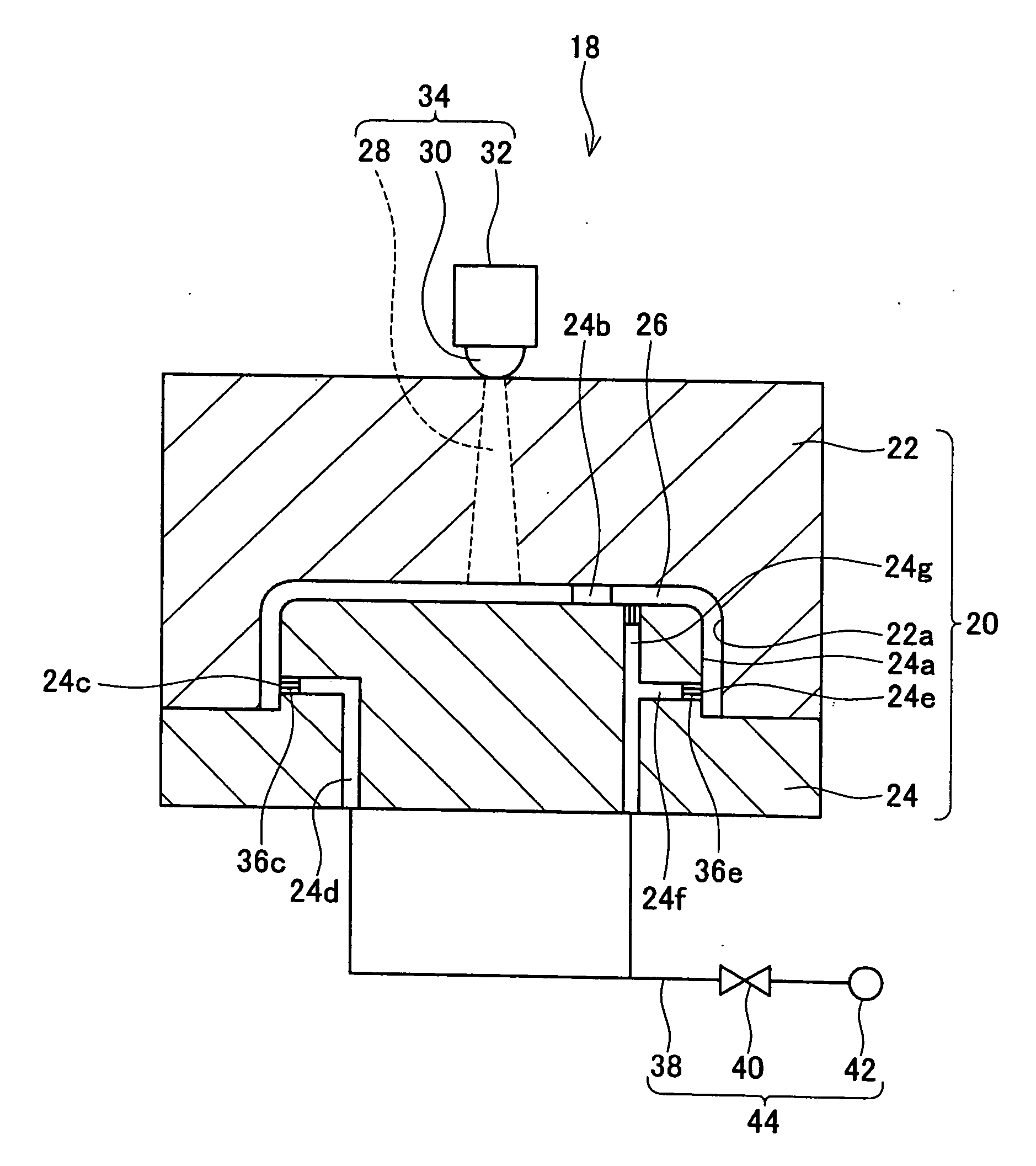

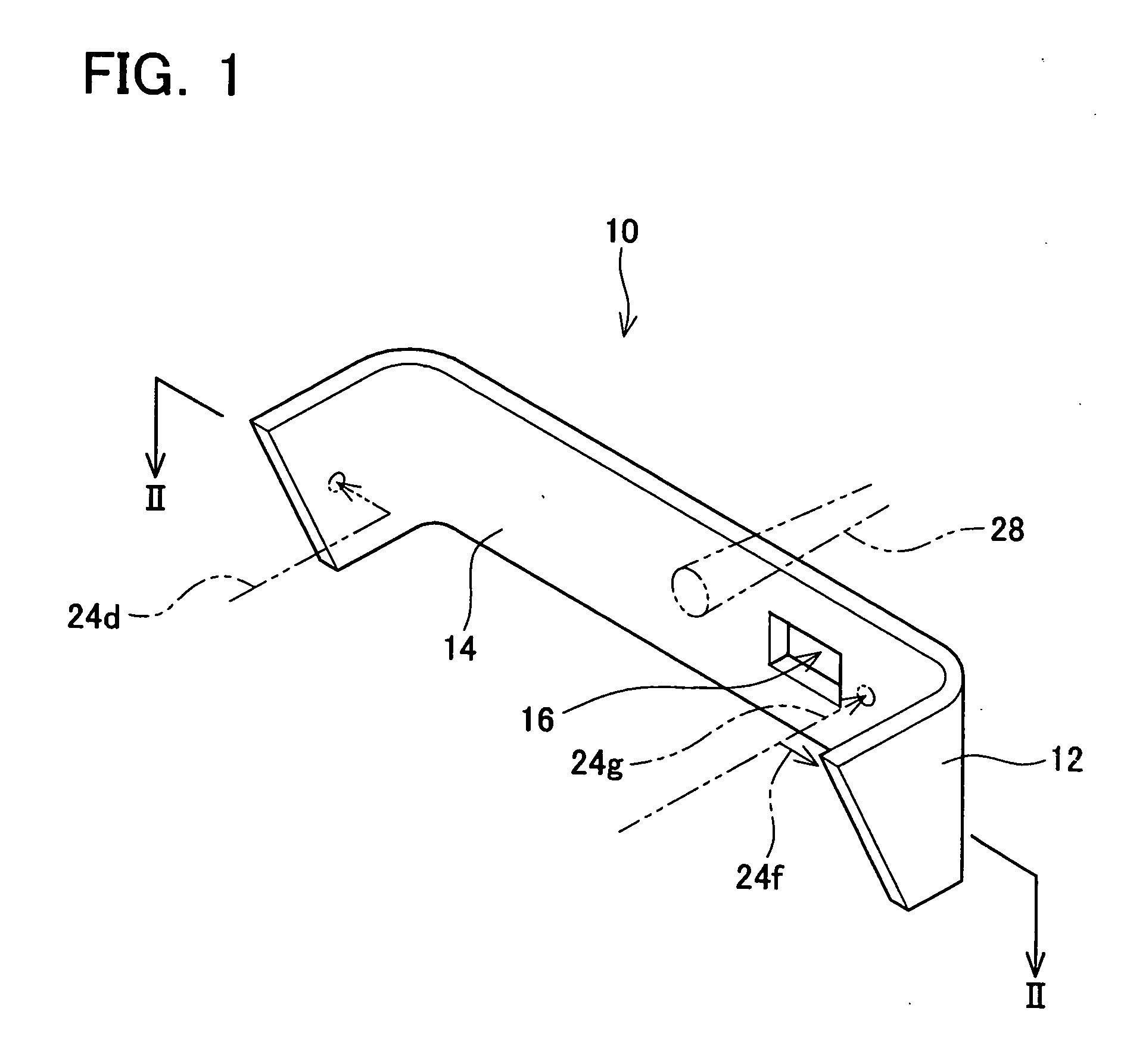

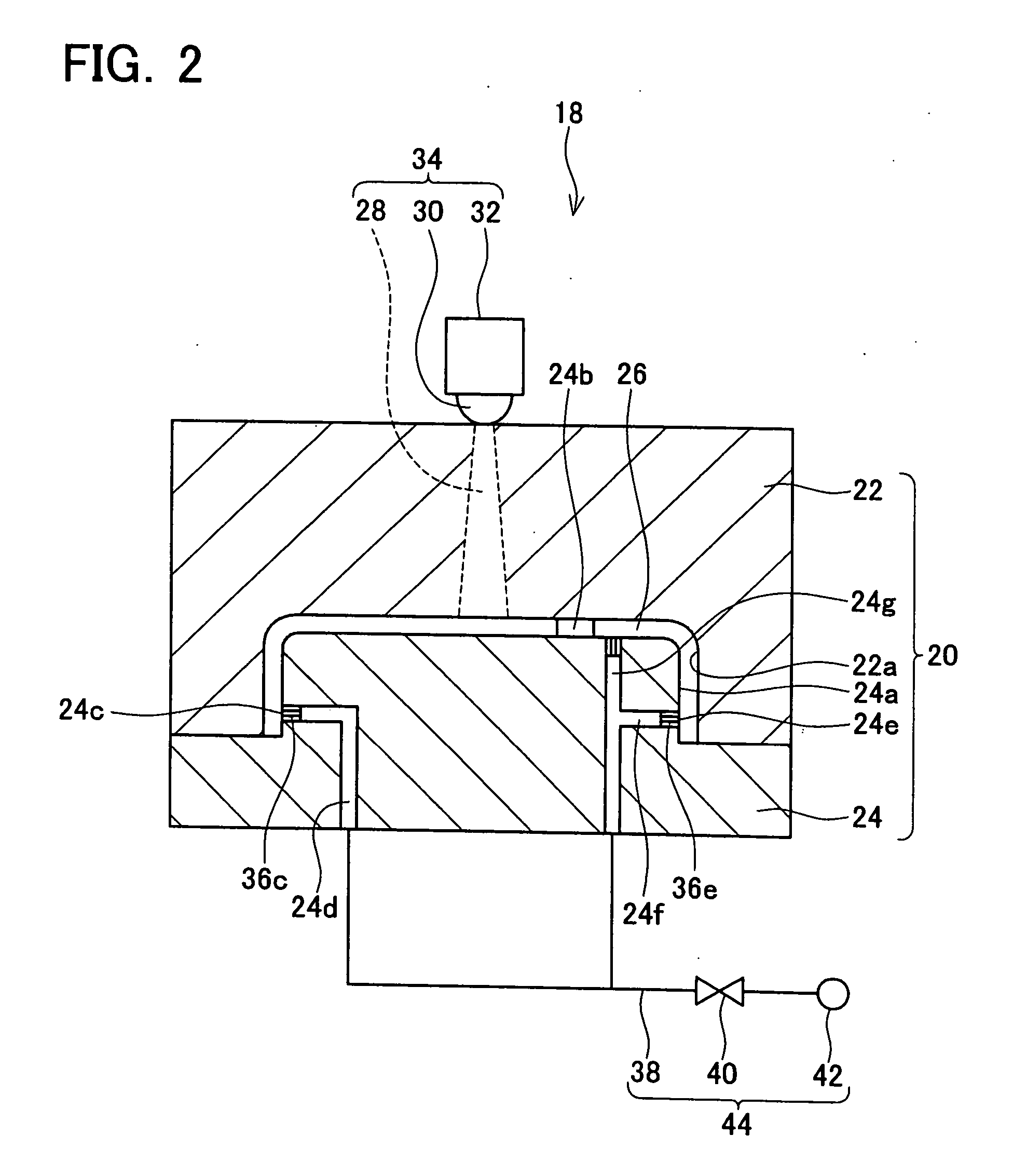

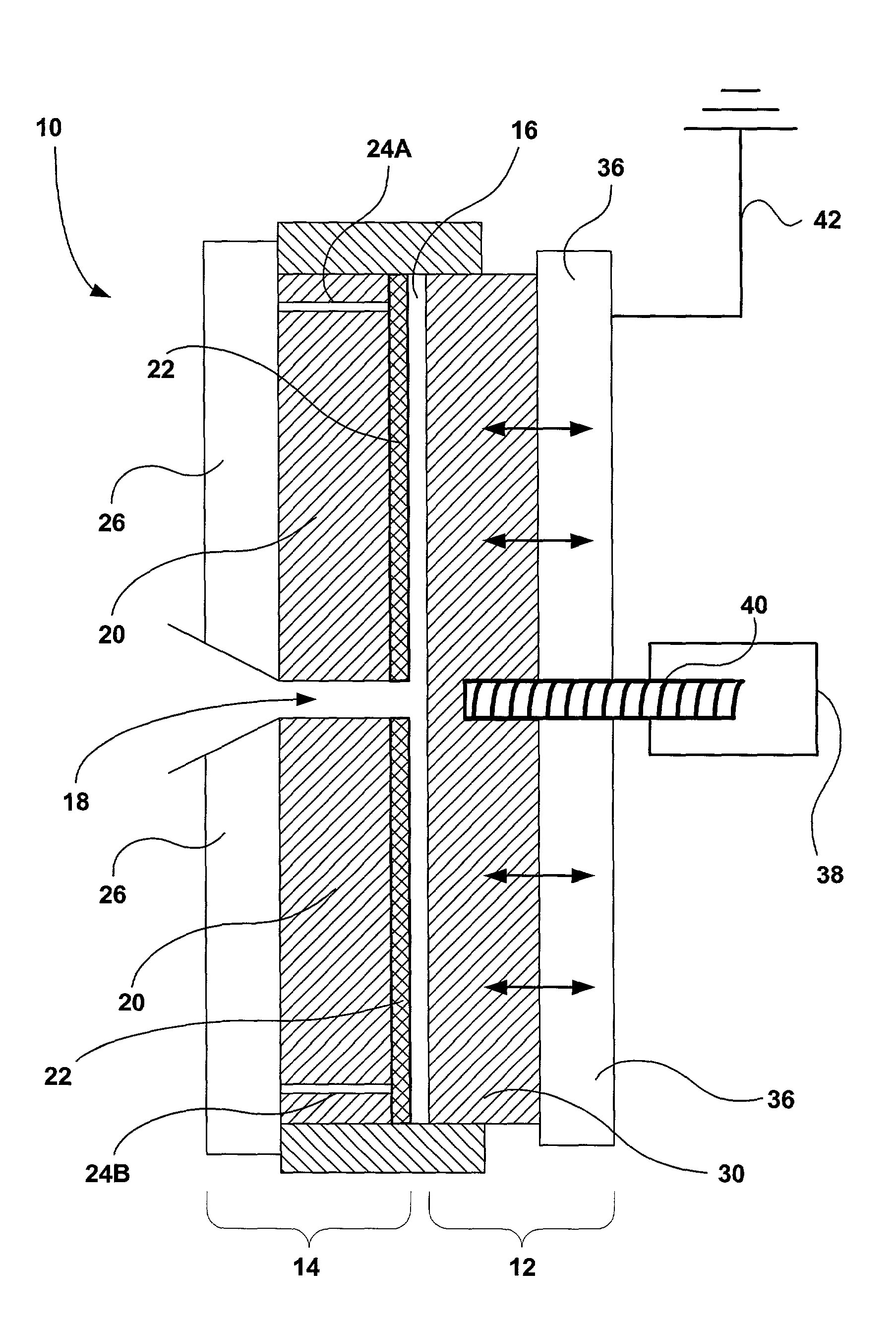

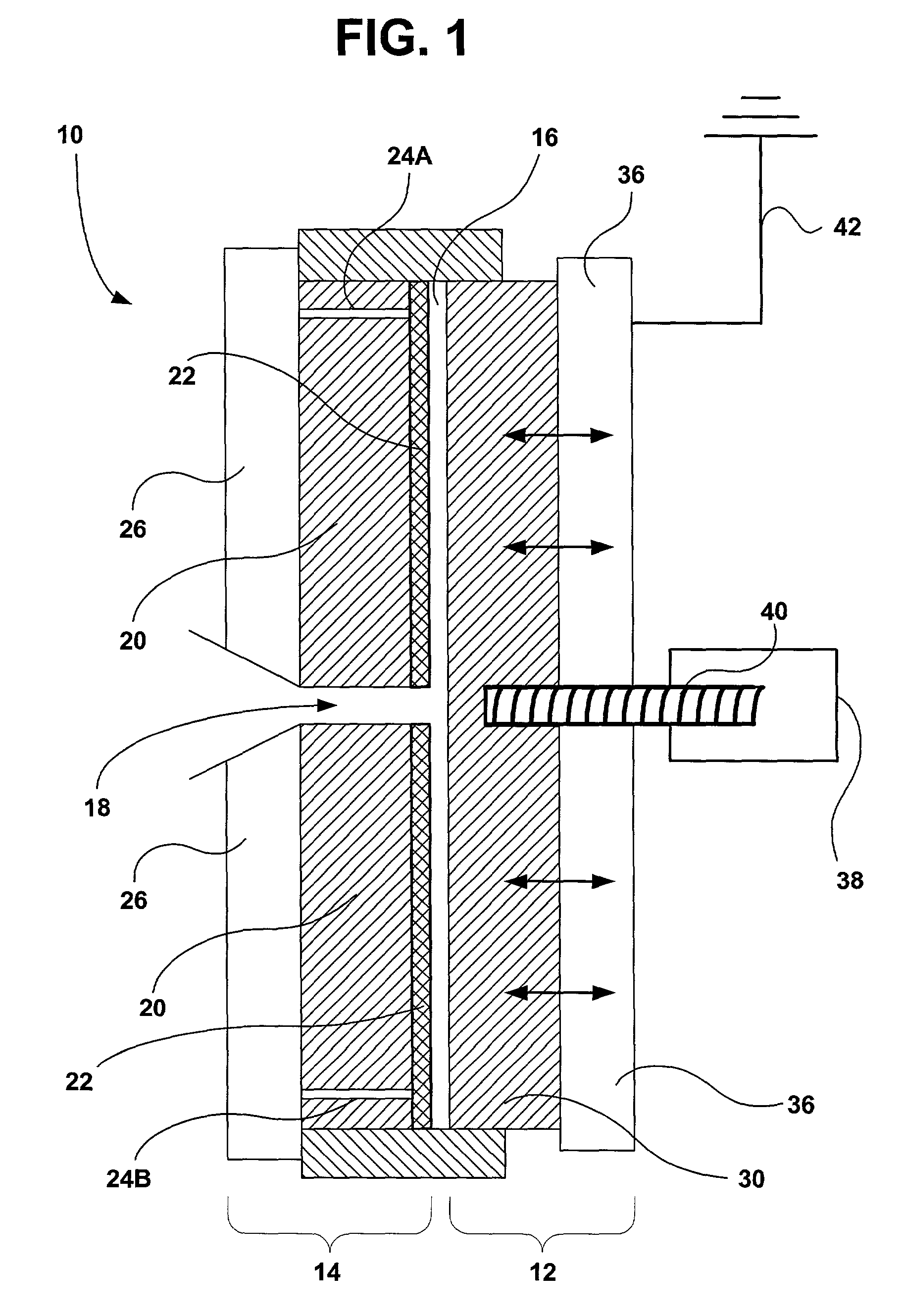

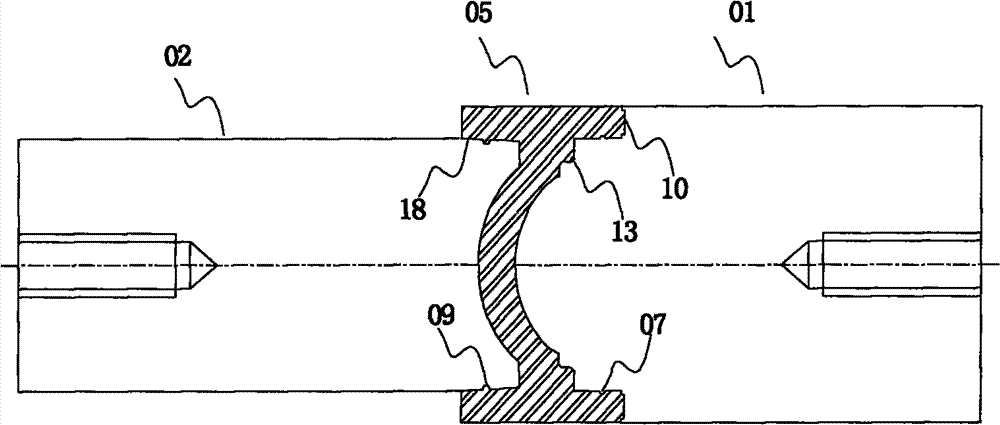

Injection molding method and injection molding apparatus

ActiveUS7582250B2Reduce pressureReduce pressure requirementsConfectionerySweetmeatsInjection molding machineFluid injection

This invention relates to an injection molding method using an injection mold. The method comprises (1) a molten resin injection step for injecting the molten resin from a gate into a cavity, (2) a pressure-keeping step for continuously applying pressure from the gate after the molten resin injection step, and (3) a fluid injection step for injecting a fluid toward the back surface of the molded product. The pressure-keeping step and the fluid injection step are simultaneously executed.Simultaneously executing these two steps can lower the pressure that is to be continuously applied from the gate. The present injection molding method can reduce the pressure of the fluid to be injected toward the back surface of the molded product in order to cause the back surface of the molded product to separate from the cavity surface.

Owner:TOYOTA JIDOSHA KK

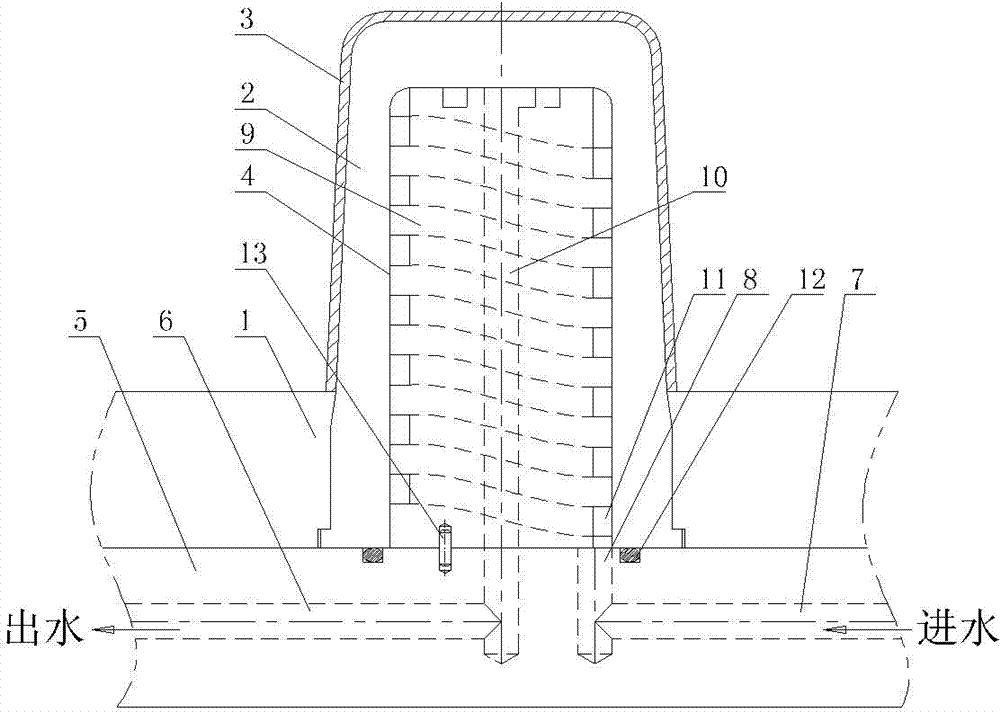

Spiral-type cooling water channel mold structure

The invention provides a spiral-type cooling water channel mold structure which cools rear mold inserts deeply and uniformly, and guarantees that the rear mold inserts are not deformed, further the service life of a mold is long, and the injection molding cost is reduced. The spiral-type cooling water channel mold structure comprises a front mold, a rear mold, a front mold insert and a rear mold insert which define a cavity; the cavity is internally provided with a product. The spiral-type cooling water channel mold structure is characterized in that the center of the rear mold insert is provided with a central cylindrical cavity body; the rear mold is supported to a plate