Patents

Literature

52results about How to "Uniform heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature lithium-ion battery

InactiveCN109888368AGood for group consistencyEasy to design and layoutCell electrodesSecondary cellsManganateSingle crystal

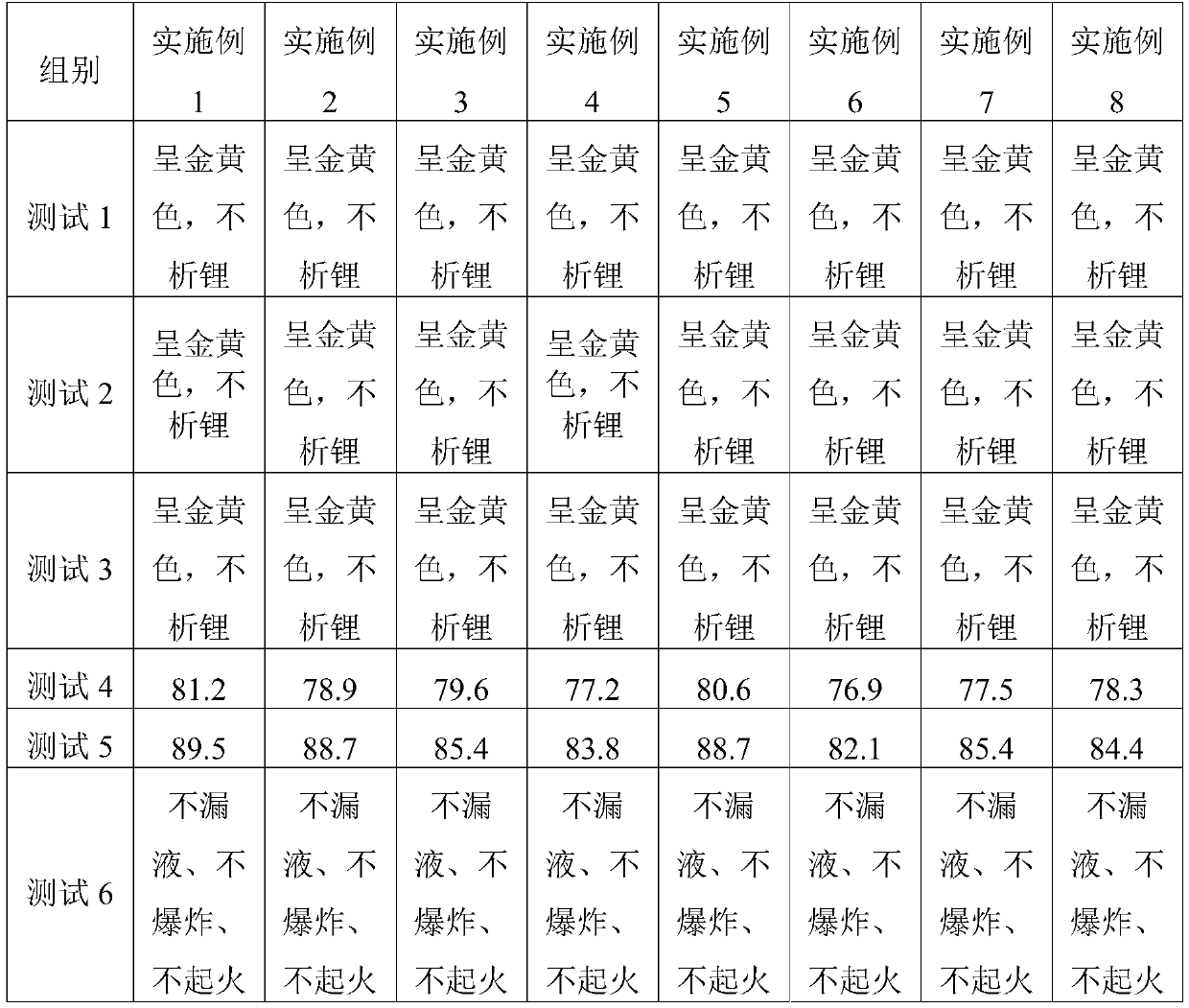

The invention discloses a low-temperature lithium-ion battery. The low-temperature lithium-ion battery comprises a positive plate, a membrane, a negative plate and an electrolytic solution, wherein the positive plate comprises a ternary lithium nickel-cobalt manganate material, the ternary lithium nickel-cobalt manganate material is a composite material of an aggregate material and a quasi-monocrystalline material, and the median particle diameter of the aggregate material is smaller than the median particle diameter of the quasi-monocrystalline material; the negative plate comprises a carbonmaterial, the carbon material comprises synthetic graphite and natural graphite, and the synthetic graphite and the natural graphite are both carbon-coated secondary particles; and the electrolytic solution comprises a solvent, lithium salt and an additive, the solvent comprises EC, DEC, EMC and an auxiliary solvent, the solvent is a quaternary or above compound, the lithium salt comprises LiPF<6>, LiFSI and LiPO<2>F<2>, and the additive comprises VEC, DTD and GBL. The low-temperature lithium-ion battery has good charge / discharge properties, high safety and high energy density under low temperature and can be well suitable for a low-temperature environment.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

