Patents

Literature

68results about How to "Reduced soldering area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

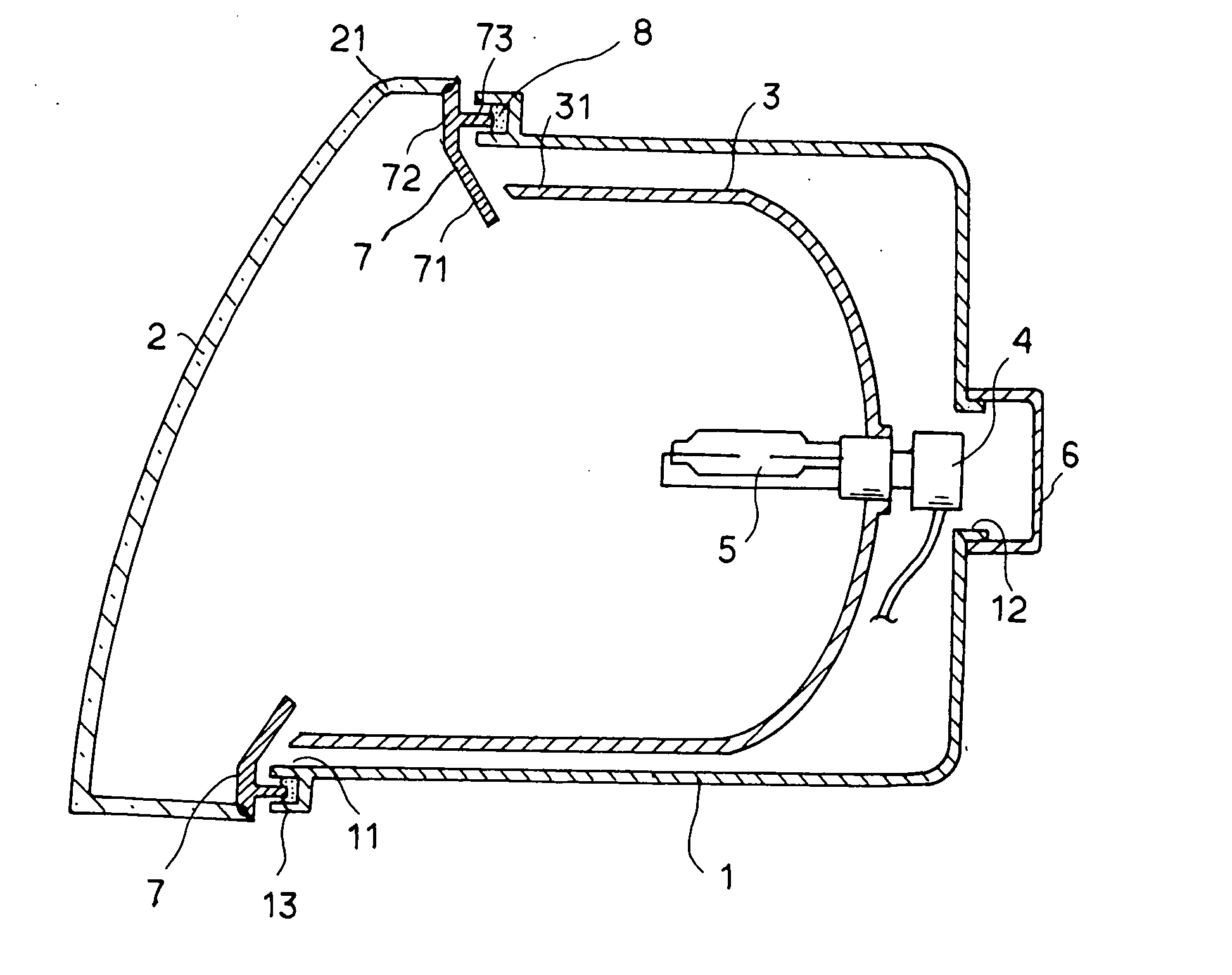

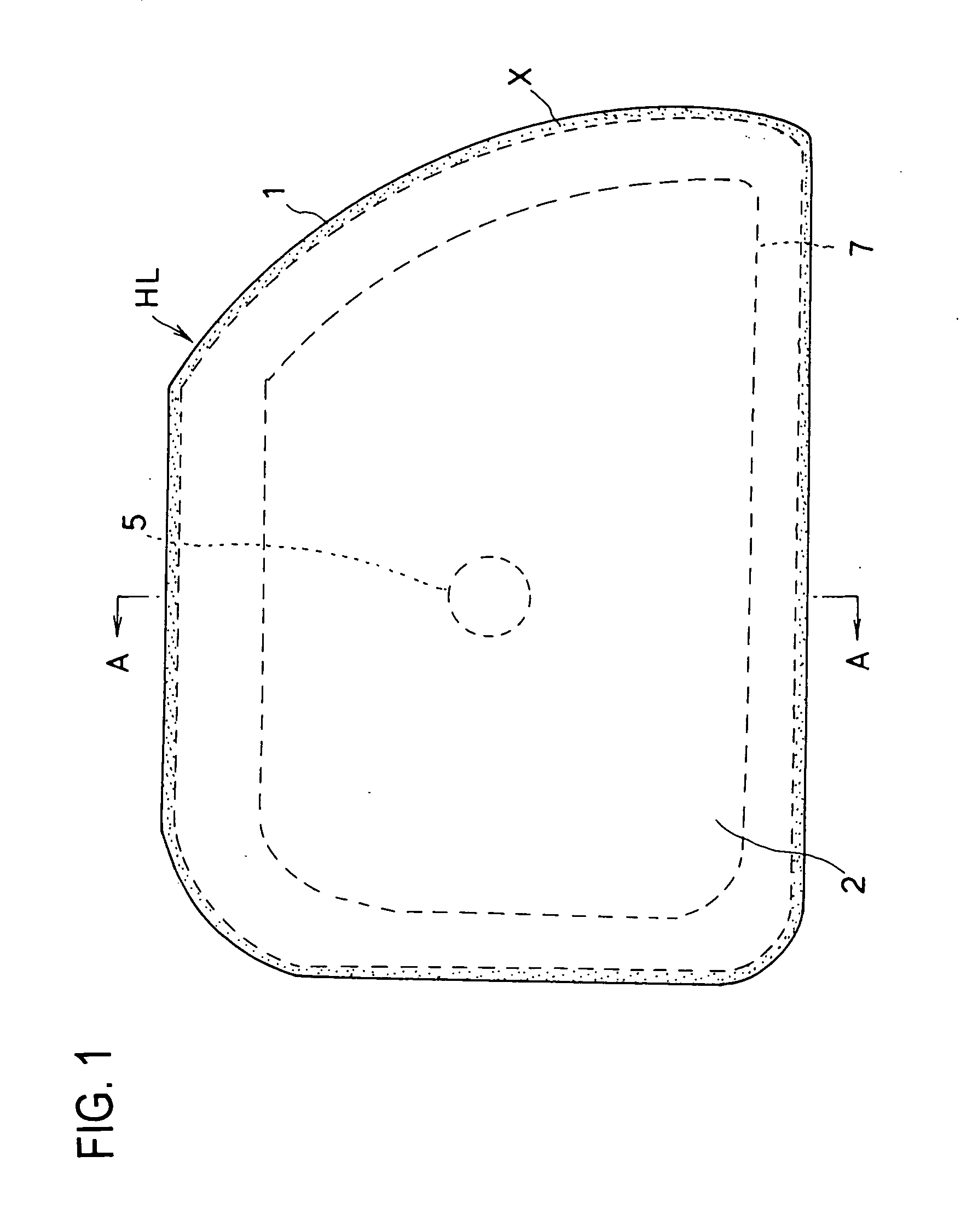

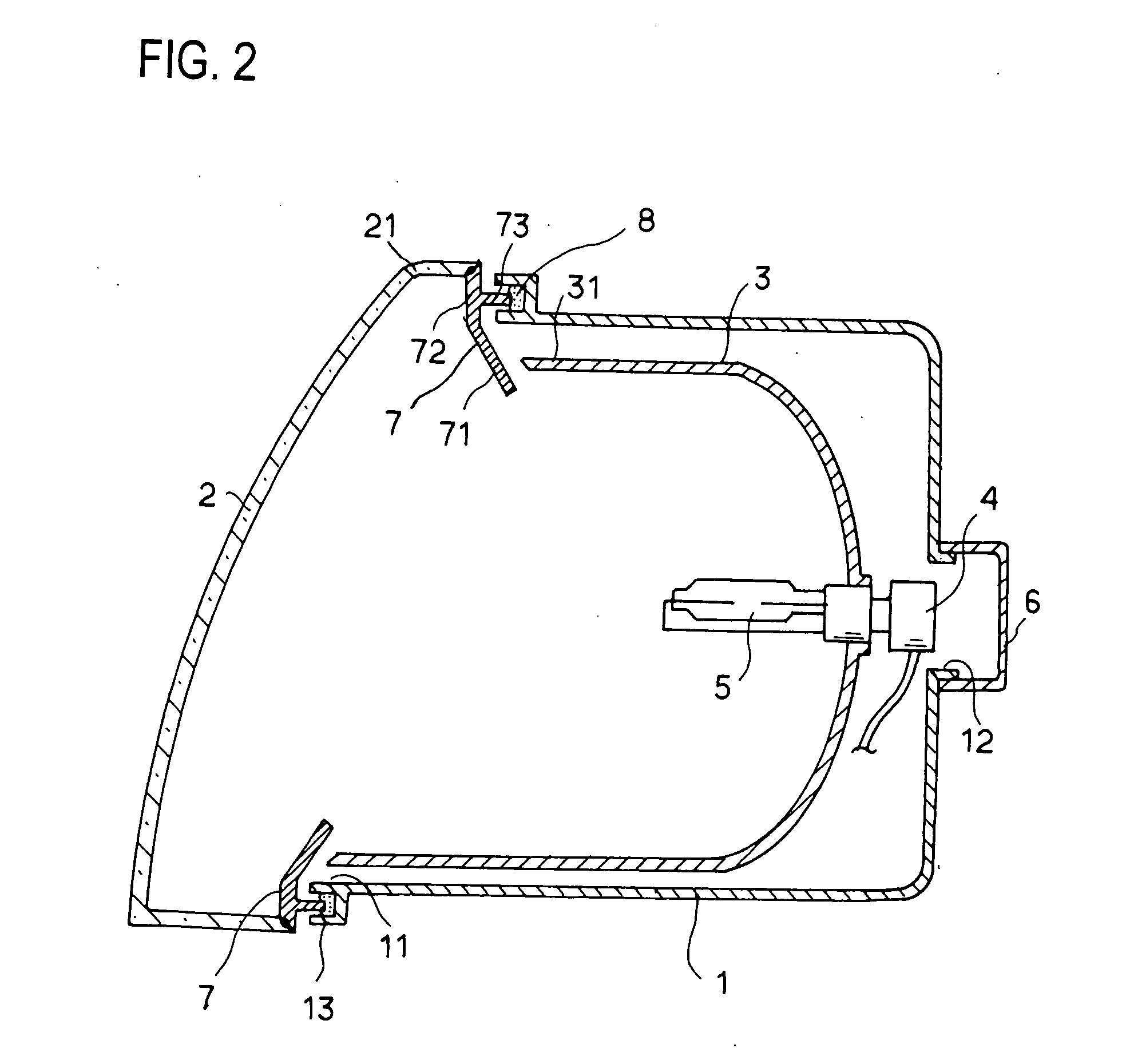

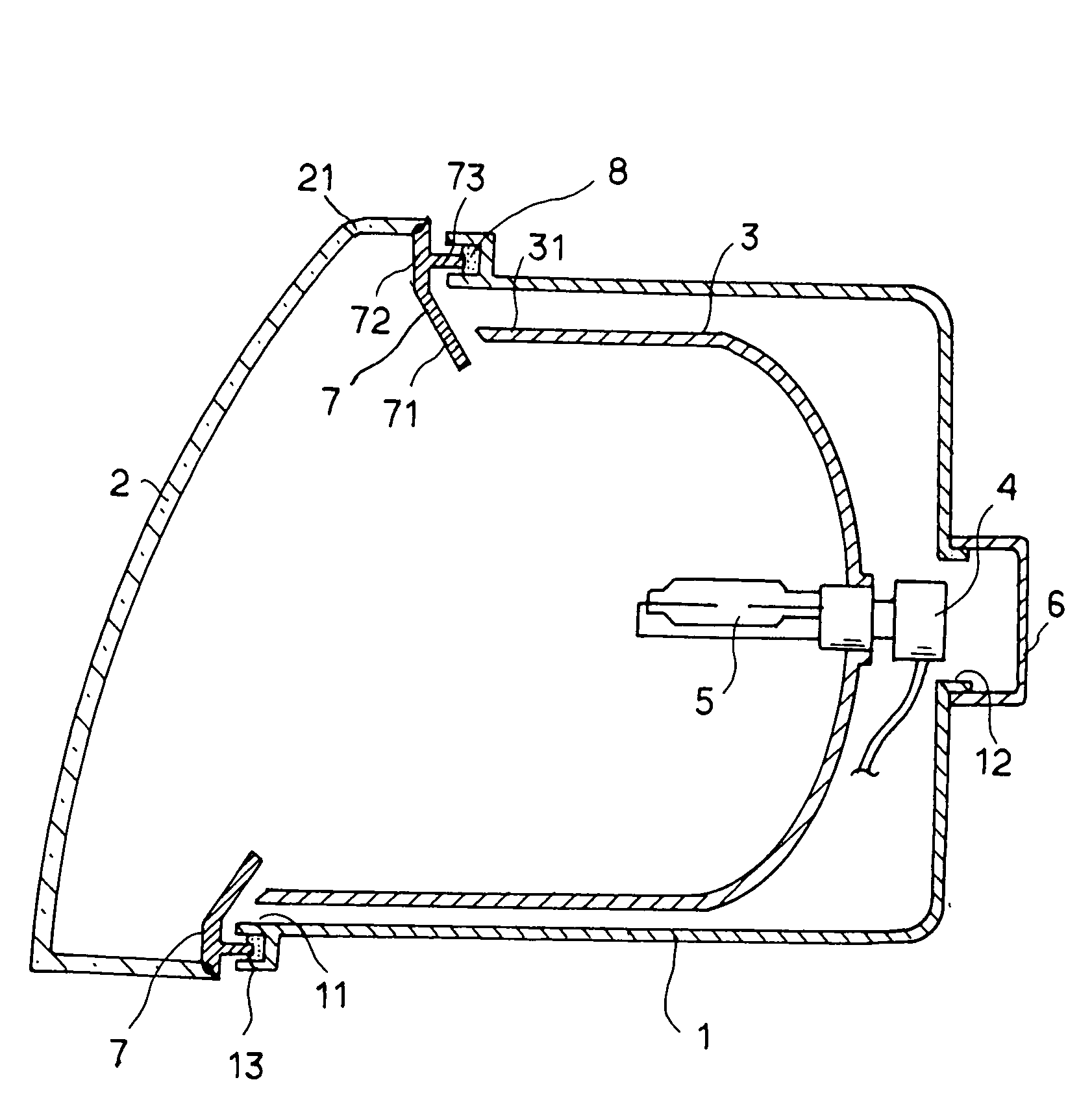

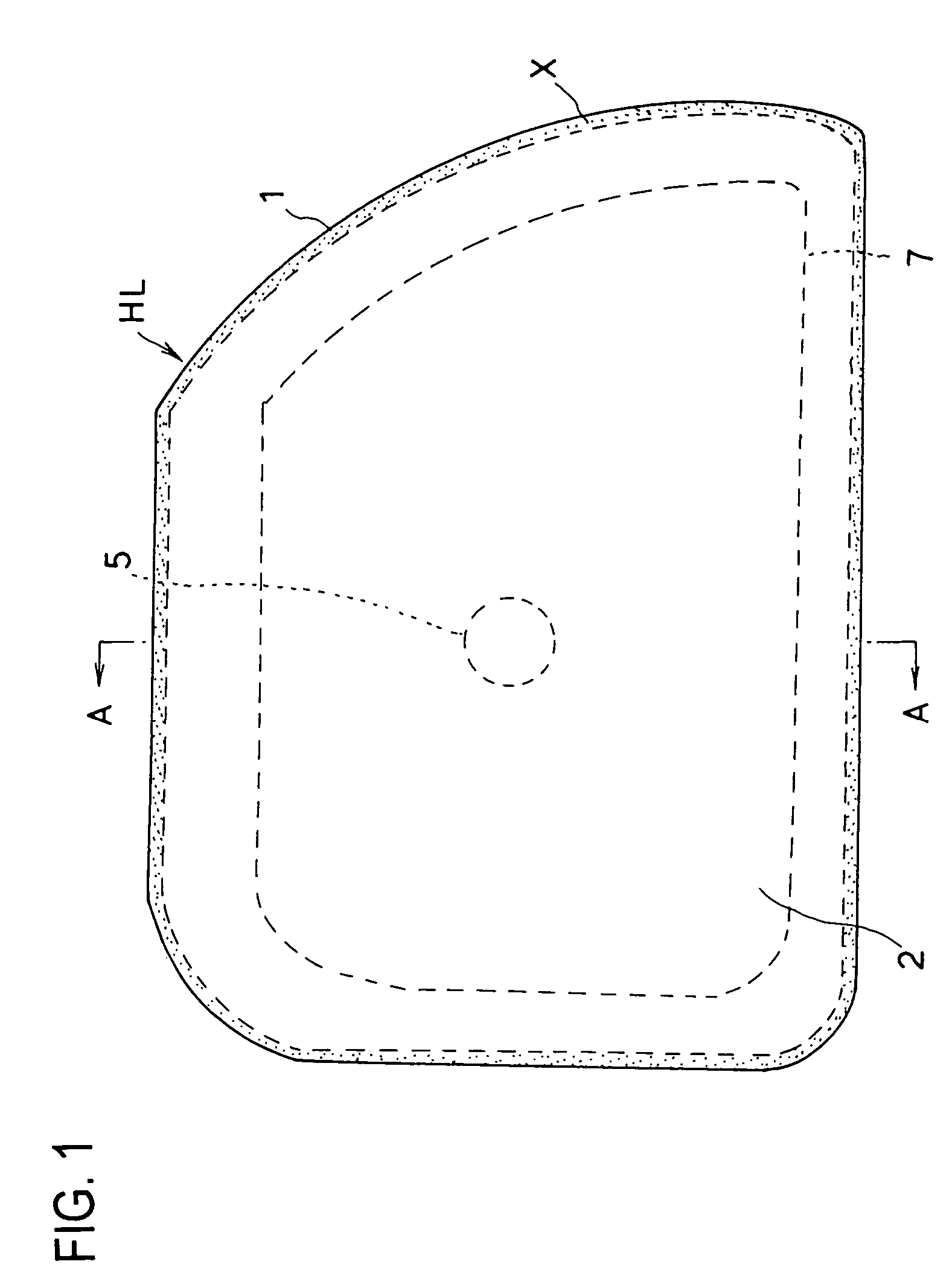

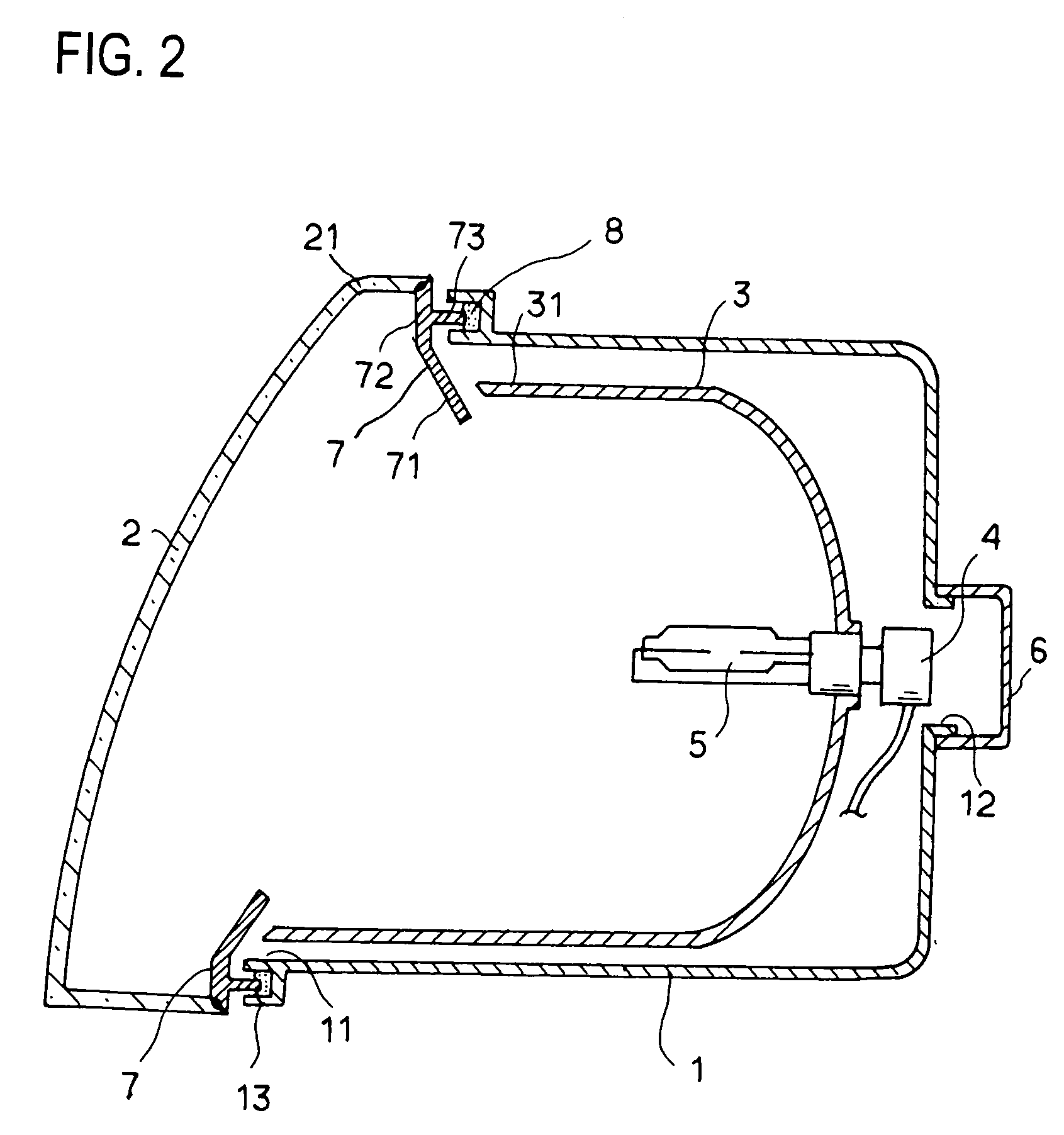

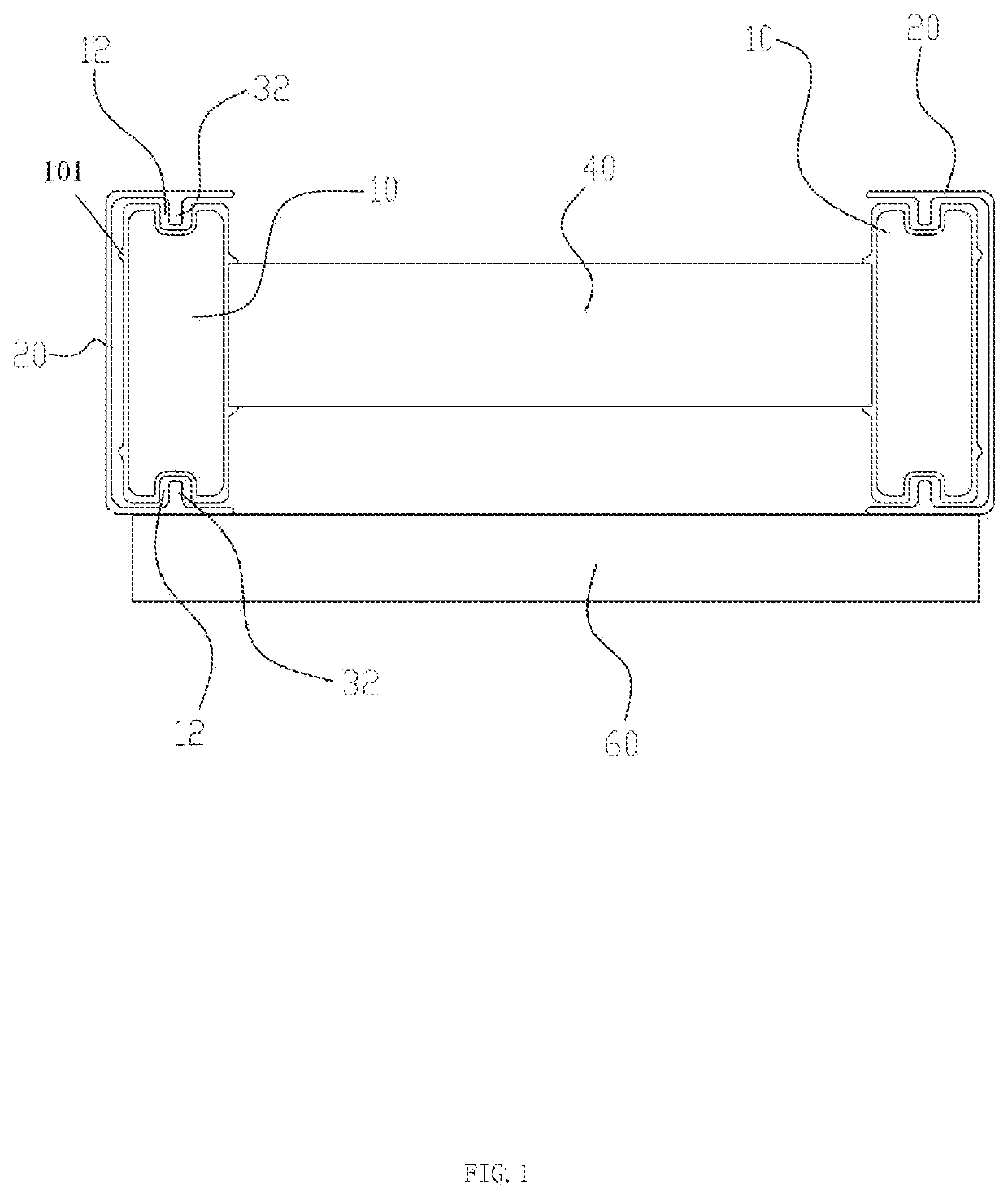

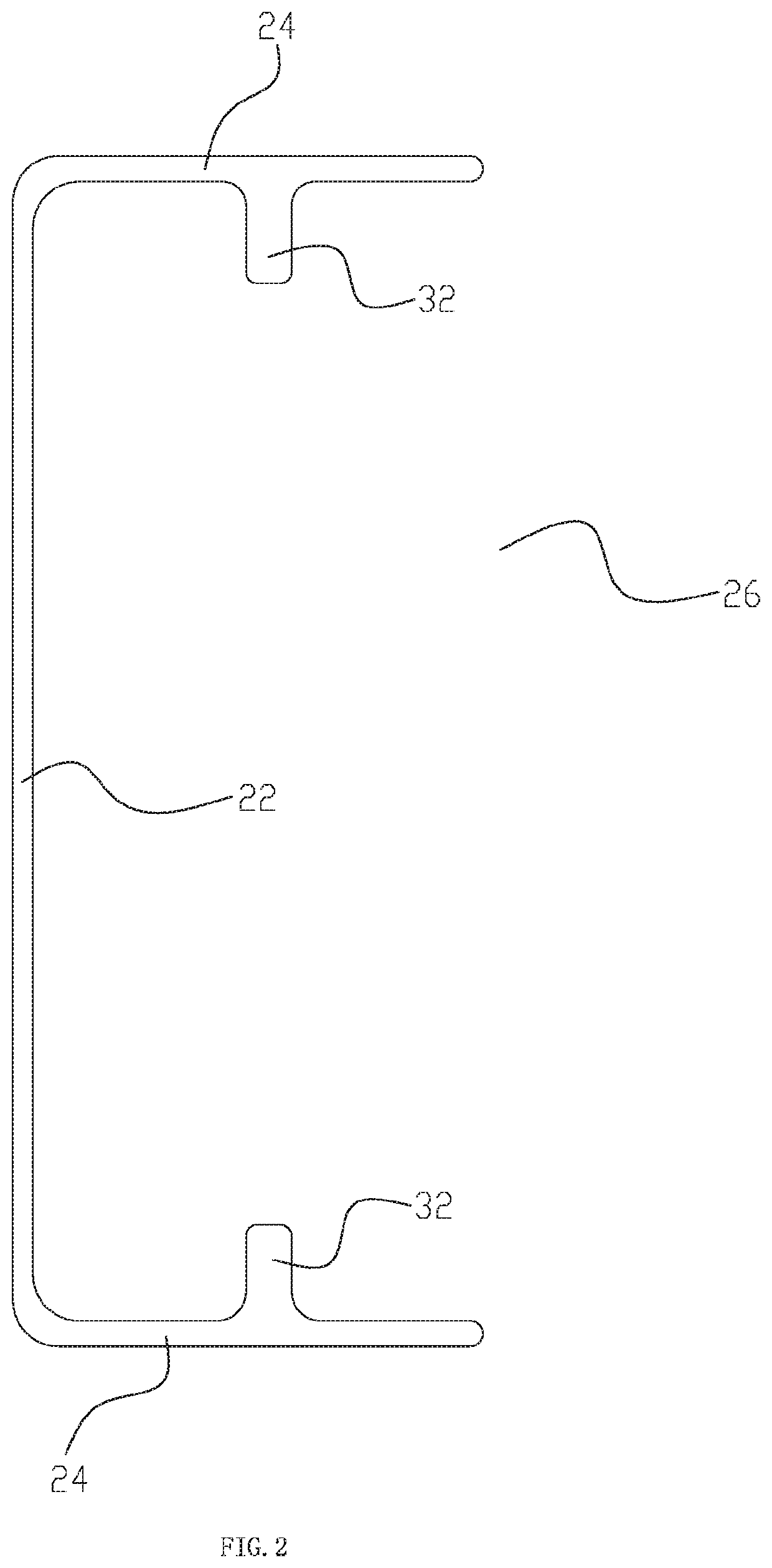

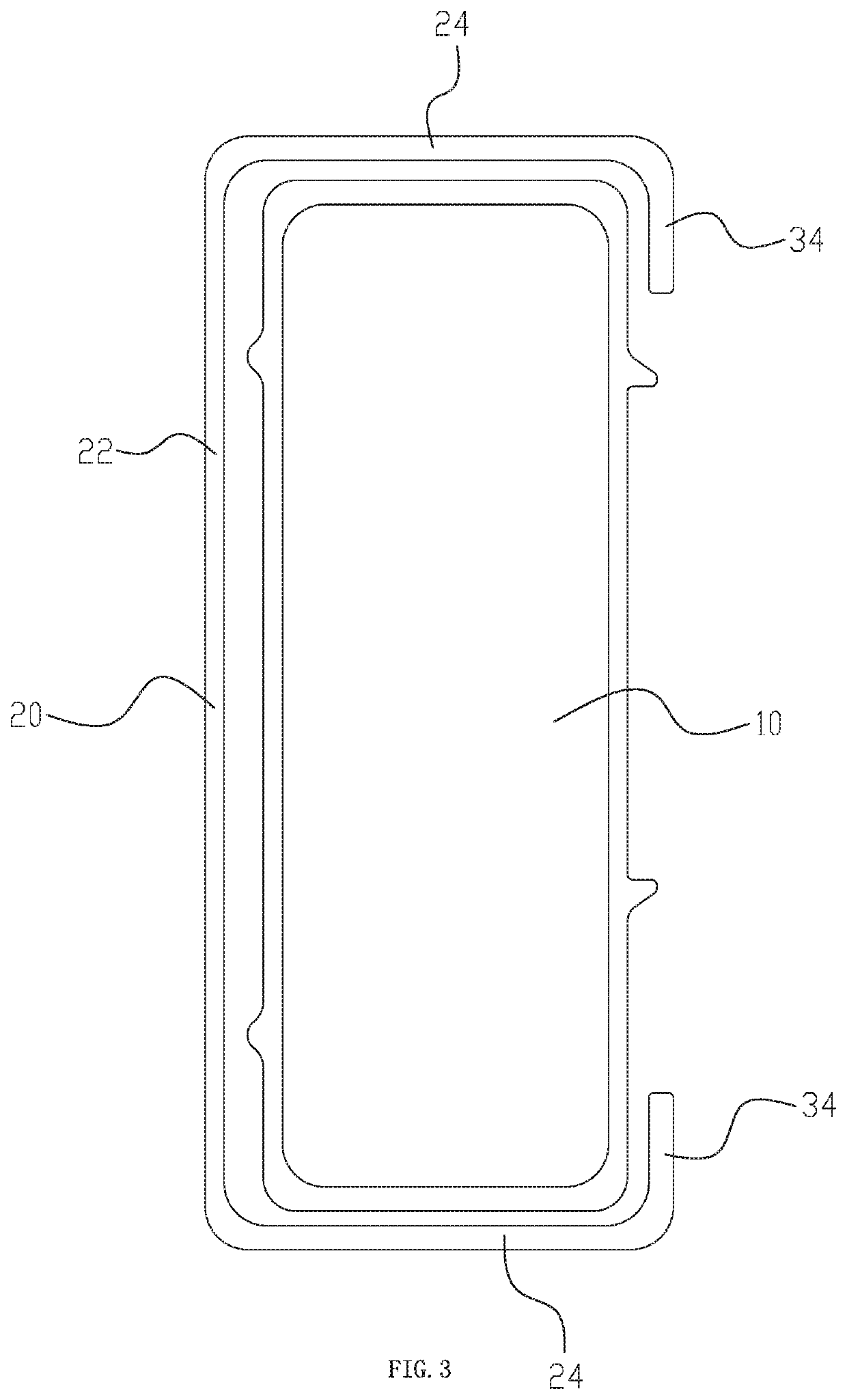

Vehicular lamp having a removable lens with an extension reflector

InactiveUS20050024888A1Avoiding increasing number of partDiminishing aesthetic appearanceVehicle headlampsVehicle interior lightingEngineeringTroffer

A vehicular headlamp includes a lamp body having an opening, a first reflector disposed within the lamp body, a lens, and a second reflector. The second reflector serves as an extension reflector to cover a gap between the opening of the lamp body and the first reflector. The lens and the second reflector are joined together at an edge portion thereof by laser welding. The second reflector has a leg portion on a back surface thereof. An edge portion of the opening has a groove to receive the leg portion, and seal material having a predetermined adhesibility, which can be pulled off, is injected into the groove. The second reflector joined to the lens is mounted on an edge of the opening of the lamp body via the seal material.