B; a water intake cavity is formed in one side of the plate B, and a water drainage cavity is formed in the other side of the plate B; the water intake cavity comprises a horizontal end and a vertical end; the bottom of the vertical end is communicated with the inner side of the horizontal side; a spiral water conveying sleeve is sleeved in the central cylindrical cavity body.

Owner:WUXI NEST BIOTECHNOLOGY CO LTD

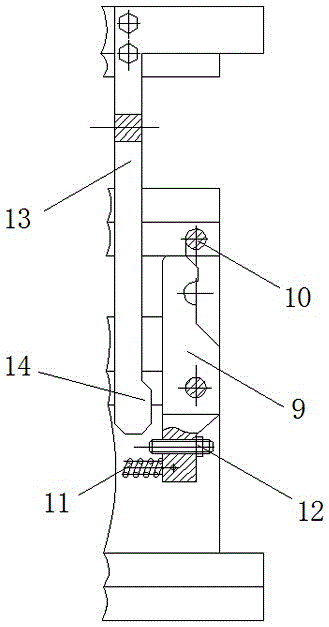

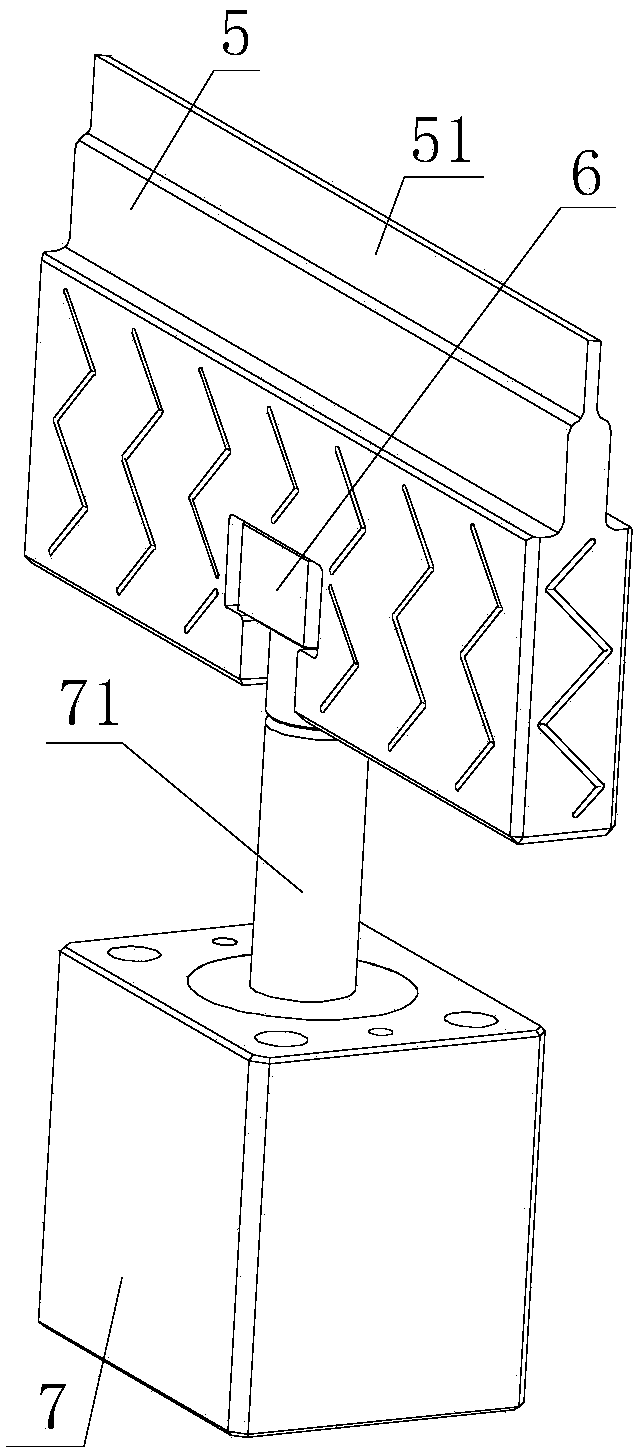

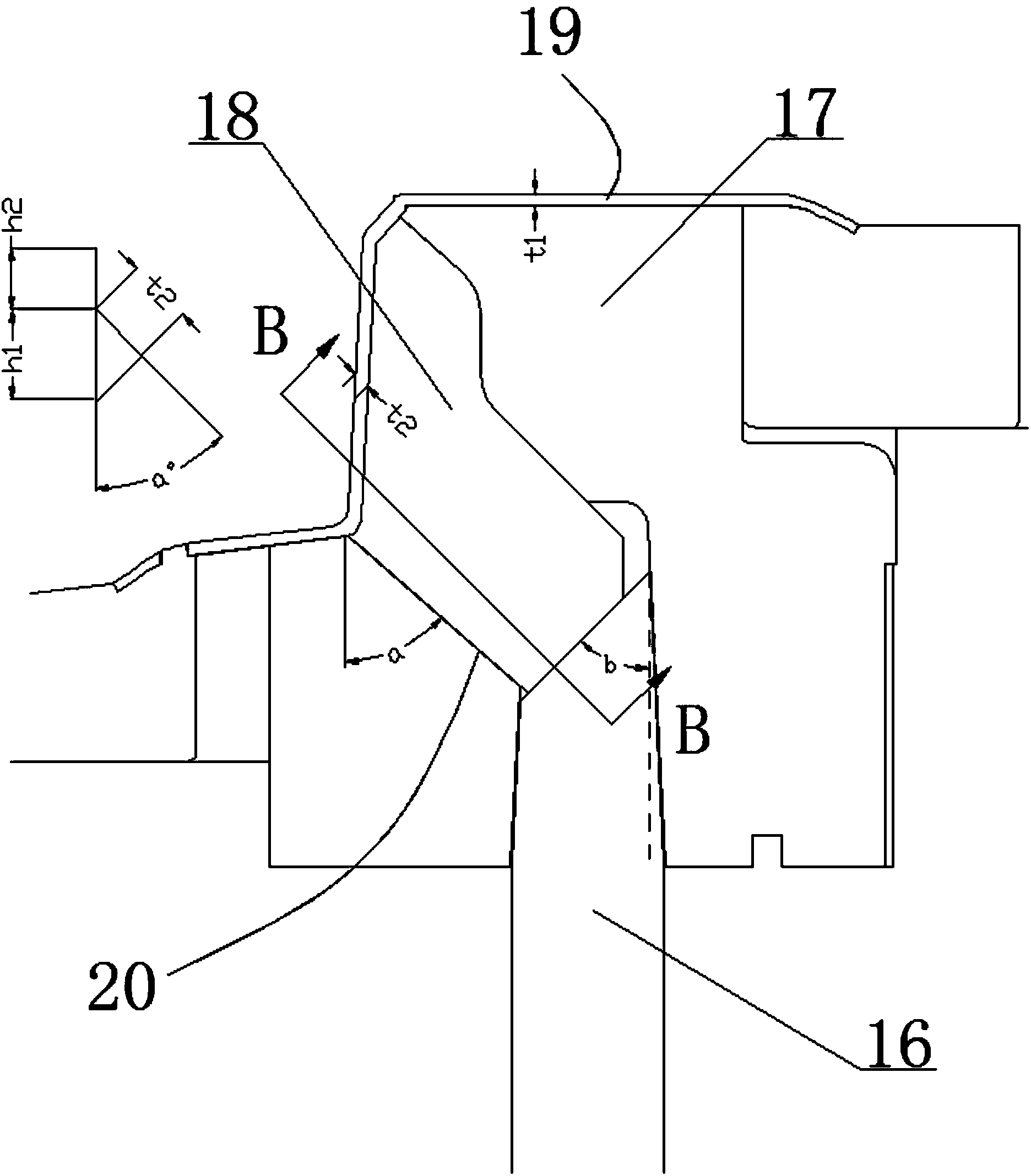

Mechanism assisting in oblique ejection of centre through injection mold

InactiveCN105415609AReliable structureReduce mold opening cost and injection molding costSlide plateIndustrial engineering

Owner:宁波正佳模塑有限公司

Micro-fluidic chip convenient for droplet tiling

PendingCN112121875AUniform sizeGuaranteed not to flowBioreactor/fermenter combinationsBiological substance pretreatmentsGeneration processEngineering

The invention discloses a micro-fluidic chip convenient for droplet tiling. The micro-fluidic chip comprises a chip body, a sealing layer and a plurality of PCR reaction units arranged on the chip body, each PCR reaction unit comprises a micro-channel arranged on the surface of the chip body, and a sample storage area, a first oil phase pool, a droplet generation area, a droplet transition area, adroplet tiling area and a collection area which are communicated with one another through the micro-channel; and the sealing layer is arranged on the surface of the chip body and is used for sealingthe micro-channel. Droplets are not directly tiled in the droplet tiling area during droplet generation, but are collected in the first oil phase pool firstly and then distributed into the droplet tiling area through the droplet transition area so that compared with the existing chip, the design solves the problem that the droplet tiling is not disturbed even if bubbles are generated in the droplet generation process, meanwhile, the problem of oil shortage in the droplet generation process is also solved.

