Fuel pump support assembly for vehicle

A technology of bracket assembly and fuel pump, which is applied in the direction of liquid fuel feeder, engine components, machine/engine, etc. Solve problems such as installation difficulties, and achieve the effects of improving production stability, good heat dissipation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

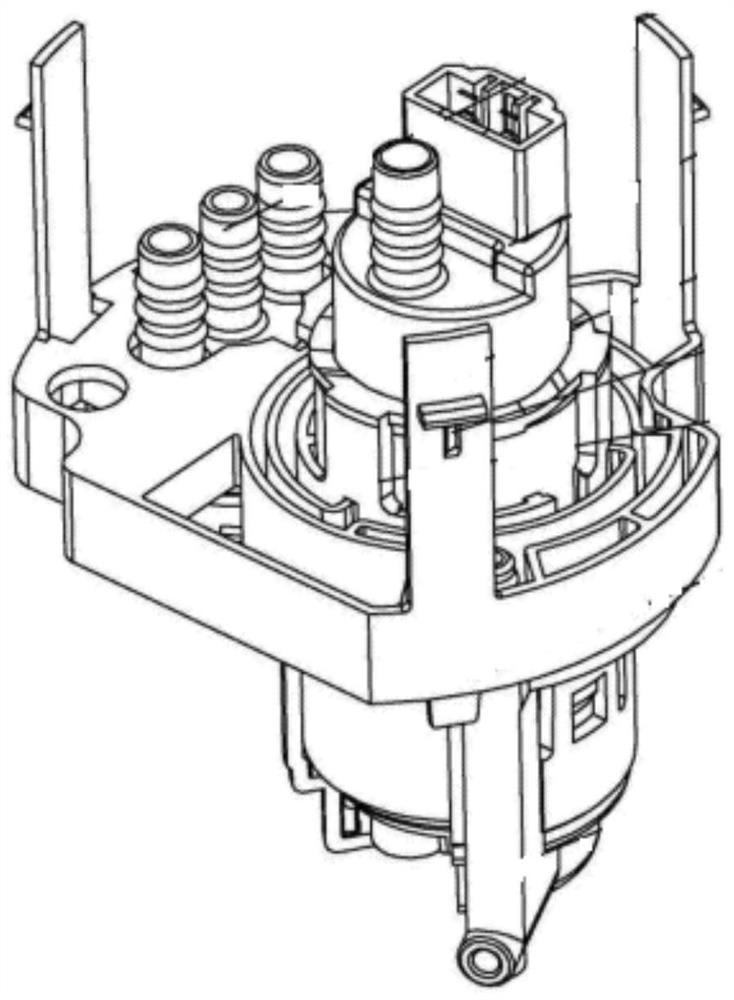

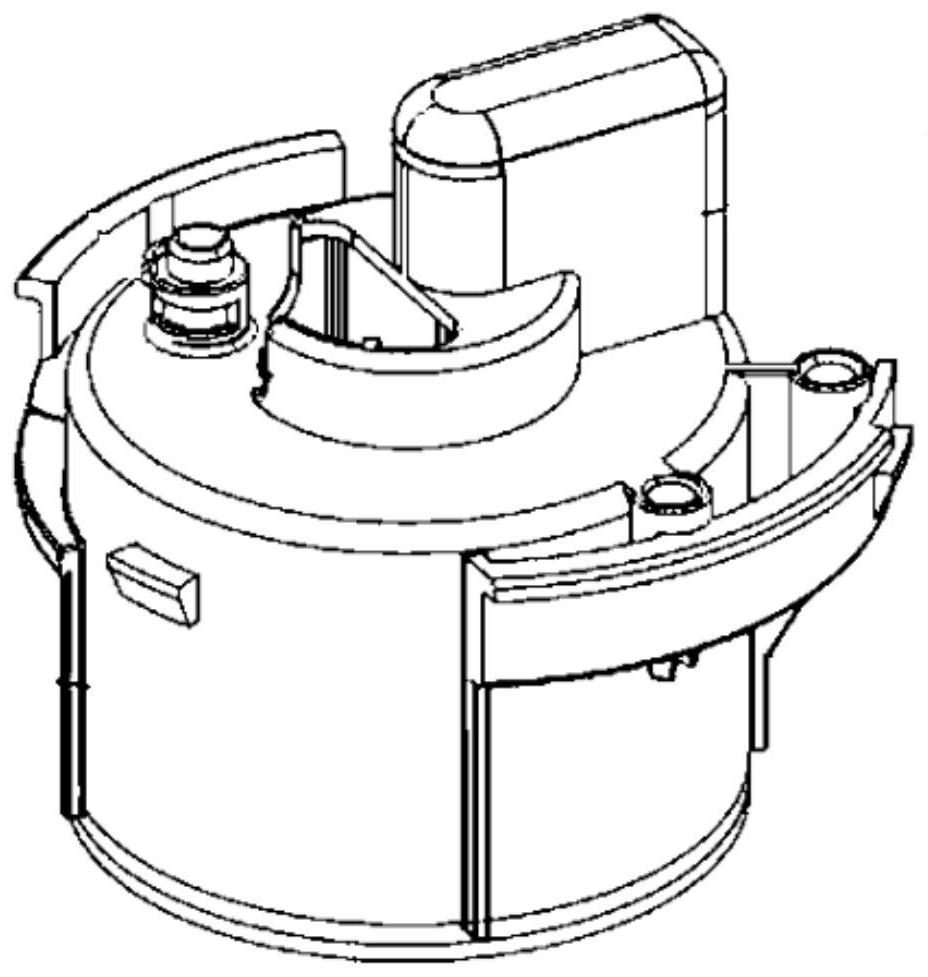

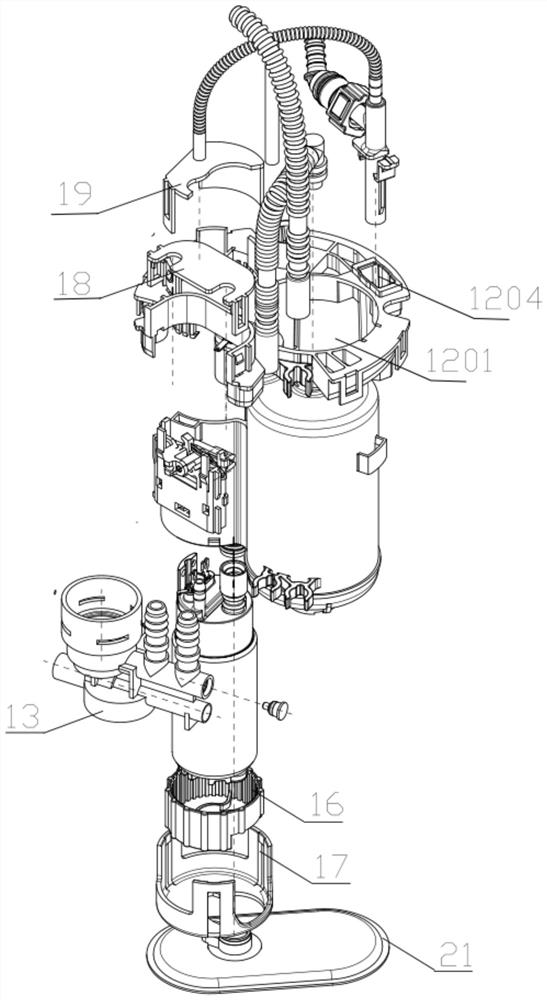

[0035] Example 1, such as Figure 1-12 As shown, a vehicle fuel pump bracket assembly consists of a disc-shaped bracket body 12, a fuel fine filter, a regulator assembly 13, a remote injection joint 14, a pump core 15, a shock absorber 16, and a fixing card 17 , Oil level gauge cover plate 18, pump core cover 19 composition.

[0036] The center of the disc-shaped support body 12 corresponds to the mounting hole 1201 extending up and down the fuel fine filter installation axis. Specifically, the center of the support body 12 corresponds to the fuel fine filter. There are two interconnected mounting holes, one large and one small. 1201, wherein the upper side and the lower side of the opening of the smaller installation hole 1201 are respectively provided with elastic cards 1202 for clamping the pump core 15. Barbs are provided on the elastic card 1202 located at the lower side of the opening of the installation hole.

[0037] The bracket body 12 is provided with a heating pip...

Embodiment 2

[0045] Others are the same as in Embodiment 1, except that a pressure relief regulator installation chamber 9 is provided on the lower end surface of the filter element housing 1 , and the pressure relief regulator installation chamber 9 communicates with the cavity 2 . After the filter element 8 is installed, the pressure relief regulator installation chamber 9 communicates with the oil passage in the filter element 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com