Owner:KOITO MFG CO LTD

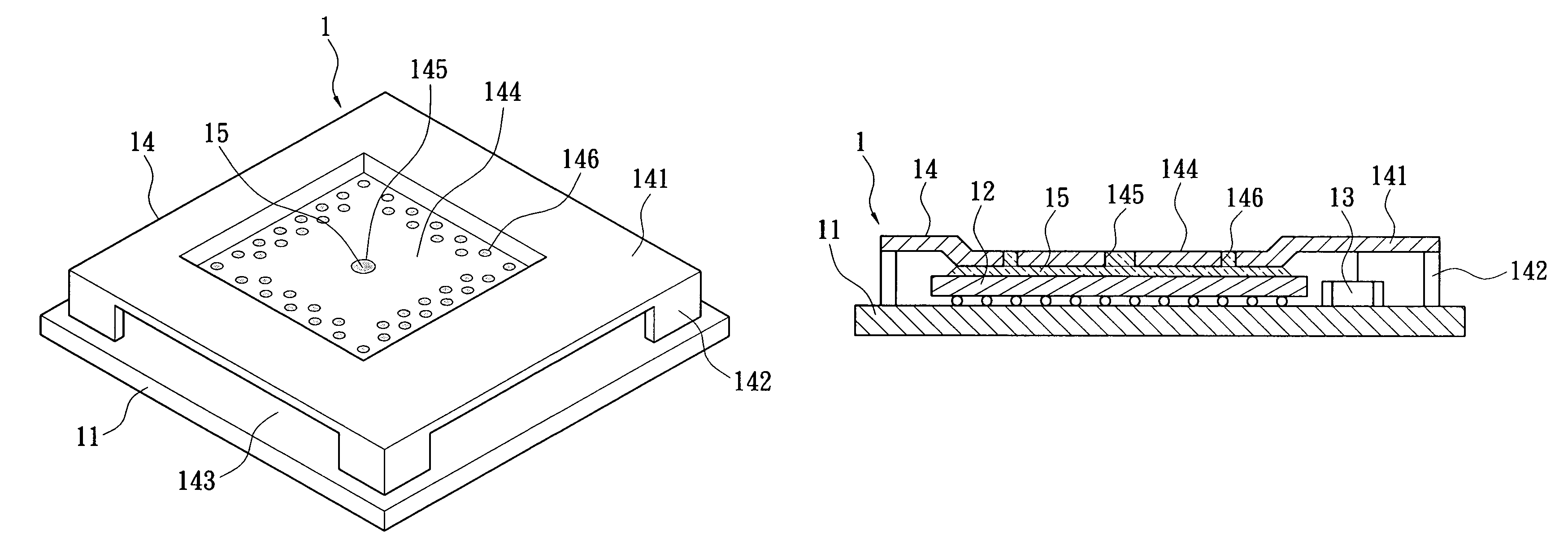

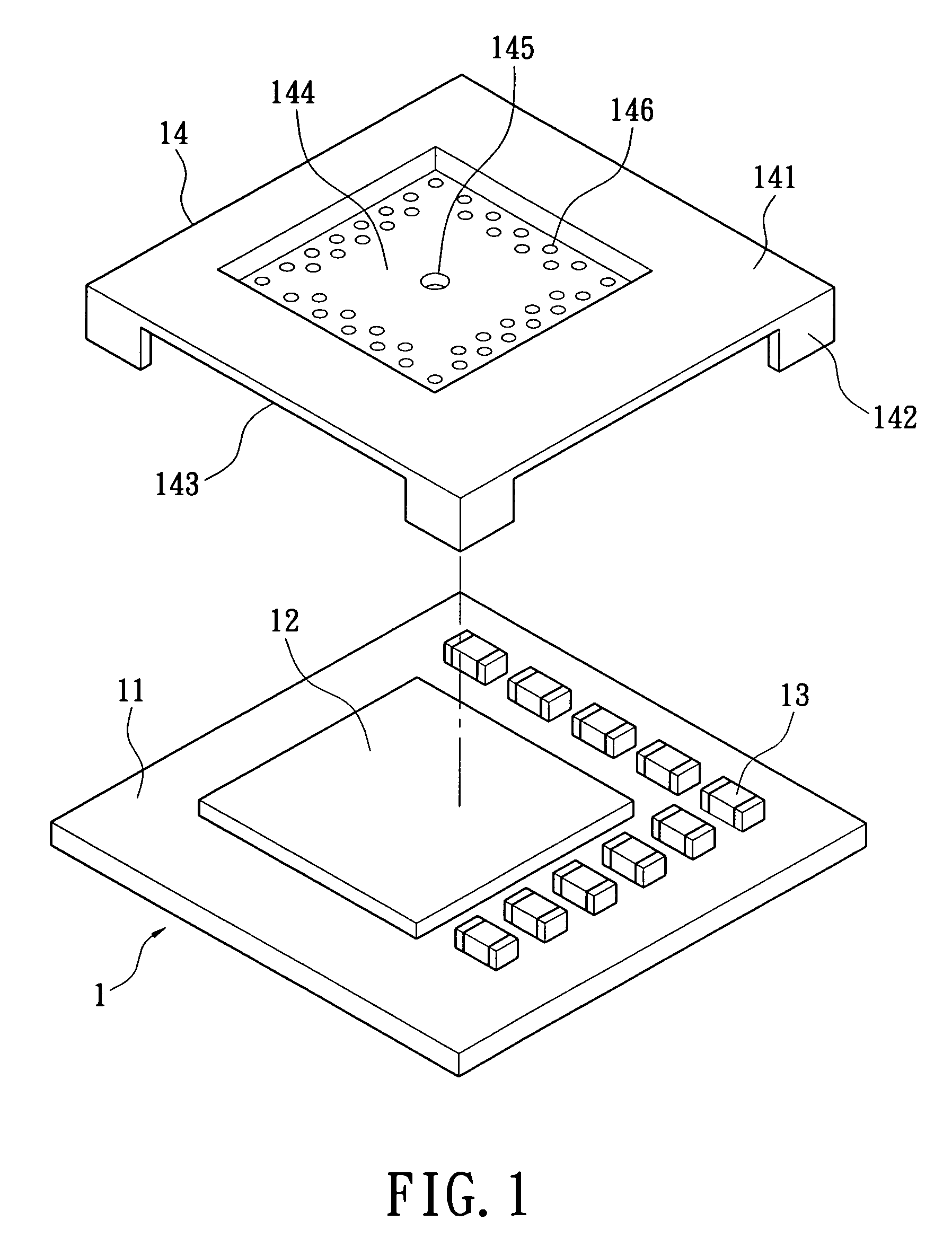

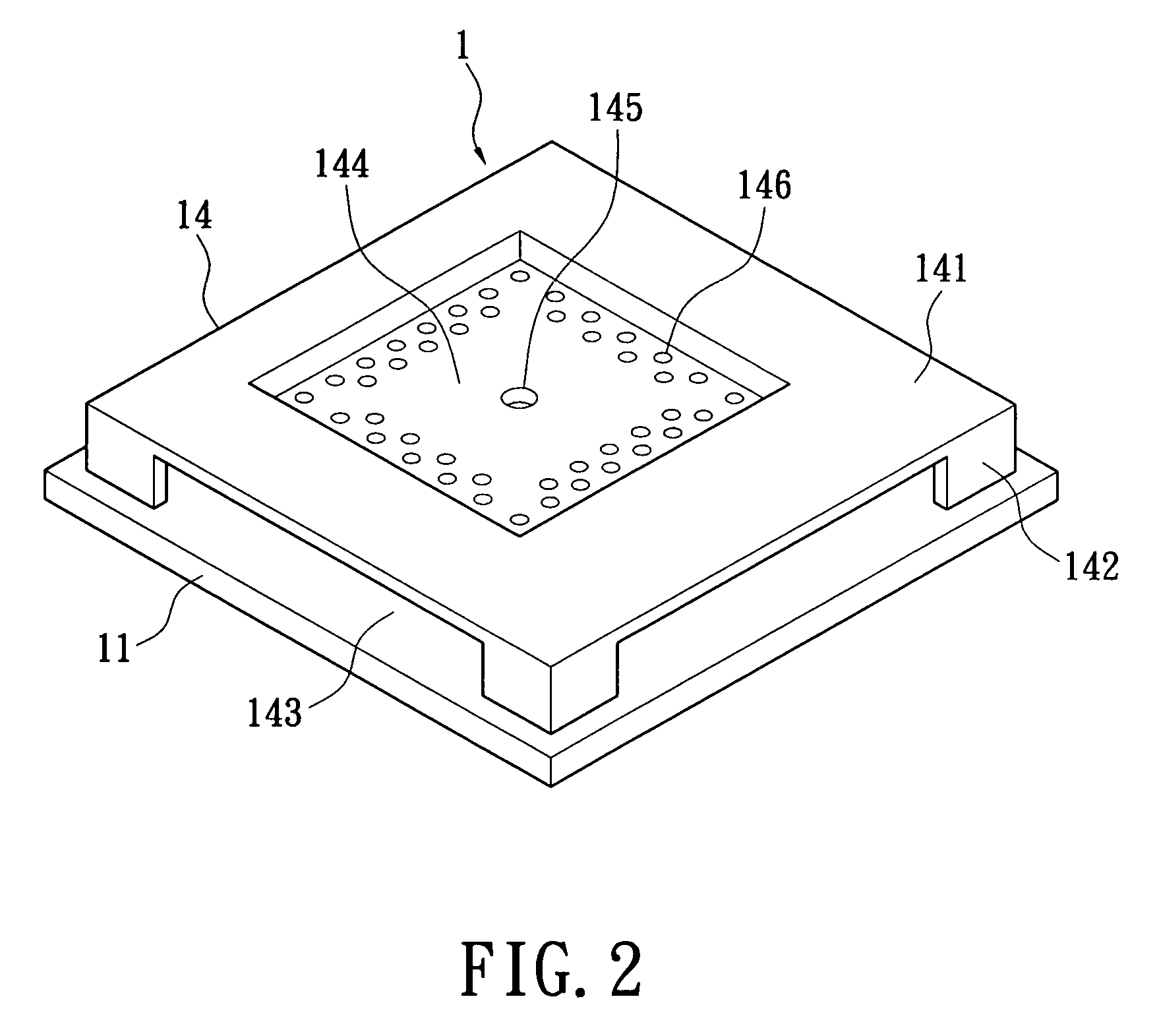

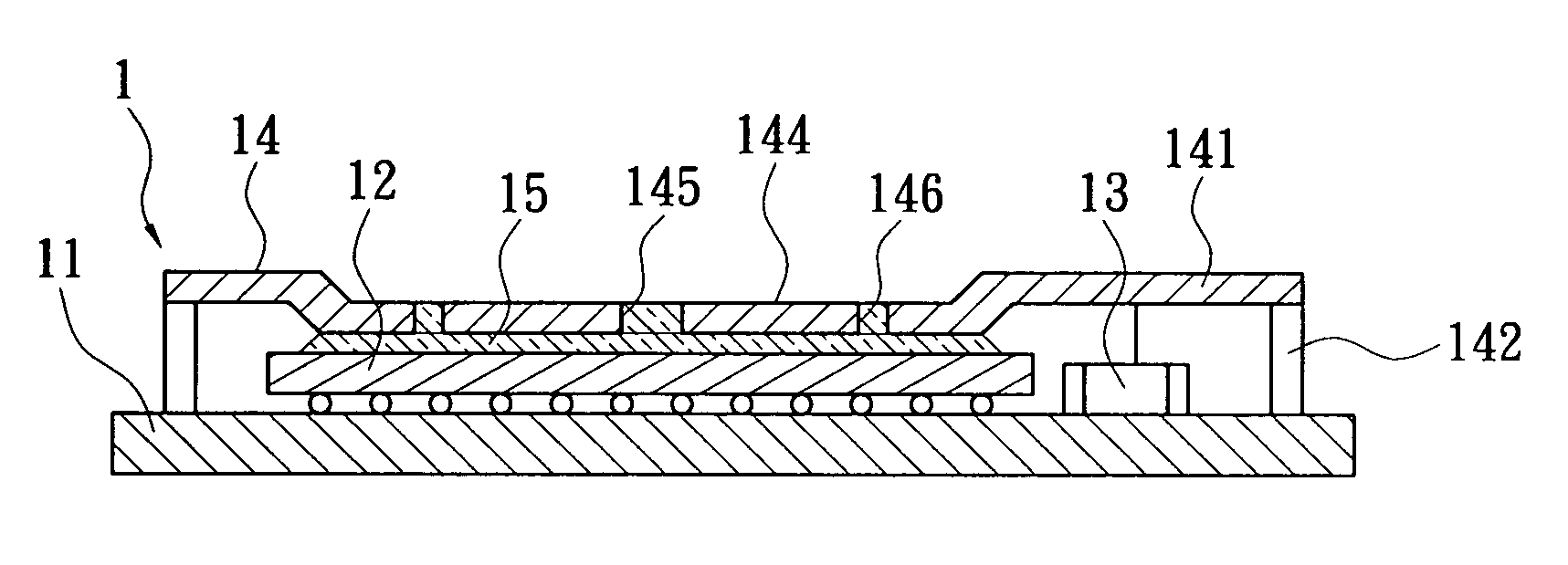

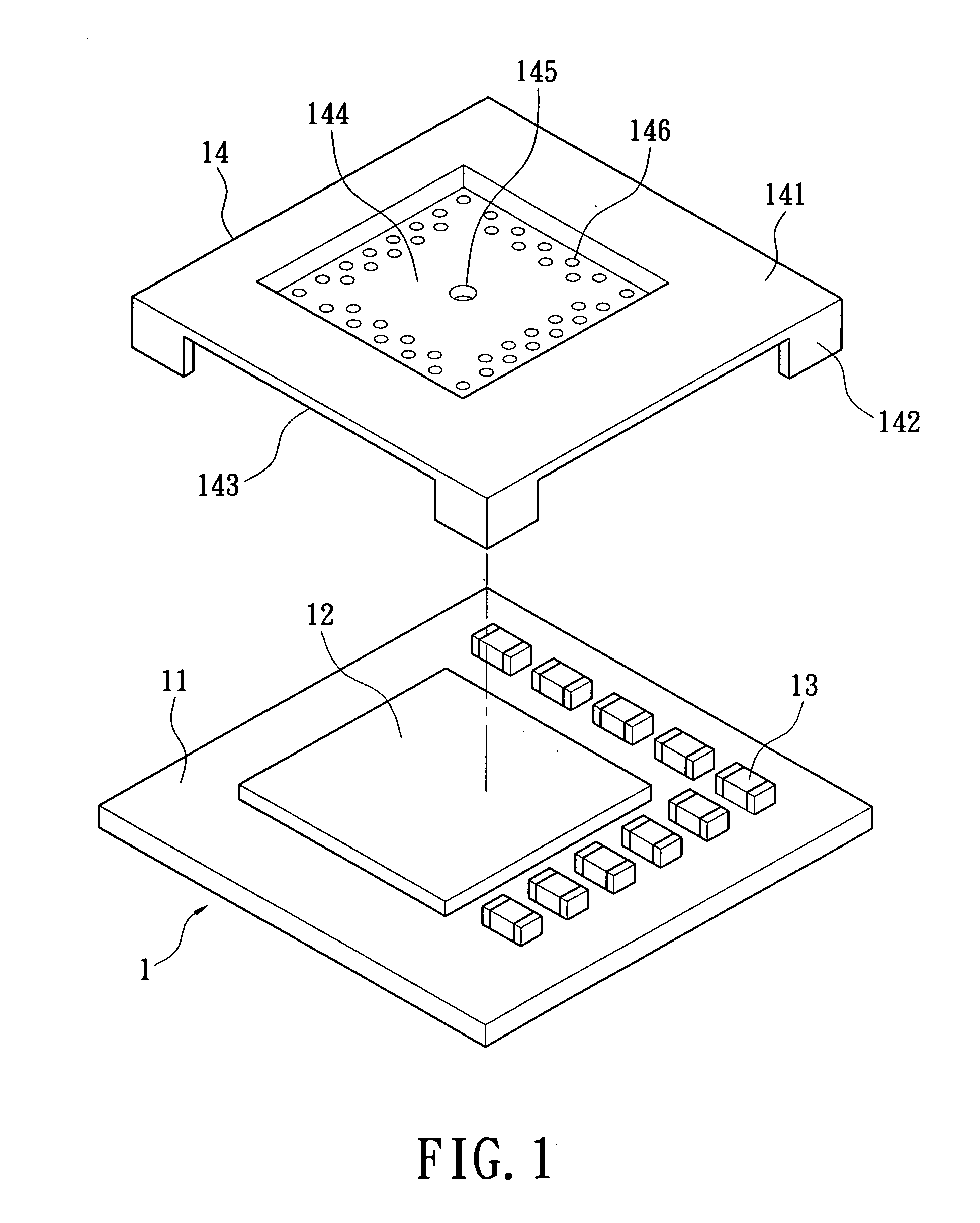

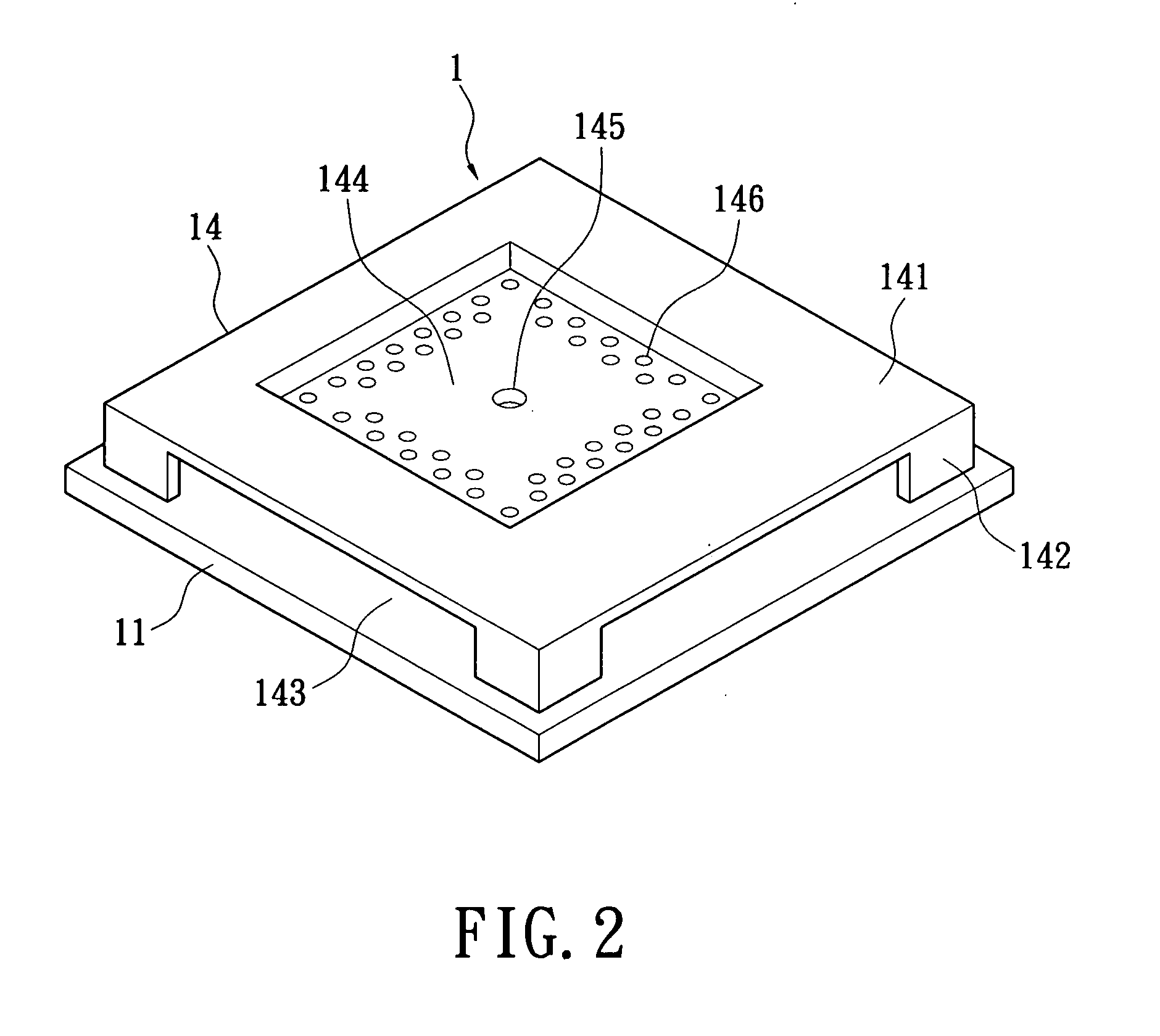

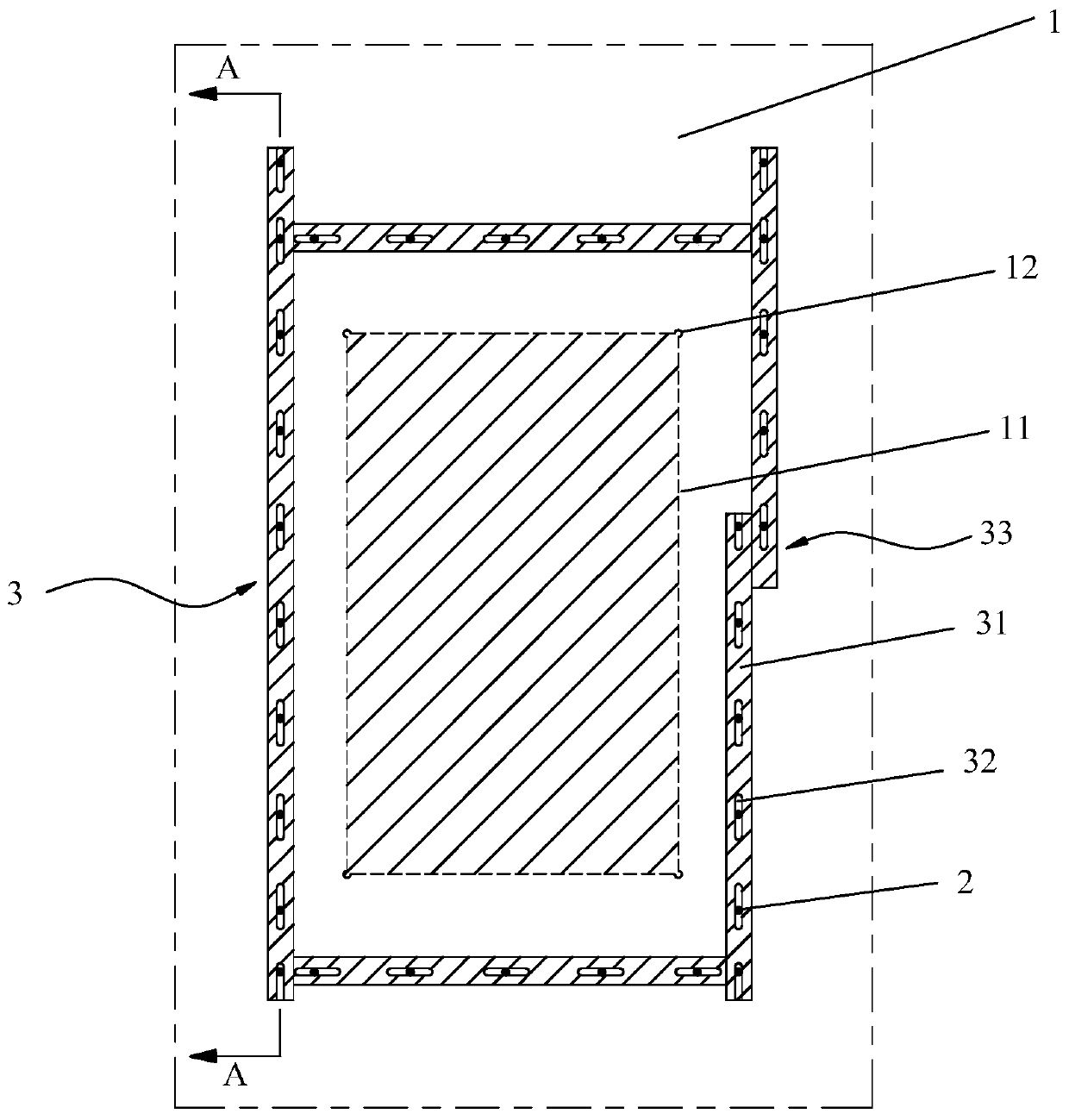

Metallic cover of miniaturization module

ActiveUS7787250B2High mechanical strengthEasy to transformMagnetic/electric field screeningSemiconductor/solid-state device detailsMiniaturizationPartial filling

A metallic cover of a miniaturization module includes a substrate, a SMD chip unit and a metallic cover, the metallic cover embracing the SMD chip unit and having at least one sizing hole and a plurality of venting holes, the venting holes being disposed around the sizing hole, and the sizing hole and the venting holes being positioned above the SMD chip unit so that glue portions fill up slits between the metallic cover and the SMD chip unit. The venting holes stop the glue portion from running over the second chip unit. The glue-filled slits between the top lid and the SMD chip unit provides a strong support to prevent any deformation of the metallic cover when the metallic cover is tested and processed.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