Owner:SHENZHEN BIORAIN BIOTECHNOLOGY CO LTD

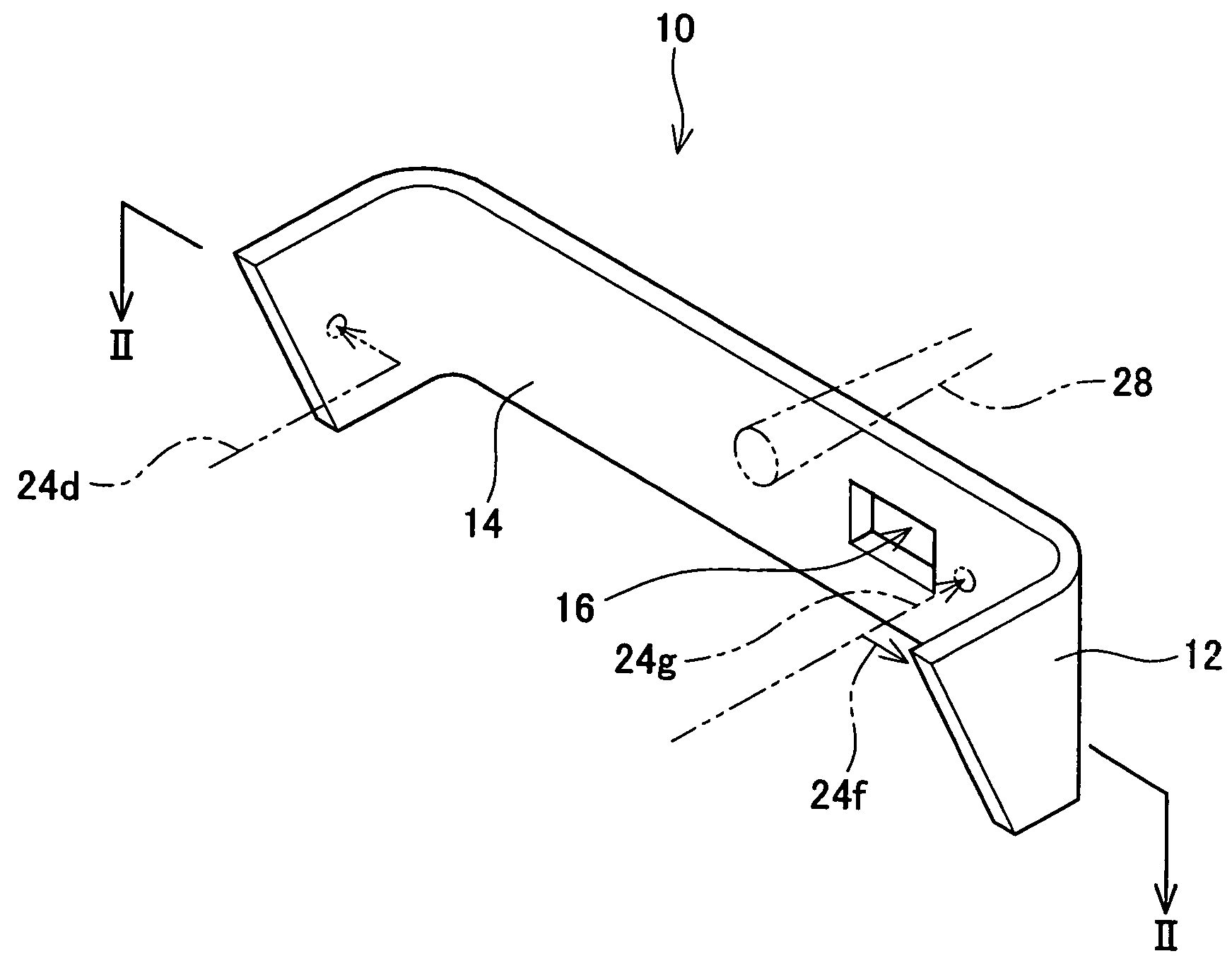

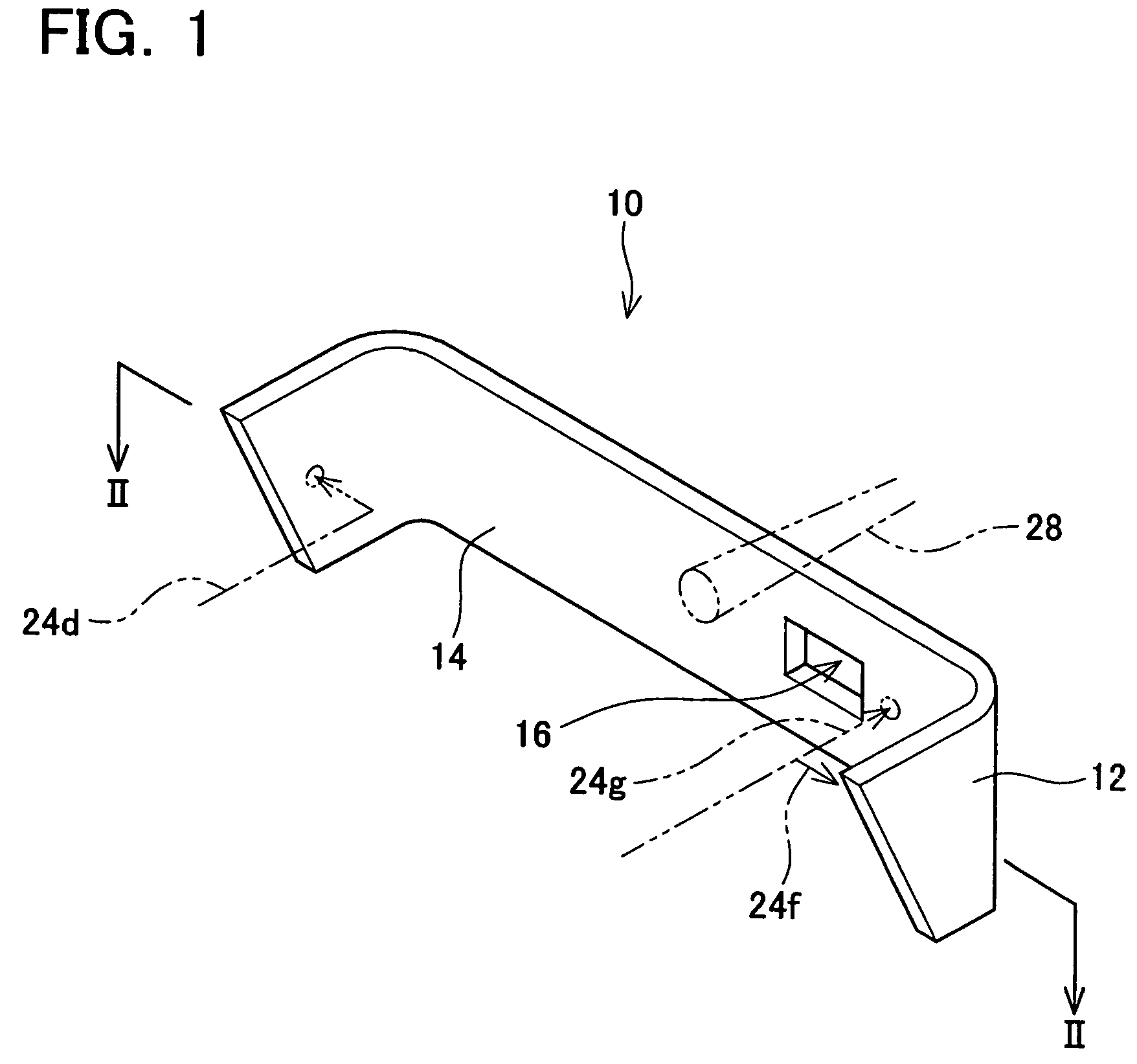

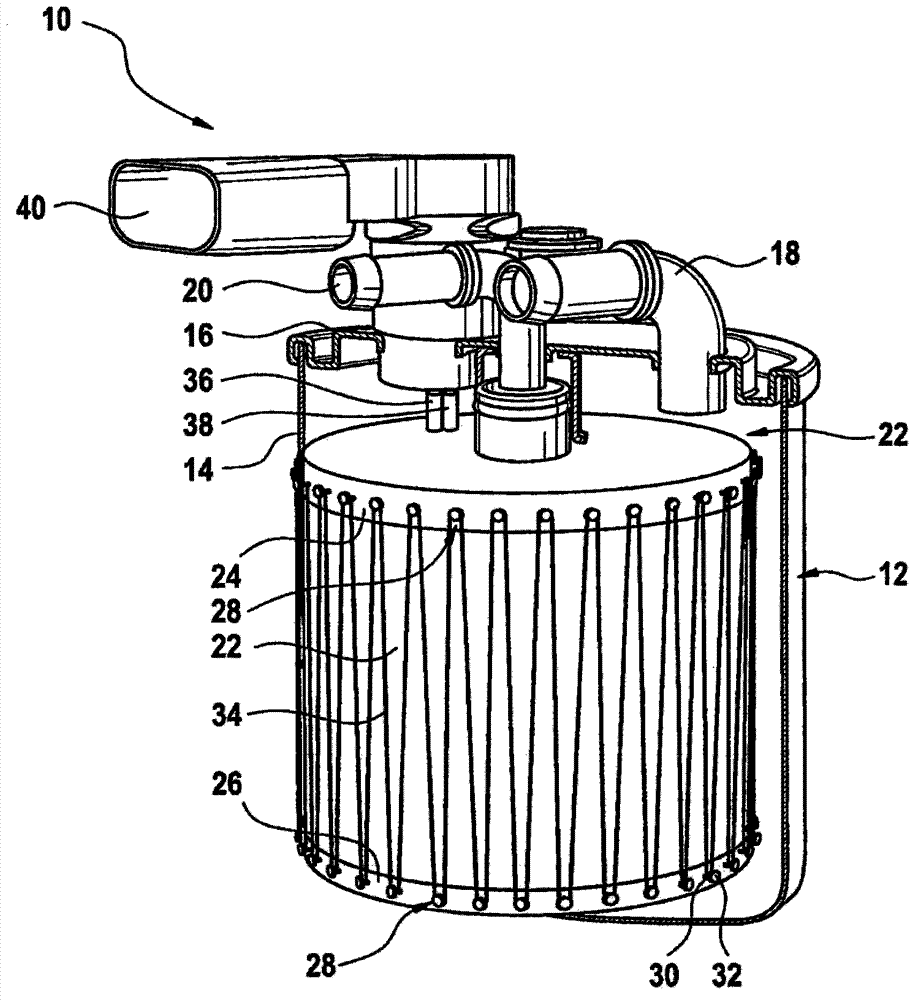

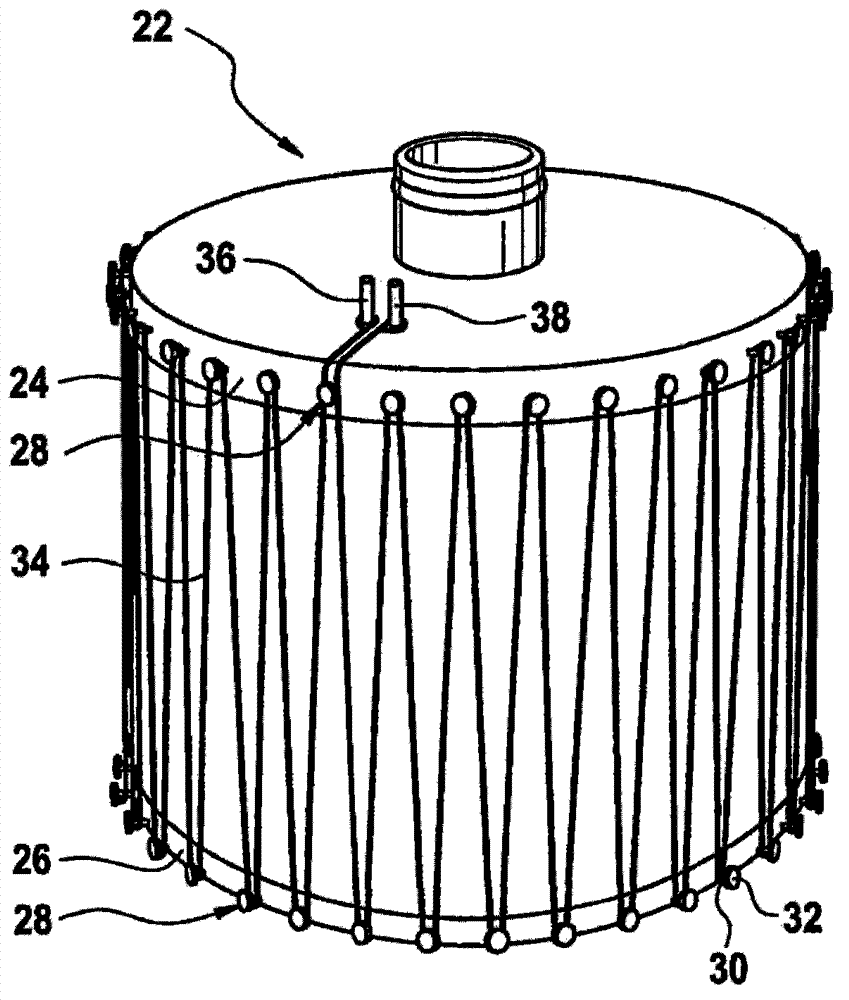

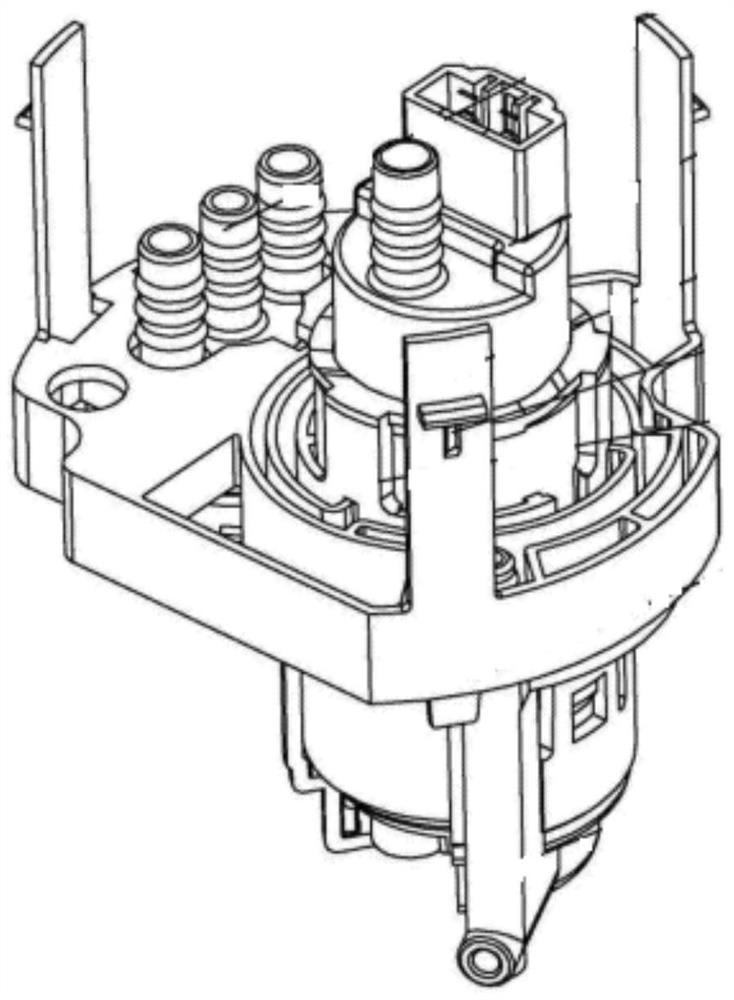

Filter device with heating device used for heating medium

ActiveCN103174496AUse fineEasy to useExhaust apparatusDispersed particle separationEngineeringFilter element

In a filter device (10) with a filter element (22) arranged in a filter casing (12) and with a heating device used for heating the medium flowing through the filter casing (12), the heating device is provided with a heating wire (34) tensioned between at least two supports (28).