Balanced high-heat type aluminum hot-welding agent

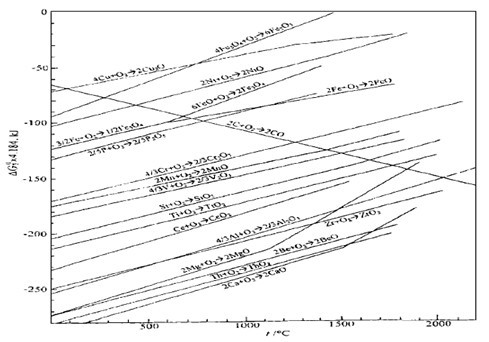

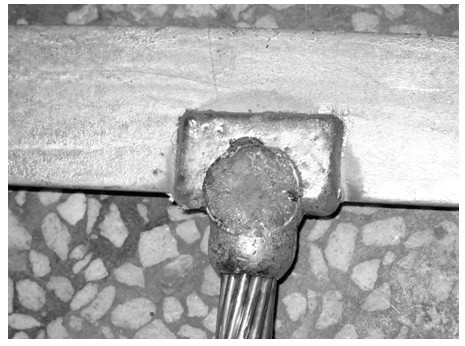

InactiveCN102152026AAchieve redistributionUniform heat generationWelding/cutting media/materialsSoldering mediaElectricityAl powder

The invention discloses a balanced high-heat type aluminum hot-welding agent. MgO is added into components and is reduced into elementary substance Mg under high temperature and heat is absorbed; and then Mg is oxidized into MgO under low temperature and the heat is released. Through this process, the redistribution of the heat during thermit reaction is realized and the purpose of uniform heat production is reached. The balanced high-heat type aluminum hot-welding agent comprises the components by weight portions as follows: 80-85 percent of CuO powder, 6-12 percent of Al powder, 6-9 percent of MgO, 0-1 percent of CaF2, and 0-1 percent of SiO2. The balanced high-heat type aluminum hot-welding agent has the characteristics of high heat, balance, and safety. The heating volume of the balanced high-heat type aluminum hot-welding agent is not sensitive to component parameters, thus being convenient for scale batch production, and being capable of being broadly used for quickly and reliably connecting metal structures or connection under outdoor power-less conditions.