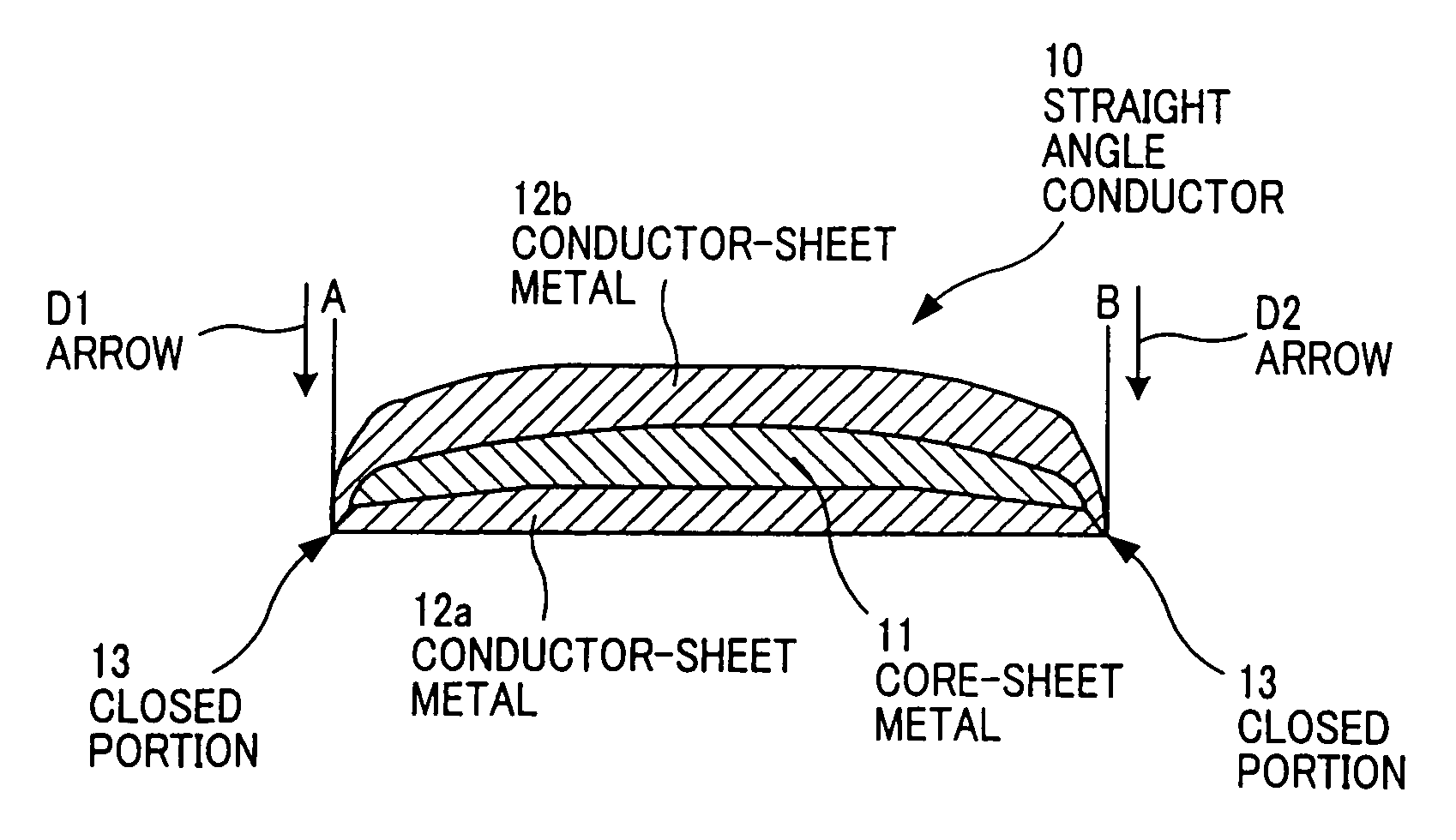

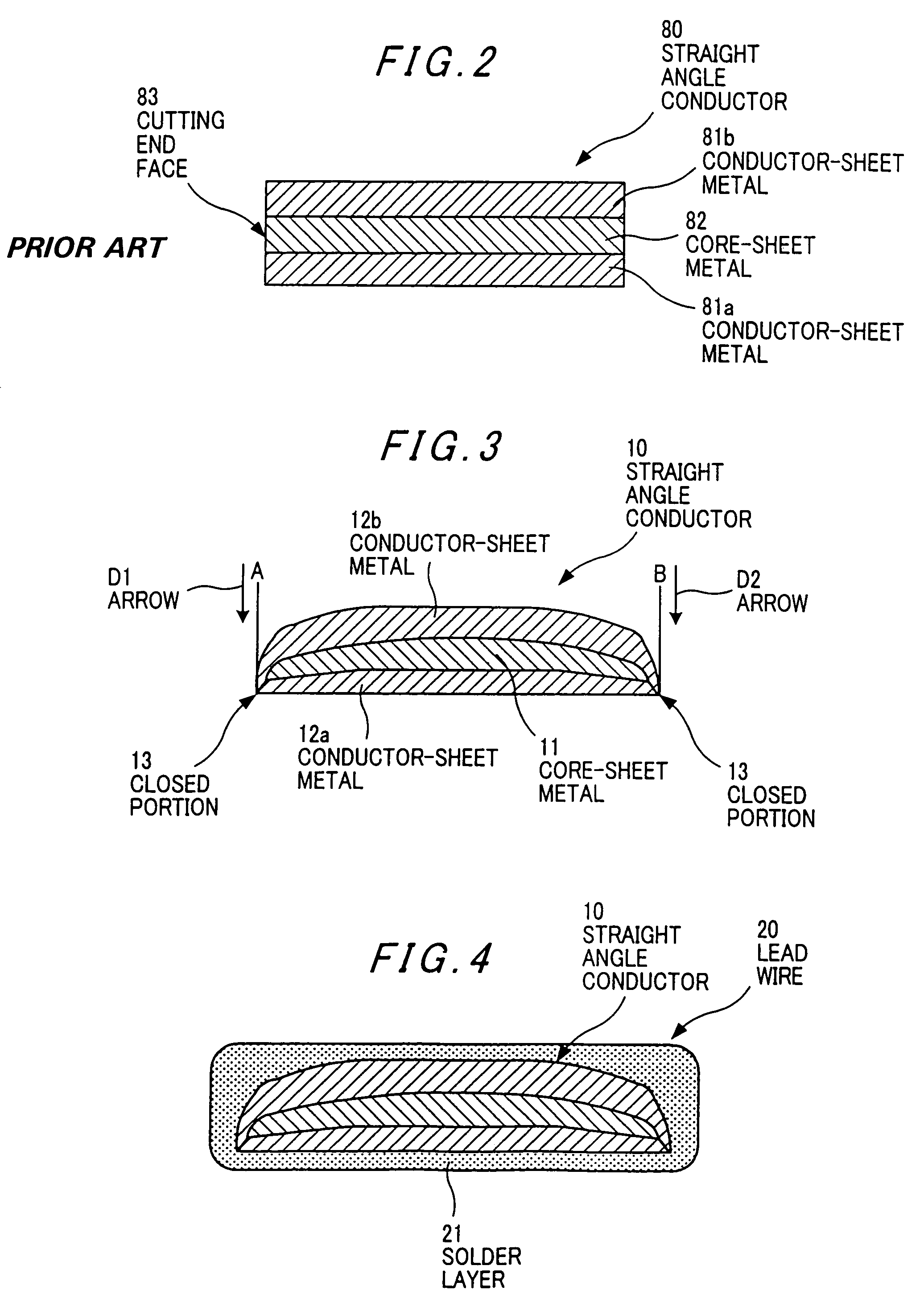

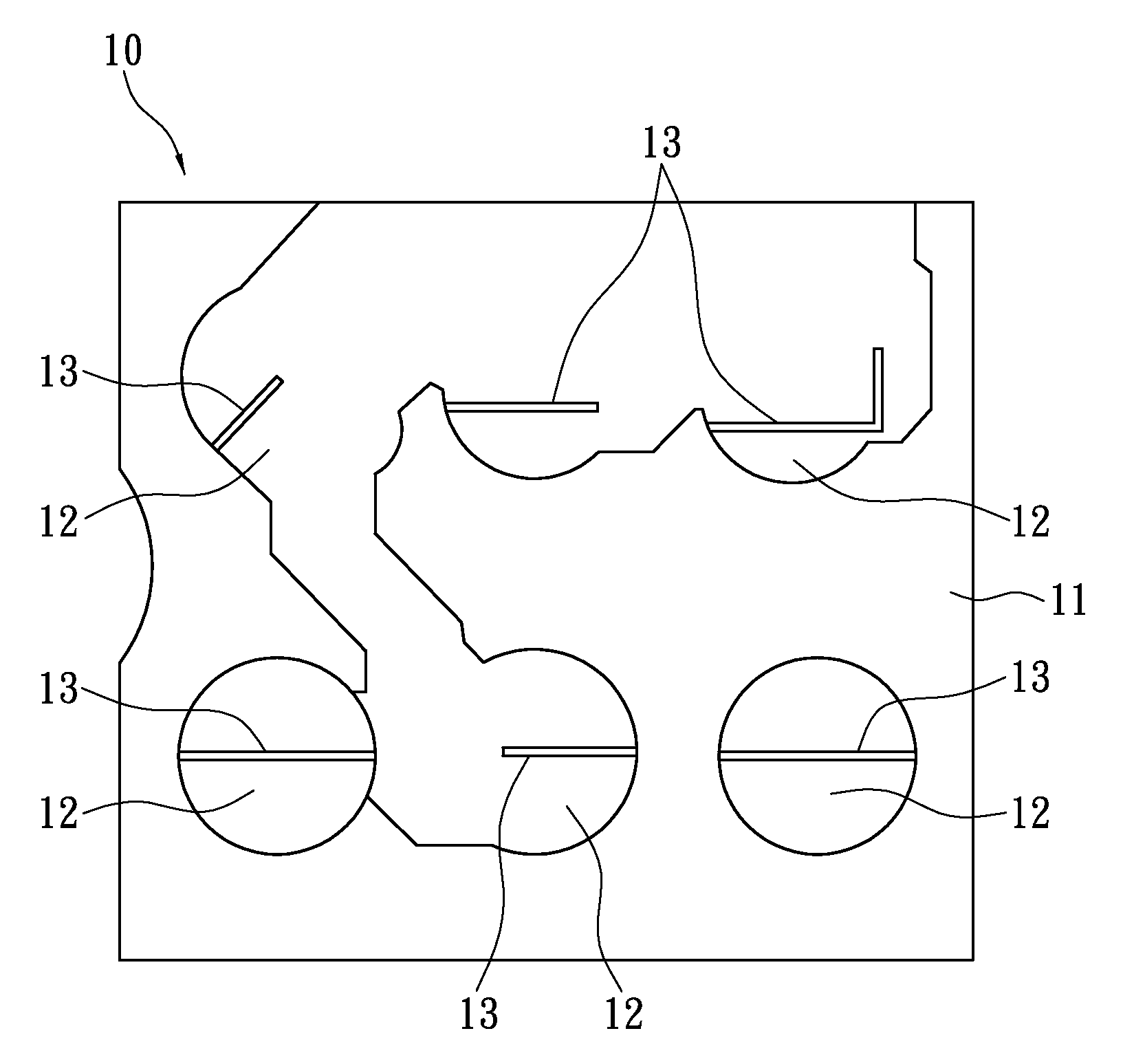

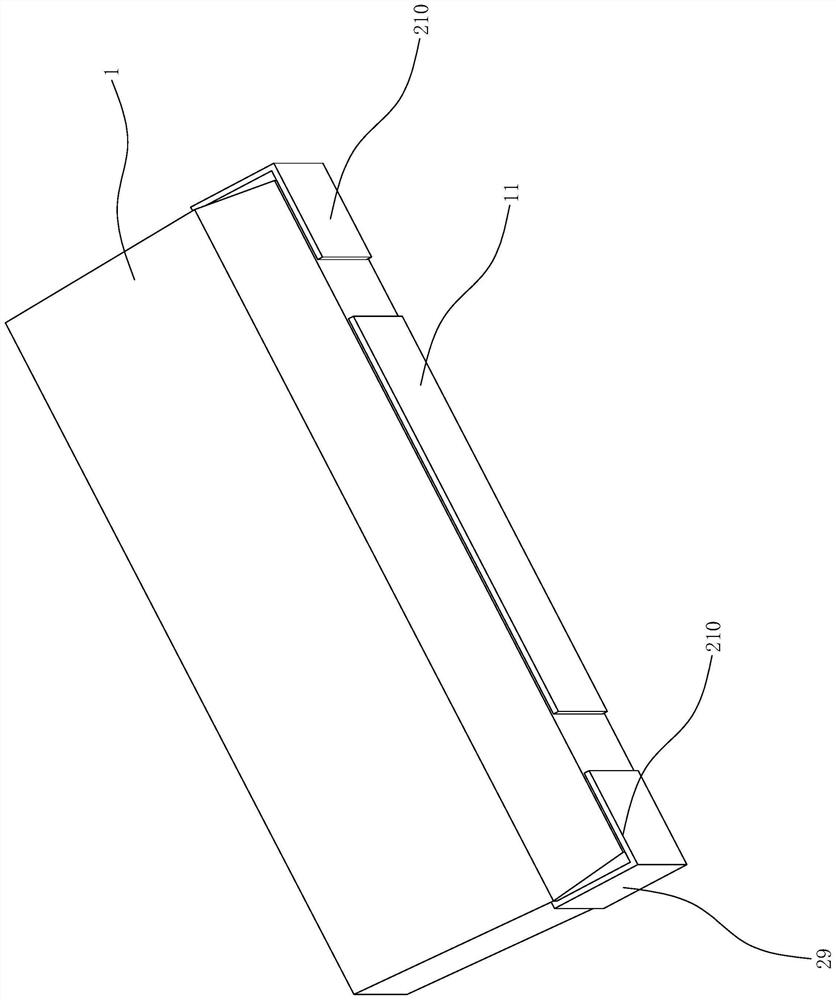

Straight angle conductor and method of manufacturing the same

ActiveUS7173188B2Improve performanceAvoid damageSingle bars/rods/wires/strips conductorsSemiconductor/solid-state device detailsElectrical conductorThermal expansion

A straight angle conductor 10 is provided with a cladding material including a core-sheet metal 11 and conductor-sheet metals 12a, 12b that sandwich both surfaces of the core-sheet metal 11. The conductor-sheet metals 12a, 12b having a volume resistivity equal to or less than 5.0 (μΩ·cm) wraps both sides of the core-sheet metal 11 having a thermal expansion coefficient equal to or less than 10 (×10−6 / C. °) to prevent the core-sheet metal 11 from being exposed to an outside of the conductor-sheet metals 12a, 12b. As a result, it prevents occurrence of an electrical potential difference in a boundary side face between the core-sheet metal 11 and the conductor-sheet metals 12a, 12b to improve corrosion resistance. Especially even when the straight angle conductor 10 is used on a silicon crystal wafer for a solar cell, damage of the silicon crystal wafer caused by heat occurring in soldering process of the conductor 10 or a change in temperature on use thereof for a solar cell is avoided.

Owner:HITACHI METALS LTD

Metallic cover of miniaturization module

ActiveUS20090166830A1High mechanical strengthAvoid deformationMagnetic/electric field screeningSemiconductor/solid-state device detailsMiniaturizationEngineering

A metallic cover of a miniaturization module includes a substrate, a SMD chip unit and a metallic cover, the metallic cover embracing the SMD chip unit and having at least one sizing hole and a plurality of venting holes, the venting holes being disposed around the sizing hole, and the sizing hole and the venting holes being positioned above the SMD chip unit so that glue portions fill up slits between the metallic cover and the SMD chip unit. The venting holes stop the glue portion from running over the second chip unit. The glue-filled slits between the top lid and the SMD chip unit provides a strong support to prevent any deformation of the metallic cover when the metallic cover is tested and processed.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

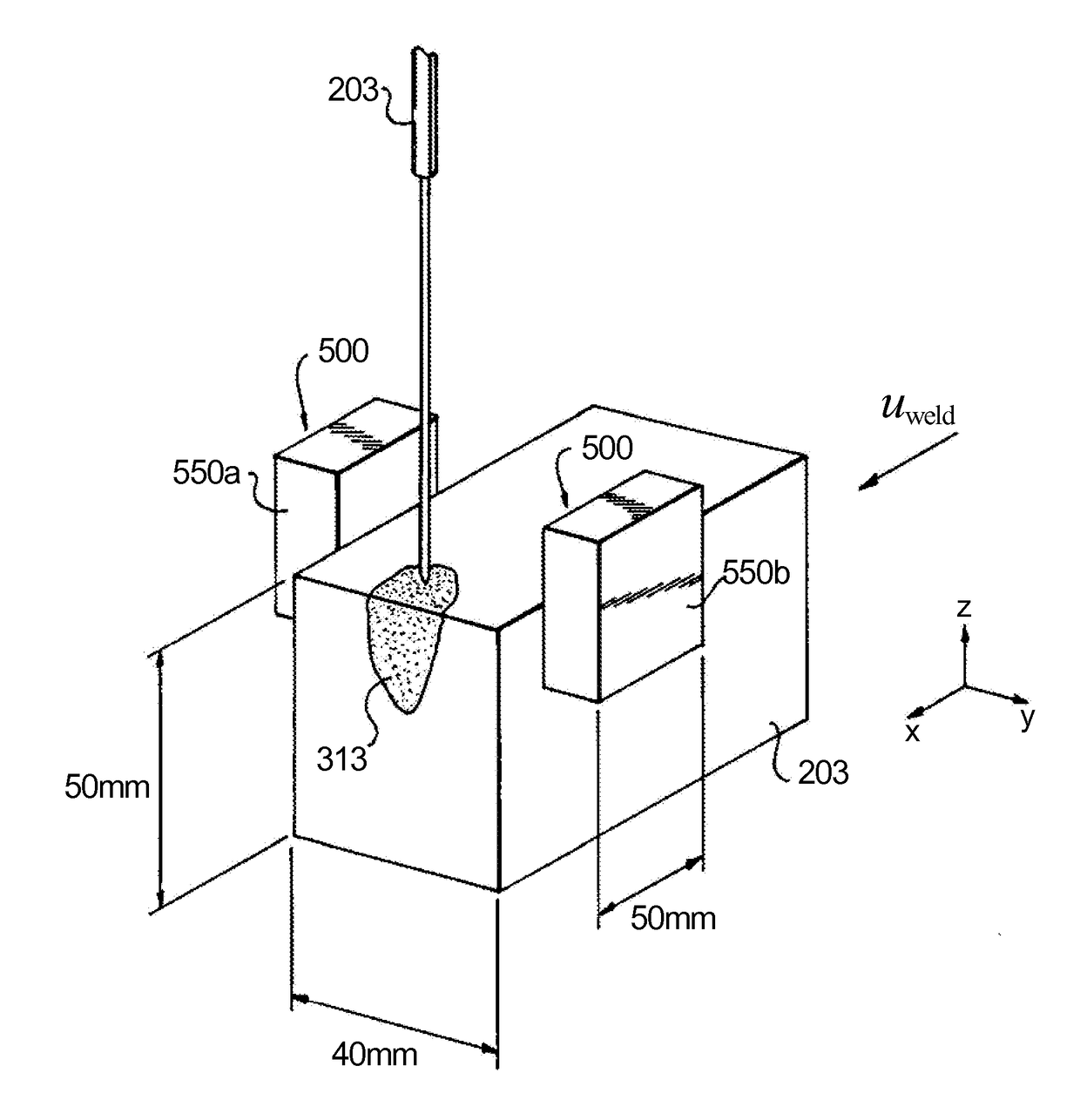

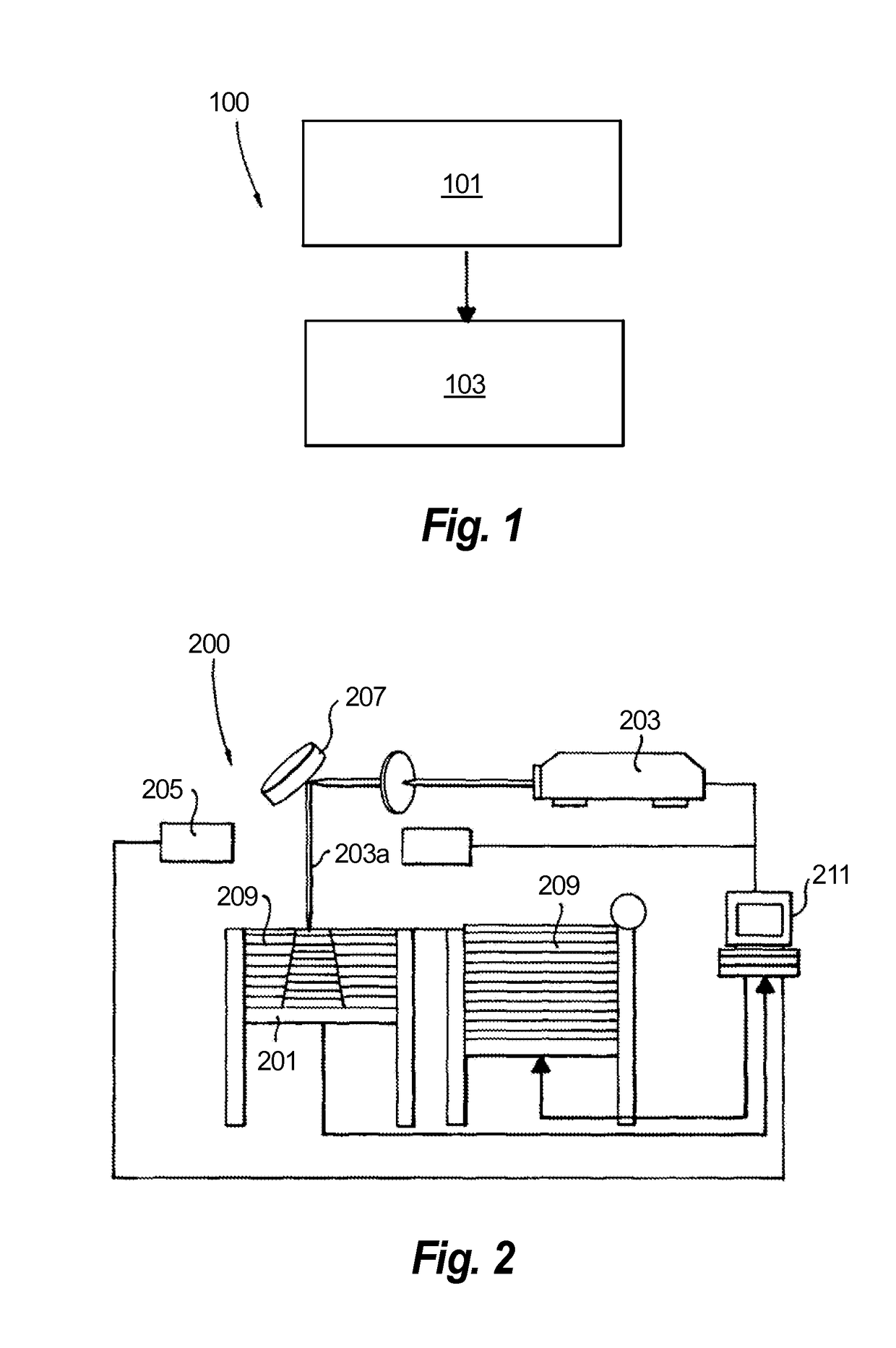

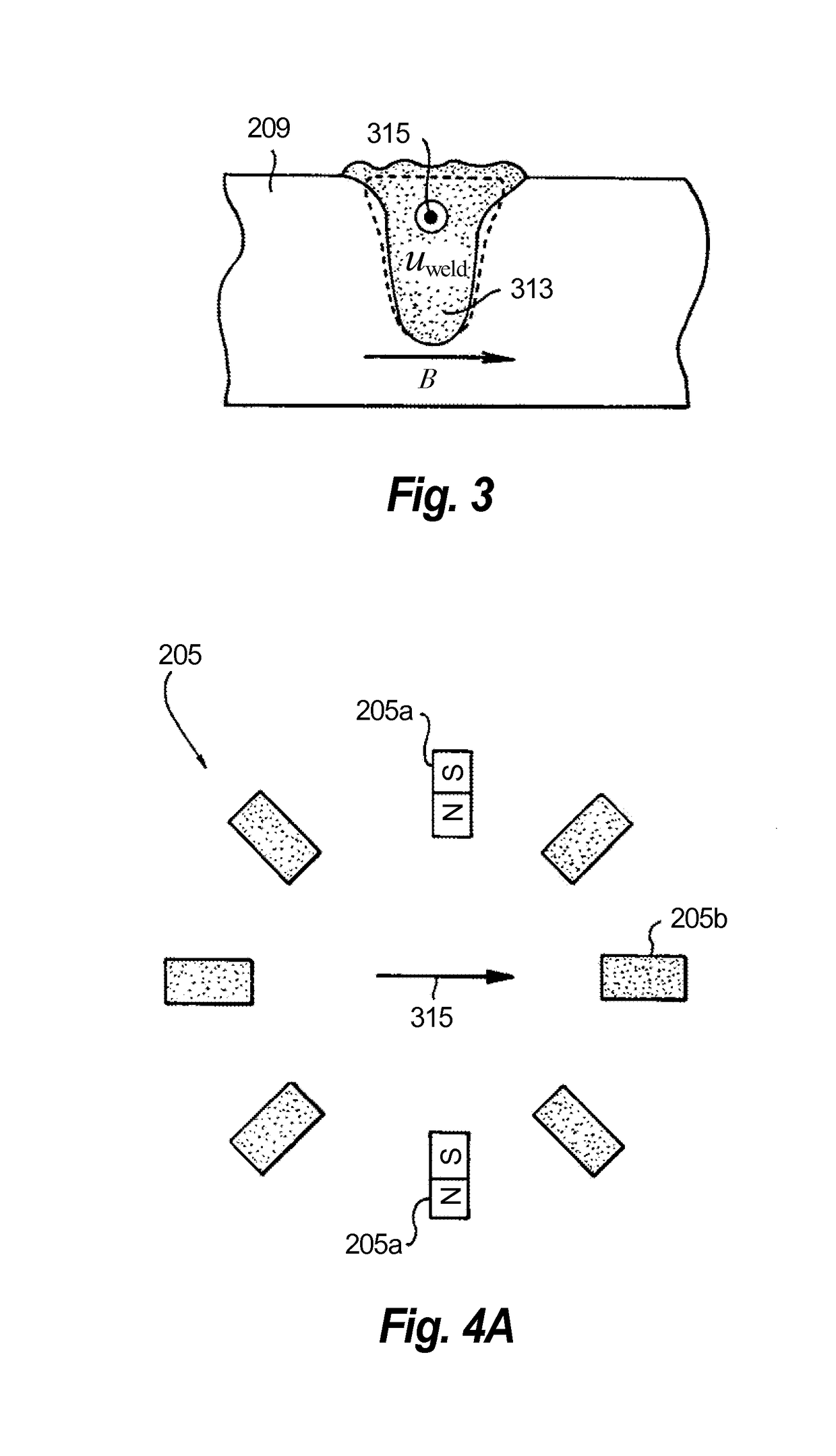

Additive manufacturing systems and methods

InactiveUS20170106477A1Reduced soldering areaReduce wall thicknessIncreasing energy efficiencyManufacturing environment conditioningMelting tankElectromagnetic field

A method for additively manufacturing an article includes applying energy to a powder to produce a weld pool of molten powder and applying an electromagnetic field to the weld pool to control one or more characteristics of the weld pool. Applying the electromagnetic field can include applying an electric field and / or a magnetic field to the weld pool.

Owner:DELAVAN

Accumulation slippage construction device in icesword manner and construction method thereof

The invention relates to an accumulation slippage construction device in an icesword manner and a construction method thereof. The accumulation slippage construction device comprises gliders at the lower part of a steel truss and a slide rail fixed above a steel truss support, wherein the gliders are icesword-type gliders distributed at the lower part of the steel truss at intervals along the direction of the slide rail; each section of icesword-type glider is two plain round bars parallel to the slide rail; the top of the plain round bar is welded together with the bottom of the steel truss; the bottom of the plain round bar is linearly contacted with the upper surface of the slide rail; and the bottoms of the steel truss closed to the slide rail are respectively connected with limit baffle plates. Using slippage contacting plain round bars with profile steel flat rails to replace slippage contacting flat gliders with train steel rails, the invention is economical, convenient, practical and effective, is applicable to places where cranes can not enter into the construction area in the presence of basement or other structures, as well as steel structures of small and intermediate spans where pushing jacks and train steel rails are difficult to purchase or the construction is not economical, and has great influence on the construction period by other construction methods.

