One-mold 512-hole optical lens mold and molding processing technology

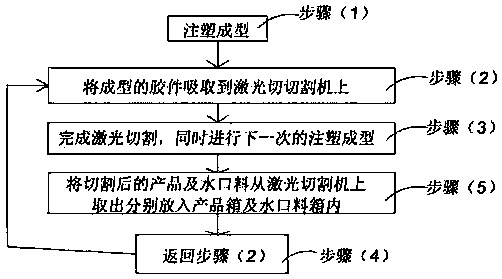

An optical lens, molding and processing technology, applied in the field of optical lens molds, can solve the problems of long laser cutting processing time, inconsistent processing time of injection molding machine molding cycle, affecting production capacity, etc., to ensure smooth production, simple structure, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with accompanying drawing and embodiment:

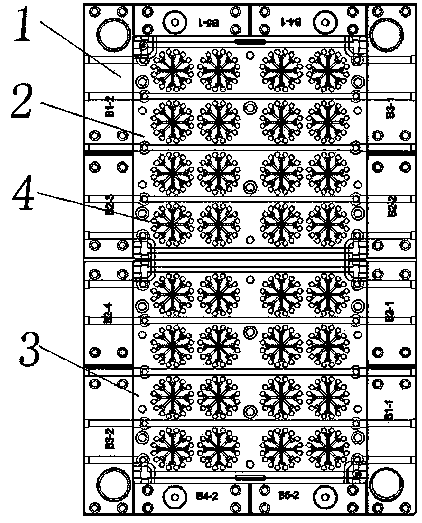

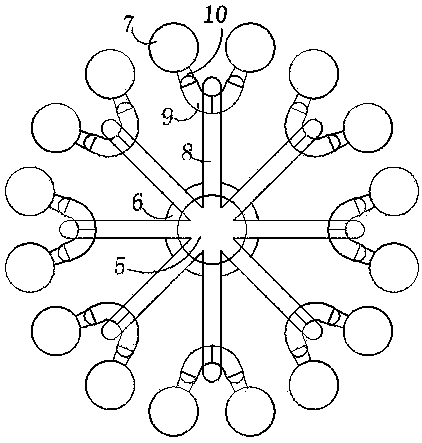

[0029] like Figure 1-3 As shown, a mold with 512 cavities for an optical lens includes a mold 1, a first product area 2 and a second product area 3 are arranged on the mold 1, and 16 product areas 2 and 3 are respectively arranged on the mold 1. Evenly distributed cavity groups 4, each cavity group 4 includes a cavity 7, a hot nozzle glue inlet 5 and a glue inlet flow channel, and the mold cavities 7 are evenly distributed around the hot nozzle glue inlet 5 in an annular array, and The mold cavity 7 is connected to the glue inlet channel, and the glue inlet runner is connected to the hot nozzle glue inlet 5, wherein the hot nozzle glue inlet 5 is respectively connected to the injection port through the corresponding hot runner.

[0030] The glue inlet flow channel includes the main channel 8 and the branch channel 9. The hot nozzle glue inlet 5 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com