Owner:ROBERT BOSCH GMBH

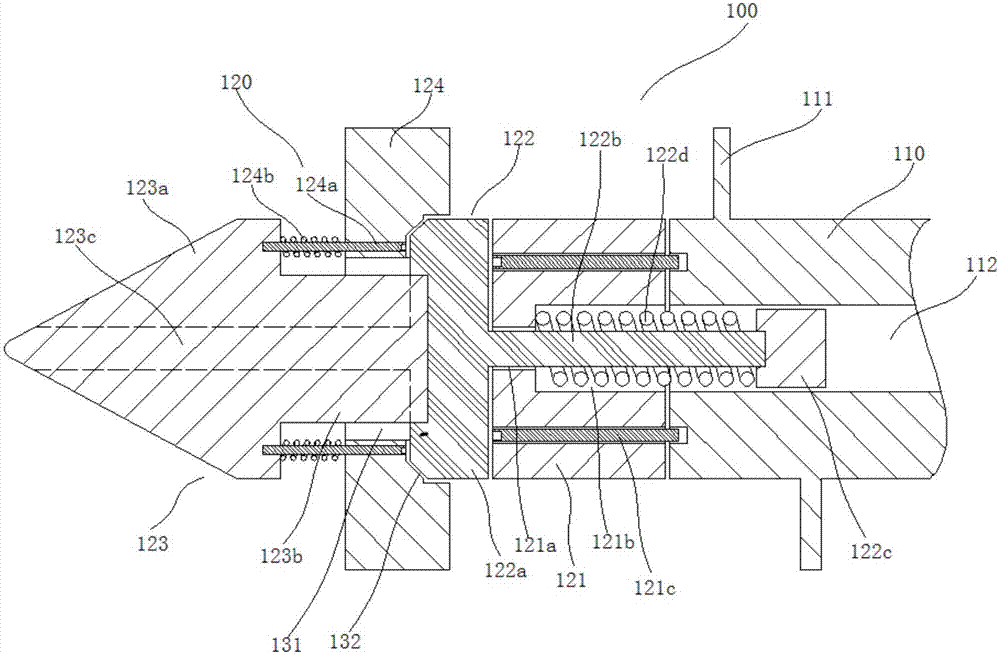

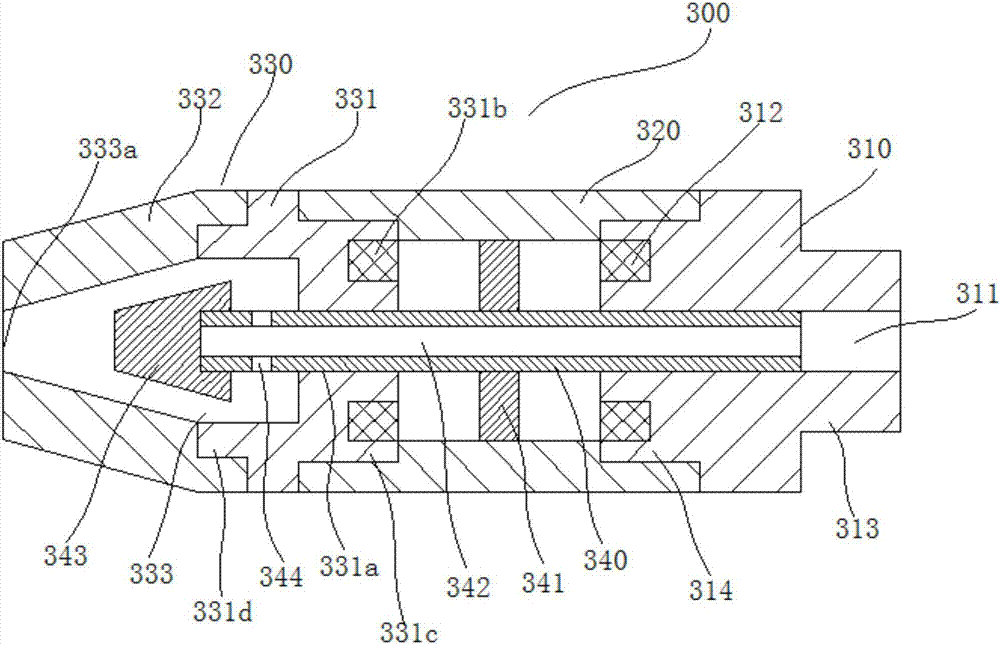

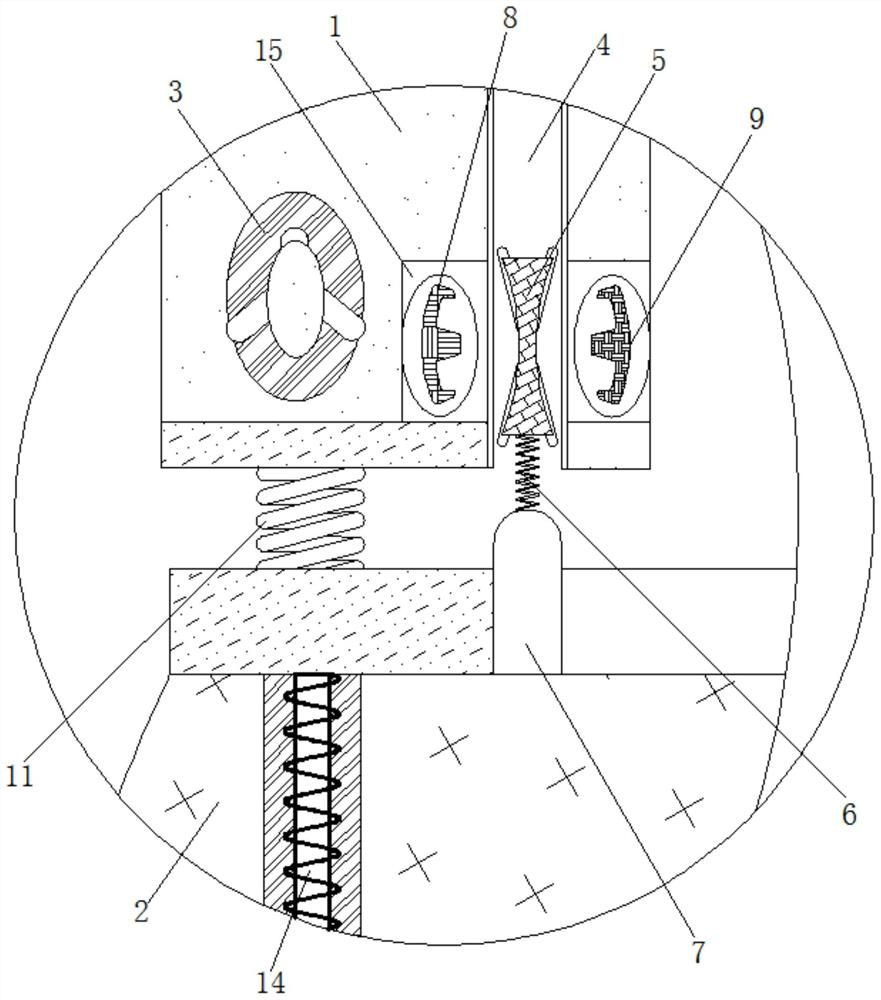

Injection molding machine screw rod

The invention relates to the technical field of injection molding machines, in particular to an injection molding machine screw rod. The injection molding machine screw rod is characterized in that a hydraulic channel is formed in a screw rod main body; a screw rod head is arranged at the left end of the screw rod main body, and comprises a mounting seat, a screw rod head seat, a screw rod head body and a check ring; the mounting seat is arranged at the end face of the screw rod main body; a mounting channel is formed in the middle of the mounting seat; a spring cavity is formed in the mounting channel; the screw rod head seat comprises a screw rod head seat connecting seat and a screw rod head seat connecting rod; the screw rod head seat connecting rod stretches into the hydraulic channel; a piston is arranged at the right end of the screw rod head seat connecting rod; a first compression spring is arranged between the piston and the spring cavity; the screw rod head body comprises a screw rod head body head and a screw rod head body connecting part; the check ring is connected with the right end face of the screw rod head body head through connecting screw rods; the connecting screw rods are sleeved with second compression springs; a material channel is formed between an inner hole of the check ring and the screw rod head body connecting part; and a sealing surface is formed between the right end face of the check ring and the left end face of the screw rod head seat connecting seat. The injection molding machine screw rod is reasonable in structure and convenient in assembly.

Owner:芜湖三顺机械制造有限公司

Injection molding method and injection molding apparatus

ActiveUS20070182066A1Reduce pressureReduce pressure requirementsMouldsConfectioneryMaterials scienceFluid injection

Owner:TOYOTA JIDOSHA KK

Double-parting-surface structure die capable of achieving stable and rapid parting

The invention relates to a double-parting-surface structure die capable of achieving stable and rapid parting. The double-parting-surface structure die comprises a fixed die plate located on the upper side, and a movable die plate located on the lower side. An upper cooling plate is arranged on the lower side of the fixed die plate. The lower side of the upper cooling plate is provided with a cavity plate connected with the upper cooling plate together. A lower cooling plate is arranged on the lower side of the cavity plate. A cavity used for pouring a product is formed between the cavity plate and the lower cooling plate. A bearing plate is arranged on the lower side of the lower cooling plate. A connecting column is connected between the bearing plate and the movable die plate. The double-parting-surface structure die capable of achieving stable and rapid parting is good in cooling effect, die component losses are reduced, the service life of the die is prolonged, and the injection molding period is shortened; and the production efficiency is improved, the product precision is guaranteed, and the product quality is improved.

Owner:FUZHOU UNIV

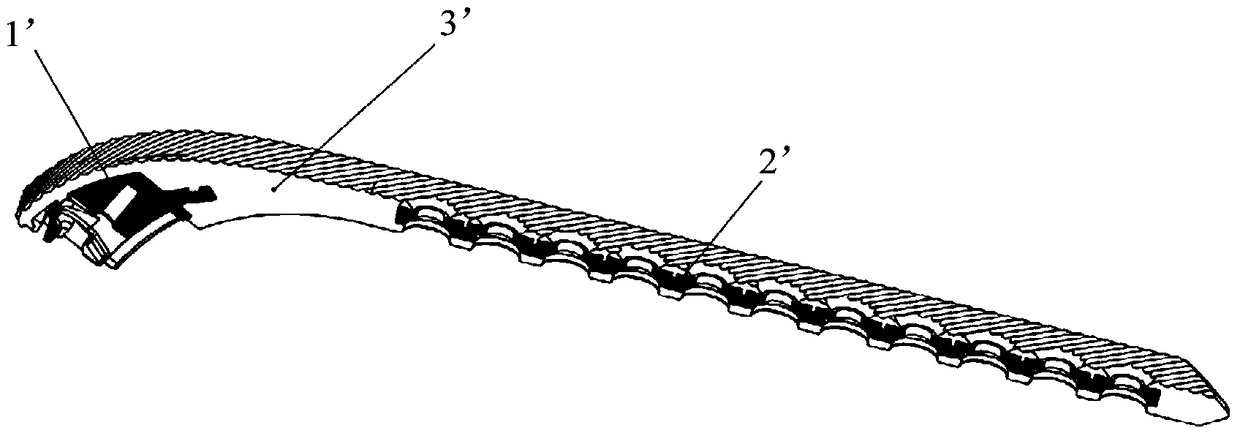

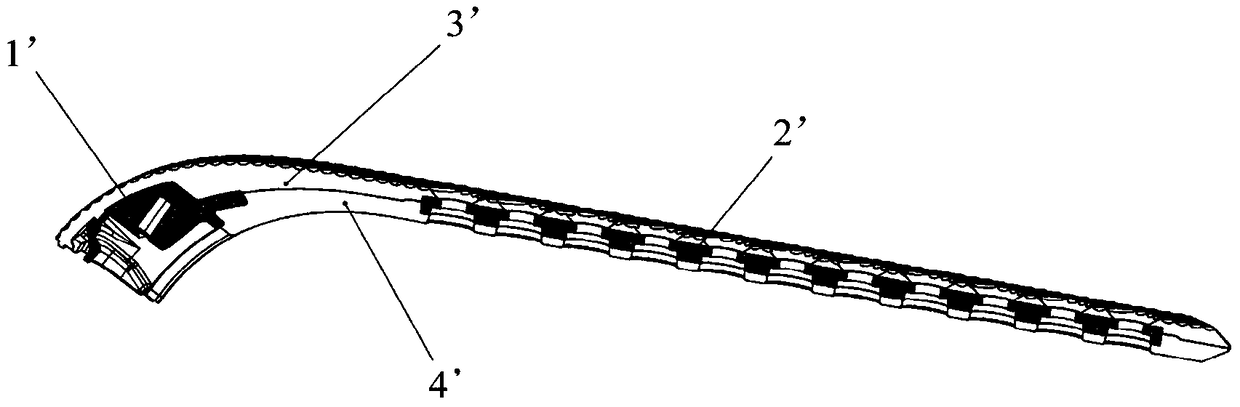

High-performance flame-retardant mica tape

InactiveCN106782831AImprove flame retardant performanceIncrease fire resistance pass rateInsulated cablesMicaMicaHigh-density polyethylene

The invention relates to a manufacturing technology of an electrical insulating material, specifically to a manufacturing method for a high-performance flame-retardant fireproof mica tape. For solving the problems of low fireproof passing rate, low flame retardancy and the like of the mica tape, a technical scheme as follows is adopted: (1) preparing coating glue; (2) putting the coating glue into a stirring pool on a scraping apparatus to be fully stirred; (3) adjusting the temperature of a curing box; (4) pulling a common mica tape to the scraping apparatus through a traction apparatus; (5) starting up and operating, and coating glass fabric grids of the common mica tape with the coating glue firstly; (6) compounding a high-density polyethylene film; (7) performing traction and curing on the mica tape; and (8) performing rolling and pressing and taking up. The manufacturing method has the beneficial effects of improving the flame retardancy of the mica tape by taking full advantages of the characteristics of a mica tape reinforcing material.

Owner:湖北平安电工材料有限公司

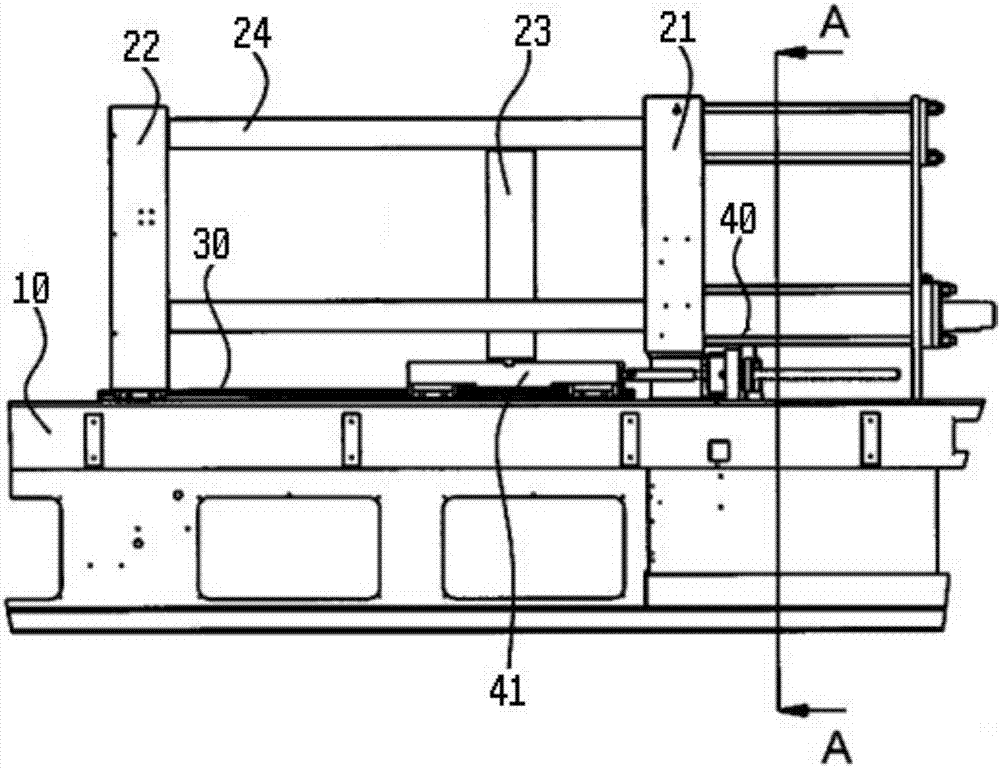

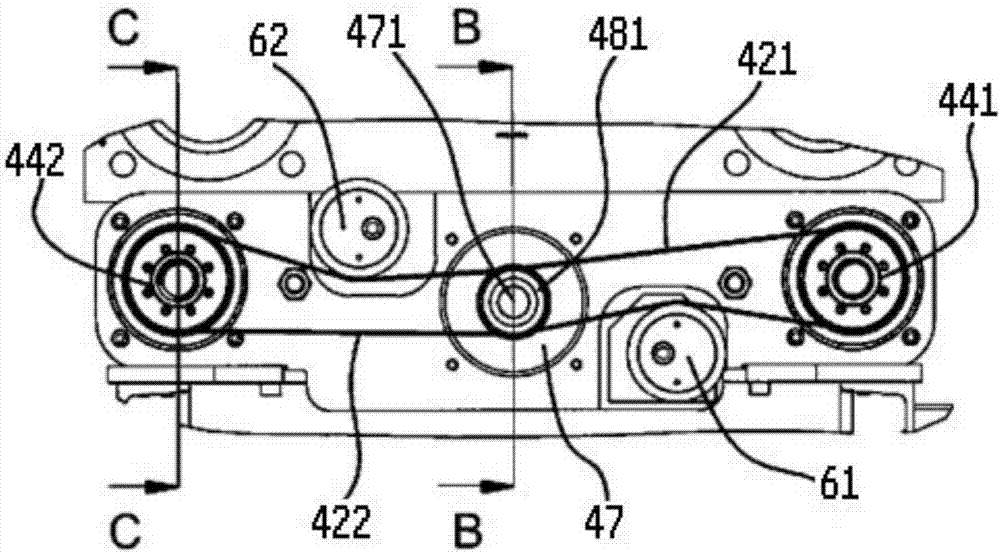

Horizontal injection press

The invention discloses a horizontal injection press which comprises a working table, an injection molding mechanism, a fixed pressing plate, a movable pressing plate, a formwork plate, a horizontal driving mechanism, a guide rail and a plurality of guide columns; the movable pressing plate and the formwork plate slide in the extending direction of the guide columns, and the horizontal driving mechanism comprises a sliding table, a first transmission belt, a second transmission belt, a first connecting rod, a second connecting rod, a first main shaft nut, a second main shaft nut, a first driven belt wheel, a bearing plate, at least one driving motor, a driving sliding wheel, a first main shaft with an external thread and a second main shaft with an external thread; and the bearing plate and the driving motor are fixedly arranged on the working table, and the sliding table is arranged on the guide rail in a horizontally-sliding manner. The horizontal injection press is simple in structure and low in cost, the die opening and closing accuracy is high, multiple dies can be subject to injection molding through one-time injection molding operation, the injection molding efficiency is high, and the injection molding quality is good.

Owner:嘉善优联物流装备有限公司

High-strength ultrathin carbon fiber die

The invention provides a high-strength ultrathin carbon fiber die. By means of the high-strength ultrathin carbon fiber die, products are outstanding in exhaust, the die is stable in temperature, the injection molding period is short, and automatic production of the die can be achieved on an electric high-speed machine. The high-strength ultrathin carbon fiber die comprises a female die portion and a male die portion. The middle of the female die portion and the middle of the male die portion are combined to form a cavity. An ultrathin carbon fiber product is arranged in the cavity. The female die portion is arranged on the upper portion of the cavity, and the male die portion is arranged on the lower portion of the cavity. The female die portion comprises a female die plate and a female die kernel. The male die portion comprises a male die plate, a male die kernel and hot runner nozzles. The high-strength ultrathin carbon fiber die is characterized in that the hot runner nozzles penetrate through the cavity from the bottom to the top; at least one exhaust insert is formed at the final filler feeding position, corresponding to the cavity, of the male die kernel; exhaust grooves which are mutually communicated are formed in the upper end faces of the exhaust inserts in a concave mode, through holes are formed in the exhaust inserts, and the upper ends of the through holes are connected with any exhaust groove; a plurality of female die kernel steam holes are formed inside the female die kernel.