Owner:北京城建精工钢结构工程有限公司

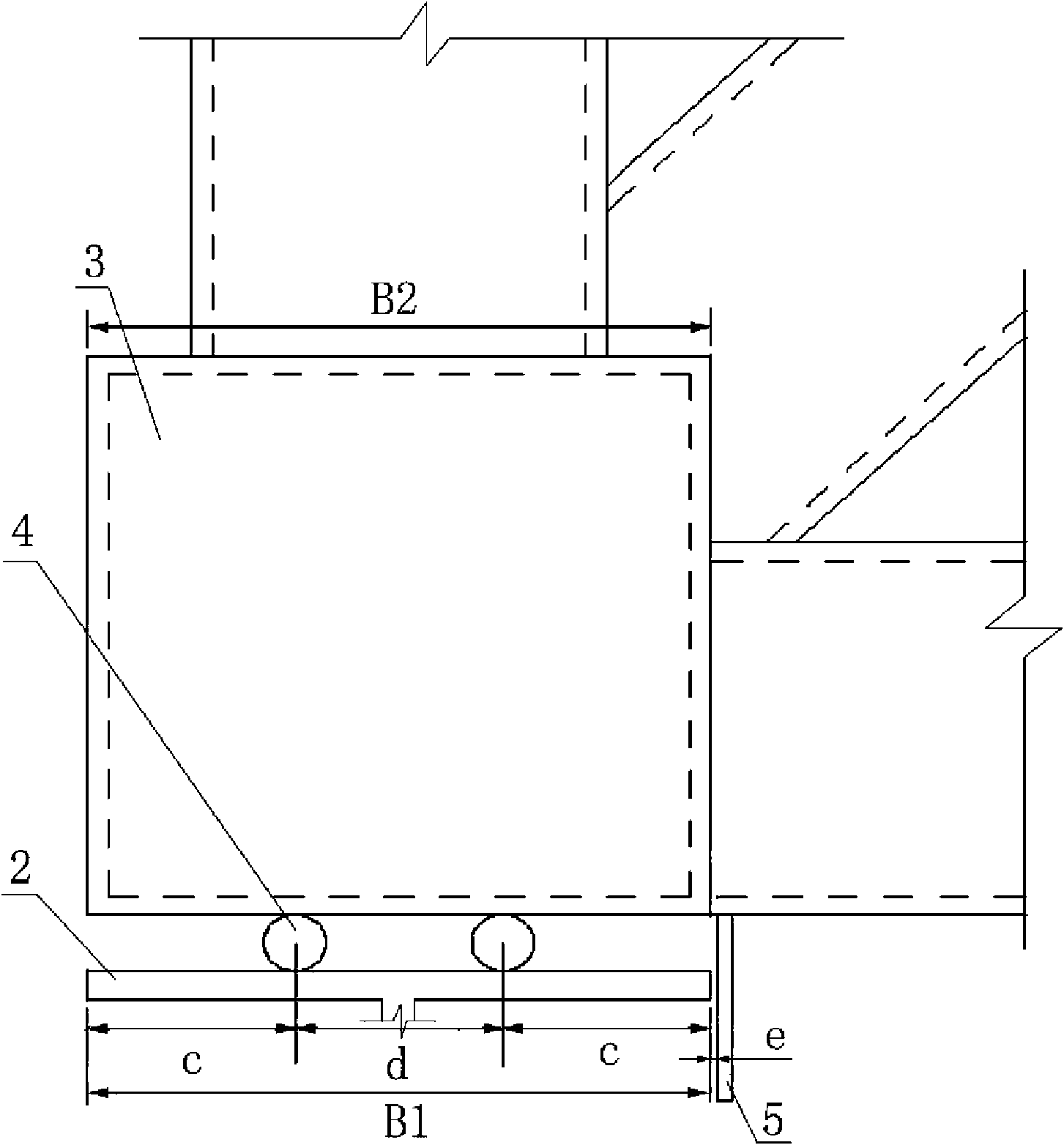

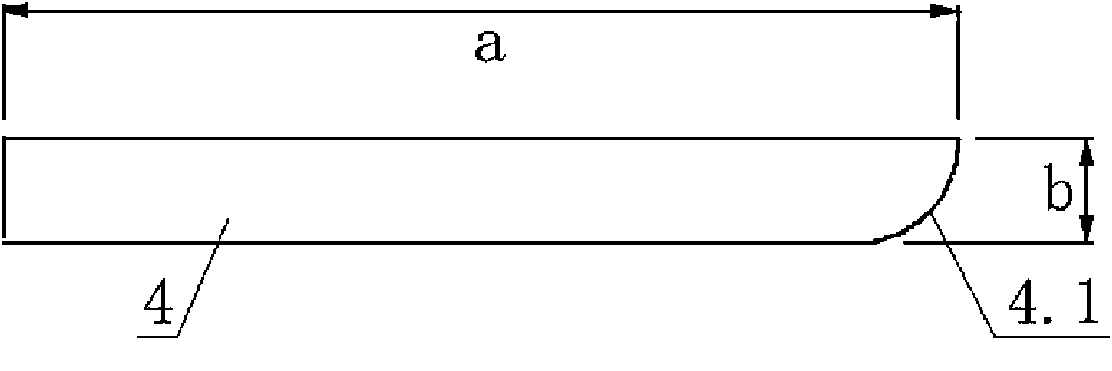

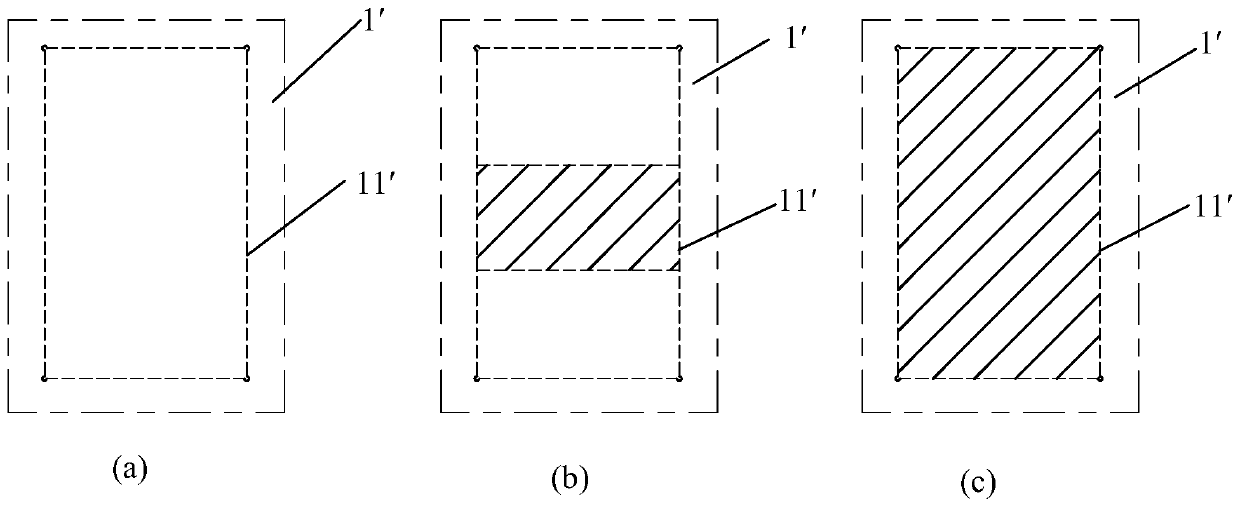

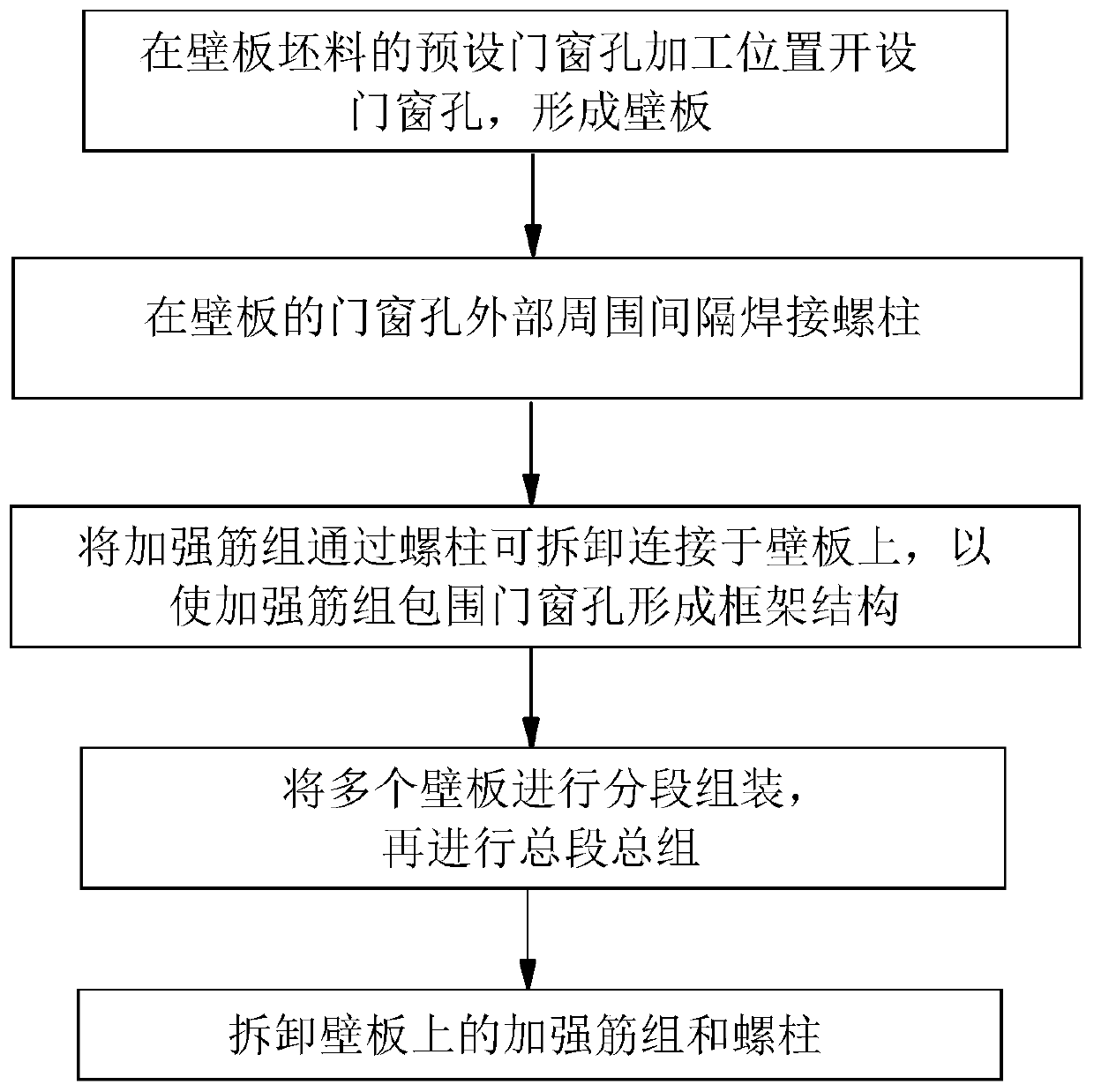

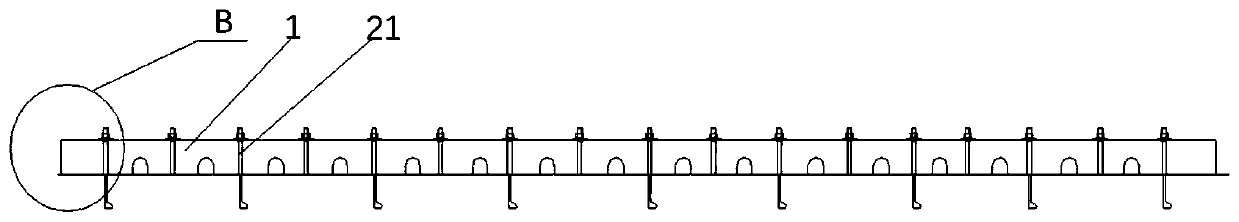

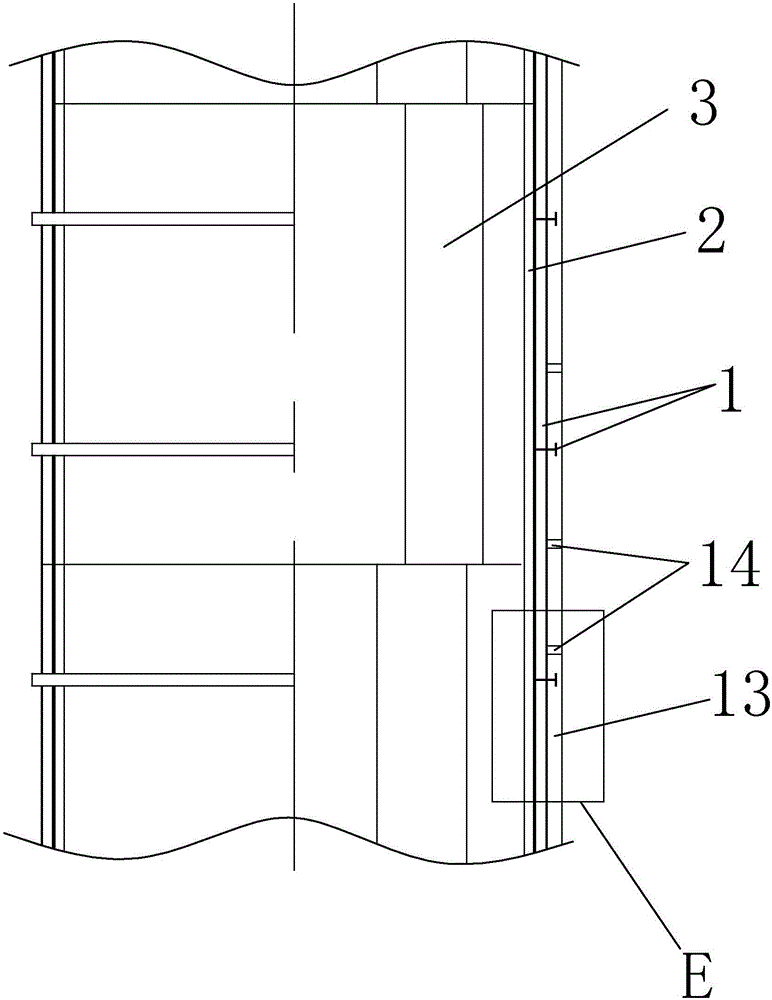

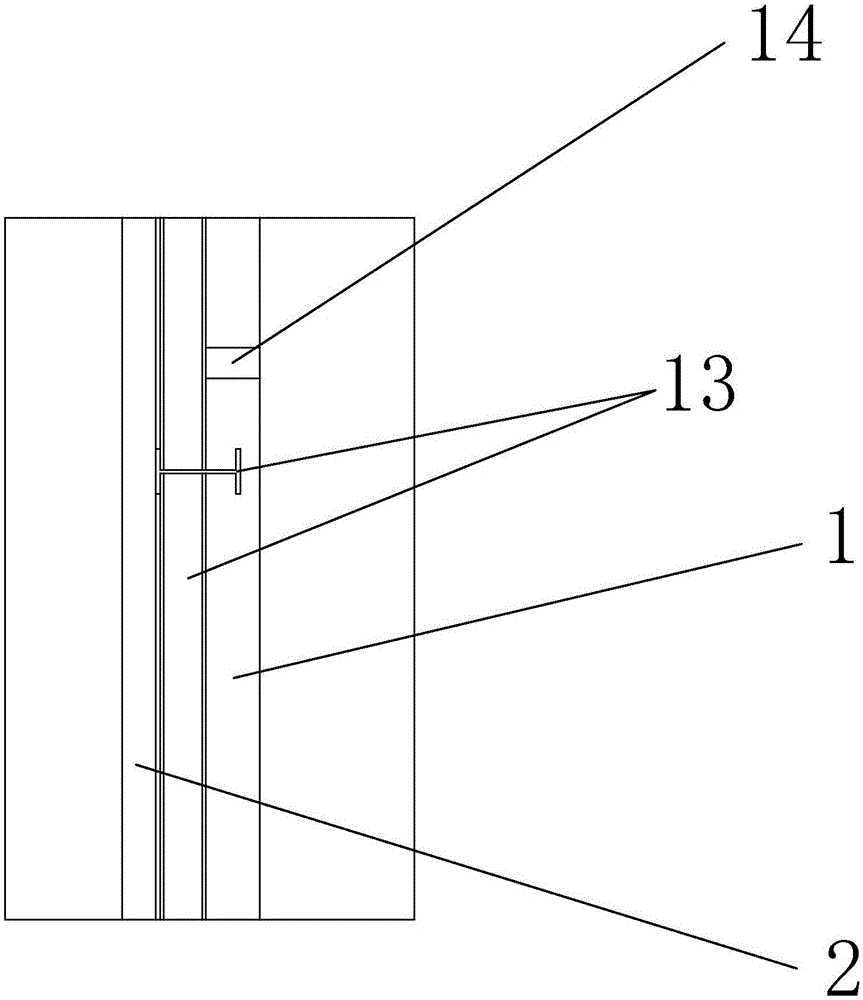

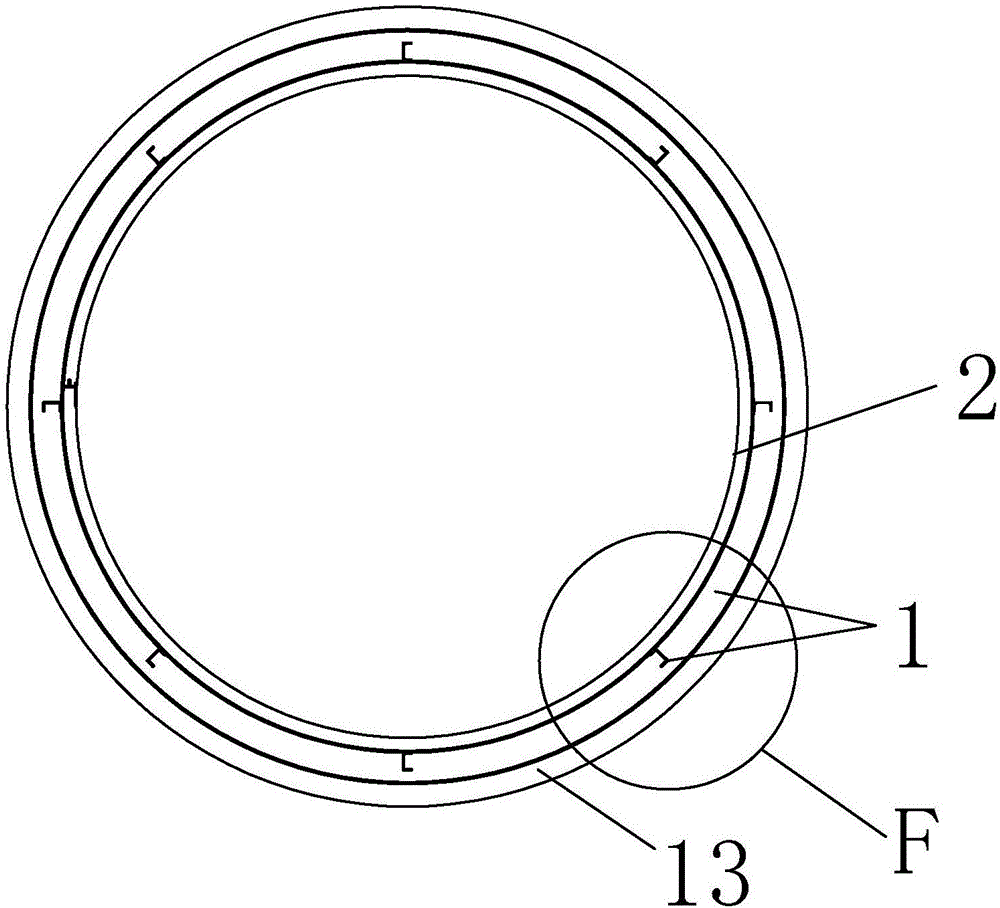

Ship wall door and window hole machining method and door and window hole shape maintaining tool

InactiveCN111470002AImprove construction efficiencyAvoid damageWaterborne vesselsAssembly disassemblyStructural engineering

The invention relates to the technical field of shipbuilding, and discloses a ship wall door and window hole machining method and a door and window hole machining hole shape maintaining tool. The shipwall door and window hole machining method comprises the steps of forming a door and window hole in the preset door hole machining position of a wallboard blank to form a wallboard; welding studs tothe periphery of the exterior of the door and window hole of the wallboard at intervals; detachably connecting a reinforcing rib set to the wallboard through the studs, and enabling the reinforcing rib to surround the door and window hole to form a frame structure; carrying out assembly segmentation on a plurality of wallboards, and then carrying out block assembling; and disassembling the reinforcing rib set and the studs on the wallboards. The door and window hole machined through the ship wall door and window hole machining method is small in deformation, and the damage to base metal is small. The door and window hole shape maintaining tool is easy and convenient to operate through the ship wall door and window hole machining method, and the deformation generated in the assembly segmentation process and the block assembling after door and window hole machining can be reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