Owner:RAINBOWALLY CHENGDU LIGHTNING PROTECTIVE TECH +1

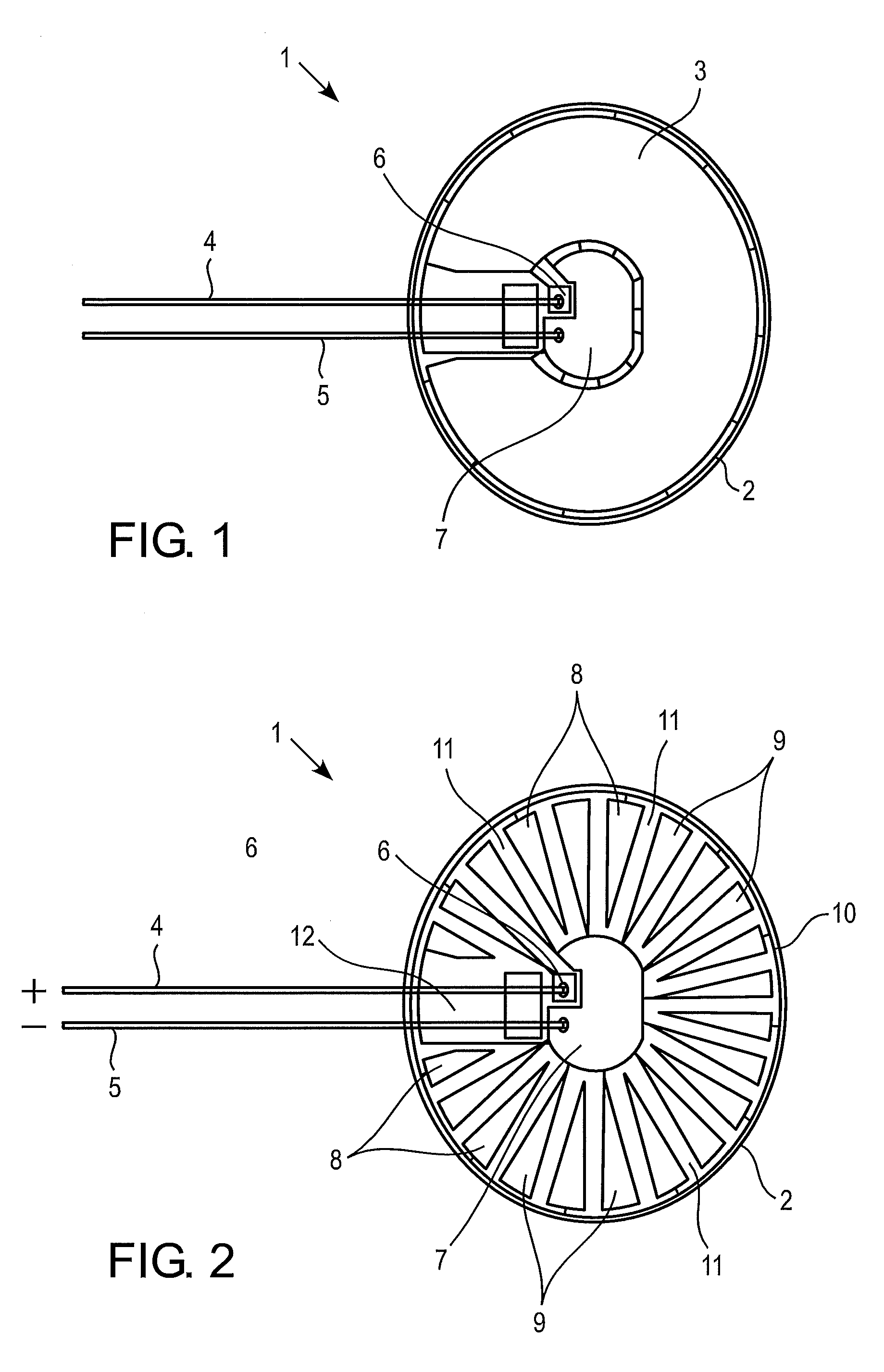

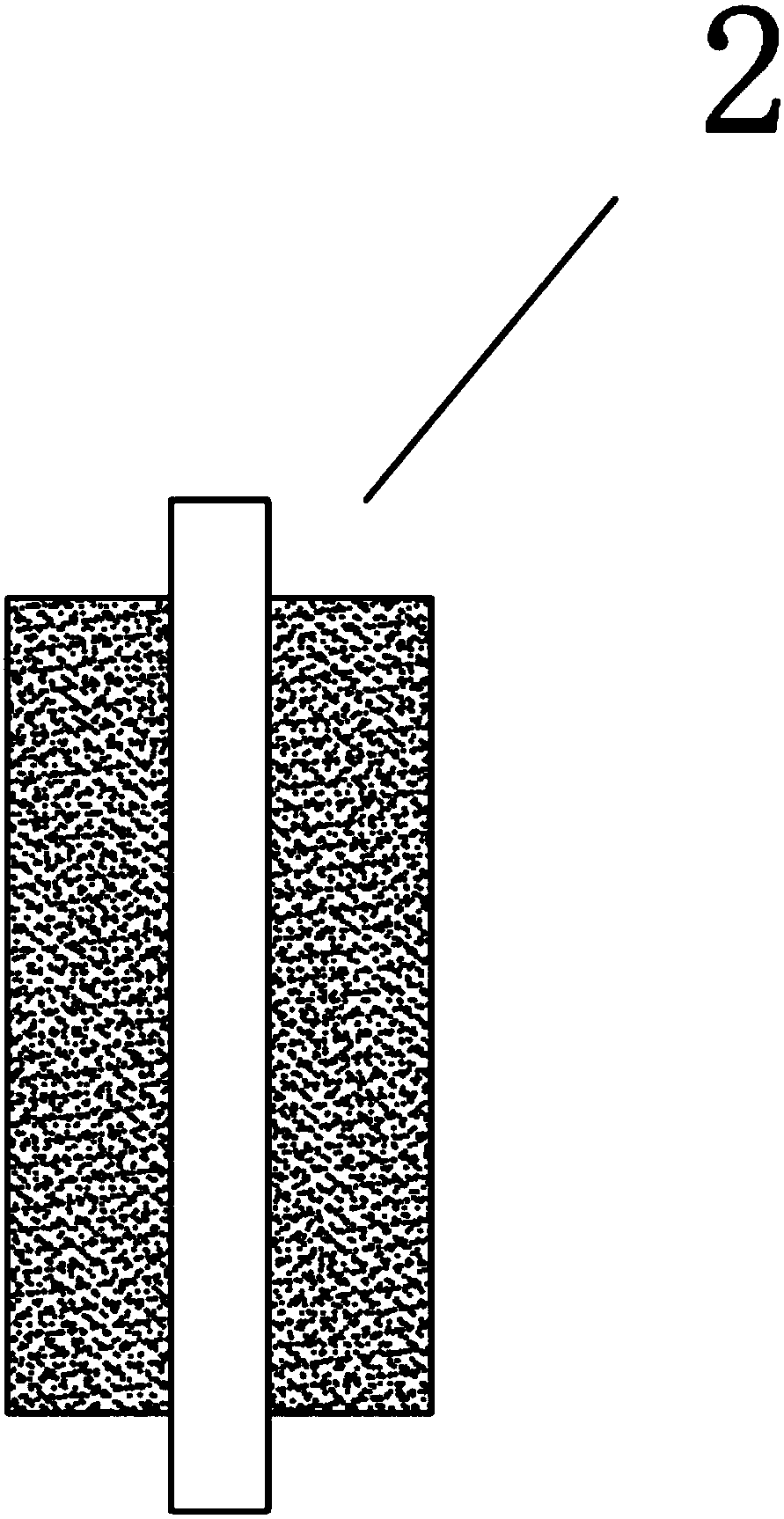

Electric heating element for insoles

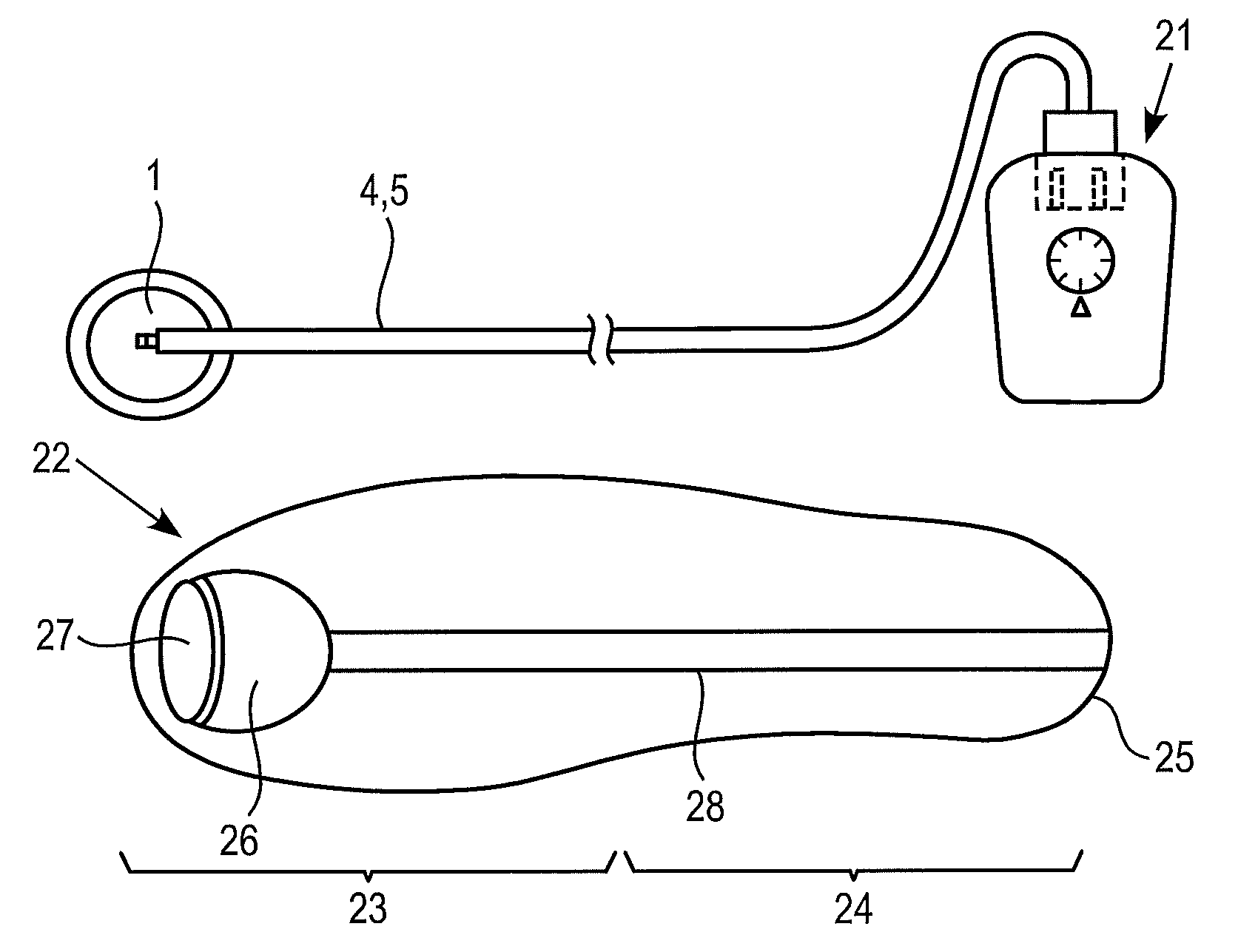

InactiveUS20110127249A1Promotes even distributionEqually distributedSolesOhmic-resistance heatingElectricityNegative power