Owner:SUZHOU FEITUO PRECISION MOLD

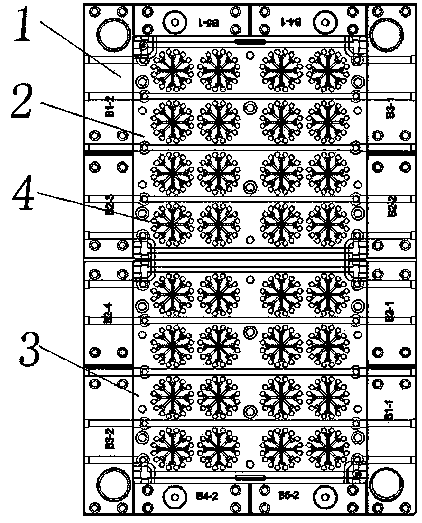

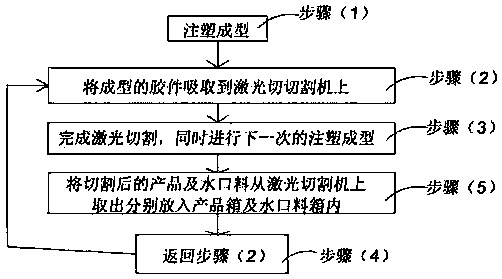

One-mold 512-hole optical lens mold and molding processing technology

The invention discloses a one-mold 512 optical lens mold and a molding processing technology. The mold is provided with a first product region and a second product region, the first and second productregions are provided with 16 uniformly distributed cavity groups respectively, each cavity group comprises a cavity, a thermal nozzle glue inlet and a glue inlet flowing passage, each glue inlet flowing passage comprises a main flowing passage and a secondary flowing passage, each thermal nozzle glue inlet is communicated with the main flowing passage, eight main flowing passages are arranged, the eight main flowing passages are uniformly distributed, the end of each main flowing passage is connected with two splitting passages, and the splitting passages are communicated with the cavities. According to the mold, 512 optical lenses can be molded by one mold, the productivity is effectively improved, and the injection molding cost is reduced. The mold has the advantages of simple structureand convenient operation, four efficient fully automatic laser cutting machines are used for ensuring that the molding period is conformed to the processing period, smooth production is ensured, andthe maximization of the productivity is achieved.

Owner:SHENZHEN MINGZHI ULTRA PRECISION TECH CO LTD

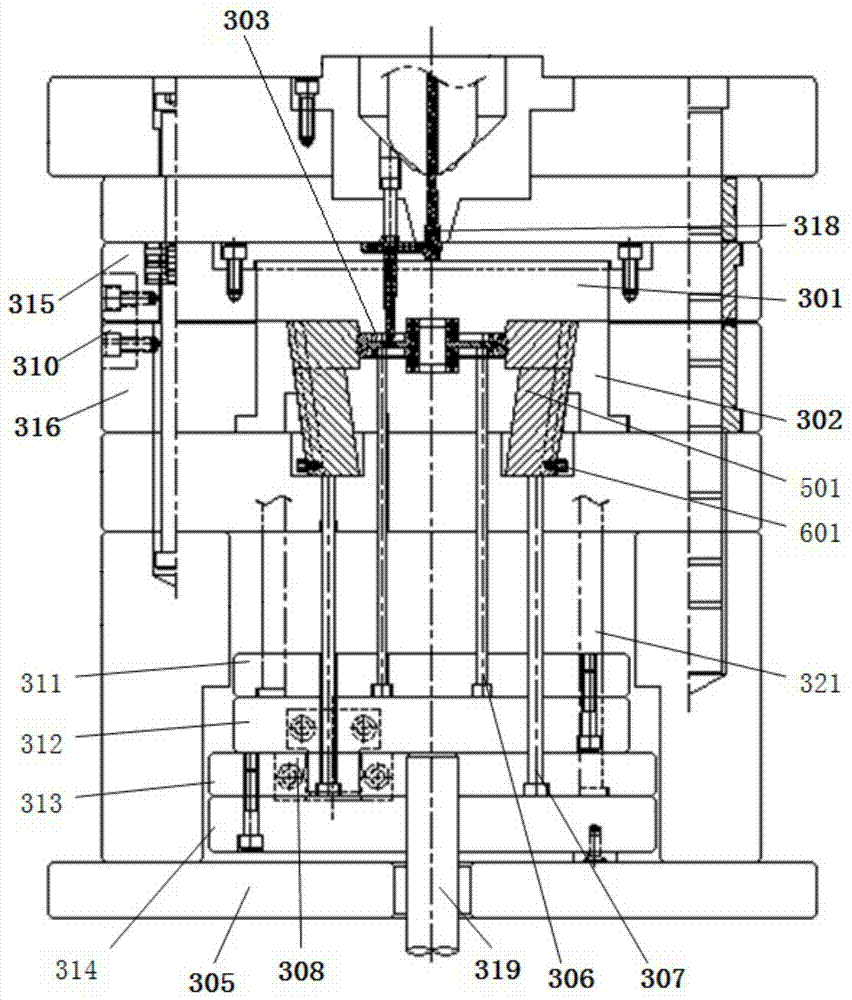

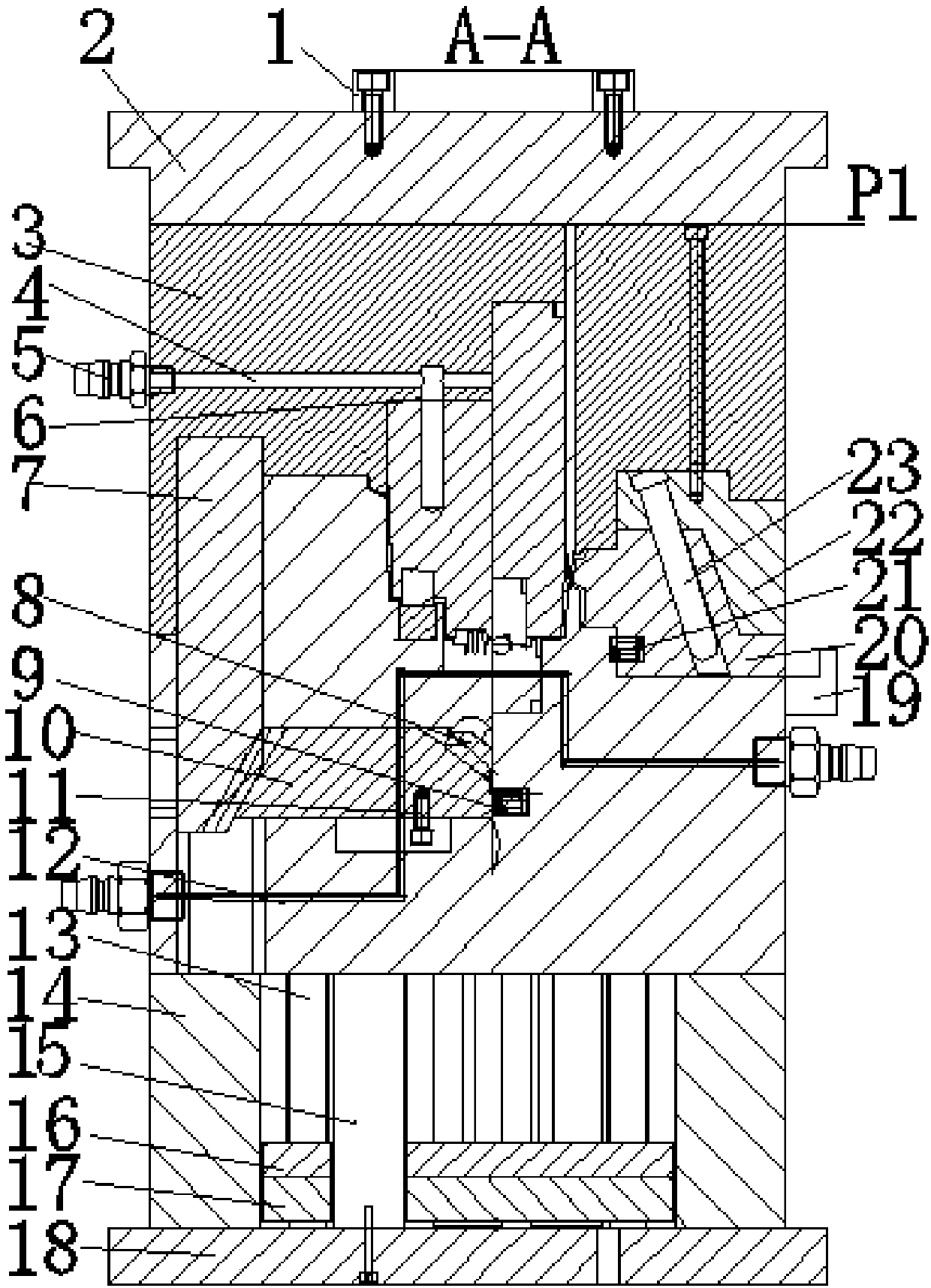

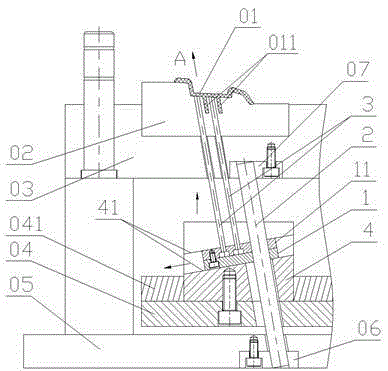

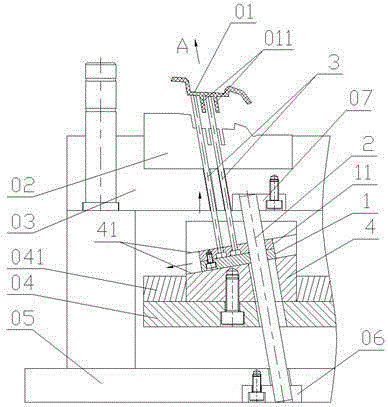

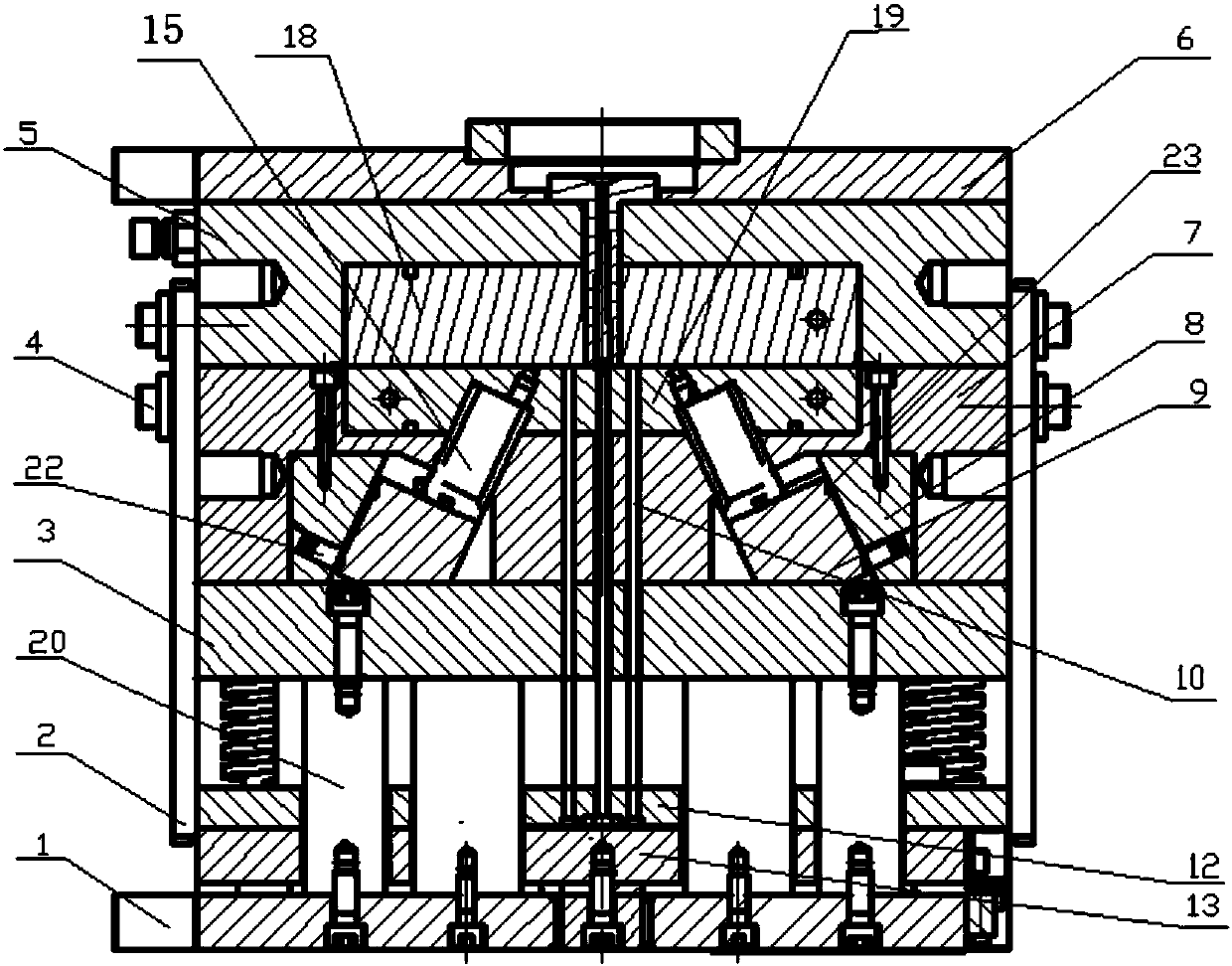

Injection mould utilizing moving mould pull plate to drive oblique sliders to pull cores

The invention relates to an injection mould utilizing a moving mould pull plate to drive oblique sliders to pull cores and solves the problems of complicated structure, core pulling interference and poor synchronism, which occur when the existing injection mould is provided with lateral pulling cores in multiple directions. According to the technical scheme, the injection mould comprises a fixed mould part and a moving mould part, wherein the moving mould part comprises a moving mould plate at the upper end, a moving mould bottom plate at the lower end and an ejecting mechanism in the middle;the upper end of the ejecting mechanism is connected with a mould core on the moving mould plate, and the lower end of the ejecting mechanism penetrates through the moving mould bottom plate and is connected with a driving device; a sliding limiting mechanism is arranged between a fixed mould plate of the fixed mould part and the moving mould plate of the moving mould part; at least one lateral mould core is arranged below the moving mould plate, and the lower end of the lateral mould core is mounted on the moving mould pull plate through a connecting assembly; and the moving mould pull plateis arranged on the ejecting mechanism in a sleeving manner and connected with the moving mould bottom plate through a fixing component. The structure is very simple and compact. Lateral core pulling is simultaneously carried out in multiple different directions by adopting one core pulling mechanism. The service life is long, the production efficiency is high, and maintenance is convenient.

Owner:XIANNING HONGSHENG MOLD TECH CO LTD

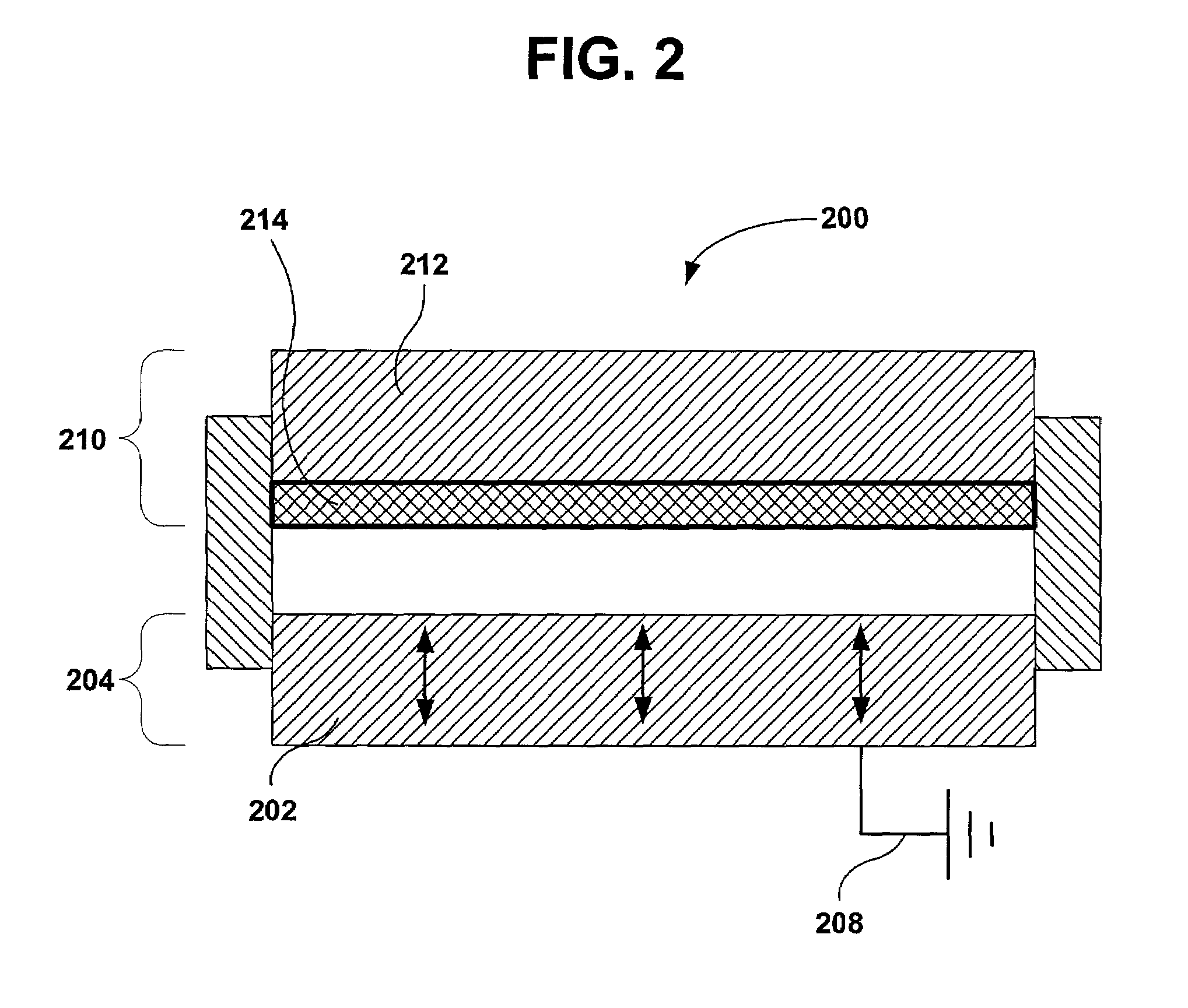

Grounded molding tool for manufacture of optical components

In one embodiment, the invention is directed to an injection molding tool that has improved grounding. The injection molding process creates significant amounts of static electricity in the molten thermoplastic. This static electricity can be more adequately dissipated from the system through the addition of one or more paths to ground. In this manner, a significant reduction in charge passing between the stamper and the mirror block can be achieved. By reducing or eliminating the amount of charge passing between the stamper and the mirror block, erosion of the mirror block can be reduced or avoided.