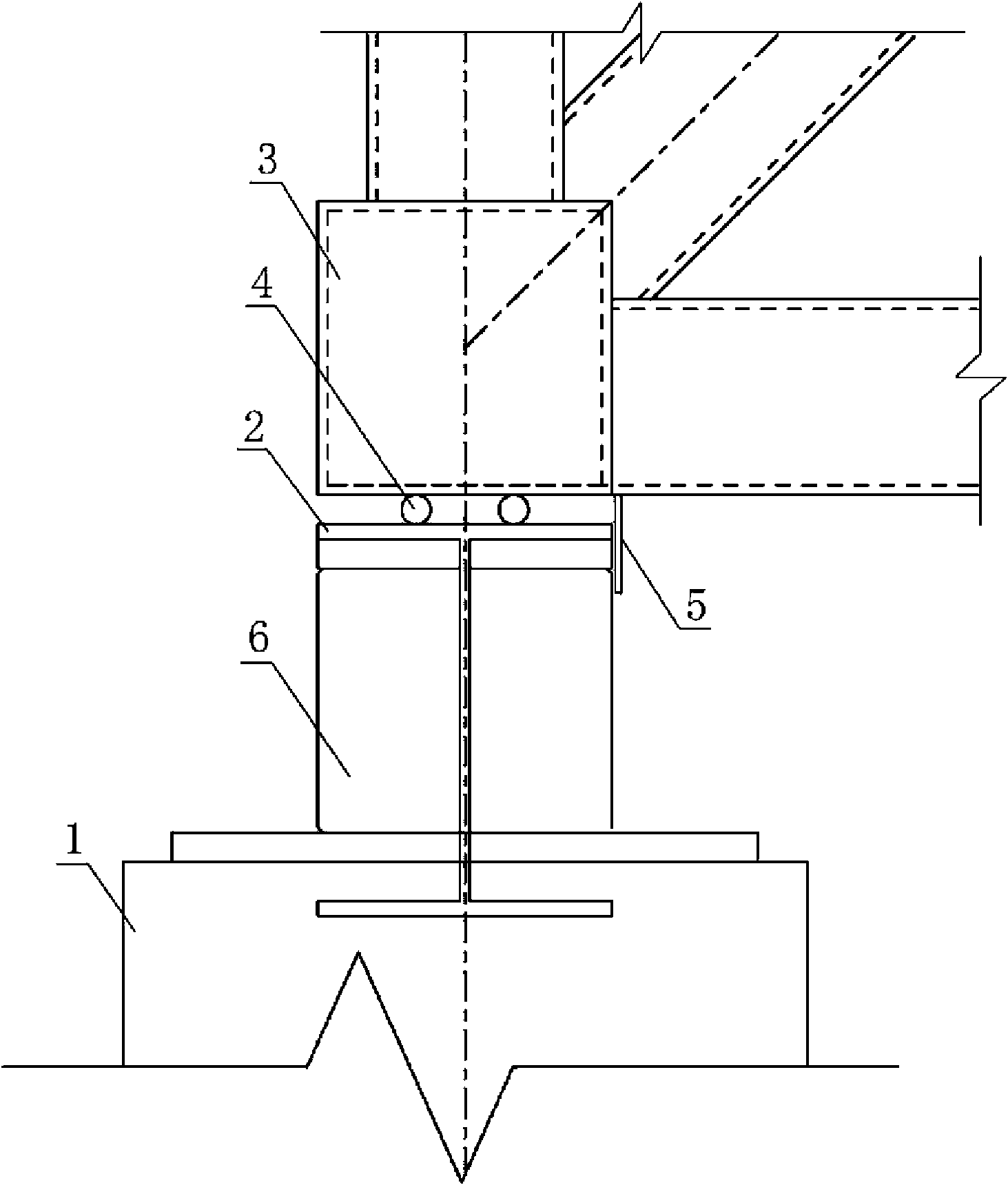

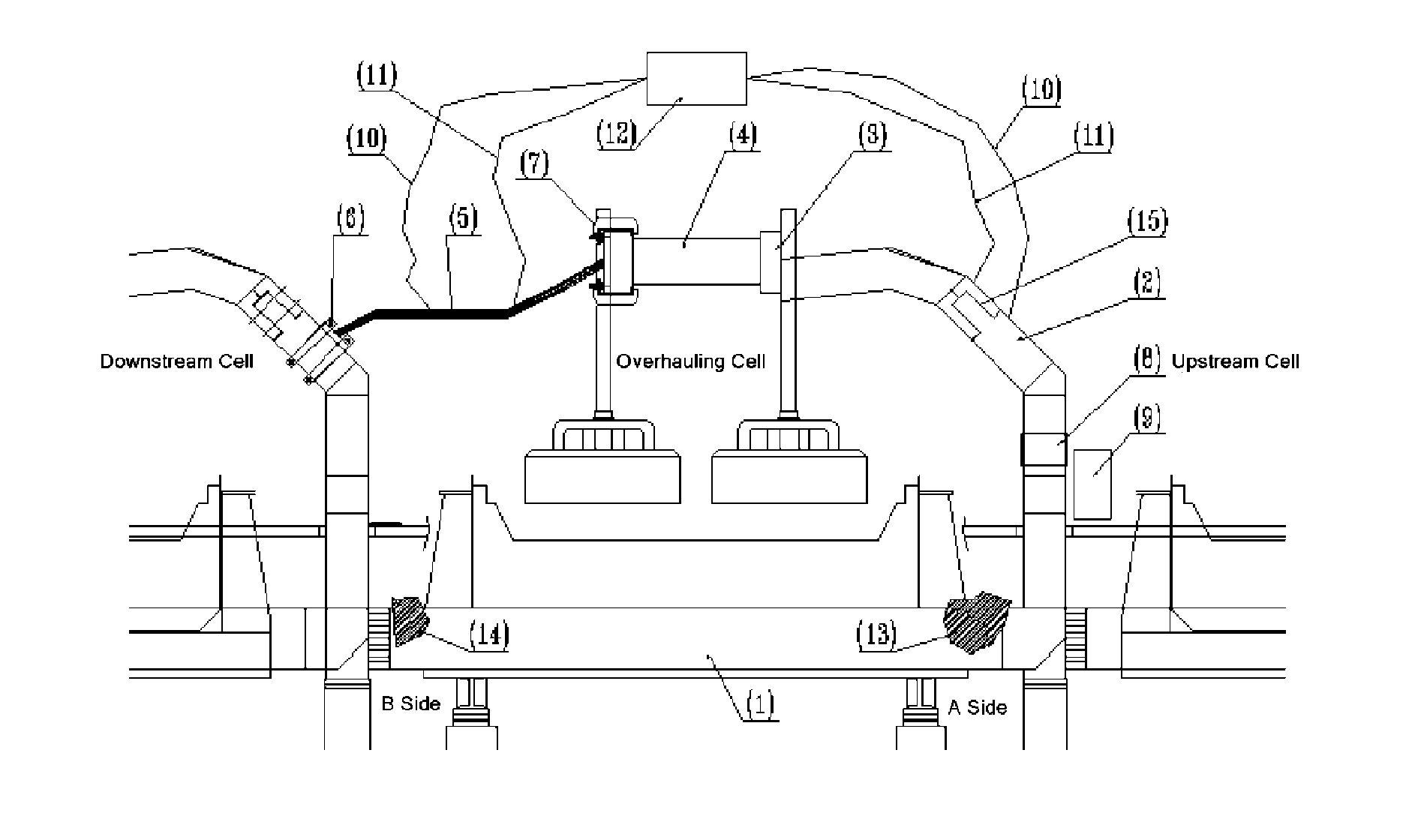

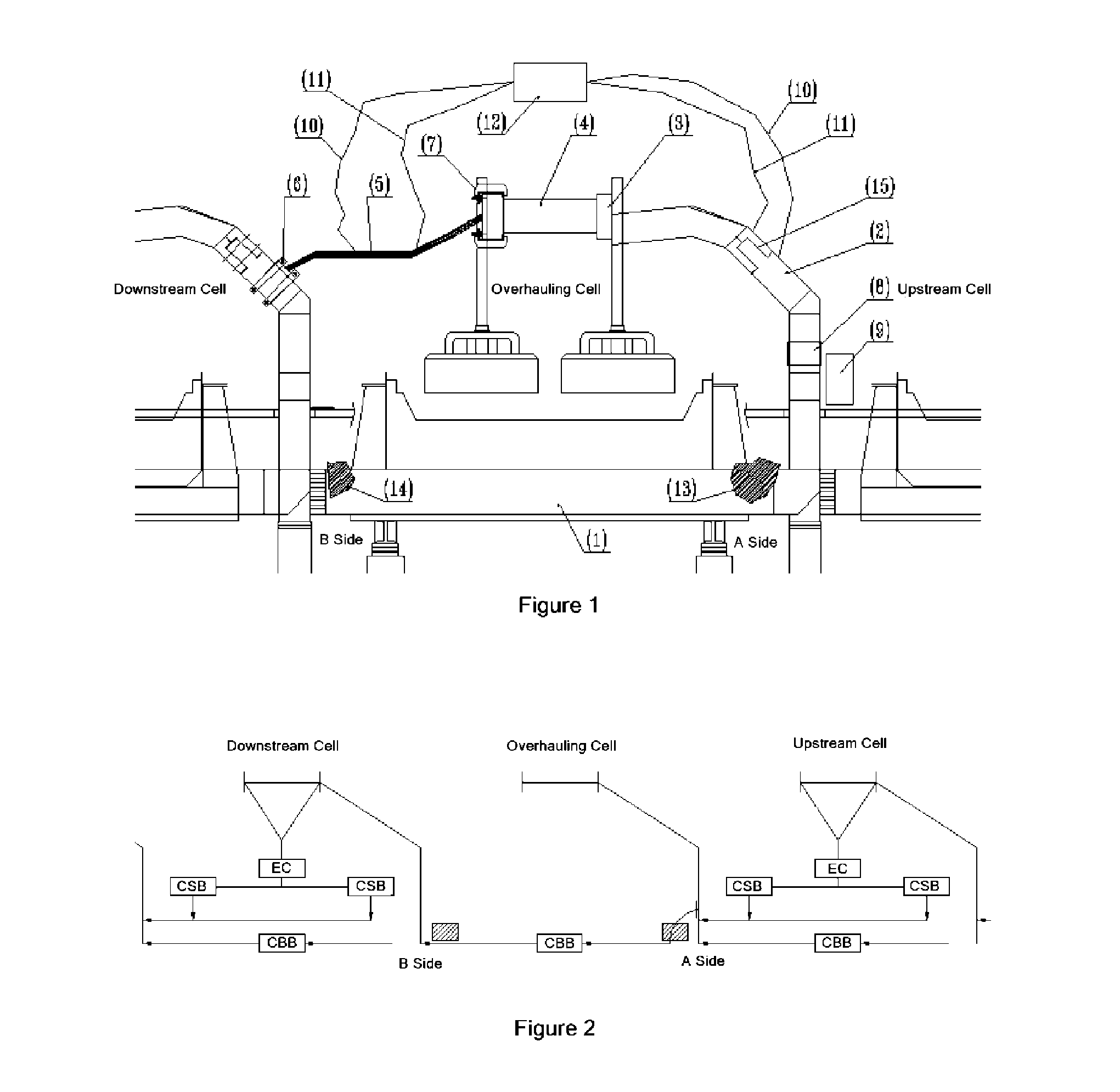

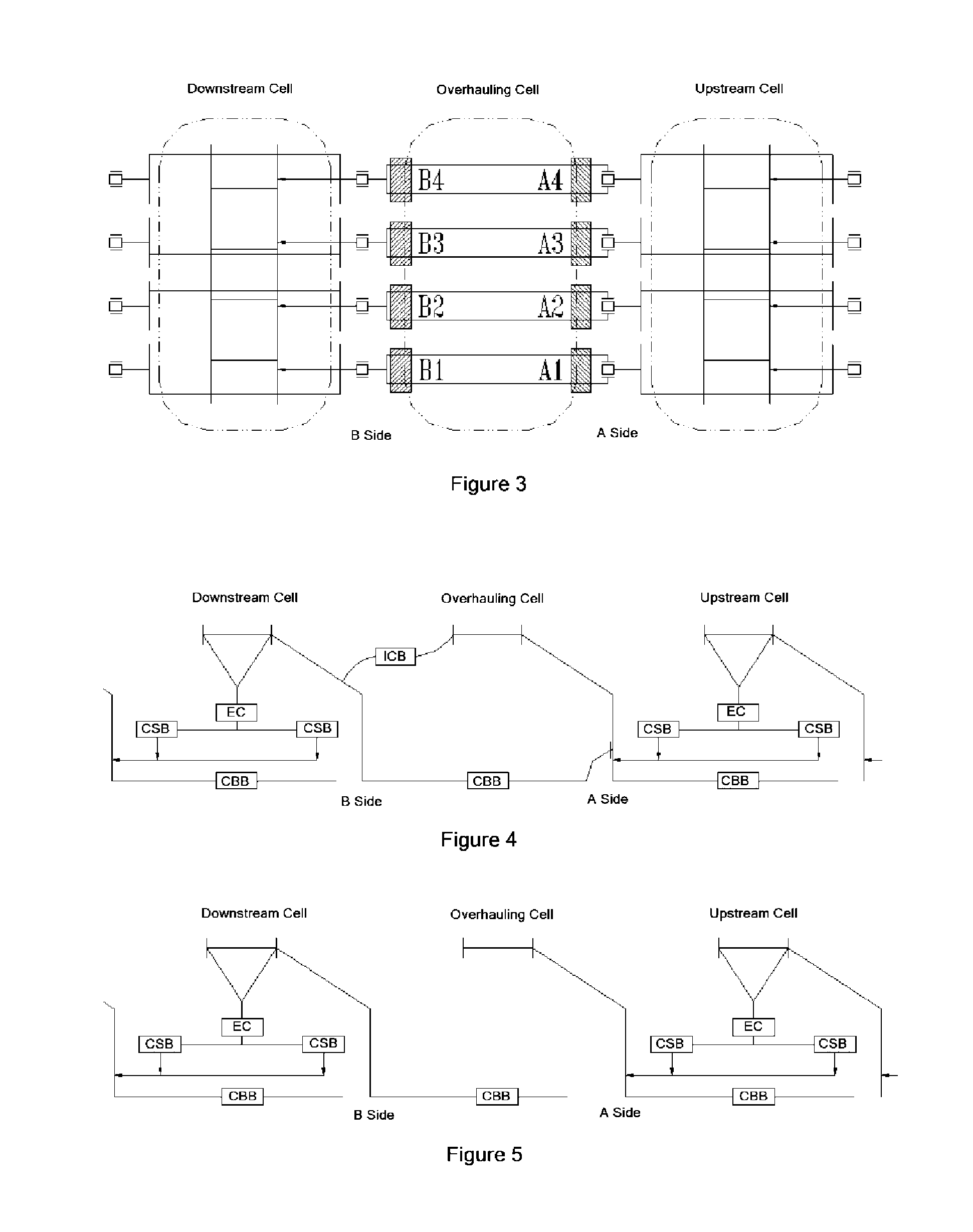

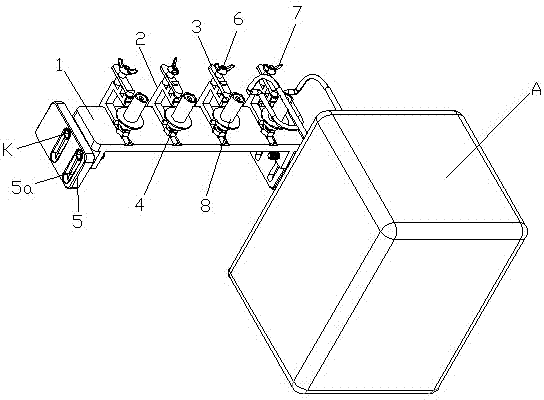

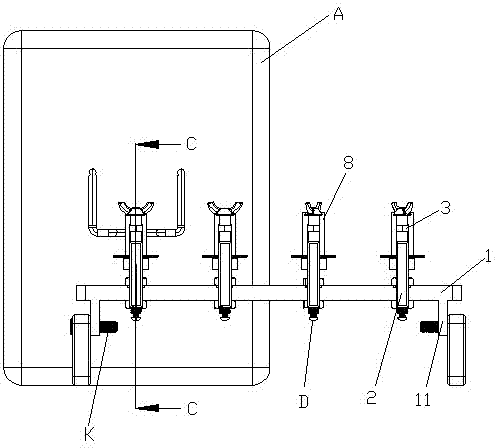

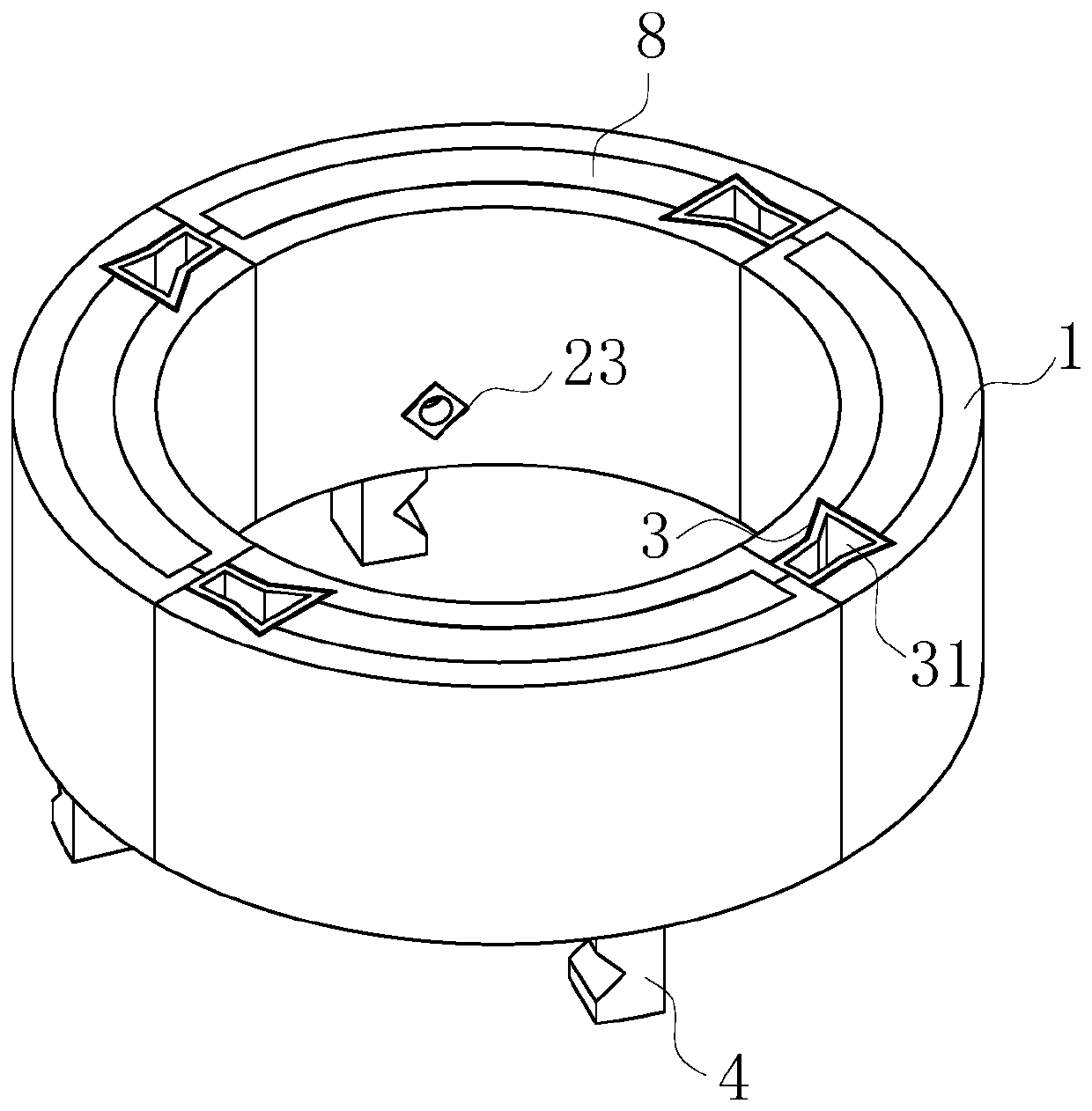

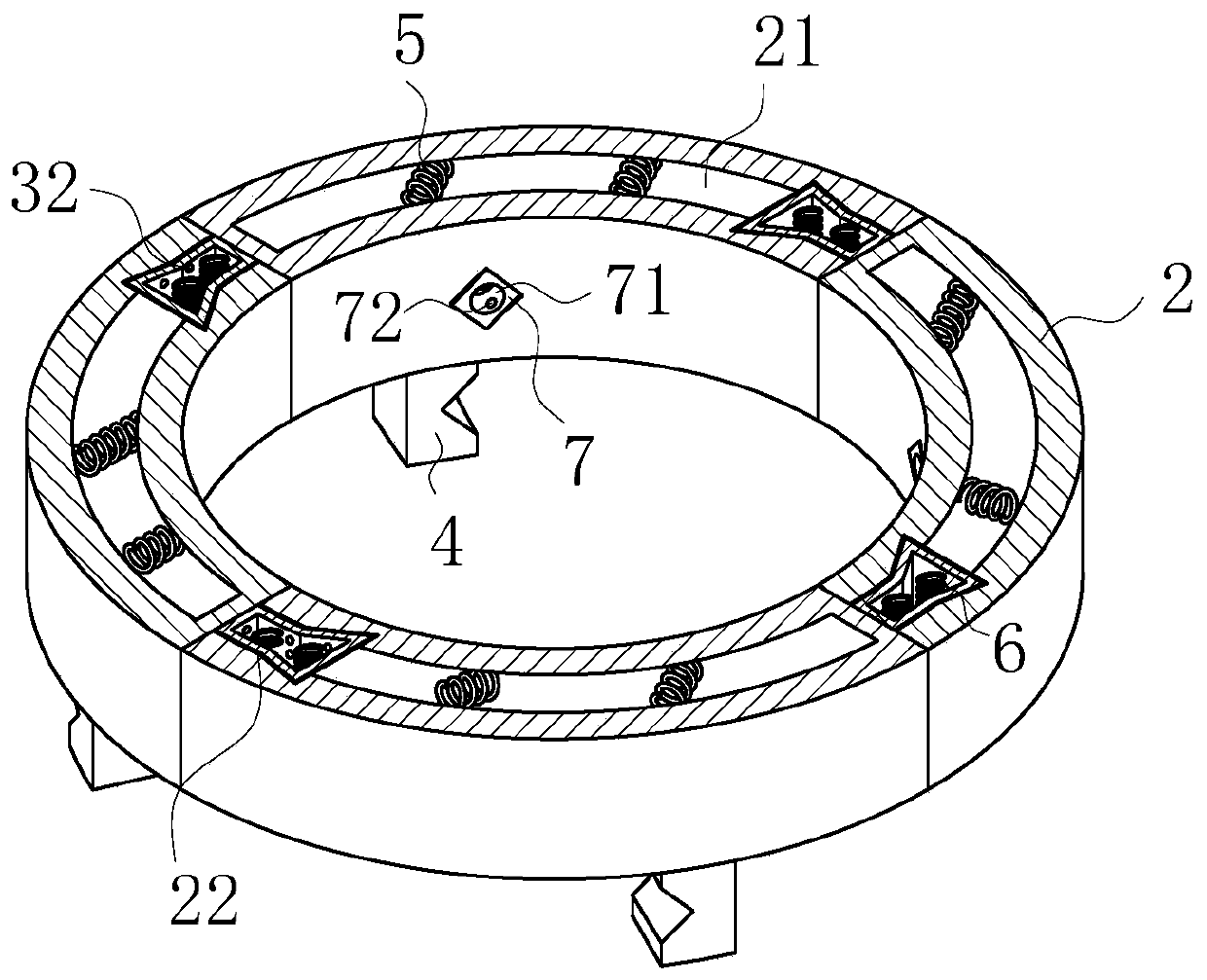

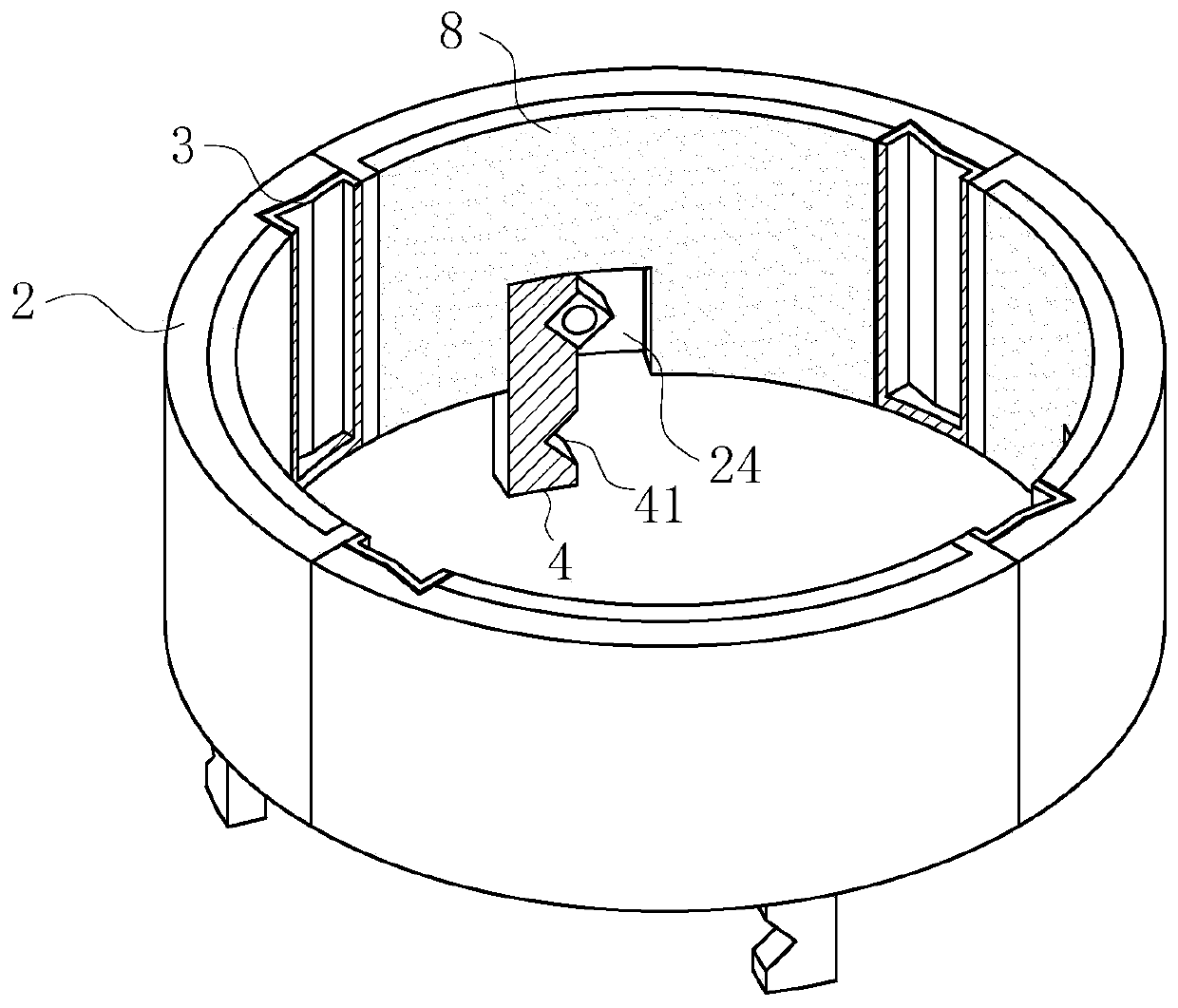

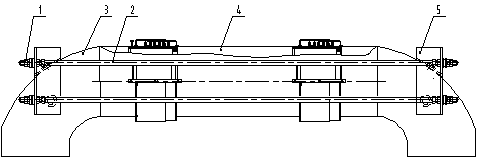

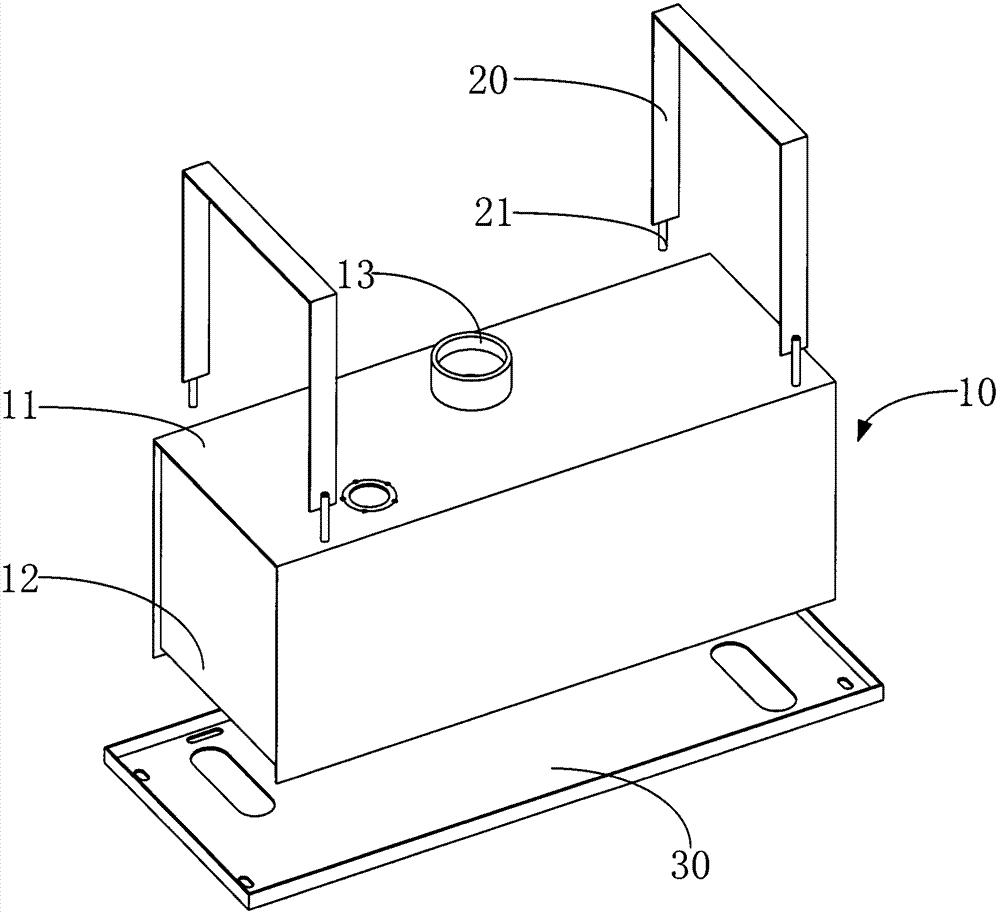

Live welding method and arrangement for aluminum electrolytic cell under series full current

ActiveUS20120305630A1Reduce energy lossInhibit productionWelding/cutting auxillary devicesAuxillary welding devicesData acquisitionEngineering

A device using the live welding method for aluminum electrolytic cell overhauling under series full current consists of short-circuit buses at the bottom of the cell (1), pillar buses (2), an anode bus (3), a balance bus (4), a inter-cell standby bus (5), a door-shaped pillar clamp (6), an arcuate clamp (7) of anode buses, a current conversion switch (8, a mechanical switching device (9) for the short-circuit port, a voltage sensor and wires thereof (10), a temperature sensor and wires thereof (11), a system (12) for data acquiring, displaying, analyzing and alarming, an A-side welding area (13), a B-side welding area (14) and compression-joint points (15) on pillar soft belts of overhauling cells; and the live welding method comprises the following steps: when welding is required to be performed in some zone, the currents of short-circuit buses at the bottom of the cell (1) and pillar buses (2) which influence the welding area most are cut off, the serial currents are shunted to other pillar buses (2), other buses at the bottom of the cell (1) and the inter-cell standby buses (5) such that the magnetic field intensity at the welding area can be lowered to the extent that welding can be performed so as to perform welding, and such a device and method can achieve live welding of aluminum electrolytic cells overhauling under series full current.

Owner:CHINA ALUMINUM INT ENG CORP

Vehicular lamp having a removable lens with an extension reflector

InactiveUS7175325B2Avoiding increasing number of partReduce appearanceVehicle headlampsVehicle interior lightingEngineeringTroffer

A vehicular headlamp includes a lamp body having an opening, a first reflector disposed within the lamp body, a lens, and a second reflector. The second reflector serves as an extension reflector to cover a gap between the opening of the lamp body and the first reflector. The lens and the second reflector are joined together at an edge portion thereof by laser welding. The second reflector has a leg portion on a back surface thereof. An edge portion of the opening has a groove to receive the leg portion, and seal material having a predetermined adhesibility, which can be pulled off, is injected into the groove. The second reflector joined to the lens is mounted on an edge of the opening of the lamp body via the seal material.

Owner:KOITO MFG CO LTD

Printed circuit board unit

InactiveUS20100206626A1Small sizeIncrease connection forceFinal product manufacturePrinted circuit aspectsElectronic equipmentReflow soldering

A printed circuit board unit includes a substrate and at least one connecting pad on the substrate. The connecting pad is used for electrically connecting to an electronic device by welding method. The connecting pad has at least one venting opening thereon. Therefore, the steam and gas by-produced in reflow soldering process can escape into the environment from the venting opening. Accordingly, the problem of large bubbles formed in the connecting pads is solved.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

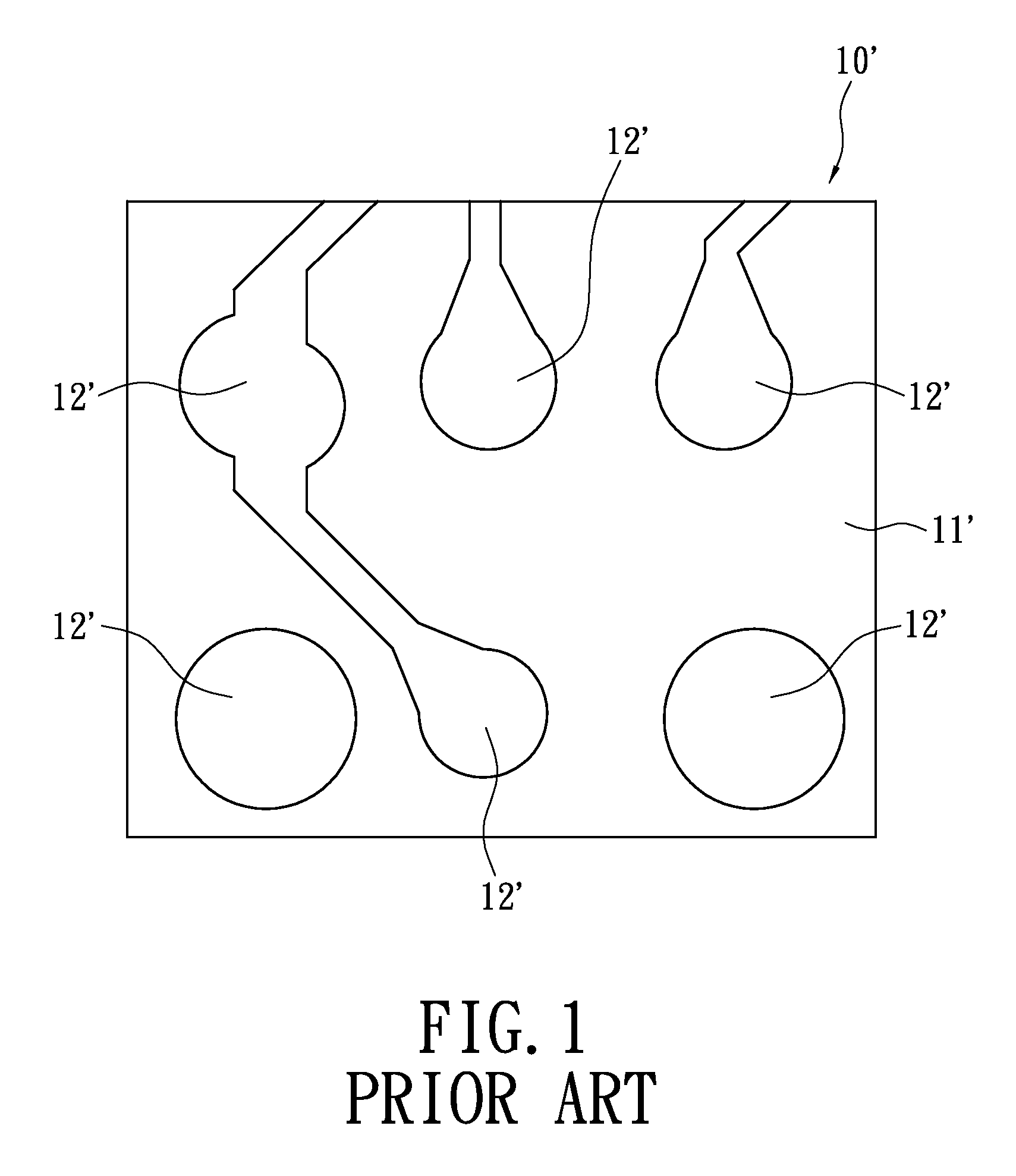

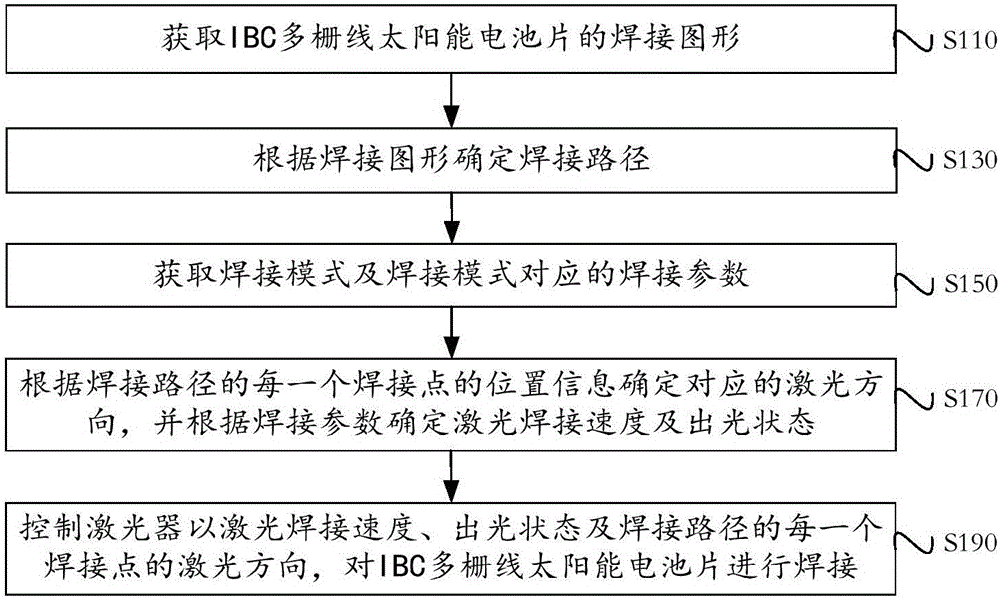

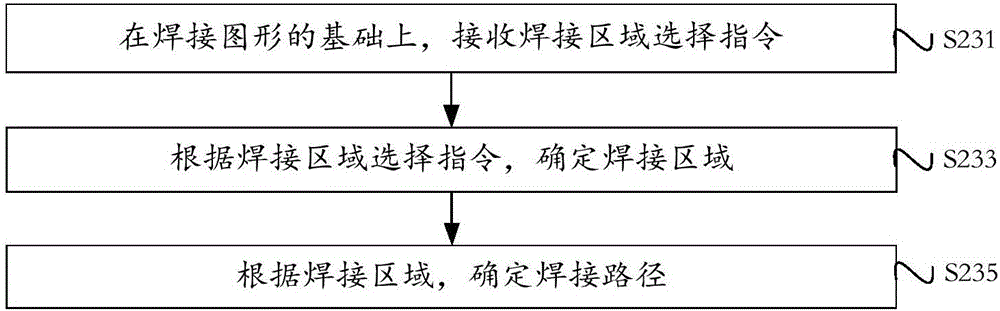

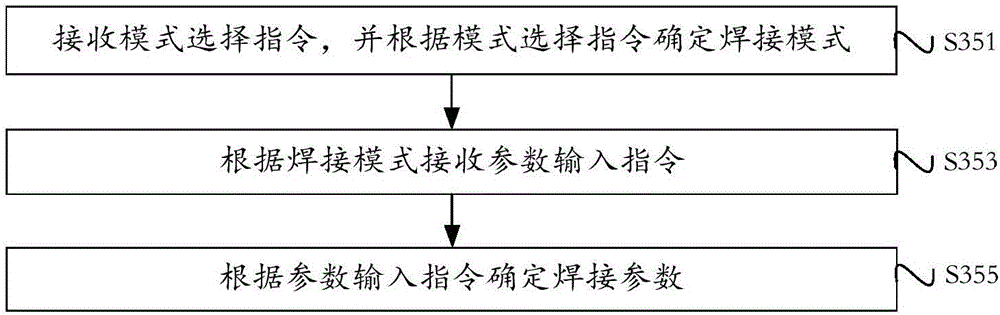

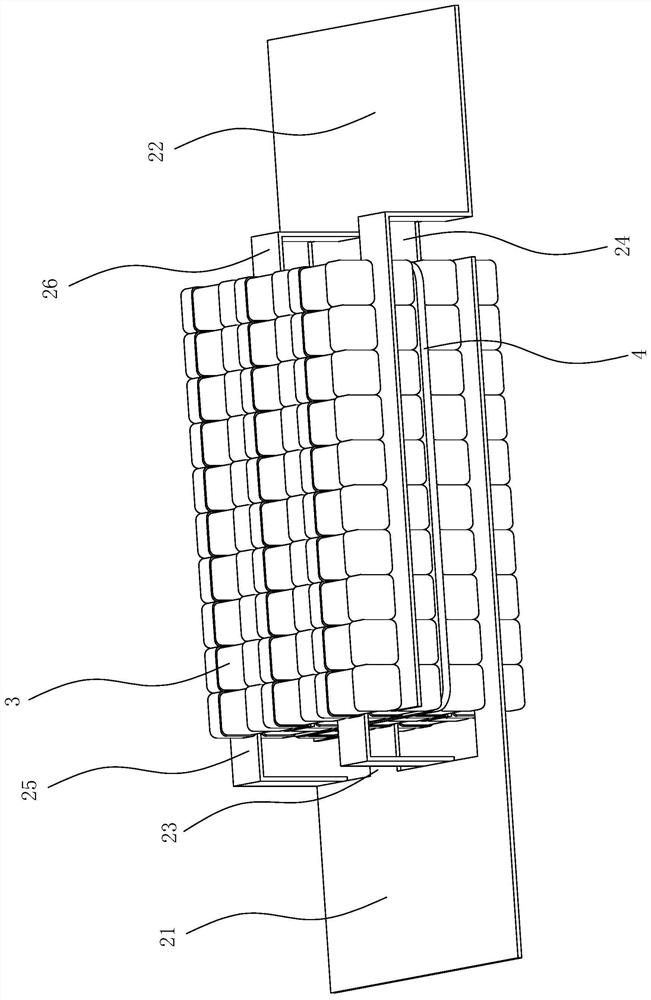

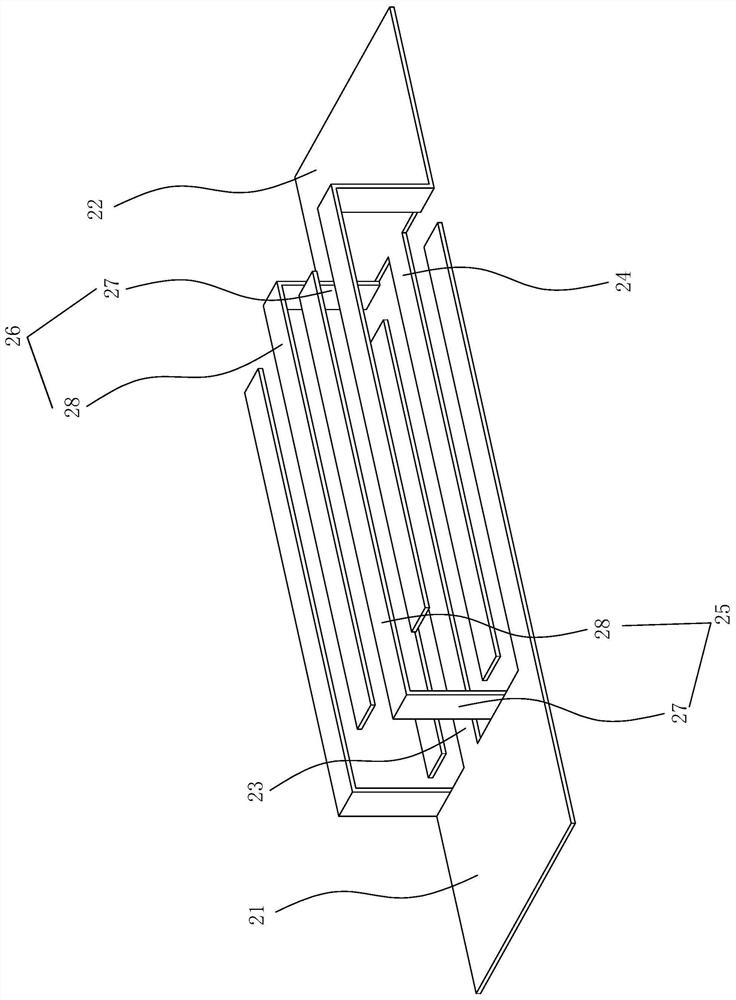

Welding method and device of IBC muti-grid line solar cell

ActiveCN106826011AReduce contact resistanceReduce Fragmentation RateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSolar cell

The invention provides a welding method and a device of an IBC muti-grid line solar cell. A welding pattern of the IBC muti-grid line solar cell is obtained; a welding path is determined according to the welding pattern; the welding path and the welding pattern include welding points; a welding mode and welding parameters corresponding to the welding mode are obtained; corresponding laser directions are determined according to position information of each welding point of the welding path, and a laser welding speed and a light emitting state are determined according to the welding parameters; and a laser is controlled to weld the IBC muti-grid line solar cell according to the laser welding speed, the light emitting state and the laser direction of each welding point of the welding path. The laser is controlled to weld the IBC muti-grid line solar cell; as the welding mode of the laser is a non-contact welding mode, the welding method and device of the IBC muti-grid line solar cell are low in fragment rate and small in welding area; and the obtained IBC muti-grid line solar cell is low in contact resistance.

Owner:HANS LASER TECH IND GRP CO LTD +1

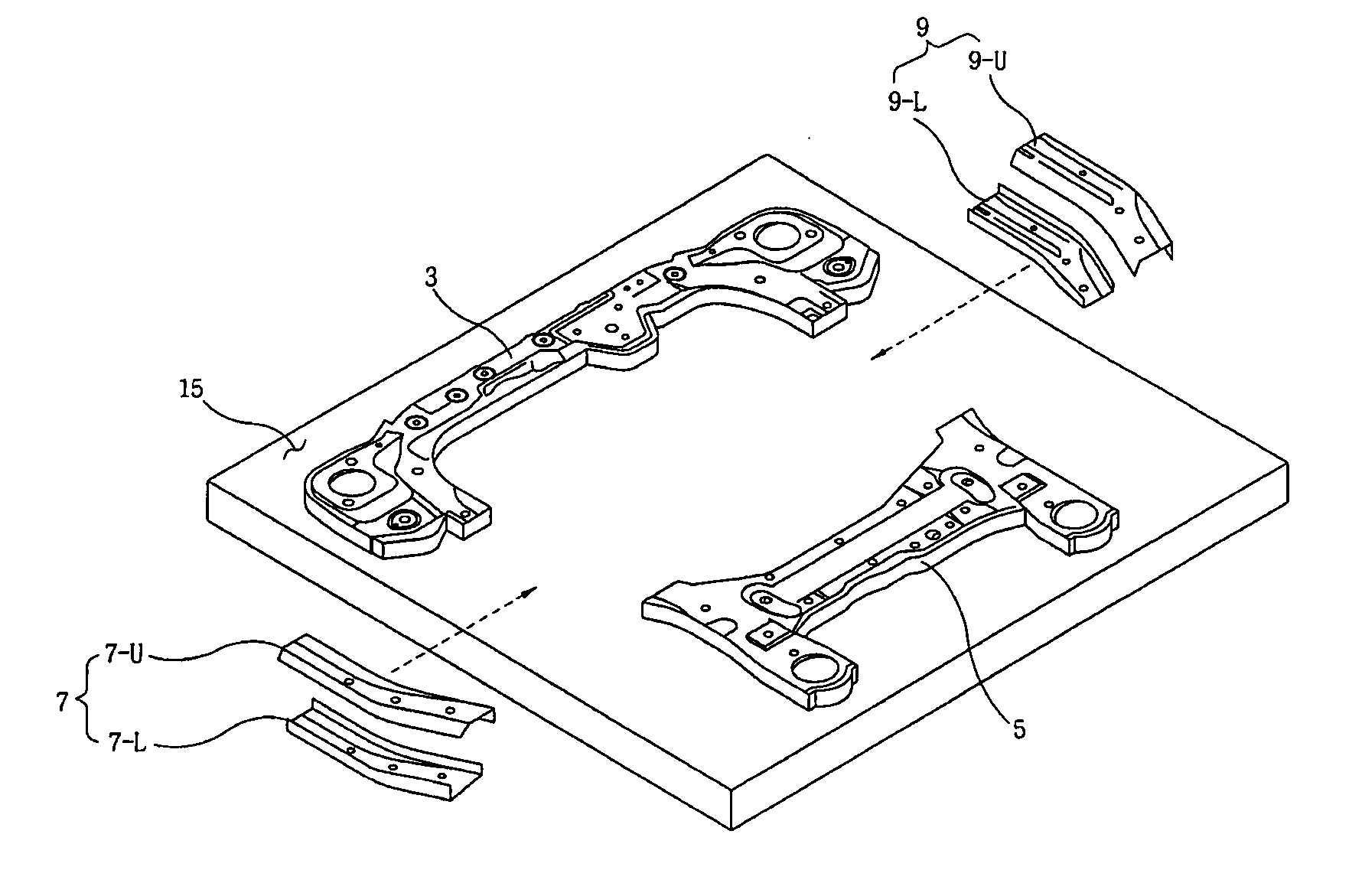

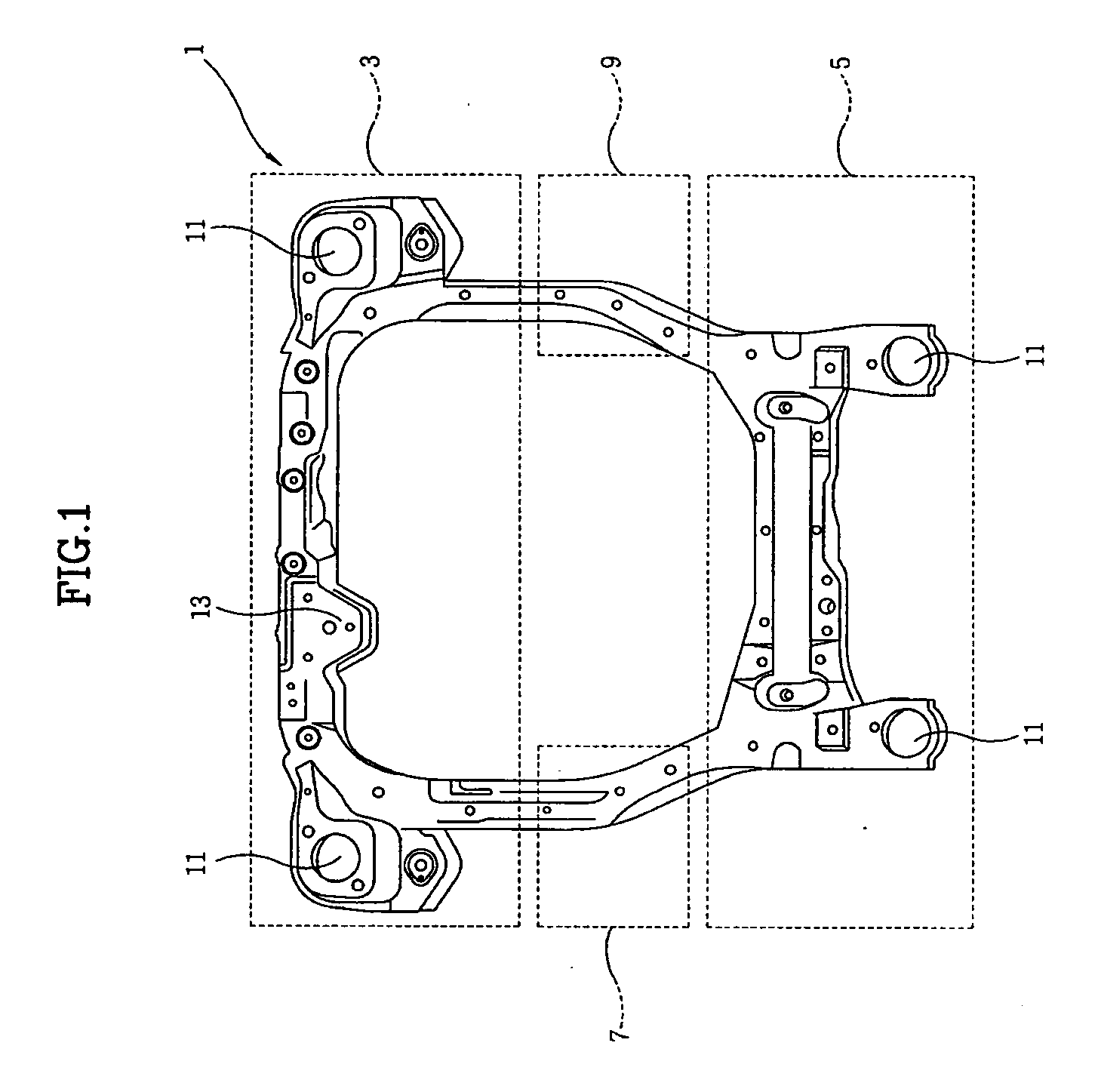

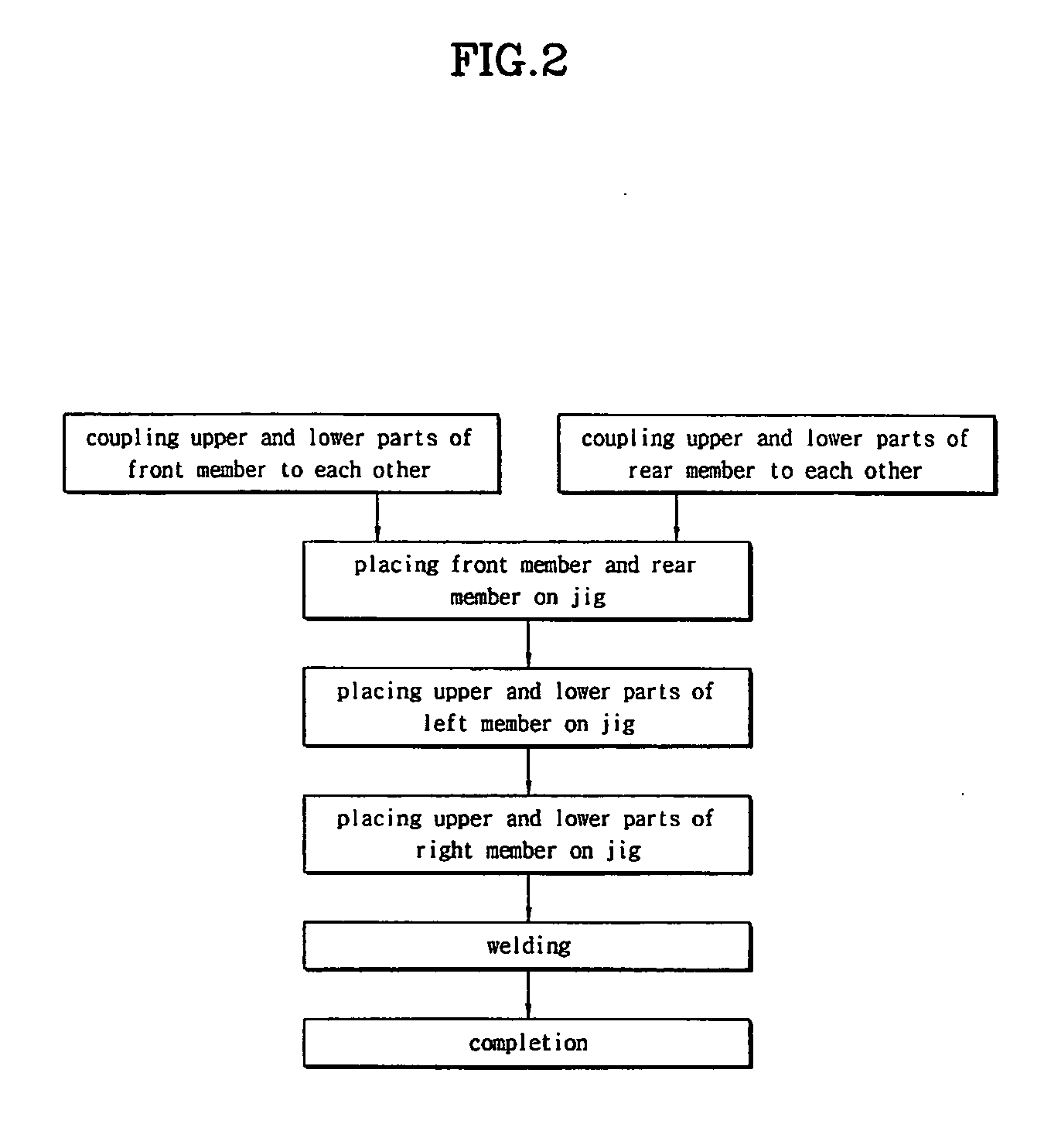

Method of manufacturing subframe for vehicles

InactiveUS20070074398A1Simple processReduce manufacturing costMetal-working apparatusUnderstructuresVehicle frameSubframe

