Molded product assembly and fastener

一种模制产品、紧固件的技术,应用在螺纹紧固件、适用紧固件的手动工具、扣件等方向,能够解决夹保持器足够空间困难、连接困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

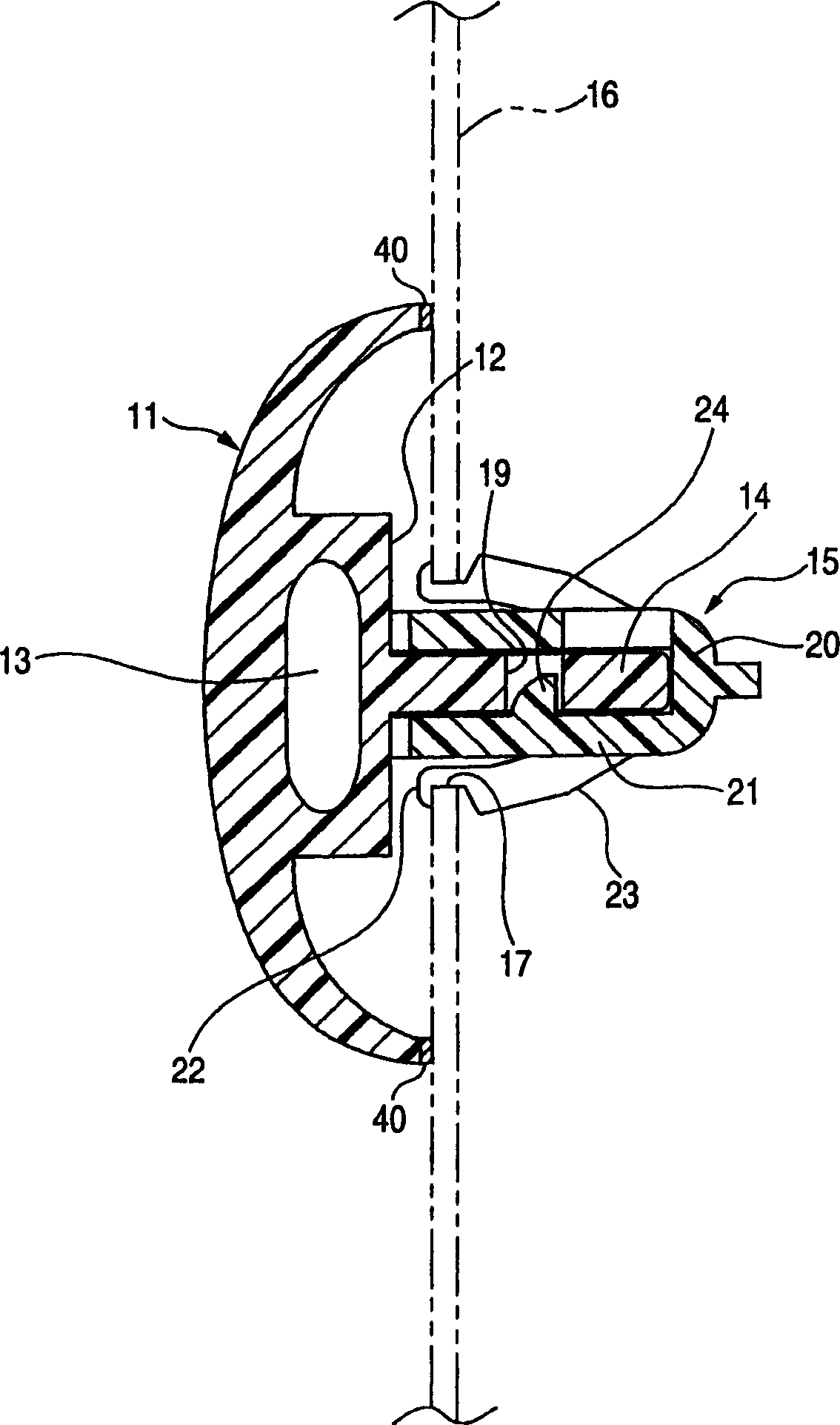

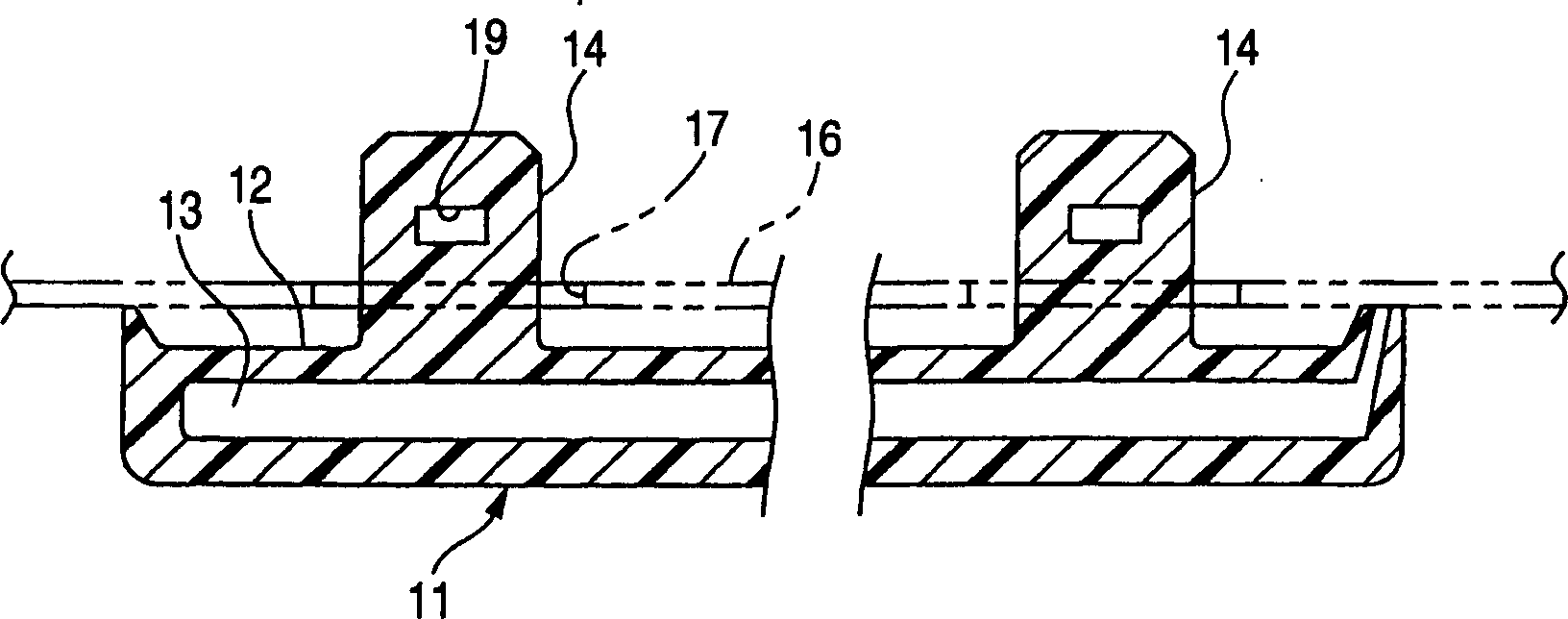

[0034] The present invention will be described below based on the first to third embodiments relating to the structure for attaching the main body side molding of the decorative side panel of the vehicle body and the main body side molding of the decorative side panel (later referred to as "side moldings").

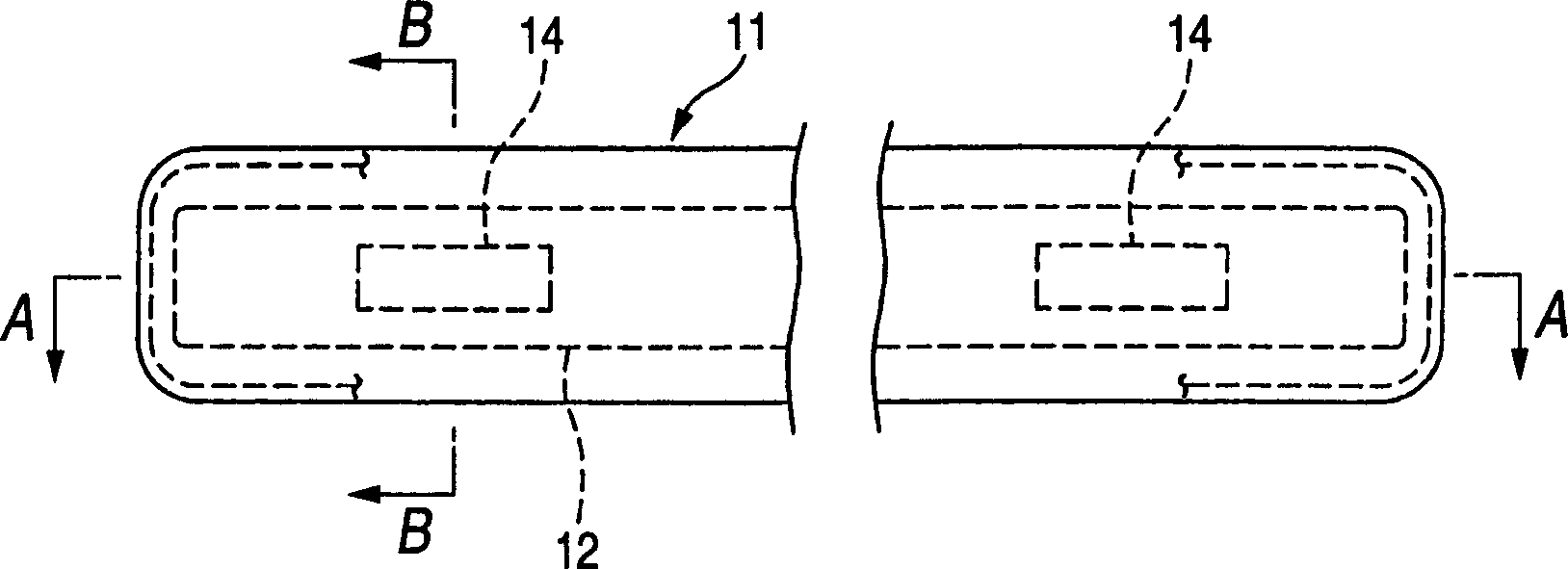

[0035] The following will refer to Figures 1 to 11 The first embodiment of the present invention will be described. First, we will use the Figures 1 to 3 A schematic configuration of the side molding 11 (molded product) is explained. The long side molding 11 is an injection-molded resin product having a longitudinal hollow inside and molded from a thermoplastic resin such as PP (polypropylene) or ABS (acrylonitrile-butadiene-styrene) resin by gas-assist injection molding. The side molding 11 may be employed without surface treatment, or a surface treatment such as coating, painting and / or plating may be applied to the surface of the side molding 11 to improve decorat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com