Owner:IMATION

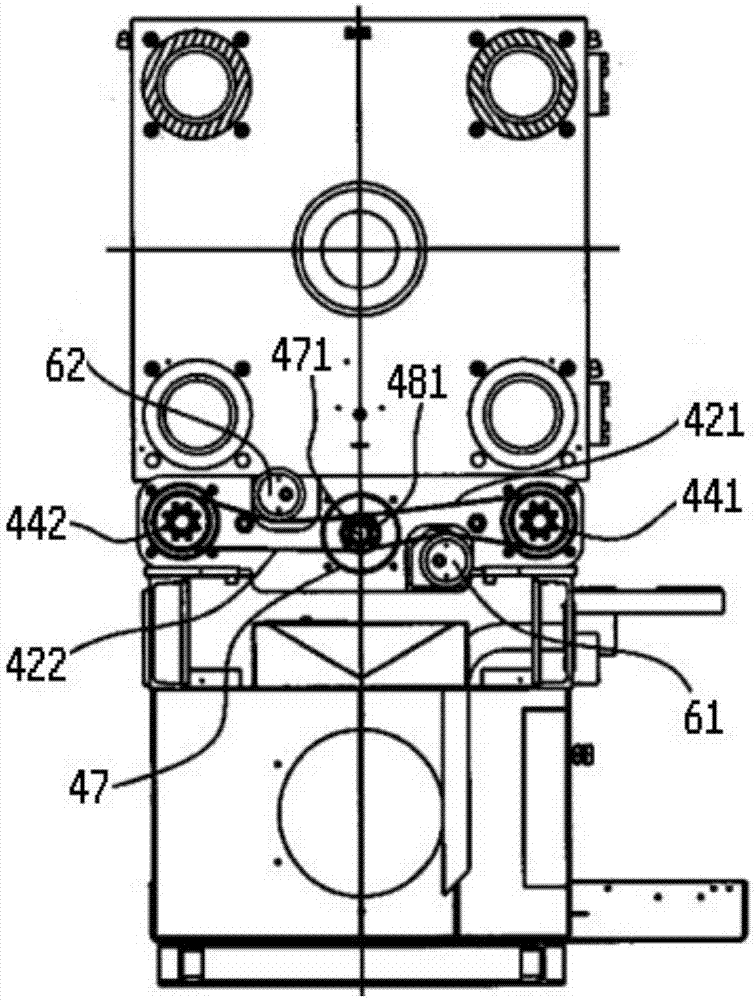

A single-cavity molding twice-sealing mechanism of an injection mold

The invention relates to a single-cavity molding twice-sealing mechanism of an injection mold. The mechanism includes an upper press plate and hot runner manifold of an injection molding machine, a fixed die and a movable die. A mold cavity is formed after the fixed die and the movable die are assembled. The mechanism also includes a sealing core-pulling slide block. The sealing core-pulling slideblock is connected to a piston rod of an oil cylinder through an oil cylinder connecting block. The oil cylinder is mounted in the upper press plate. The hot runner manifold and the fixed die are provided with slide slots. The sealing core-pulling slide block is driven by the oil cylinder to slide in the slide slots, and is provided with a stopper used for dividing the mold cavity into a first-color injection molding cavity and a second-color injection molding cavity. A first gate is disposed in the first-color injection molding cavity, and a second gate is disposed in the second-color injection molding cavity. According to the injection mold, only by designing the one mold cavity, double-color injection molding can be achieved, structures of the injection mold and the injection molding machine are greatly simplified, and the injection molding cost is greatly reduced.

Owner:浙江西诺模具有限公司

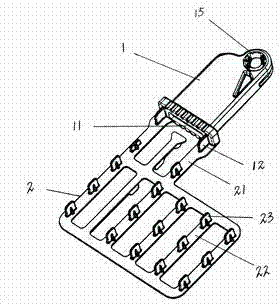

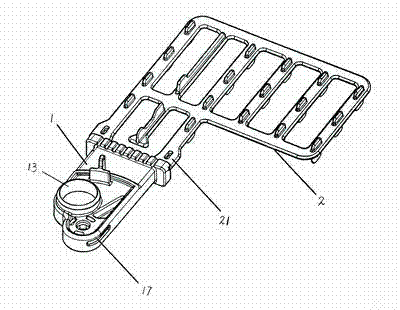

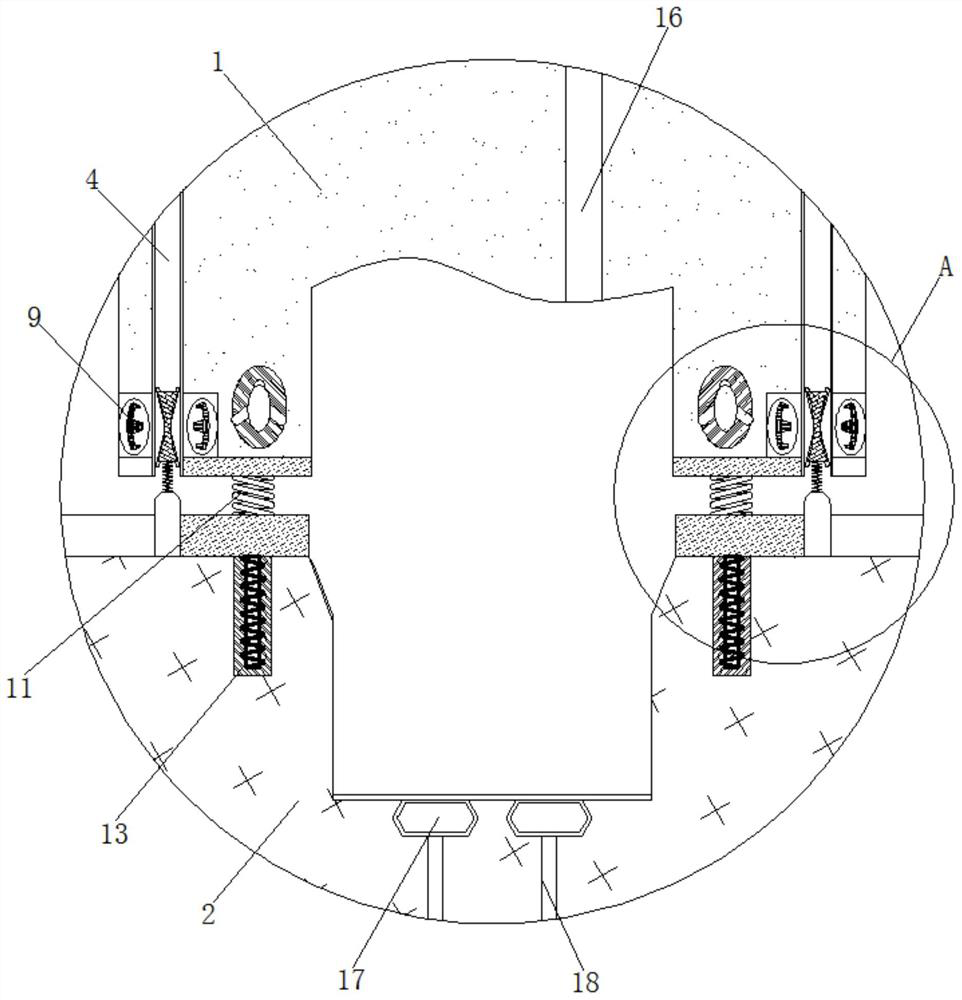

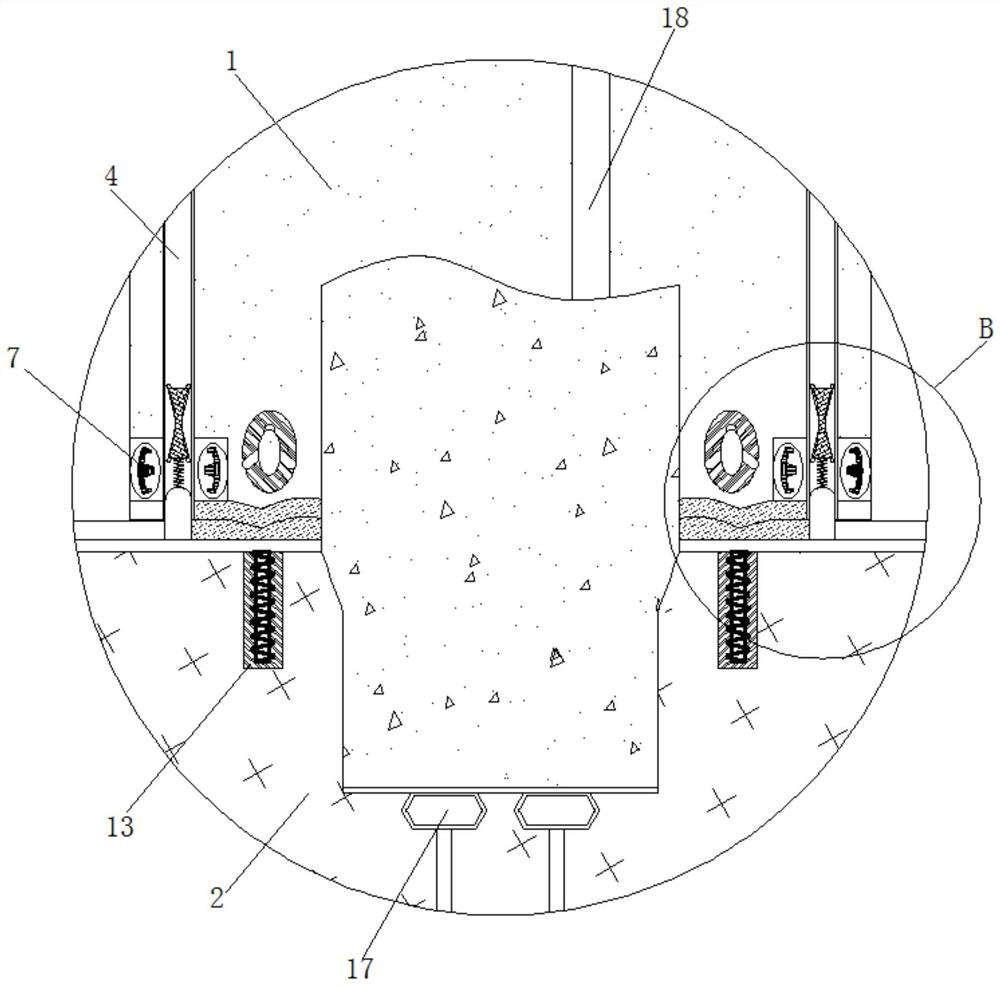

Filter screen of fuel oil pump

InactiveCN103032219AReduce injection molding costsReduce assembly processMachines/enginesLiquid fuel feedersWhole bodyFuel oil

The invention discloses a filter screen of a fuel oil pump. The filter screen comprises a connecting head, a screen cloth skeleton and screen cloth, and is characterized in that an oil inlet is arranged in one end part of the lower end of the connecting head; longitudinal blocking pieces are respectively arranged on the lower end surfaces of the two end edges of the oil inlet in a downwards extending manner; an oil outlet with an oil inlet joint is arranged in the left end part on the lower end surface of one end part of the upper end of the connecting head, and a locking ring seat with a center hole on the bottom surface is arranged at the right end part of one end part of the upper end of the connecting head in an upwards extending manner; clamping buckles are evenly distributed at the upper end part of the inner wall of the locking ring seat; an arc-shaped locking ring window is arranged in the right side wall of the locking ring seat; a locking ring formed by a ring-shaped body and upwards-extending arc-shaped blades evenly distributed on the upper end surface of the ring-shaped body is arranged in the locking ring seat; the screen cloth skeleton consists of a framework and fillets distributed in the framework; and raised longitudinal support plates are distributed on the upper end surfaces of the longitudinal fillets; the two ends of one end part of the upper end of the framework are respectively connected with the two ends of the lower end edge of the oil inlet to form a whole body; and the screen cloth is wrapped outside the L-shaped screen cloth skeleton after being folded and is sealed in a welded manner. The filter screen is suitable for being used by the fuel oil pump.

Owner:上海柱信汽车电子燃油系统有限公司

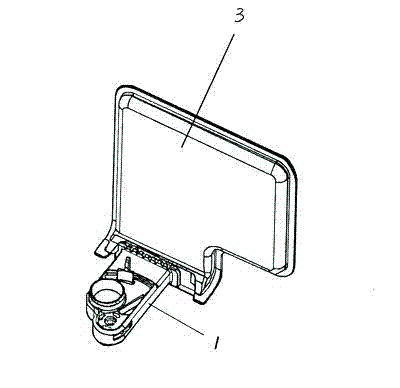

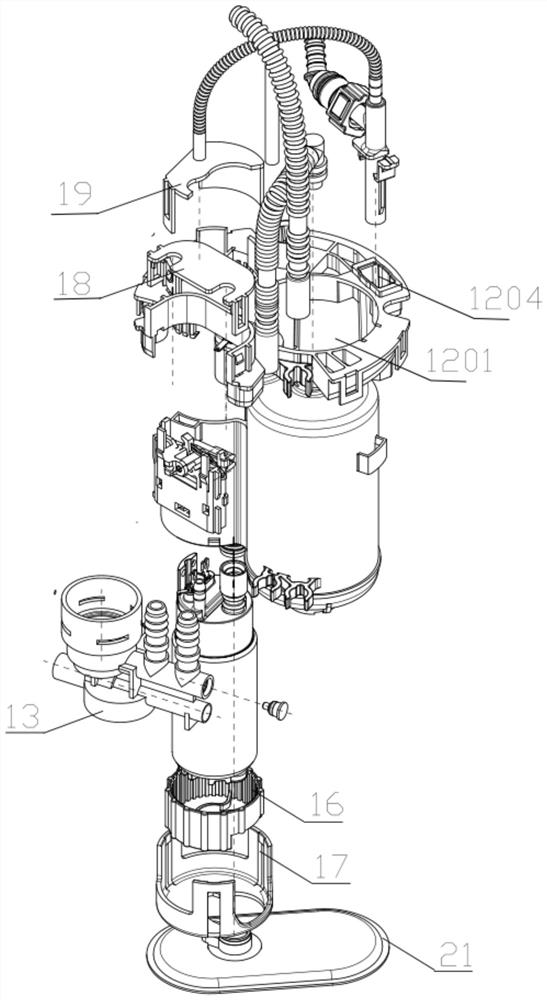

Fuel pump support assembly for vehicle

ActiveCN112539124AEasy to integrateLow costMachines/enginesLiquid fuel feedersStructural engineeringControl theory

The invention discloses a fuel pump support assembly for a vehicle. The fuel pump support assembly comprises a disc-shaped support body, a fuel refined filtration filter, an adjuster assembly, a far-end injection connector and a pump core, wherein a large mounting hole and a small mounting hole which are provided with axes extending up and down and communicate with each other are formed in the position, corresponding to the fuel refined filtration filter, of the center of the support body, a heating pipe clamping sleeve penetrating through the support body up and down is arranged on the support body, a far-end injection device clamping sleeve with the axis extending up and down is further arranged on the support body, a U-shaped oil level indicator receding notch which is concave inwards and provided with an opening in the side surface is formed in the side surface of the support body, and oil pipe clamping heads are further distributed on the side surface of the support body. The integration is high, the cost is low and mounting is convenient; the shell pump core is arranged outside and is not wrapped by a filter core, so that the heat dissipation is good; when upper and lower covers of the filter are welded, the welding area is reduced, the production difficulty is reduced, and the production stability is improved; the weight of the filter with the same filtering efficiency is greatly reduced, and the injection molding cost is reduced; and the size is small and the filtering efficiency is high.