Owner:HYUNDAI MOTOR CO LTD

Method for turning over subsections and overall section

InactiveCN105836595ASimple structureSave installation timeLoad-engaging elementsGravity centerWorkload

The invention discloses a method for turning over in subsections and total sections. According to the method, B-type lifting rings of corresponding tonnage are selected according to the weight center of gravity of the subsections and the total section, and B-type suspension rings with lighter weight are installed on the rebates of the subsections and the total section. Lifting ring, pull the turning tooling to the position of the segmental and general segmental rings, when the center line of the tooling connecting ear plate hole and the segmental and total segmental ring holes is basically on the same straight line, insert the connecting pin, screw on the fastening nut, Insert the cotter pin. When the section and the total section need to turn over, connect the hook to the lifting part structure and tighten it slowly, so that the active top plate of the tooling can be attached to the installation plane of the lifting ring. After turning over the subsection and the total section, loosen the hook, pull out the connecting pin, remove the tooling, and recycle it. The invention greatly reduces the installation time of turning over suspension rings, reduces the workload of welding and cutting and grinding of suspension rings, improves the turning efficiency of sections and total sections, and saves costs.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

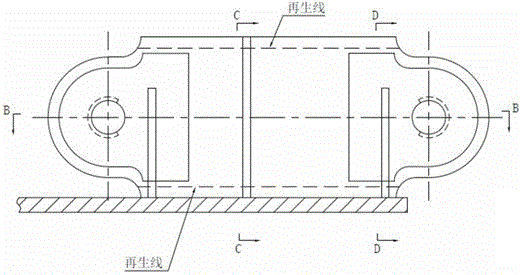

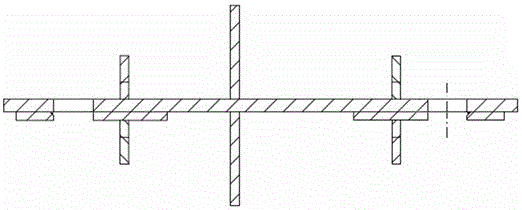

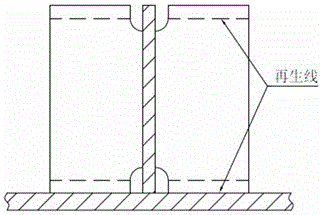

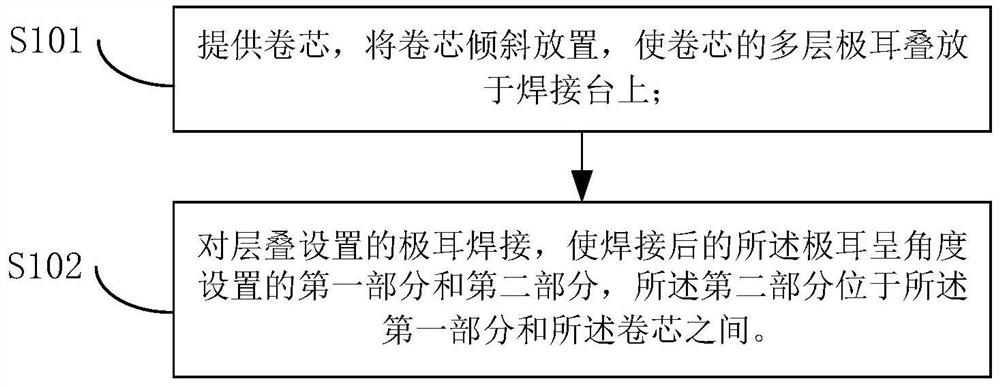

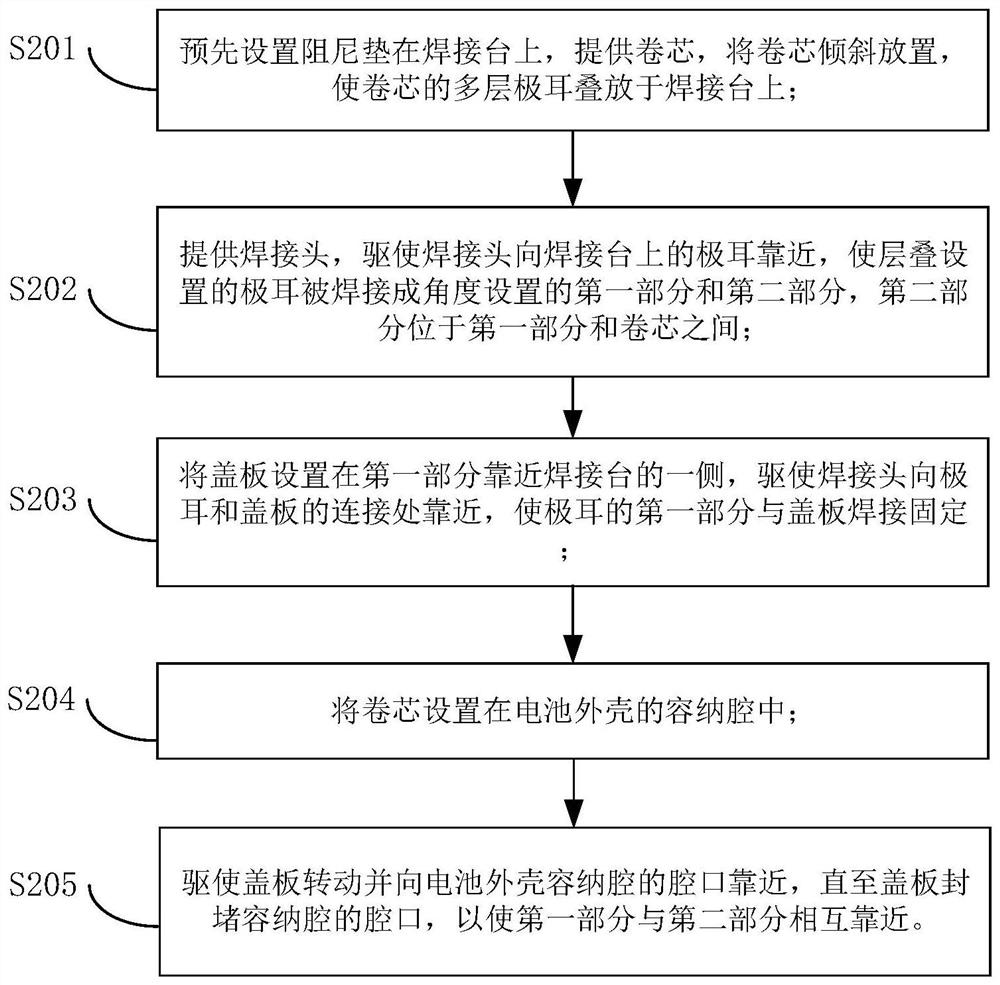

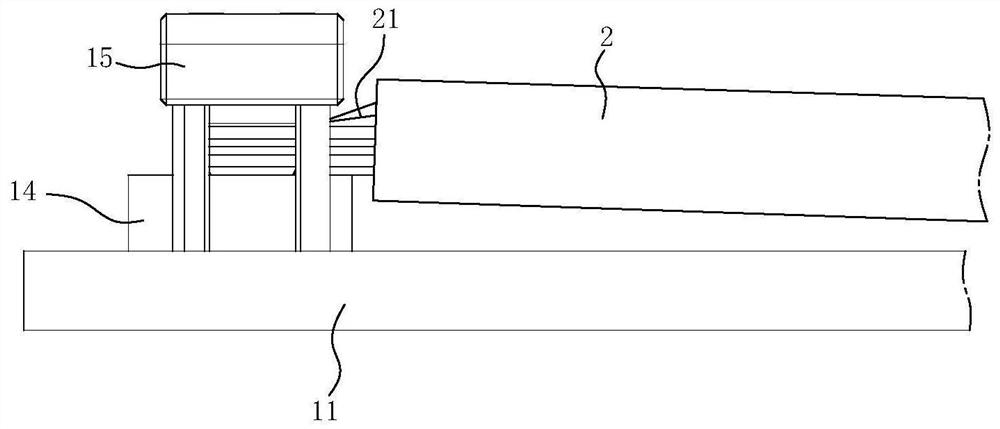

Tab welding method and tab welding device

ActiveCN112792490AReduced soldering areaReduce frictionFinal product manufactureWelding/cutting auxillary devicesElectrical batteryInternal resistance

The invention relates to the technical field of batteries, and particularly discloses a tab welding method and a tab welding device. The tab welding method comprises the following steps of providing a roll core, obliquely placing the roll core, and stacking a plurality of layers of tabs of the roll core on a welding table; and welding the stacked tabs to enable the welded tabs to form first parts and second parts at angles, wherein the second parts are located between the first parts and the roll core. According to the tab welding method, the friction force and the pressing movement distance when the tab on the upper layer is welded and pressed down can be reduced, the defect that the tab on the upper layer is torn due to excessive displacement can be overcome, the problems that the tabs and a cover plate are not firmly connected after welding, even insufficient welding and the like are solved, therefore, the risks that the internal resistance of a battery is abnormal or the tabs are disconnected from the cover plate is avoided, the fracture defect and the untight attachment defect of the tabs can be reduced, a connecting piece is not needed, an additional process and the weight of the battery are prevented form being increased, and the effective volume utilization rate and the energy density of the battery are improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

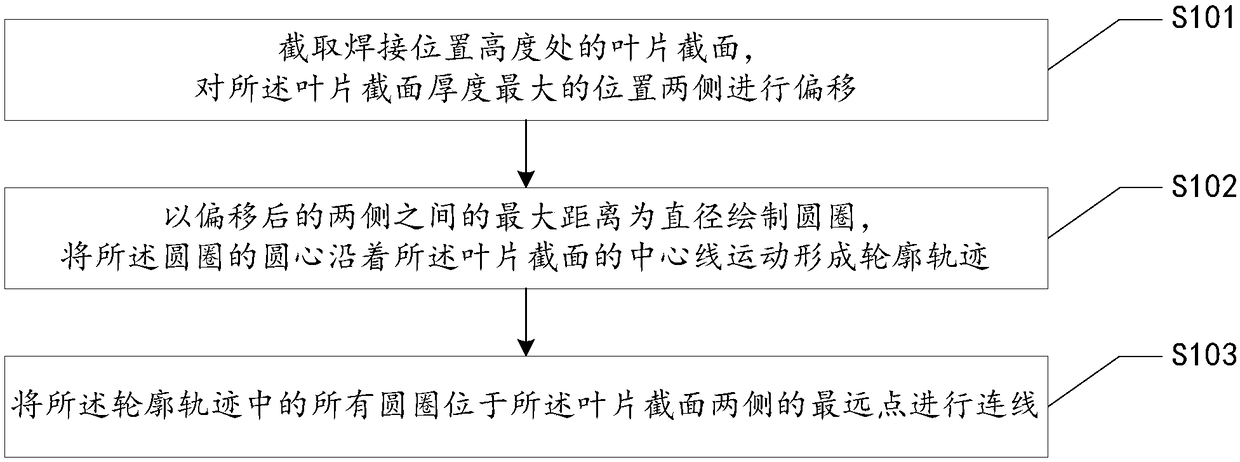

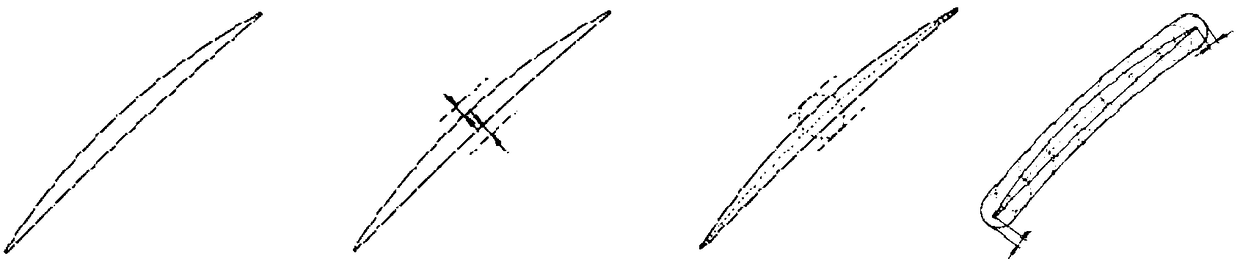

Quality control method and device for blade linear friction welding joint

ActiveCN109175673AUniform heat generationReduce wasteNon-electric welding apparatusLine segmentLarge distance

The invention discloses a quality control method for a blade linear friction welding joint. The method comprises the steps that the cross section of a blade at the height of a welding position; two sides of the position, which is the highest in thickness, of the cross section of the blade are displaced; a circle is drawn by taking the largest distance between the two sides after displacement as the diameter; the center of the circle is the middle spot of the largest distance segment between the two sides after displacement; the circle center of the circle moves along the central line of the cross section of the blade to form an outline trajectory; the farthest spots, located on two sides of the cross section of the blade, of all circles in the outline trajectory are connected; and the zonewhich is surrounded by the circles on the two ends of the cross section of the blade and two segments formed after connection is taken as the cross section zone of welding. The invention further discloses a blade linear friction welding joint quality control device. By adopting the quality control method and device, the problem that an unfused defect is prone to being formed at an angle part of atraditional rectangular or diamond cross section is overcome; the welding area of a component is effectively decreased, and the quality of the welding joint is ensured; and waste of precious metal isgreatly reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

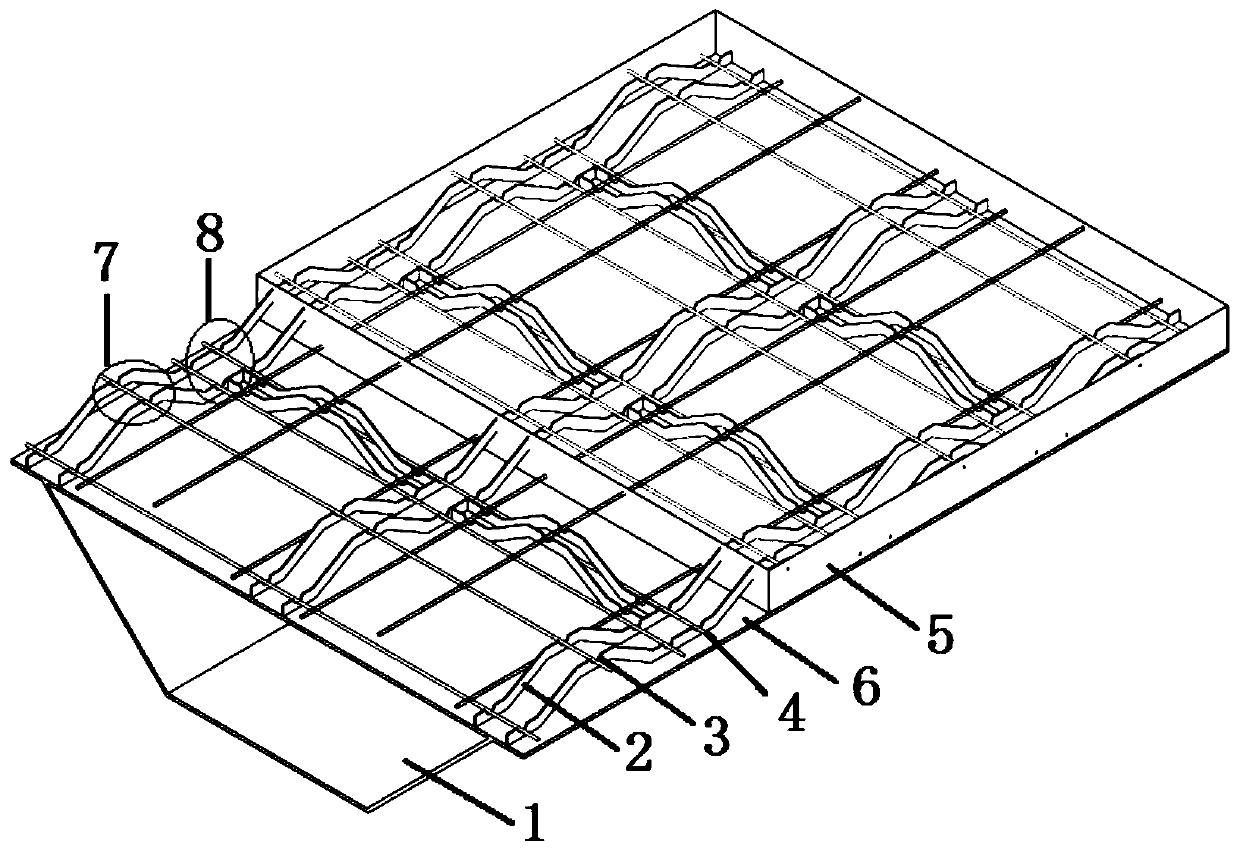

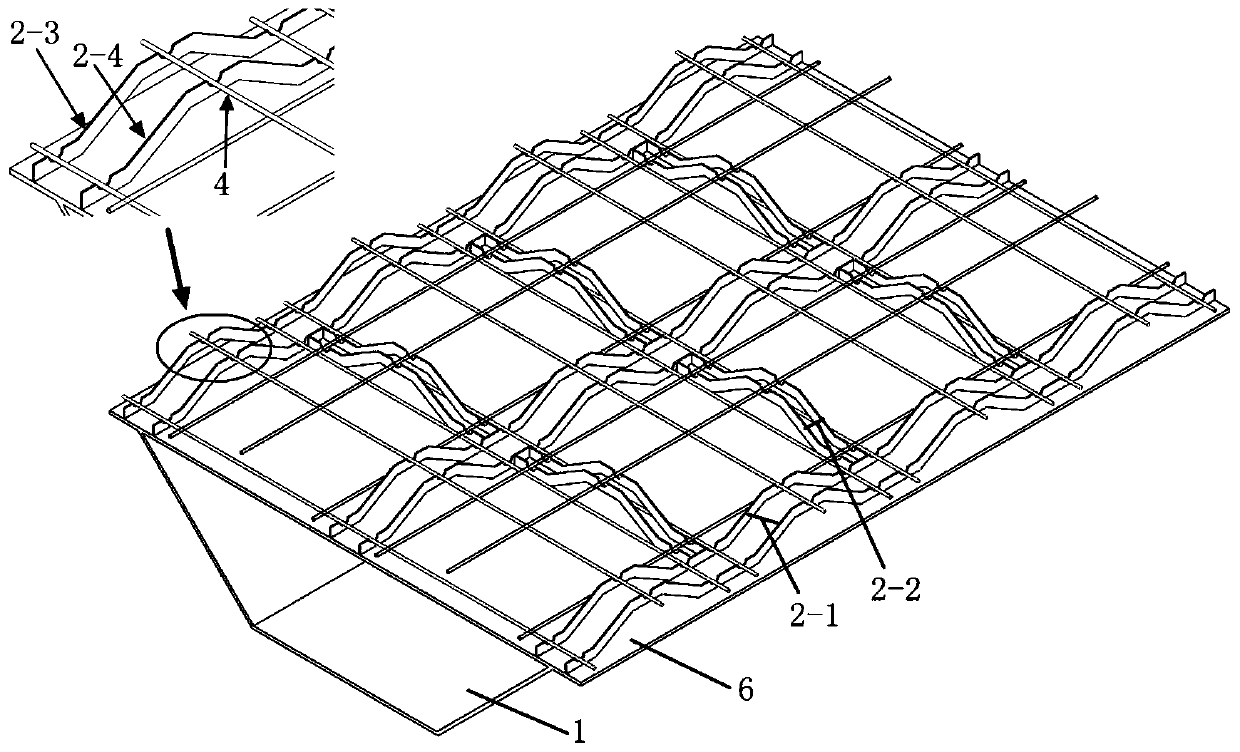

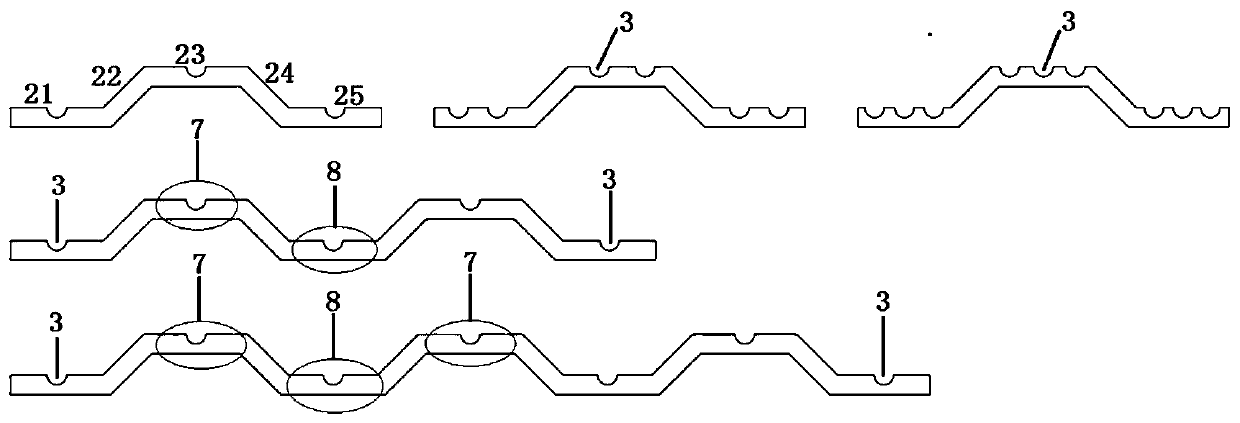

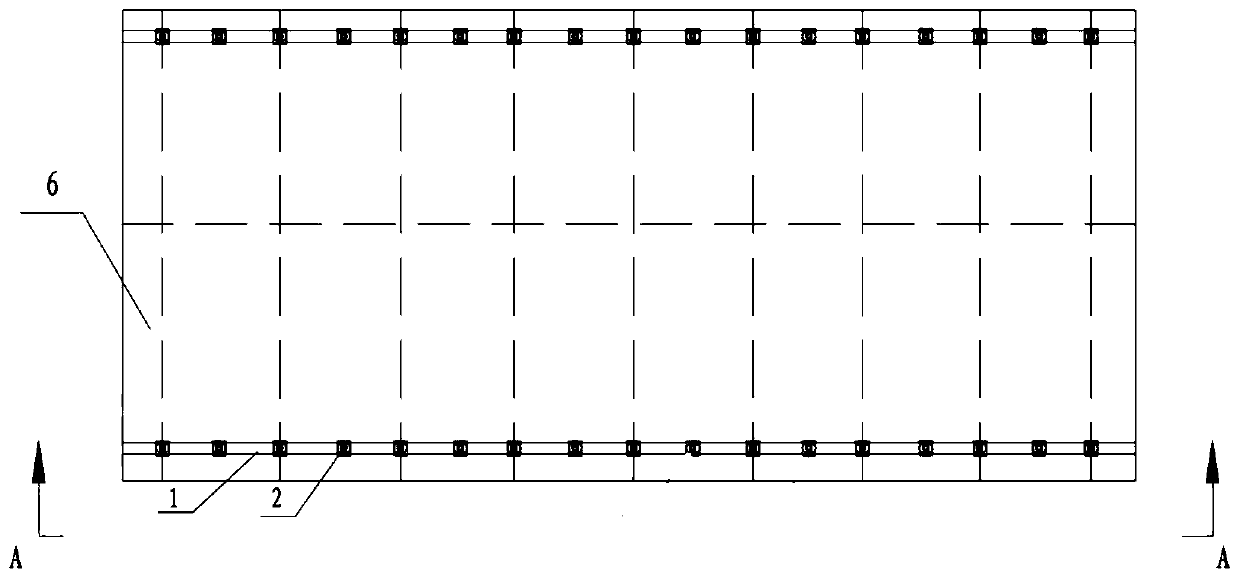

Steel-concrete composite beam containing corrugated connecting pieces and implementation method thereof

ActiveCN111041967AIncrease stiffnessReduced soldering areaBridge structural detailsBridge erection/assemblyFiberWelding residual stress

The invention discloses a steel-concrete composite beam containing corrugated connecting pieces and an implementation method thereof, and belongs to a steel-concrete composite structure. The steel-concrete composite structure comprises a steel beam, corrugated connecting pieces welded to an upper panel of the steel beam and penetrating steel bars; every two corrugated connecting pieces form a group, and the corrugated connecting pieces are arranged in groups in the longitudinal direction and the transverse direction of an upper panel of the steel beam respectively and distributed in a strip-shaped mode; open holes are formed in the wave crests and the wave troughs of the corrugated connecting pieces, the penetrating steel bars penetrate through the open holes, a layer of the penetrating steel bars are arranged at the wave crests, and a layer of the penetrating steel bars are arranged at the wave troughs in an upper-lower double-layer steel bar arrangement mode; high-performance fiberconcrete is poured on the upper portion of the upper panel of the steel beam and is used for wrapping the corrugated connecting pieces and the penetrating steel bars to form a composite shearing forcepiece. The steel structure is small in welding workload, convenient to construct, high in working efficiency, small in welding residual stress, high in bearing capacity and good in fatigue resistance.

Owner:SOUTHEAST UNIV

Ship body reinforcing structure and method, and ship

The invention relates to a ship body reinforcing structure and method, and a ship. The ship body reinforcing structure comprises a ship body, a reinforcing part and studs, wherein the reinforcing partand the studs are detachably disposed on the ship body; the studs and the ship body are perpendicular and are fixedly arranged; penetrating holes matched with the studs are formed in the reinforcingpart; the studs penetrate through the penetrating holes; and limiting structures for fixing the reinforcing part are fixed to the extending-out ends of the studs. Compared with the prior art, the Shipbody reinforcing structure and method, and the ship have the advantages that the welding area can be reduced, and the damage to the ship body is reduced; the ship body is less damaged during disassembling, and works such as grinding of the ship body after disassembling are avoided; and the reinforcing part is fixed through the studs, thus the reinforcing part can be conveniently disassembled andcan be repeatedly used, the cost is reduced, and the ship building efficiency is improved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

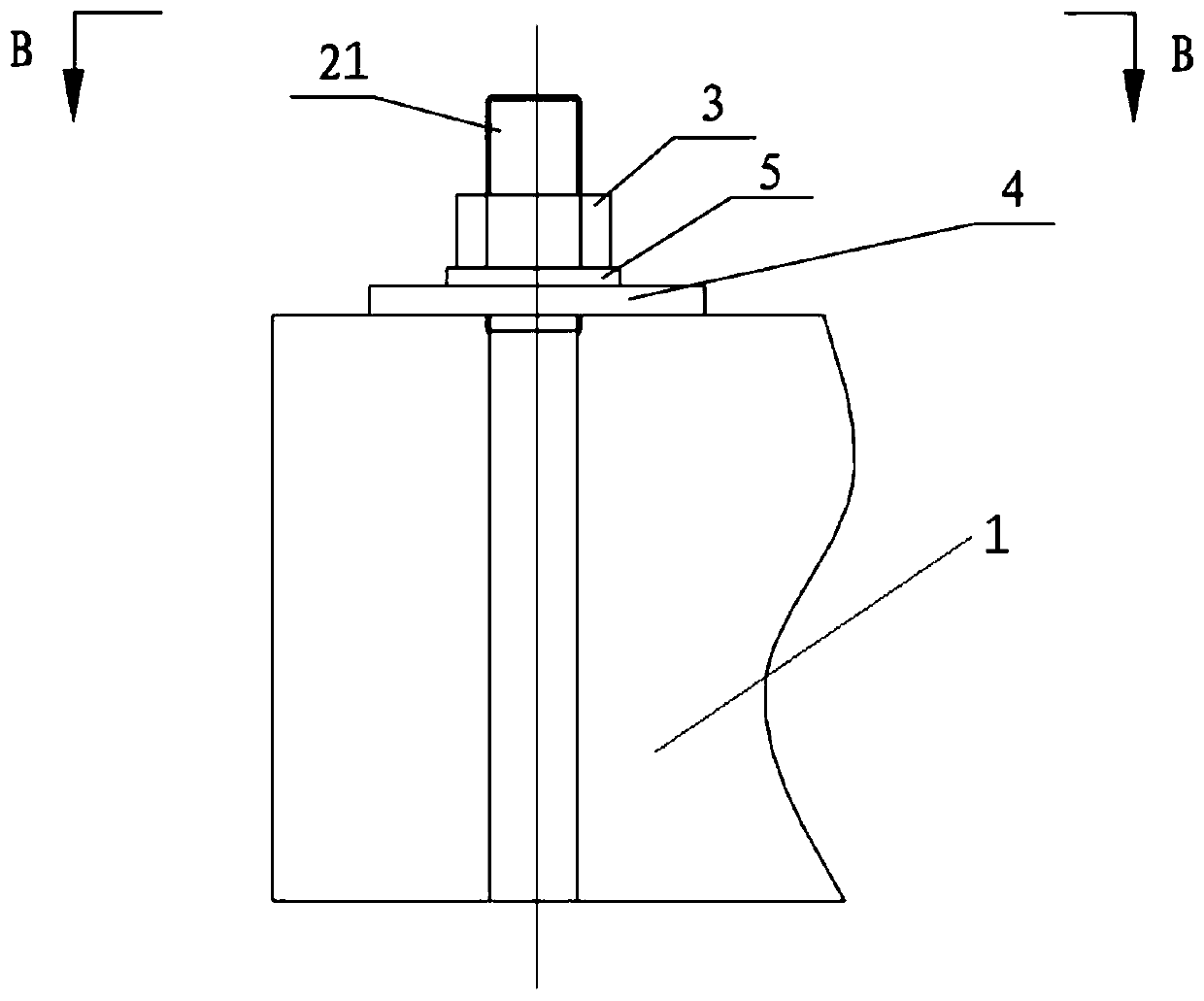

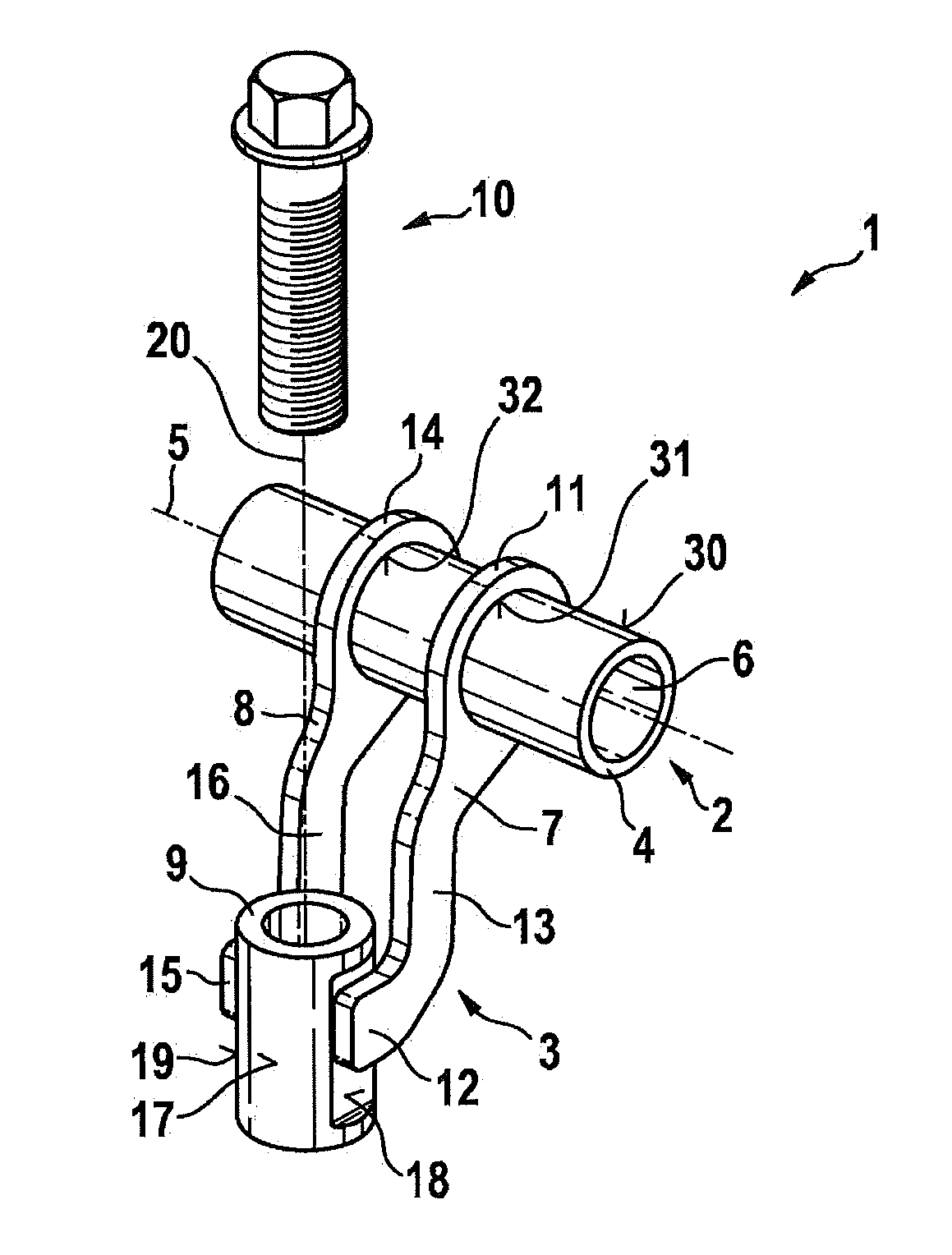

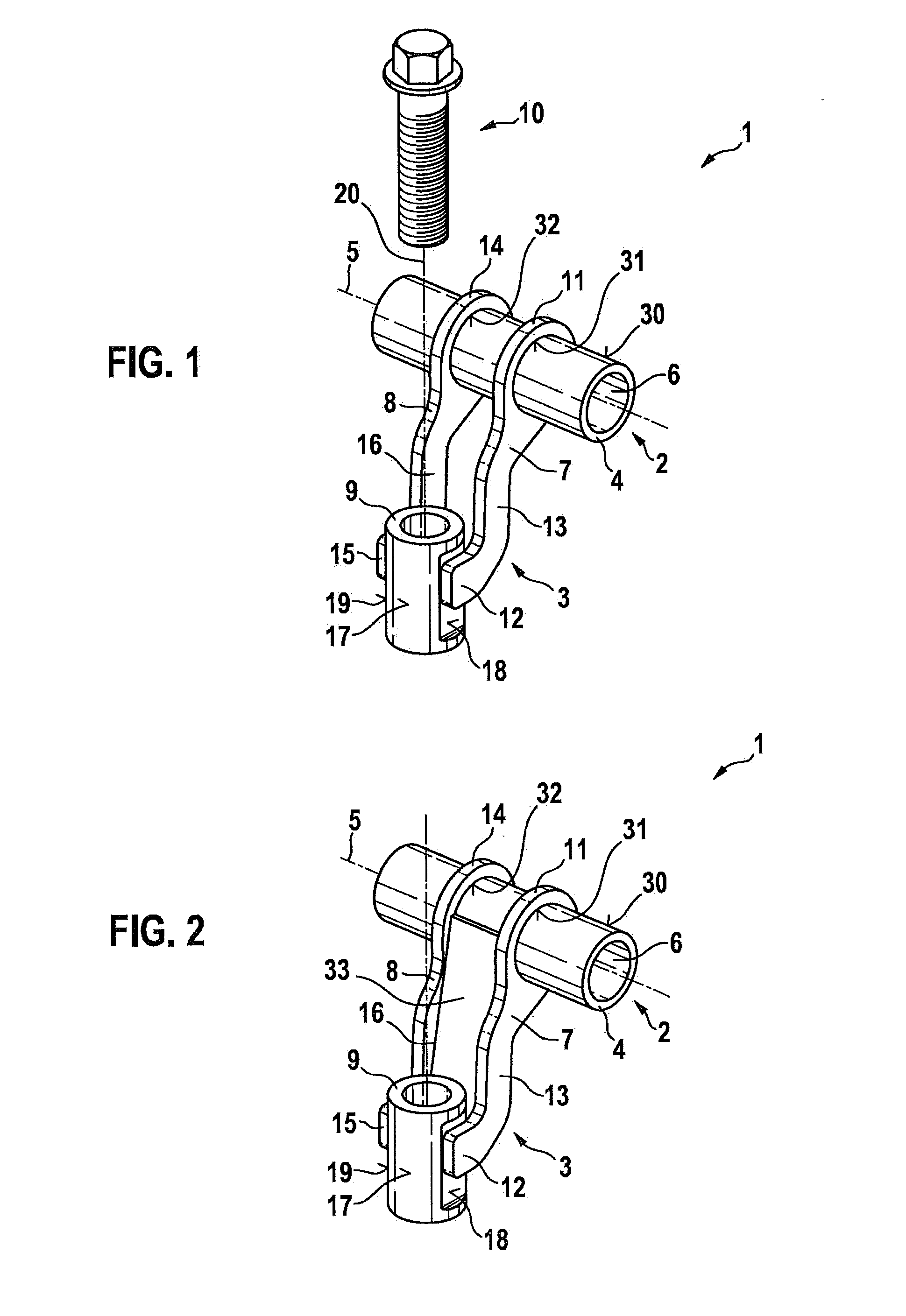

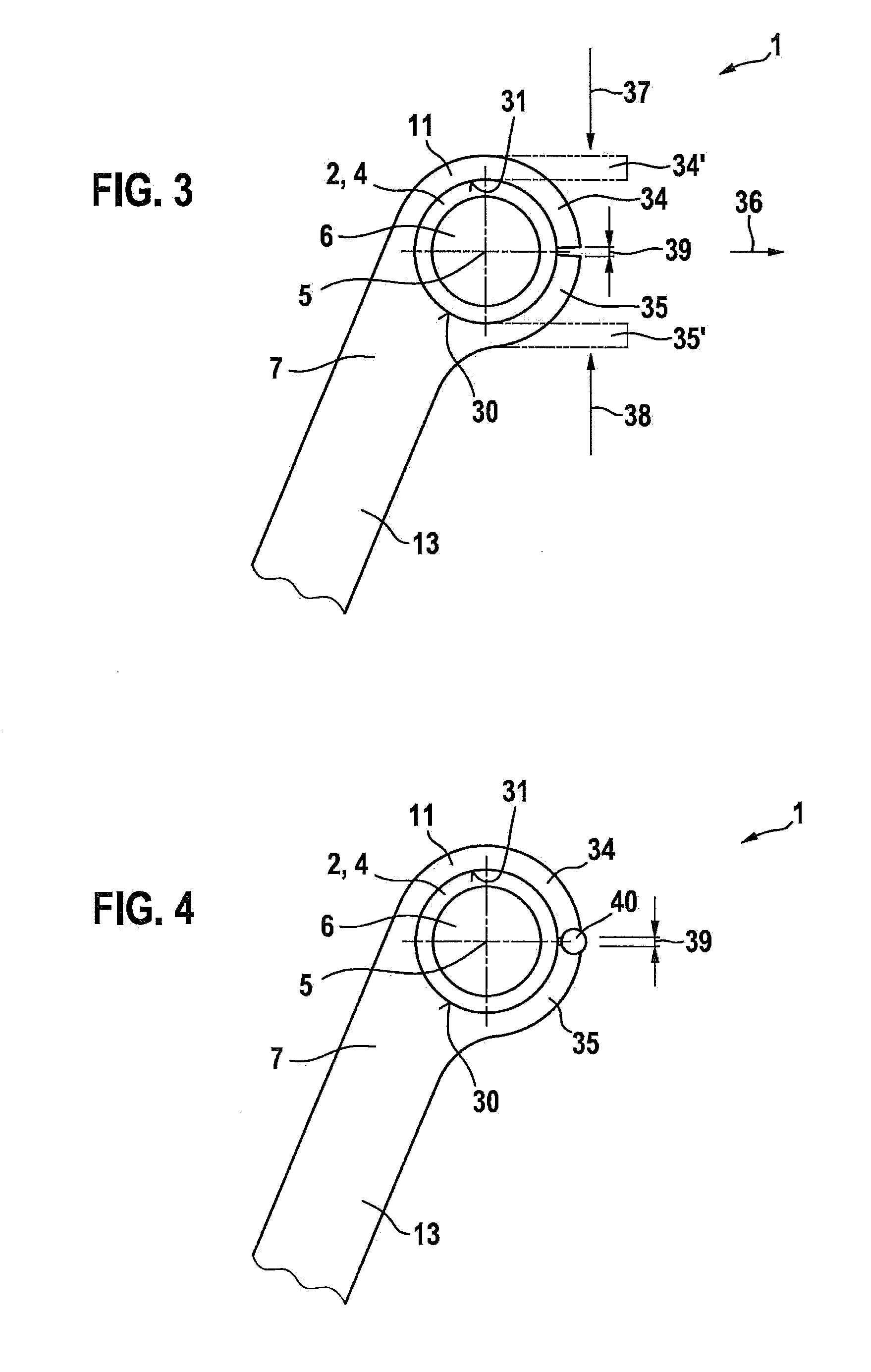

Holder for fastening a component to an internal combustion engine

ActiveUS20160222935A1Improve controllabilityLess solderPipe supportsLow pressure fuel injectionExternal combustion engineEngineering

A holder is used for fastening a component, in particular a fuel distributor, to an internal combustion engine. The holder has at least one connection element, which includes a locating area. In the installed state, in which the connection element rests against an outer side of the component via its locating area, the locating area of the connection element extends across an angle greater than 180 degrees in relation to a longitudinal axis of the component. Furthermore, in the installed state, in which the connection element is resting via its locating area against the outer side of the component, the locating area has the form of a cylinder jacket. In addition, a system having a component and such a holder is provided.

Owner:ROBERT BOSCH GMBH

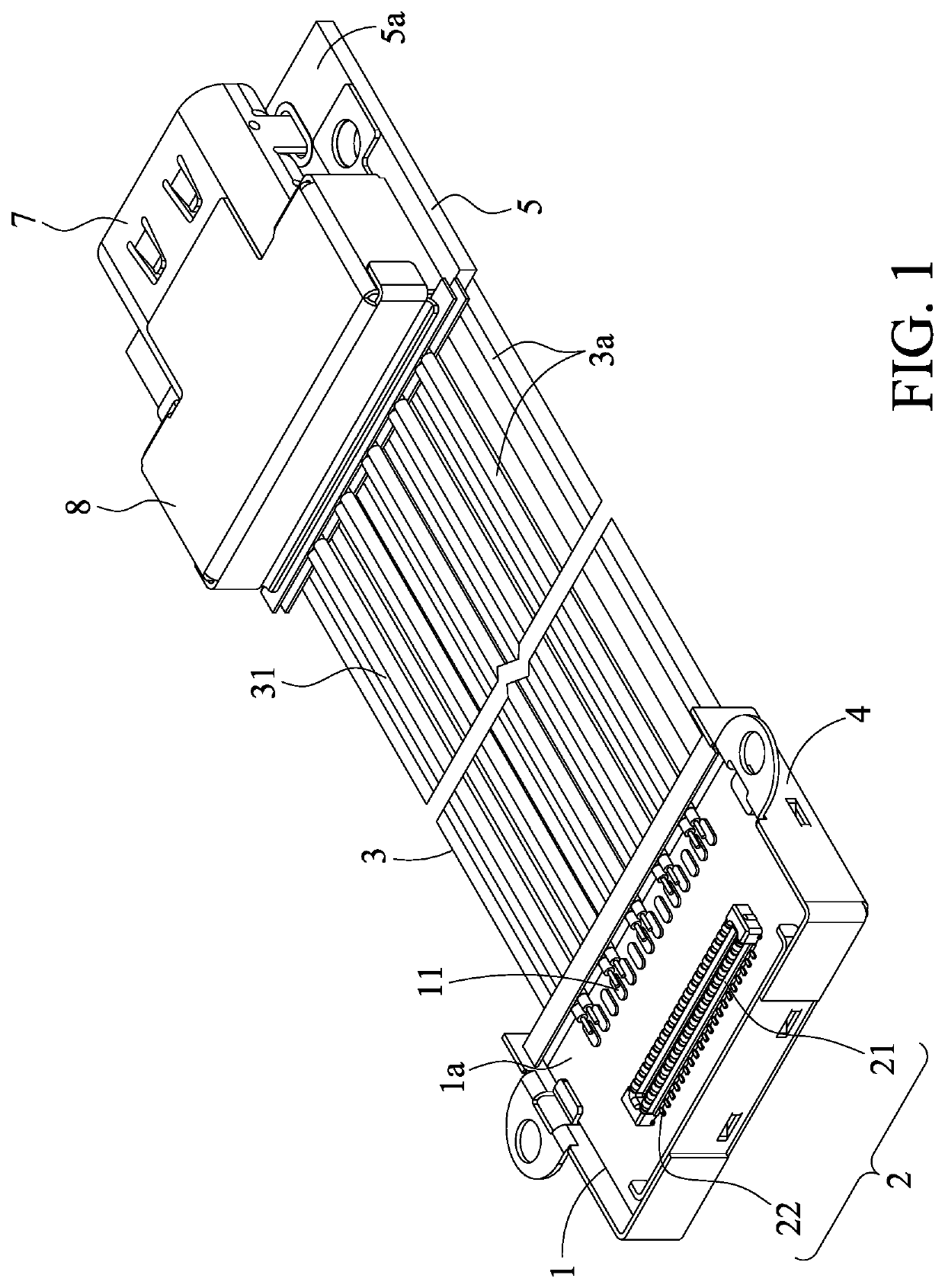

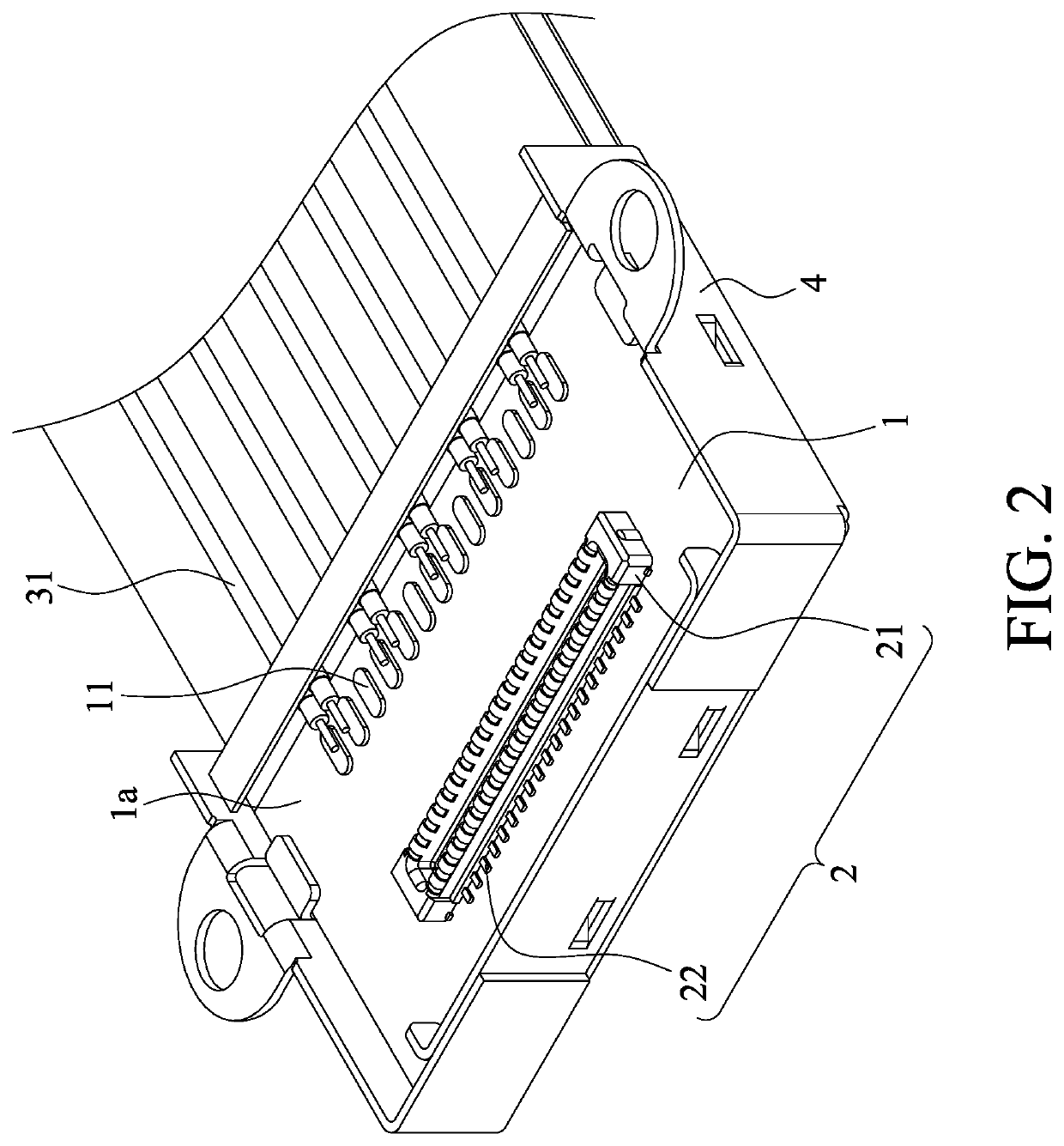

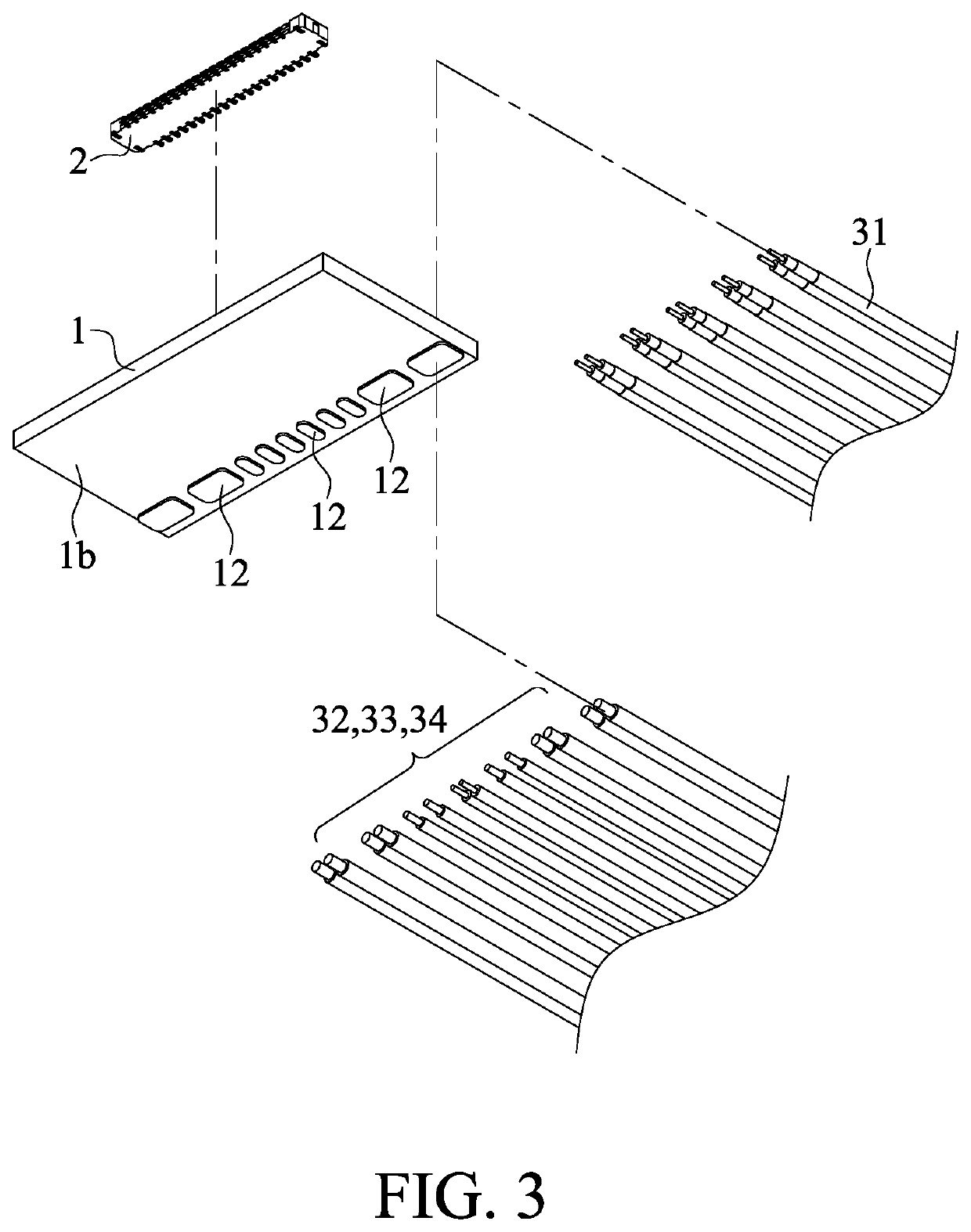

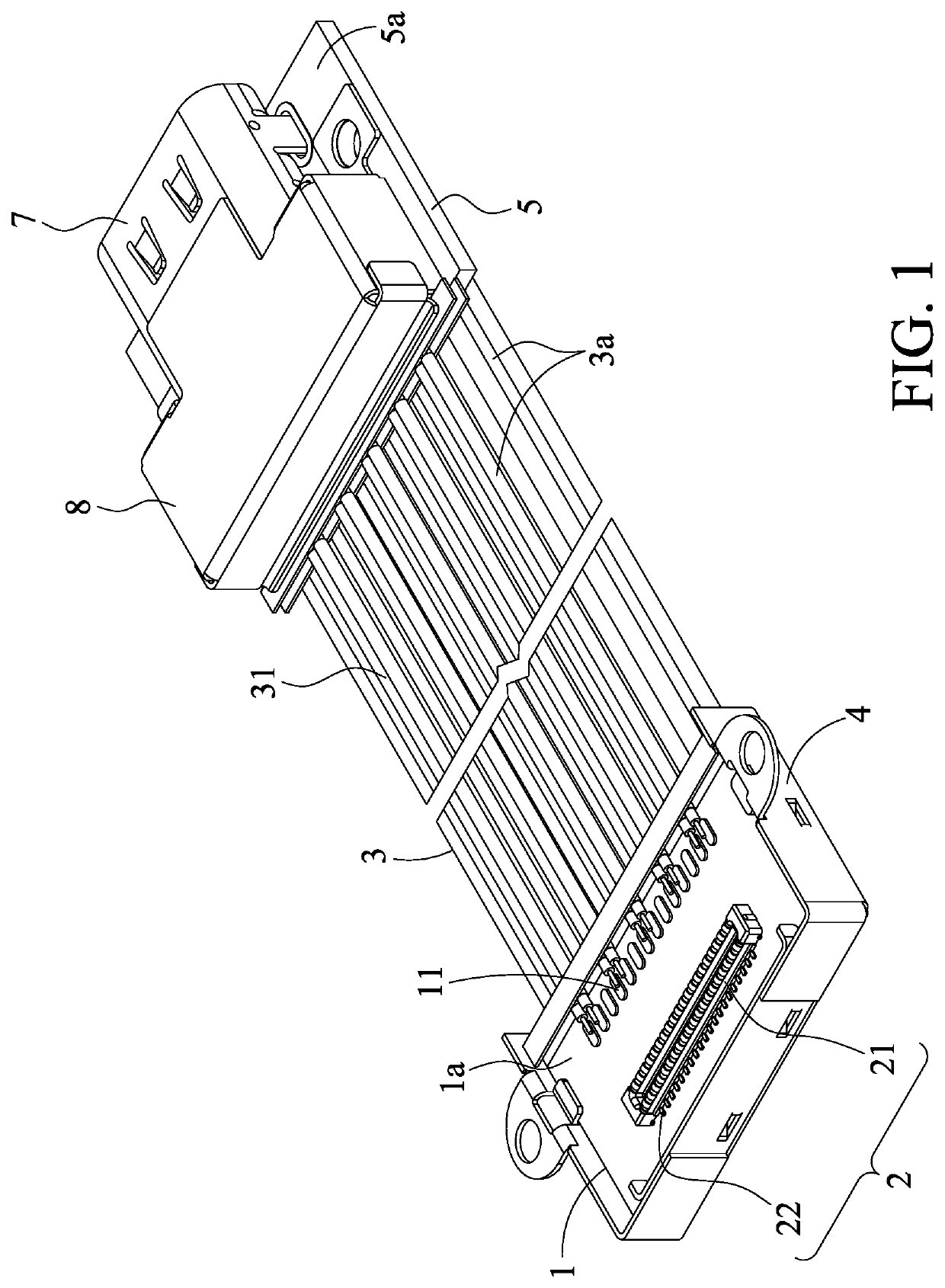

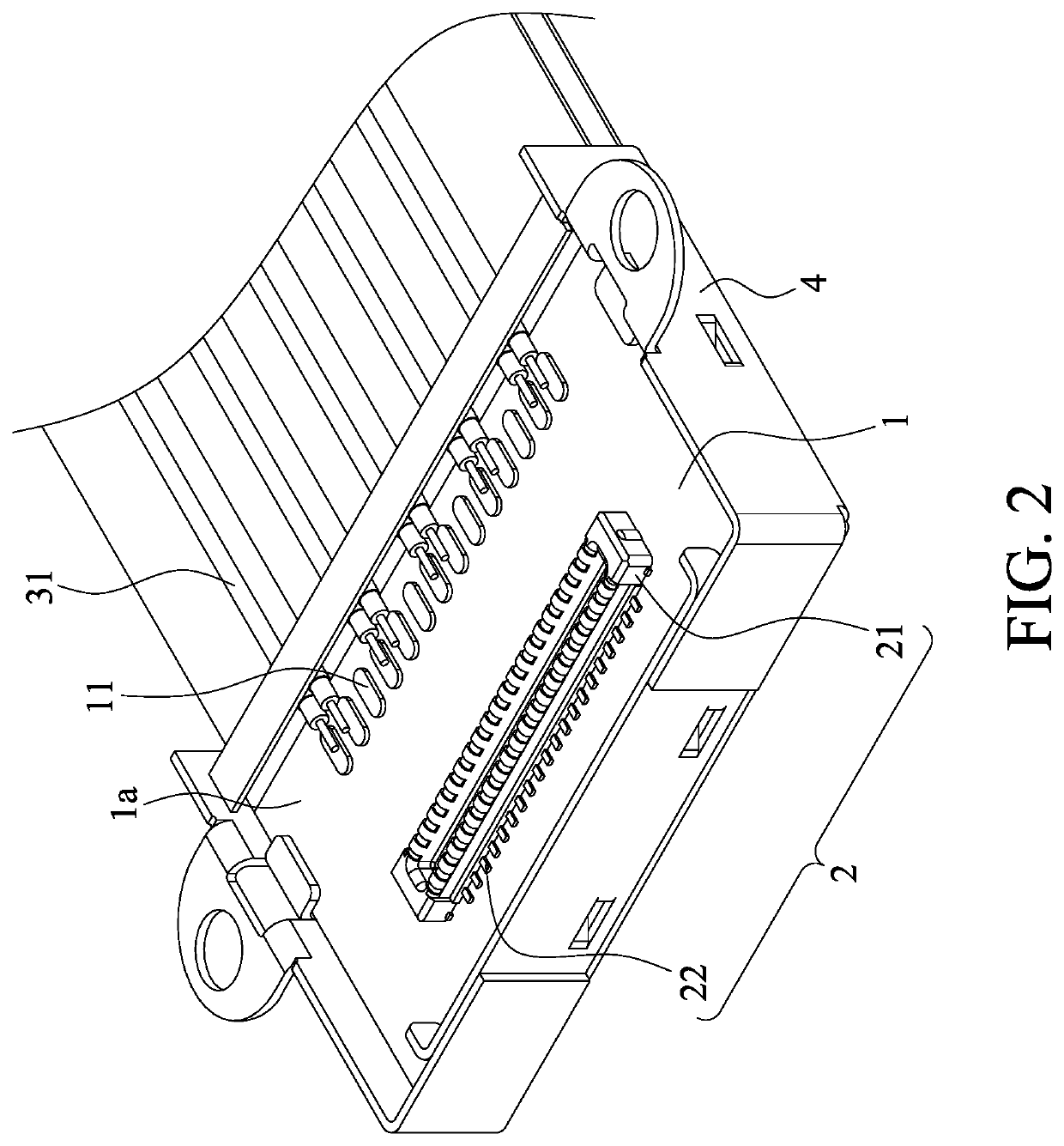

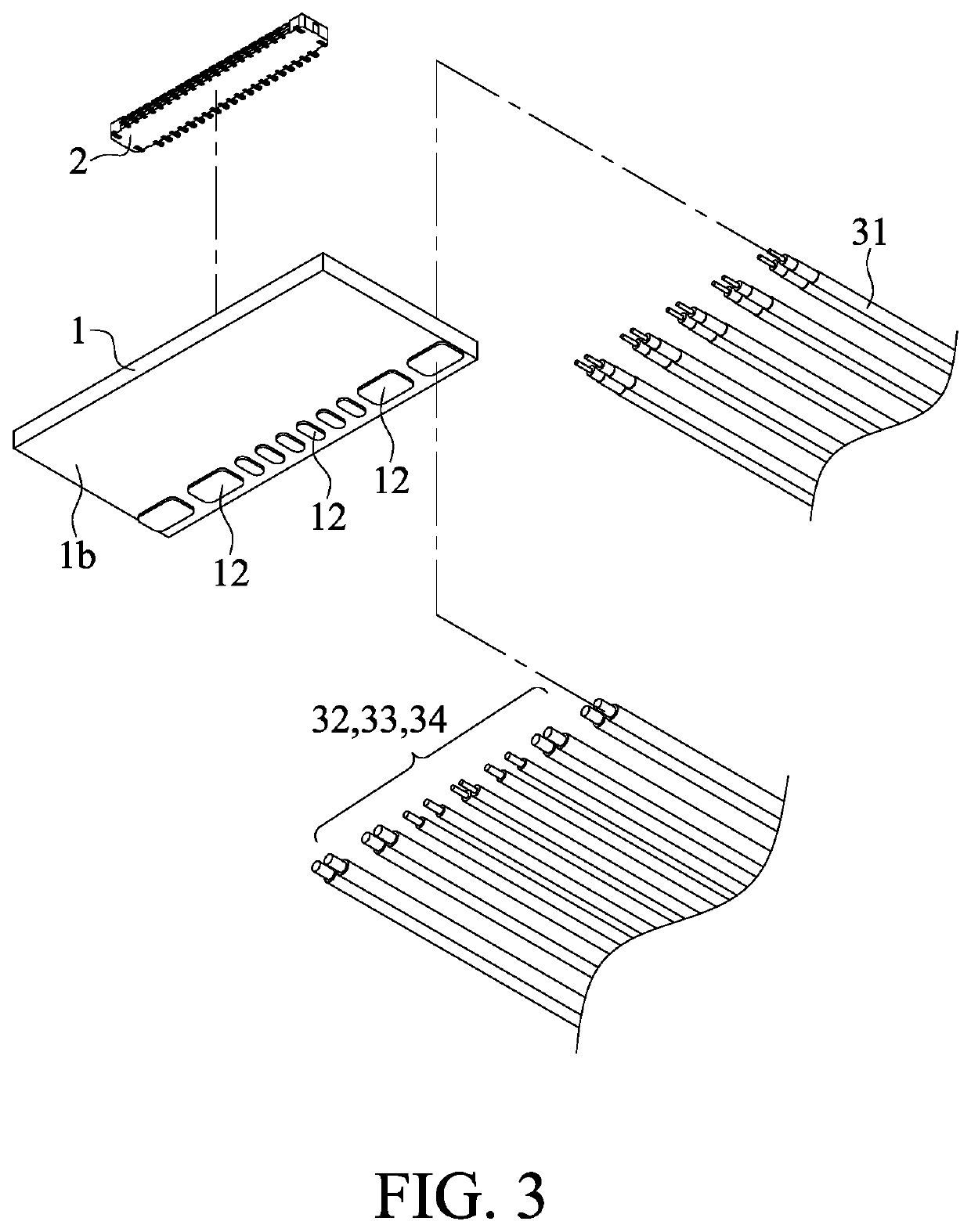

Dual-row cable structure

ActiveUS20210091491A1Reduce weld areaCost reductionTwo-part coupling devicesComputer periphery connectorsEngineeringElectrical connection

A dual-row cable structure is applied to a first circuit board and a second circuit board. A board-to-board connector is on the first circuit board, and the first circuit board includes a first group of contacts and a second group of contacts. An electrical connector is on the second circuit board. The second circuit board includes a third group of contacts and a fourth group of contacts. The dual-row cable structure includes a wire assembly including high-speed signal wires, low-speed signal wires, one or more power wires, and one or more ground wires. The high-speed signal wires are connected to the first group of contacts. The low-speed signal wires, the power wire, and the ground wire are respectively connected to the second group of contacts. The third group of contacts and the fourth group of contacts are respectively connected to the other end of the wire assembly.

Owner:ADVANCED CONNECTEK INC

Retractable ladder

ActiveUS11142949B2Improve stabilityReduce welding costsLaddersPhysical medicine and rehabilitationEngineering

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

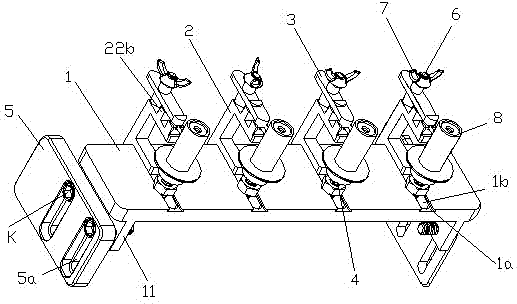

Port resonator high-frequency welding fixture

ActiveCN103495831AReduced soldering areaMeet welding needsWelding/cutting auxillary devicesHigh frequency current welding apparatusCopper wireEngineering

The invention discloses a port resonator high-frequency welding fixture which comprises a fixture table plate adjustable in height. At least one fixture sliding block is arranged on the fixture table plate in a guiding sliding mode, each fixture sliding block is provided with a copper wire clamping station used for locating welding copper wires, each fixture sliding block is spirally provided with a fixture pressing plate used in cooperation with the copper wire clamping station to fixedly press the welding copper wires, resonator clamps for locating port resonators are arranged on the fixture table plate, correspond to the fixture sliding blocks, and are adjustable in left-right position, and the resonator clamps are used for spirally adjusting the heights of the port resonators and the heights of welding points of the welding copper wires in a vertical locating mode. The port resonator high-frequency welding fixture is simple in structure, wide in application range, and high in production efficiency, and can meet welding requirements of copper wires of various specifications and sizes.