Owner:CHONGQING WANLI LIANXING IND GROUP

Mold gap treatment device during mask injection molding

The invention relates to the technical field of masks, and discloses a mold gap treatment device during mask injection molding. The mold gap treatment device comprises an upper mold and a lower mold,a magnetic block is fixedly connected to the interior of the upper mold, a limiting groove is formed in the upper mold, a dielectric plate is movably connected to the interior of the limiting groove,the bottom of the dielectric plate is movably connected with a connecting spring, and the bottom of the connecting spring is movably connected with a protrusion. According to the mold gap treatment device for mask injection molding, when the dielectric plate moves upwards, current is generated between a positive plate and a negative plate, an electromagnet is powered on to attract the magnetic block, the upper mold and the lower mold are attracted, and at the moment, an injection molding solution is poured from an injection molding opening and formed in the upper mold and the lower mold, and when the injection molding solution flows into a bottom cavity, current is generated at the two ends of a semiconductor chilling plate, a magneto-rheological body is changed into a solid state from a liquid state, the upper mold and the lower mold are completely buckled without gaps, the mask manufacturing percent of pass is increased, and the injection molding cost is reduced.

Owner:王菊英

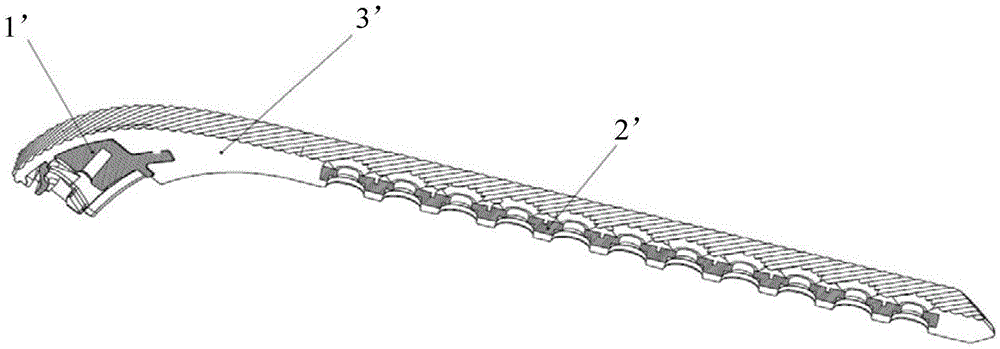

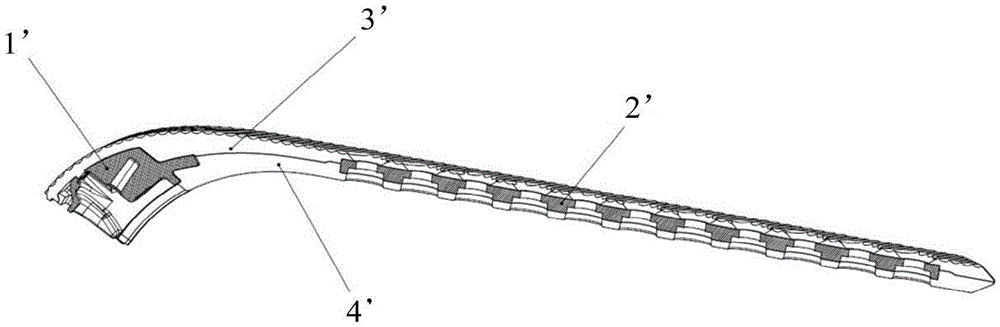

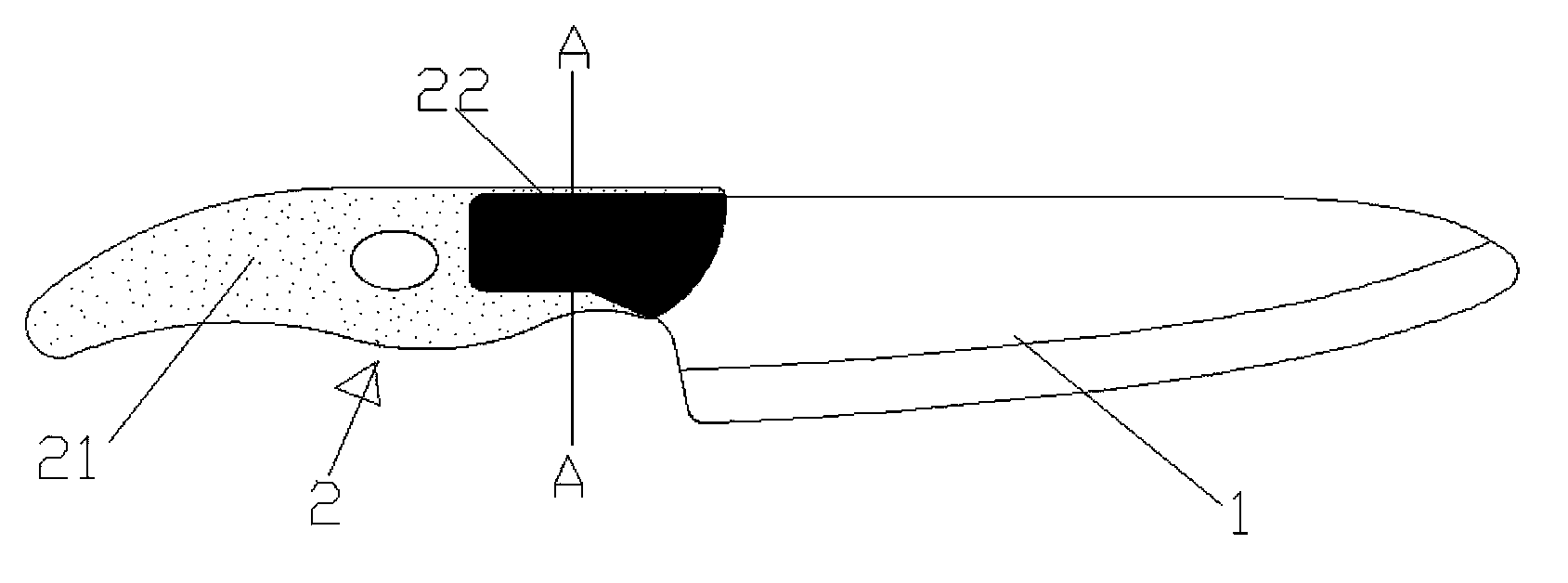

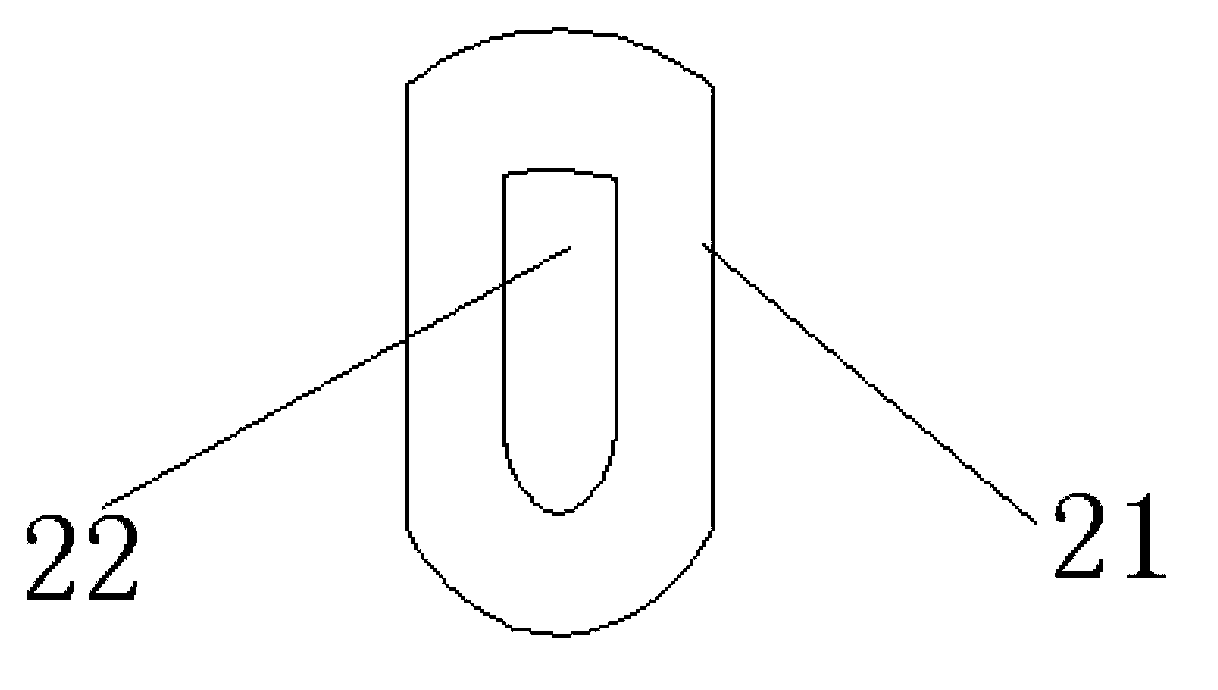

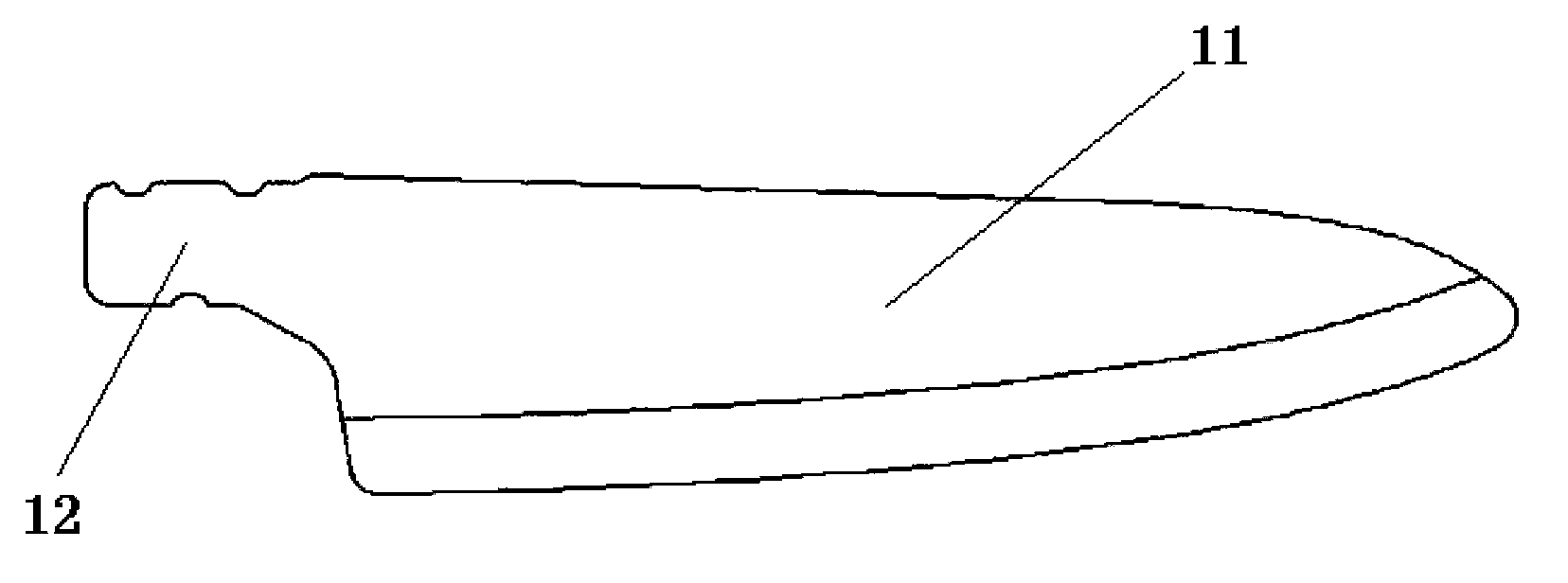

Multilayer injection molding ceramic cutting tool

InactiveCN103770127AHigh densityHigh hardnessMetal working apparatusMetal-working hand toolsMetallurgyCeramic cutting tool

The invention discloses a multilayer injection molding ceramic cutting tool. The multilayer injection molding ceramic cutting tool comprises a ceramic tool blade and a hand shank, wherein the ceramic tool blade comprises a shank portion and a blade portion, and the hand shank is molded through at least two times of injection molding, is integrally molded with the shank portion, and is of multilayer structure. Besides inherent characteristics of a ceramic cutting tool, the multilayer injection molding ceramic cutting tool further has the advantages of being simple in structure, smooth in surface, glossy, difficult to loosen due to the fact that the ceramic tool blade and the hand shank are designed in integration mode and the like.