Owner:山东泰开自动化有限公司

Dual-row cable structure

ActiveUS11355875B2Reduced soldering areaSpace neededTwo-part coupling devicesComputer periphery connectorsBoard-to-board connectorElectrical connection

A dual-row cable structure is applied to a first circuit board and a second circuit board. A board-to-board connector is on the first circuit board, and the first circuit board includes a first group of contacts and a second group of contacts. An electrical connector is on the second circuit board. The second circuit board includes a third group of contacts and a fourth group of contacts. The dual-row cable structure includes a wire assembly including high-speed signal wires, low-speed signal wires, one or more power wires, and one or more ground wires. The high-speed signal wires are connected to the first group of contacts. The low-speed signal wires, the power wire, and the ground wire are respectively connected to the second group of contacts. The third group of contacts and the fourth group of contacts are respectively connected to the other end of the wire assembly.

Owner:ADVANCED CONNECTEK INC

Prefabricated part of blast furnace throat

ActiveCN111334628AExtended service lifeAvoid breakingBlast furnace componentsBlast furnace detailsBlast furnace smeltingMaterials science

The invention belongs to the technical field of blast furnace equipment, and particularly discloses a prefabricated part of a blast furnace throat. The prefabricated part of the blast furnace throat comprises a furnace throat body, the furnace throat body is formed by mutual splicing of a plurality of prefabricated plates, each prefabricated plate is made of high-temperature resistant metal materials, a filling cavity is arranged inside each prefabricated plate, and each filling cavity is filled with clay slurry; and the clay slurry is baked at high temperature to form clay bricks, a dovetailinserting connecting groove is formed in one side of each prefabricated plate, a dovetail inserting connecting block is arranged on the other side of each prefabricated plate, the dovetail inserting connecting block on one prefabricated plate is slidably connected within the dovetail inserting connecting groove of another prefabricated plate in an inserted mode, each dovetail inserting connectinggroove communicates with the corresponding filling cavity, a positioning inserting groove is formed in the bottom end of each prefabricated plate, a positioning inserting connecting block is fixed onone side of each positioning inserting groove, and a far-infrared ceramic coating is coated on the inner wall of each prefabricated plate. According to the prefabricated part of the blast furnace throat, the fact that the safety and efficiency of blast furnace smelting is influenced due to the fact that the furnace throat body falls off from a furnace body under the upward impact force from the outside is effectively prevented.

Owner:包钢西北创业建设有限公司

Double-layer-structure mould pressing multi-core-group ceramic capacitor and production method thereof

PendingCN112802686AAvoid destructionMeet capacity needsFixed capacitor dielectricStacked capacitorsCeramic capacitorEngineering

The invention provides a double-layer-structure mould pressing multi-core-group ceramic capacitor and a production method thereof. The multi-core-group ceramic capacitor comprises a plastic package shell, a frame arranged in the plastic package shell, four capacitor chip modules and an insulating spacer, wherein the frame comprises a first leading-out end, a second leading-out end, a lower welding layer and an upper welding layer, the capacitor chip modules are welded at the upper and lower ends of the upper and lower welding layers, the insulating spacer is arranged between the two adjacent capacitor chip modules to play a role in isolation, and the first and second leading-out ends respectively extend out of the plastic package shell. The multi-core-group ceramic capacitor realizes multi-core-group capacitor lamination in space, greatly increases the capacitance, saves the welding area, and has higher electrical performance and reliability.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Bend two-way self-limiting corrugated expansion joint

InactiveCN104033686AReduced soldering areaReduce distortionPipeline expansion-compensationSelf limitingExpansion joint

The invention discloses a bend two-way self-limiting corrugated expansion joint which comprises an expansion joint body, bends, support assemblies, nuts and pull rods. The support assemblies are positioned on the back faces of the bends at the two ends in a riding mode respectively and are fixedly connected with the bends. The support assemblies at the two ends are connected through the pull rods and the nuts. Hinge pins I are arranged on the back faces of the bends, and hinge pins II are arranged on the side faces of the bends. Bend connecting plates of the support assemblies are arranged on the hinge pins I in a sleeved mode and are limited by baffle rings I, and side plates of the support assemblies are arranged on the hinge pins II in a sleeved mode and are limited by baffle rings II. The bend two-way self-limiting corrugated expansion joint is further characterized in that the bend connecting plate of each support assembly is in clearance fit with the corresponding hinge pin I, the side plate of each support assembly is in clearance fit with the corresponding hinge pin II, the baffle rings I are fixedly connected to the hinge pins I in a welding mode, and the baffle rings II are fixedly connected to the hinge pins II in a welding mode. The bend two-way self-limiting corrugated expansion joint is small in welding stress, small in distortion relative to the support assemblies, and long in service life.

Owner:江苏晨光波纹管有限公司

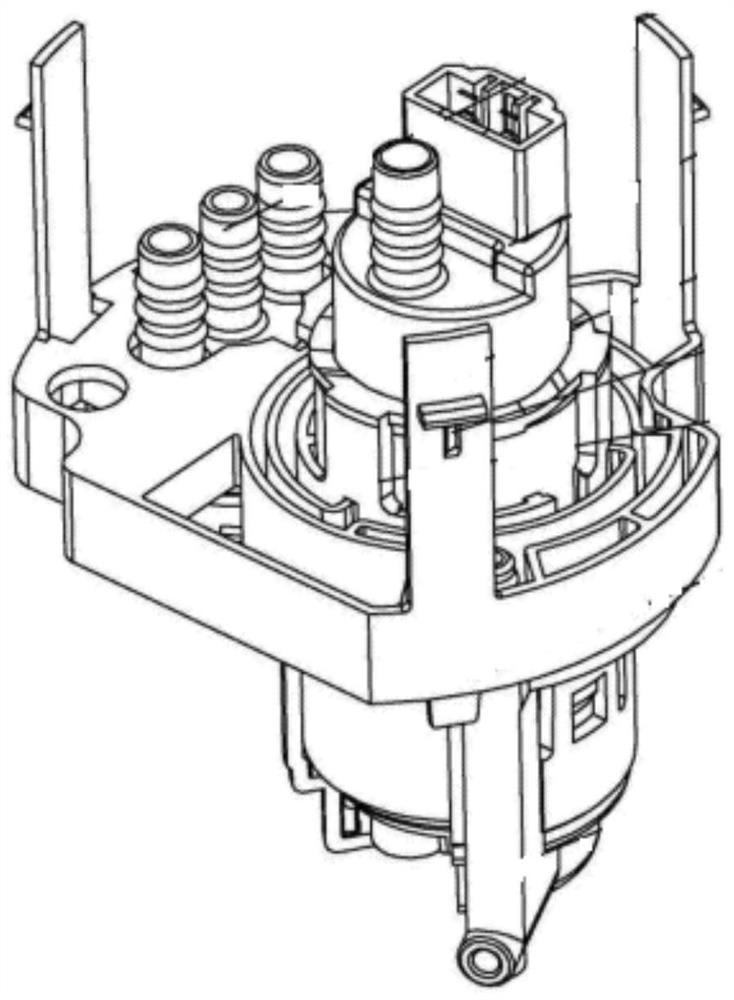

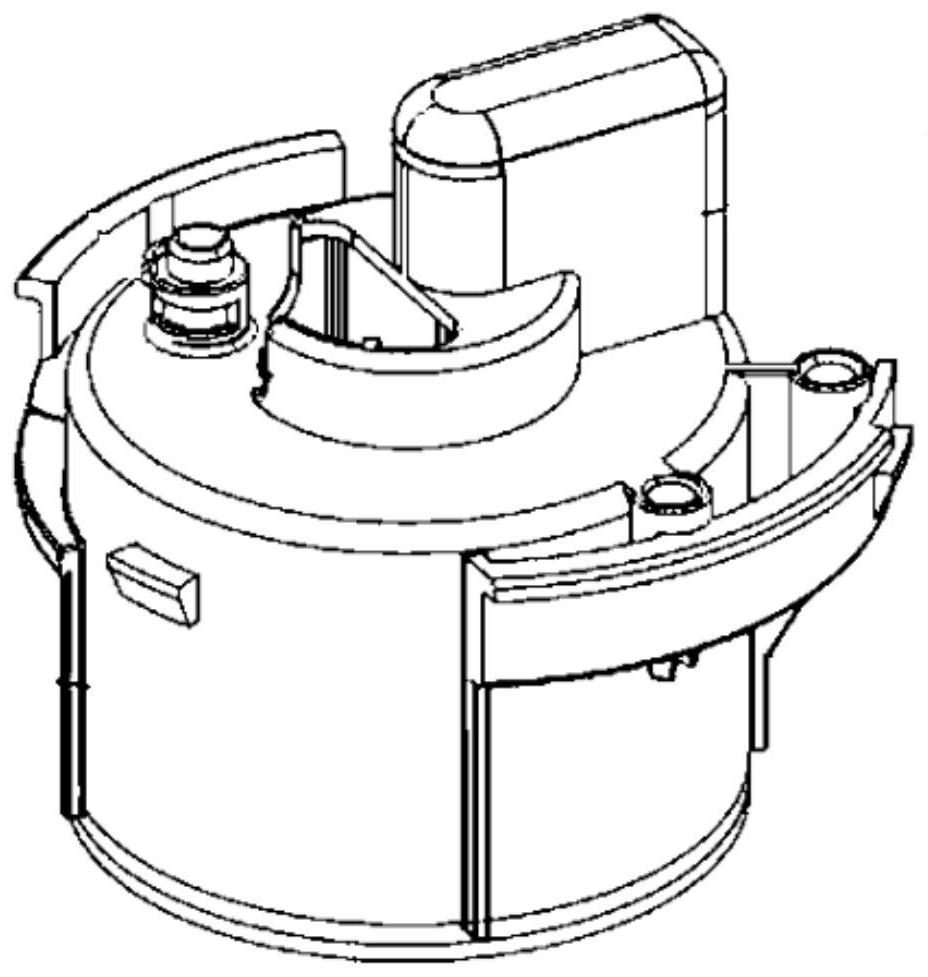

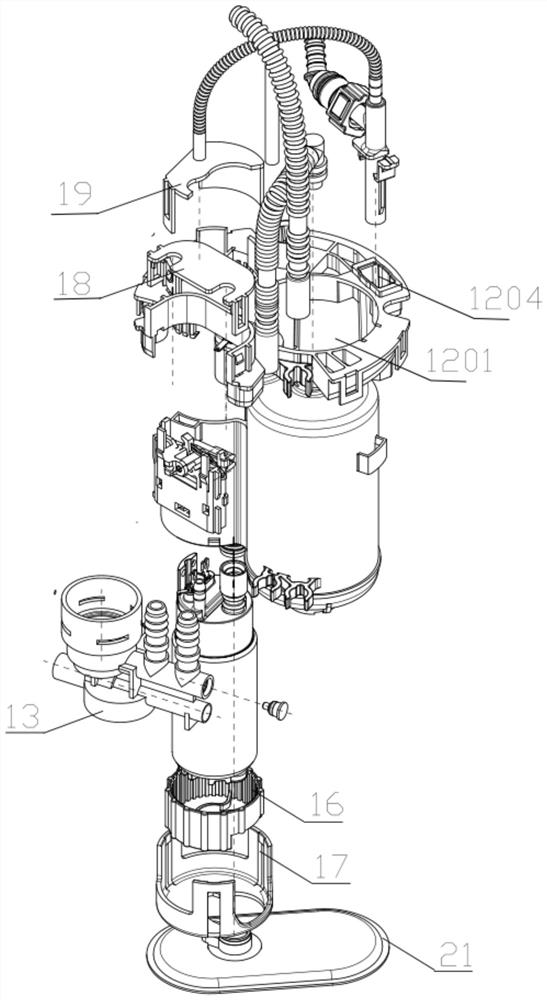

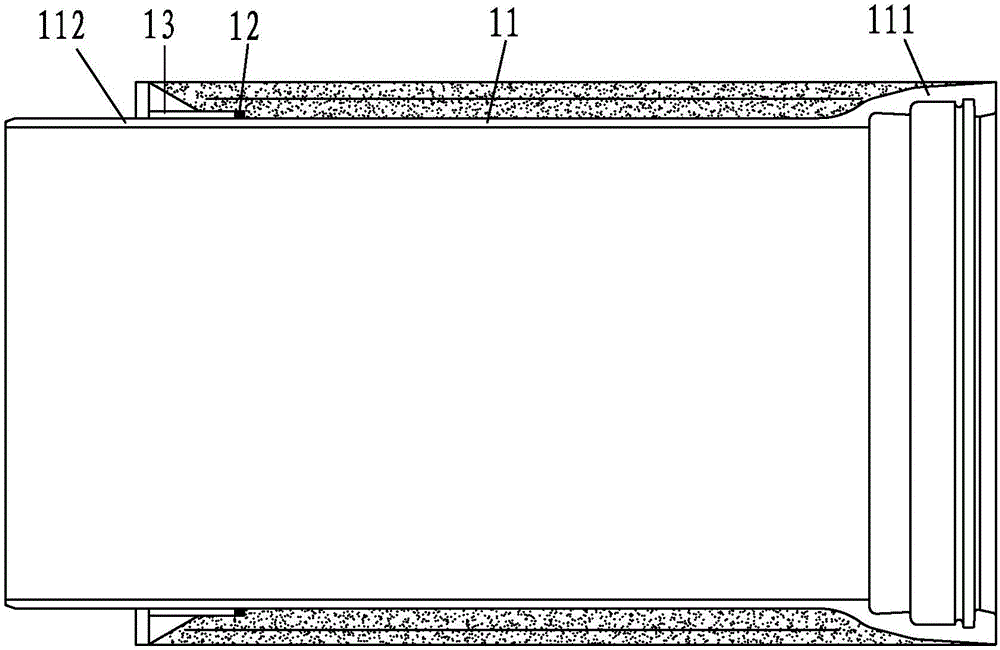

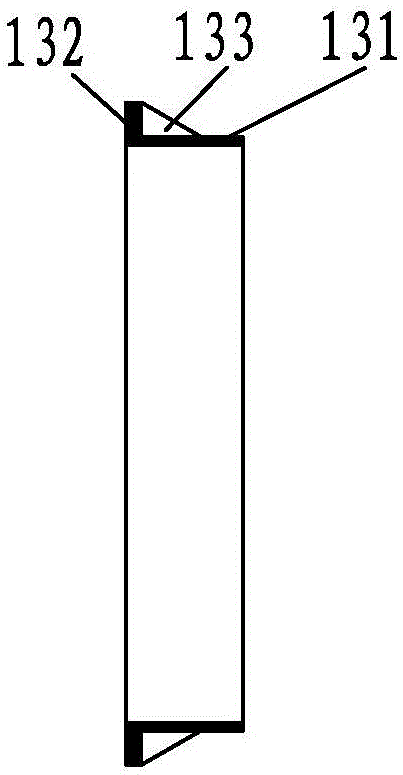

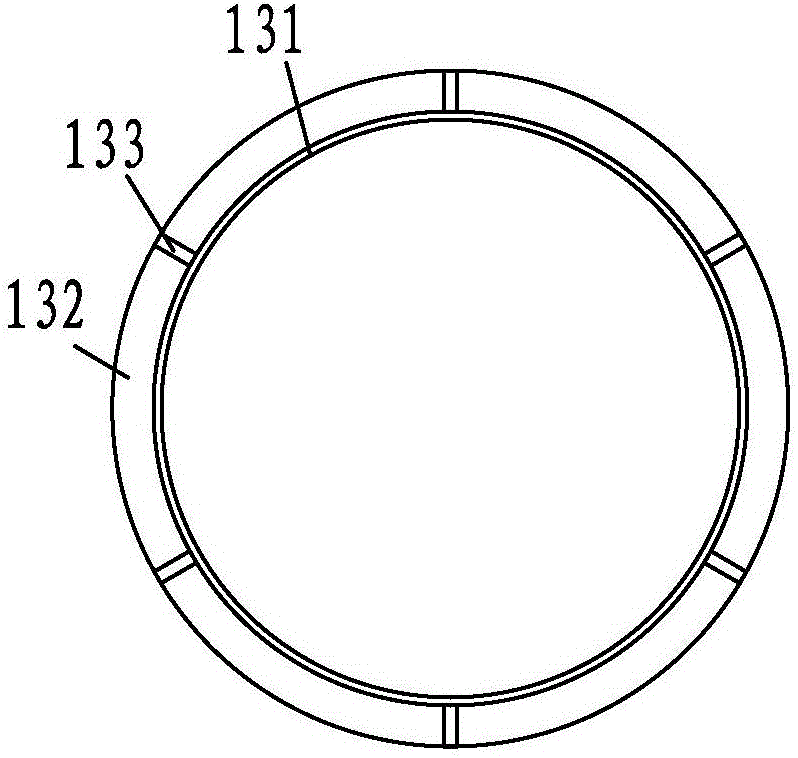

Fuel pump support assembly for vehicle

ActiveCN112539124AEasy to integrateLow costMachines/enginesLiquid fuel feedersStructural engineeringControl theory

The invention discloses a fuel pump support assembly for a vehicle. The fuel pump support assembly comprises a disc-shaped support body, a fuel refined filtration filter, an adjuster assembly, a far-end injection connector and a pump core, wherein a large mounting hole and a small mounting hole which are provided with axes extending up and down and communicate with each other are formed in the position, corresponding to the fuel refined filtration filter, of the center of the support body, a heating pipe clamping sleeve penetrating through the support body up and down is arranged on the support body, a far-end injection device clamping sleeve with the axis extending up and down is further arranged on the support body, a U-shaped oil level indicator receding notch which is concave inwards and provided with an opening in the side surface is formed in the side surface of the support body, and oil pipe clamping heads are further distributed on the side surface of the support body. The integration is high, the cost is low and mounting is convenient; the shell pump core is arranged outside and is not wrapped by a filter core, so that the heat dissipation is good; when upper and lower covers of the filter are welded, the welding area is reduced, the production difficulty is reduced, and the production stability is improved; the weight of the filter with the same filtering efficiency is greatly reduced, and the injection molding cost is reduced; and the size is small and the filtering efficiency is high.

Owner:CHONGQING WANLI LIANXING IND GROUP

Nodular cast iron pipe for jacking construction

A nodular cast iron pipe for jacking construction comprises a nodular cast iron pipe body. A bellmouth and a spigot are arranged at one end and the other end of the nodular cast iron pipe body respectively, a retaining ring and a jacking mechanism are fixed on the outer wall of one end, close to the spigot, of the nodular cast iron pipe body, the jacking mechanism comprises a barrel and a jacking flange, the jacking flange, the barrel and the retaining ring are sequentially arranged from outside to inside, and the barrel and the retaining ring are in close fit. Production efficiency of the nodular cast iron pipe is improved greatly, production cost is lowered, and reliability is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Frame type enamel block corrosion-resistant chimney and mounting method thereof

The invention provides a frame type enamel block corrosion-resistant chimney and a mounting method thereof so as to overcome the efficiencies in the prior art that a corrosion-resistant inner barrel of the industrial chimney is high in cost, tedious to construct, inconvenient to use and the like. The inner barrel of the corrosion-resistant chimney is assembled by enamel blocks which are locked with nut assemblies through bolts; a high-temperature-resistant sealing sheet is arranged between two adjacent enamel blocks, the gap between two adjacent enamel blocks is filled with an acid-resistant and high-temperature-resistant elastic sealant, so that the sealing property is good; the enamel blocks are welded to a steel frame through an arranged fixed plate, so that the enamel blocks are small in welding area and convenient to construct; and the enamel blocks are relatively small in self weight; the chimney is mounted in an inverse manner and can be mounted just by conventional hoisting equipment, so that the chimney is quite convenient to construct, and the cost of the enamel block is lower than that of a titanium steel composite board, and therefore, the cost of the chimney can be lowered.

Owner:ZHEJIANG KAIER NEW MATERIALS

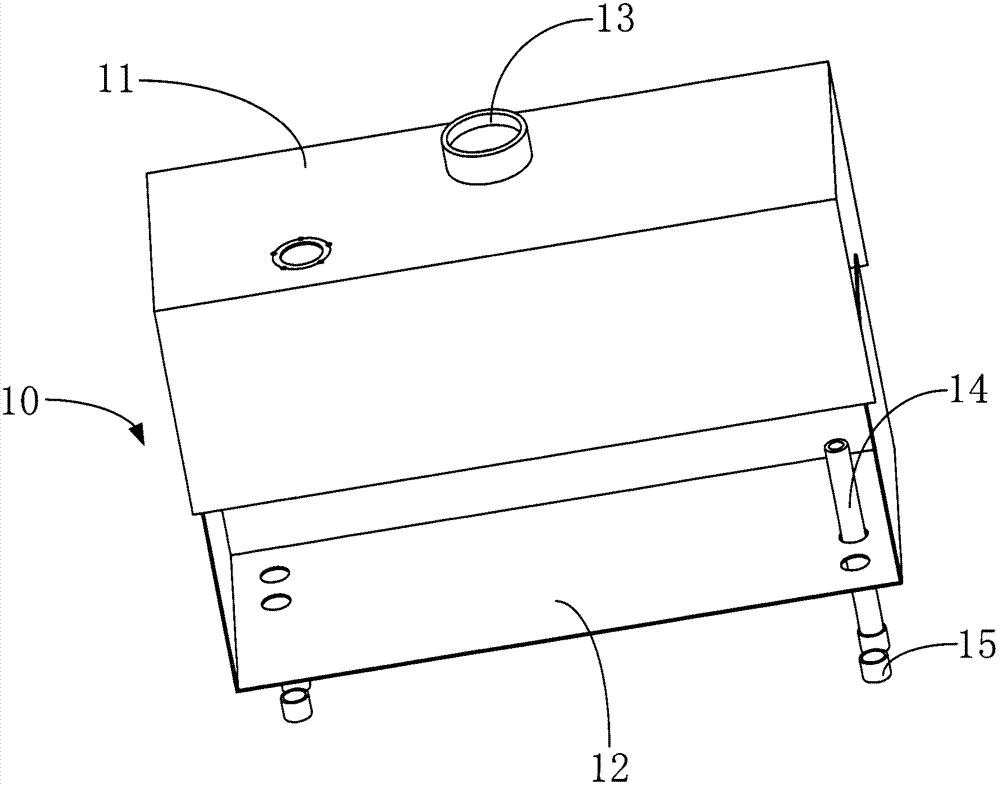

Oil tank

The invention relates to an oil tank which comprises a tank body. The tank body comprises a first U-shaped plate and a second U-shaped plate, an opening of the first U-shaped plate and an opening of the second U-shaped plate are opposite and are staggered to form a closed oil storage space in a matched manner, and fixing clamps and a supporting plate are further arranged on the top and at the bottom of the tank body respectively. On one hand, since the opening of the first U-shaped plate and the opening of the second U-shaped plate are opposite and are staggered to form the closed oil storage space in a matched manner, welding area is reduced, and sealability of the oil tank is improved; and on the other hand, mounting and transport of the oil tank are facilitated as the fixing clamps and the supporting plate are arranged on the top and at the bottom of the tank body respectively.

Owner:昆山西马克动力机械有限公司

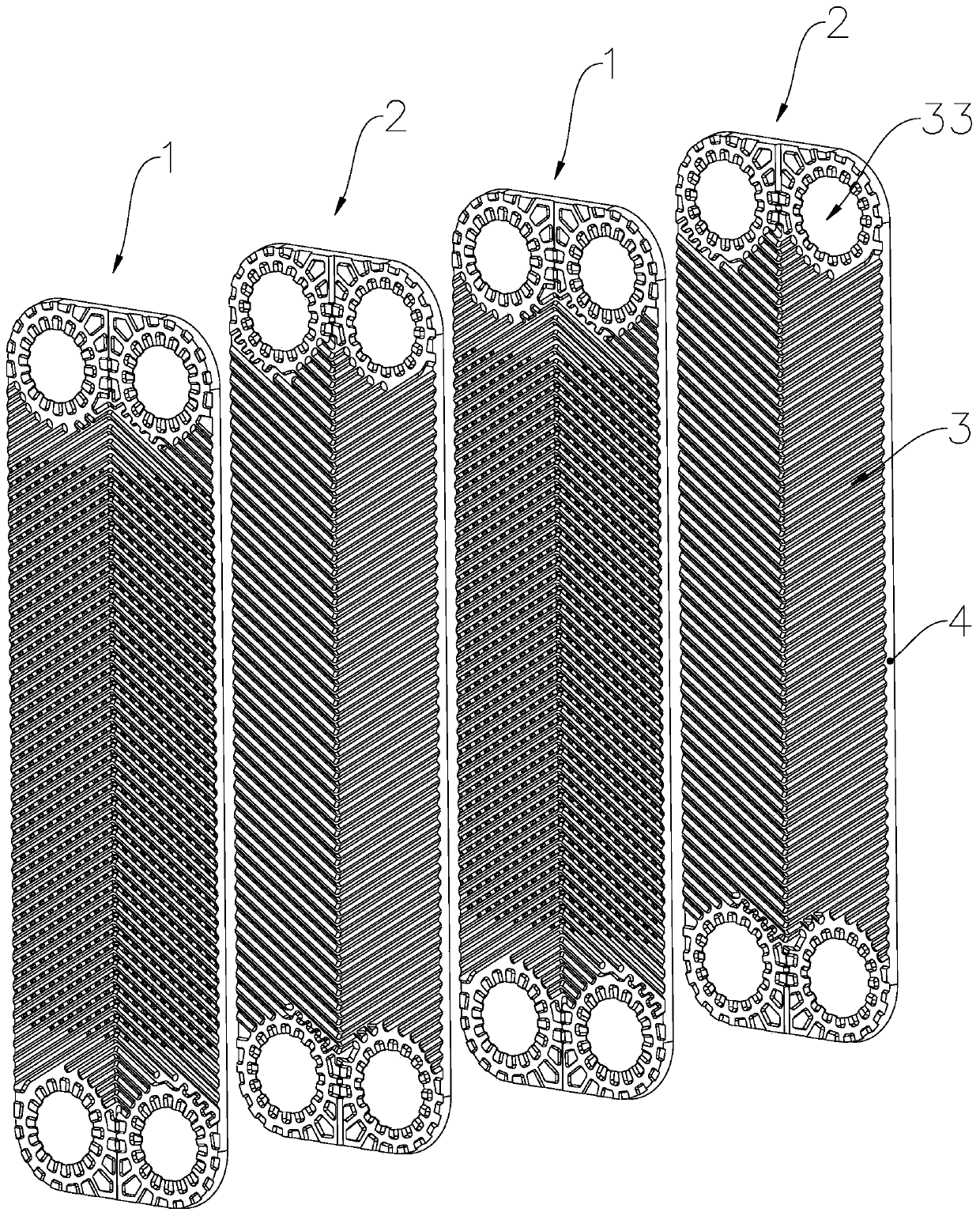

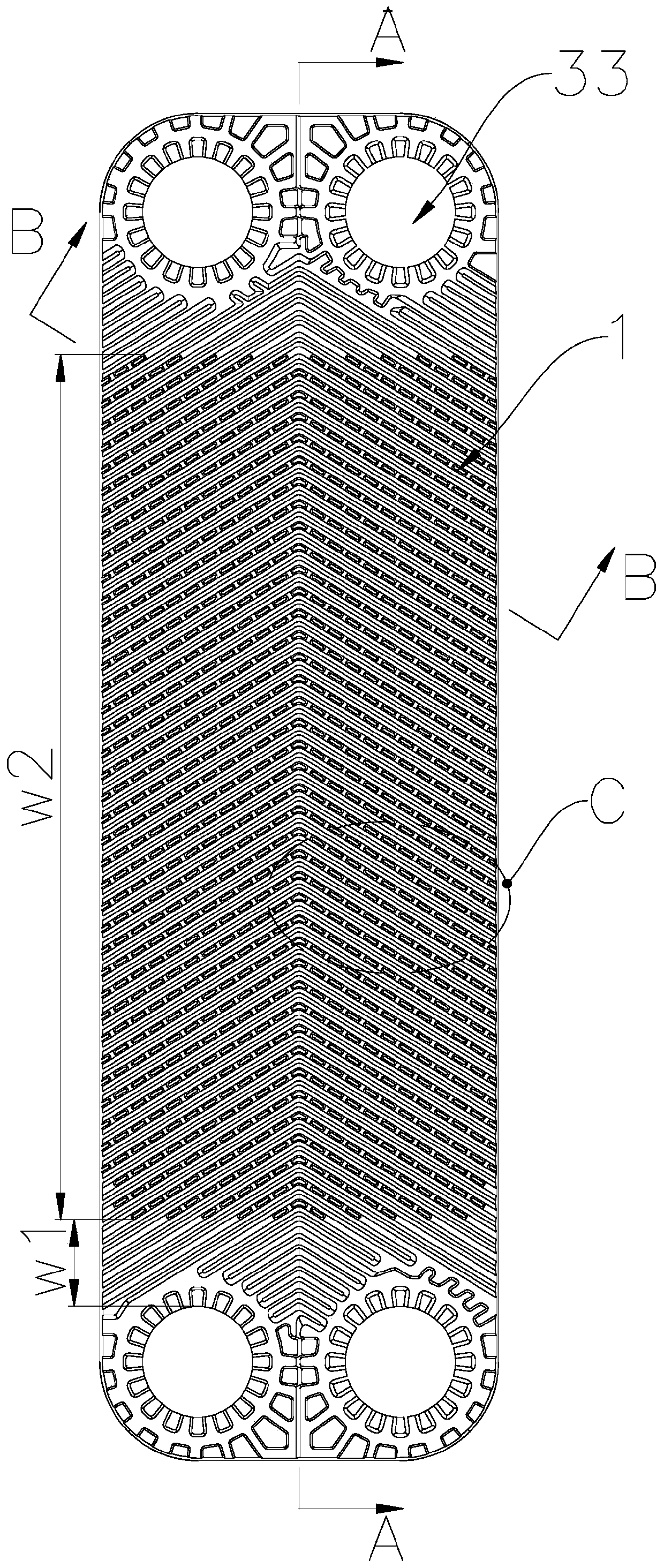

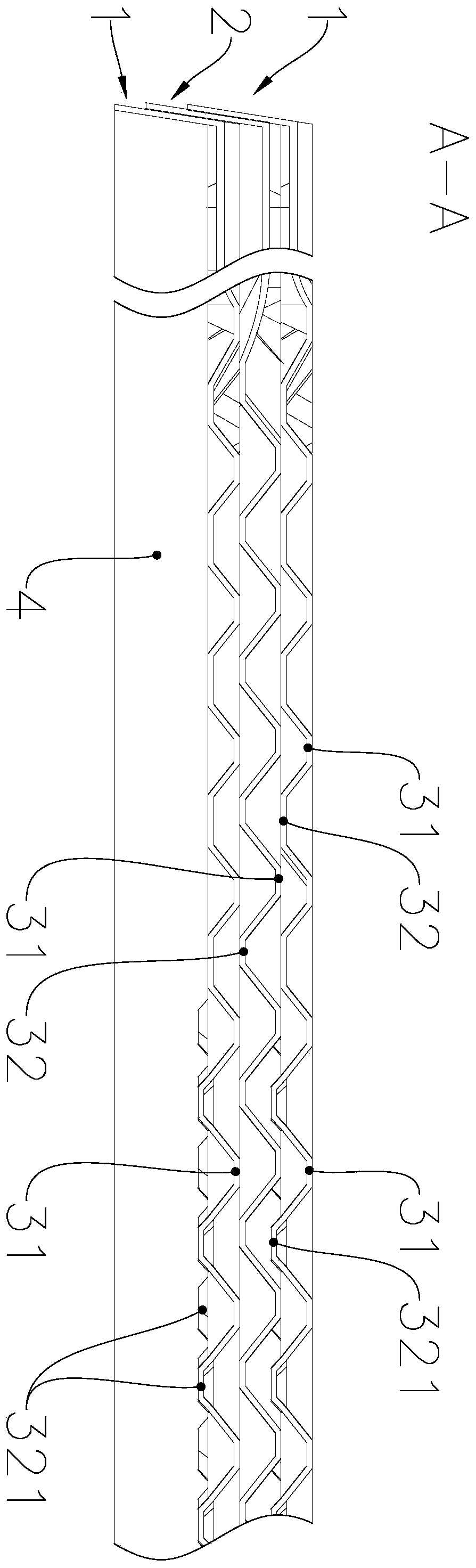

Plate type heat exchanger with asymmetric channels

PendingCN111271996AIncreased flow pressure dropIncreased turbulenceLaminated elementsStationary plate conduit assembliesEngineeringMechanical engineering

The invention relates to the technical field of heat exchangers, in particular to a plate type heat exchanger with asymmetric channels. The plate type heat exchanger comprises a plurality of heat exchange plates stacked to form heat exchange channels, the heat exchange plates are first plates and second plates which are alternately arranged, the first plates and the second plates both comprise a main panel and surrounding baffles, a plurality of convex ridges are arranged on the main panel, a concave valley is formed between every two adjacent convex ridges, and a plurality of grooves are evenly distributed in the concave valley of the first plates, so that asymmetric channels with different volumes are formed in the two sides of the second plates. According to the heat exchanger, the multiple evenly-distributed grooves are formed in the valley of the first plates, asymmetric channels with different volumes are formed in the two sides of the second plates, the heat exchange performanceis improved, due to the arrangement of the grooves, the convex ridges of the second plates are clamped between every two adjacent grooves, the inclined planes on two sides of the convex ridges and the inclined planes on two sides of the grooves which are in contact with each other effectively increase the welding area, the pressure-bearing effect of the heat exchanger is enhanced, and the heat exchange performance and the pressure-bearing effect are both considered.

Owner:WEYEE HEAT EXCHANGER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com