Owner:鸿皓钢模(昆山)有限公司

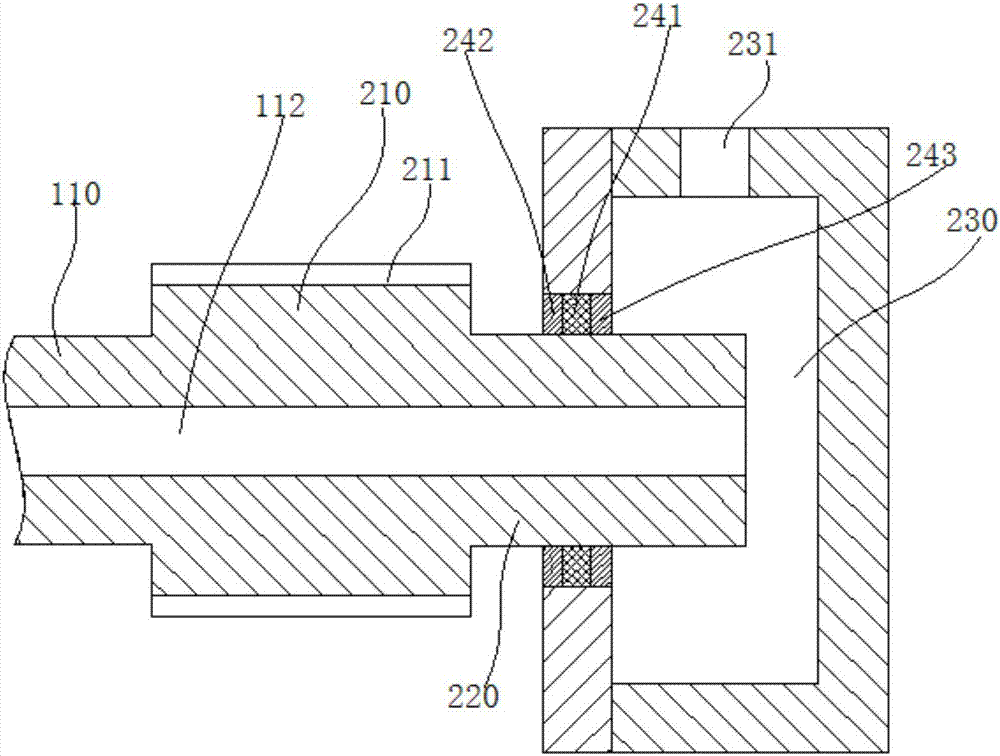

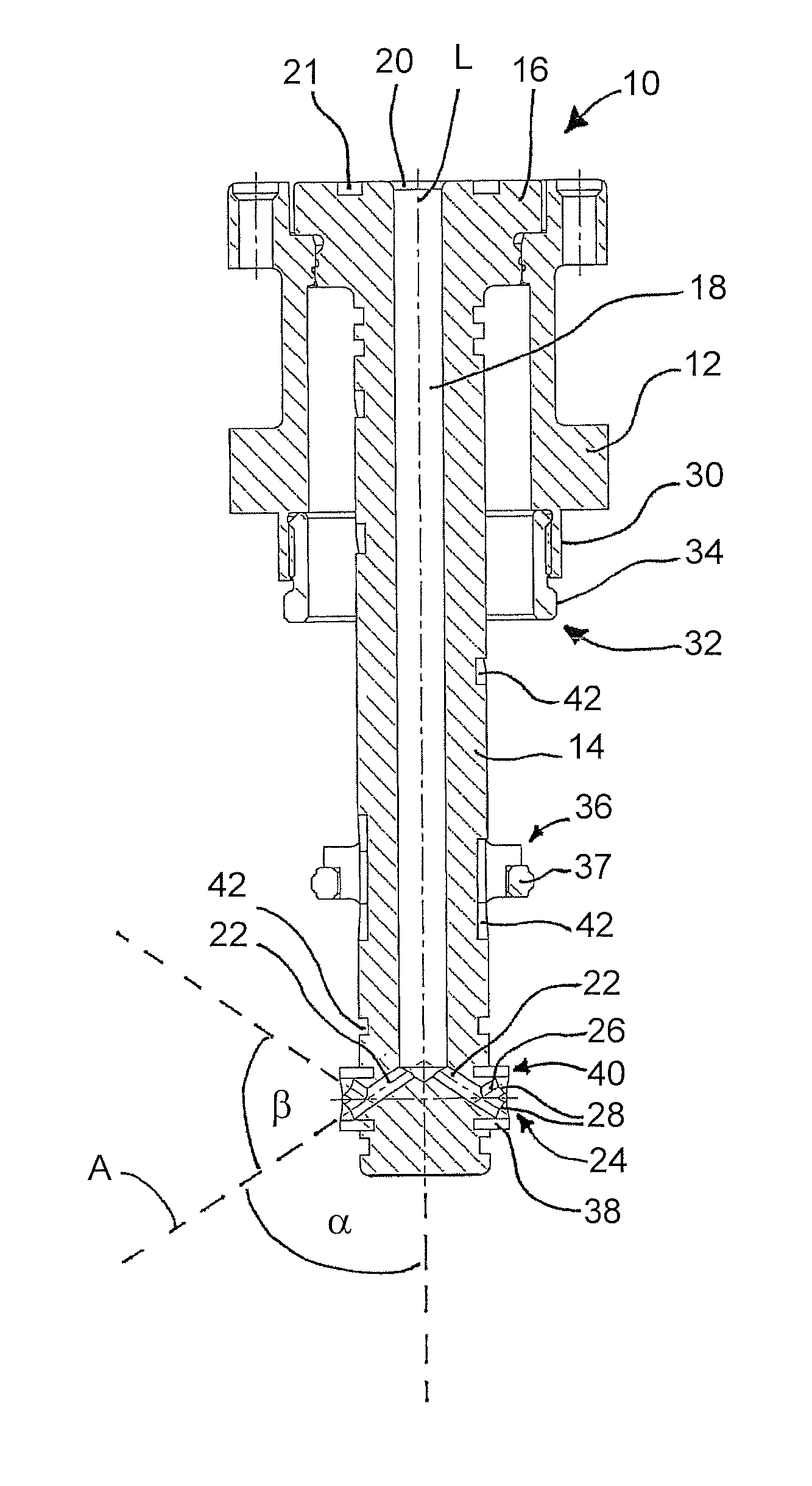

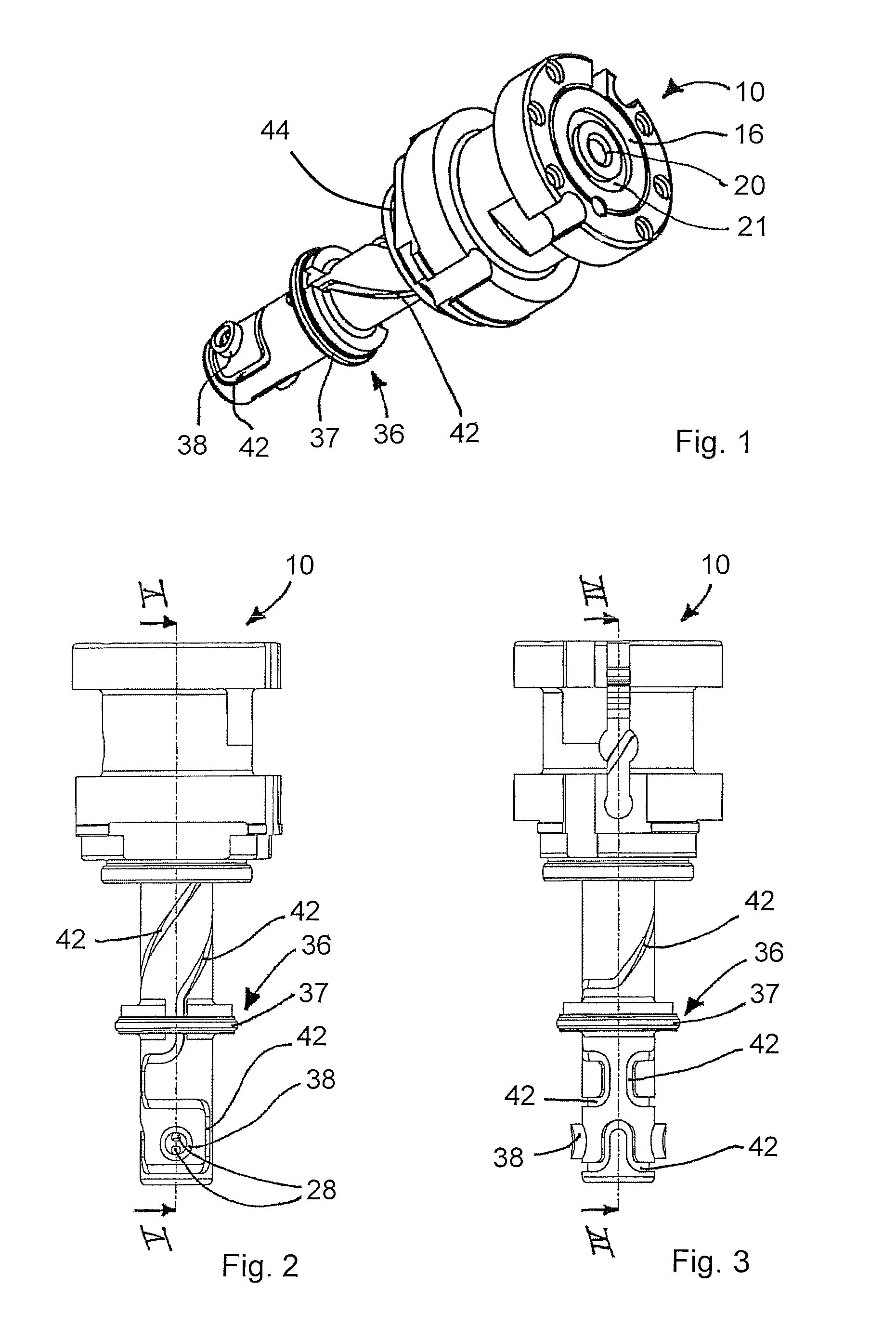

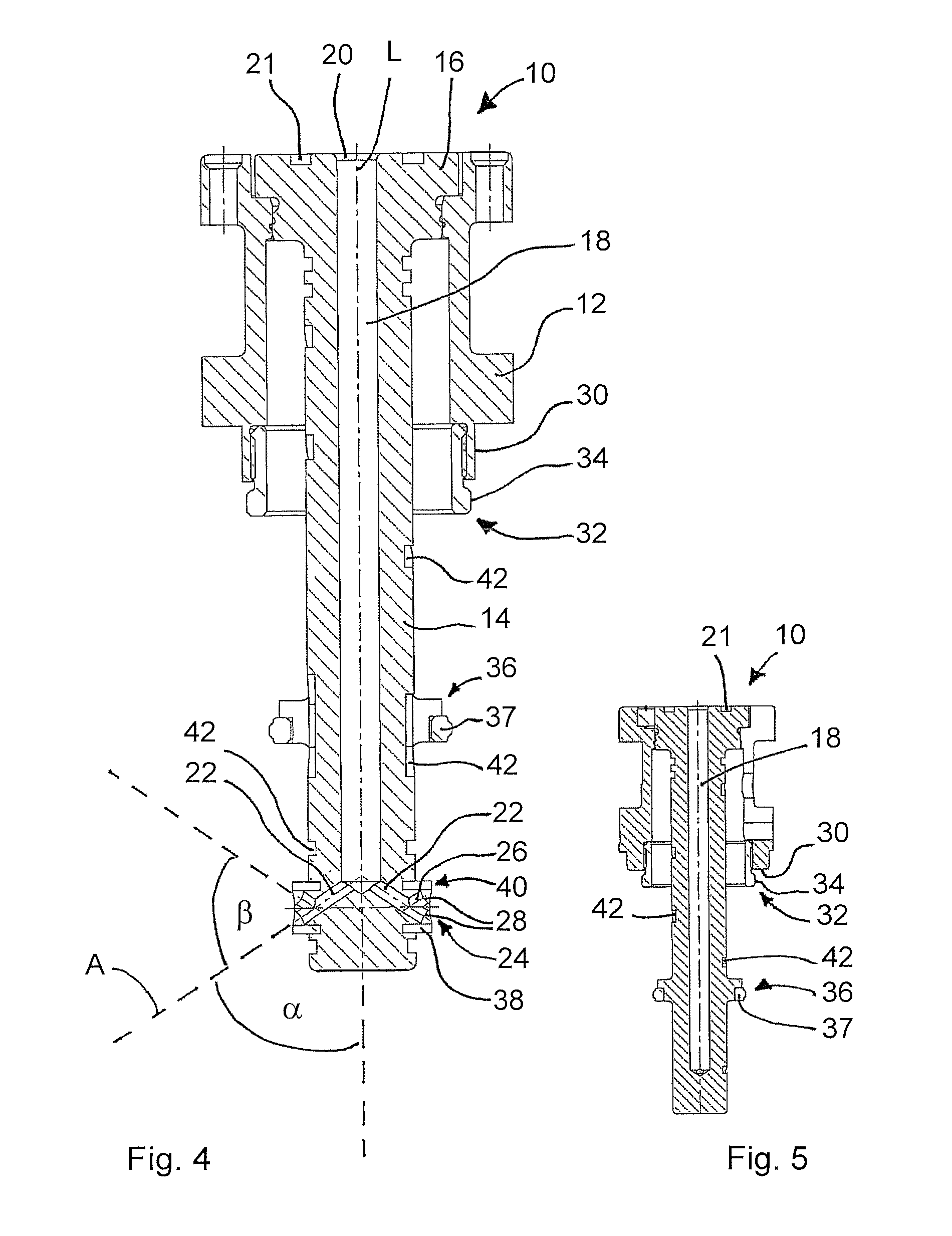

Injection moulding device

InactiveUS8246342B2Supports sealing effectivenessPrevent movementFood shapingInjection mouldingNozzle

An injection molding nozzle (10) for injection molding equipment and comprising a nozzle casing (14) subtending a longitudinal axis (L) fitted with at least one flow duct (18) for a fluid processing material, further comprising at least one nozzle tip (24) discharging the fluid processing material out of the nozzle casing (14), the minimum of one nozzle tip (24) running transversely to the longitudinal axis (L) of the nozzle casing (14), the minimum of one nozzle tip (24) being integral with the nozzle casing (14).

Owner:GUENTHER HEISSKANALTECHNIK GMBH

Multi-functional soft contact lens mould

The invention relates to a moulding method of a soft contact lens. The preparation method of the mould comprises the following steps: 1) designing and processing a metal core, 2) performing injection molding of the mould; 3) curing and forming a lens; 4) performing hydration of the lens; and 5) packaging the lens. The lens mould of the invention can be used to satisfy the forming of the soft contact lens and used as the hydration container of a semi-finished lens and as the packaging container of a finished lens too. The invention also has the advantages of stable injection, simple hydration operation and low injection low.

Owner:JIANGSU HORIEN CONTACT LENS

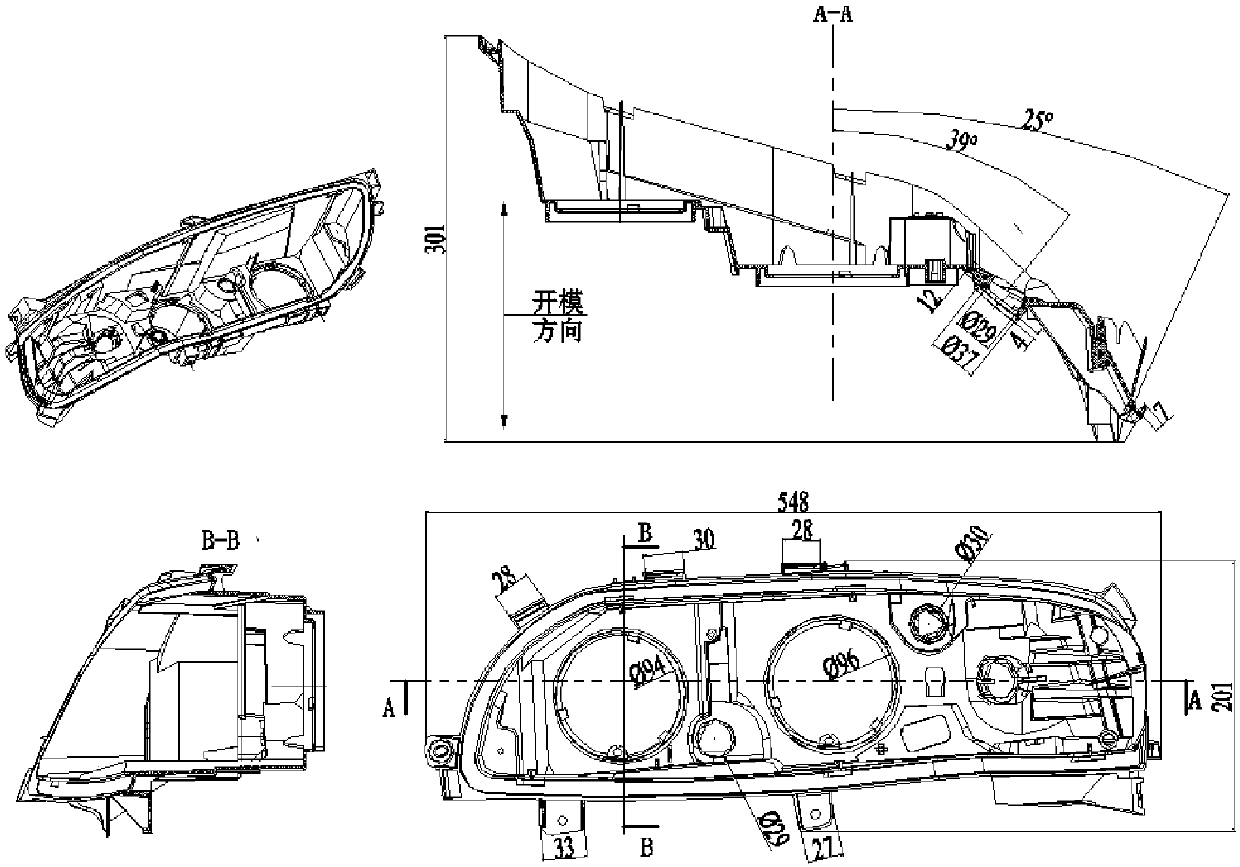

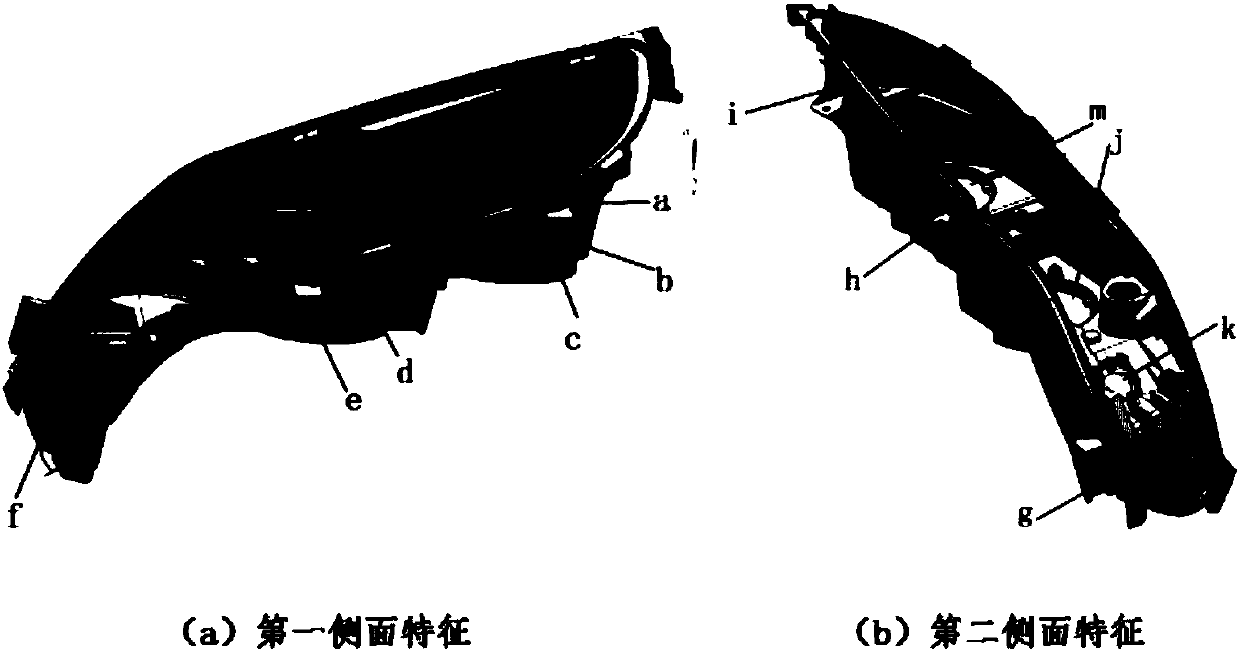

Wide-angle double-material product gate type secondary injection mold

The invention relates to a double-material product injection mold, in particular to a wide-angle double-material product gate type secondary injection mold. The wide-angle double-material product gate type secondary injection mold comprises a panel, a hot runner plate, a front mold main insert, a front template, a rear mold main insert and a rear template and is characterized by further comprising a first knife switch, a second knife switch, a first knife switch fixing plate, a second connecting rod, a second knife switch fixing plate, a limit screw and an oil cylinder for driving the second knife switch fixing plate to vertically move; a first chute is formed in the first knife switch, and the second knife switch can be arranged in the first chute in a sliding way; the bottom of the second connecting rod is fixedly connected with the second knife switch fixing plate, and the top of the second connecting rod is in contact with the second knife switch and sides relative to the second knife switch. The double-material product injection mold has the advantages that the difference between adjacent sealant surface angles of an injection molding product is large; the secondary injection molding can be finished without mold opening, the forming period is short, and the single injection molding cost is low; no material overflow occurs at the material lap joint part, the wall thickness of the product is uniform and undistorted, and the surface quality is high.

Owner:QINGDAO HUATAO AUTOMOBILE MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com