There is described an electric heating element for insoles of footwear is provided which comprises a flexible, generally flat sheet of material. The sheet of material is provided across its surface with heating means. The heating means is connected with a number of flat electrodes for electric direct current, and includes positive and negative electrodes which are electrically connectable to a positive and a negative power line, respectively. The heating means is of a planar, continuous configuration and adapted to produce heat when electric direct current flows therethrough.

Owner:HOTRONIC INT

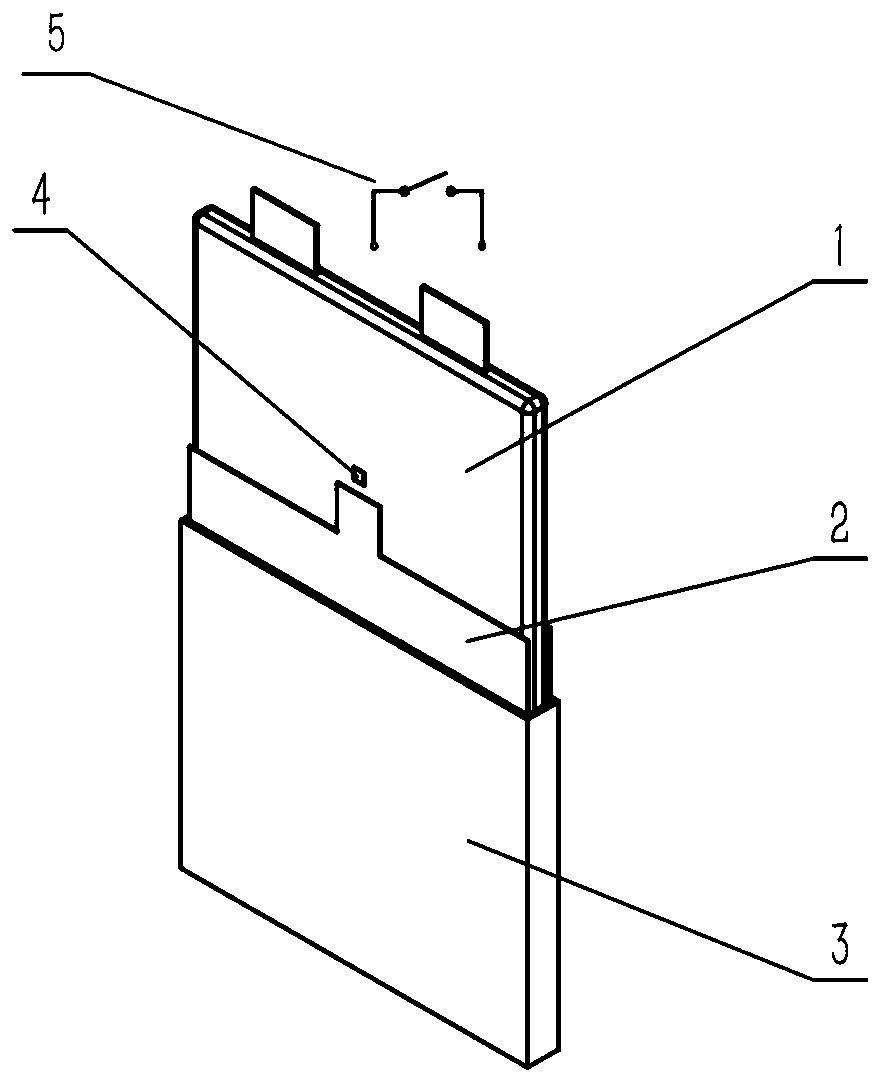

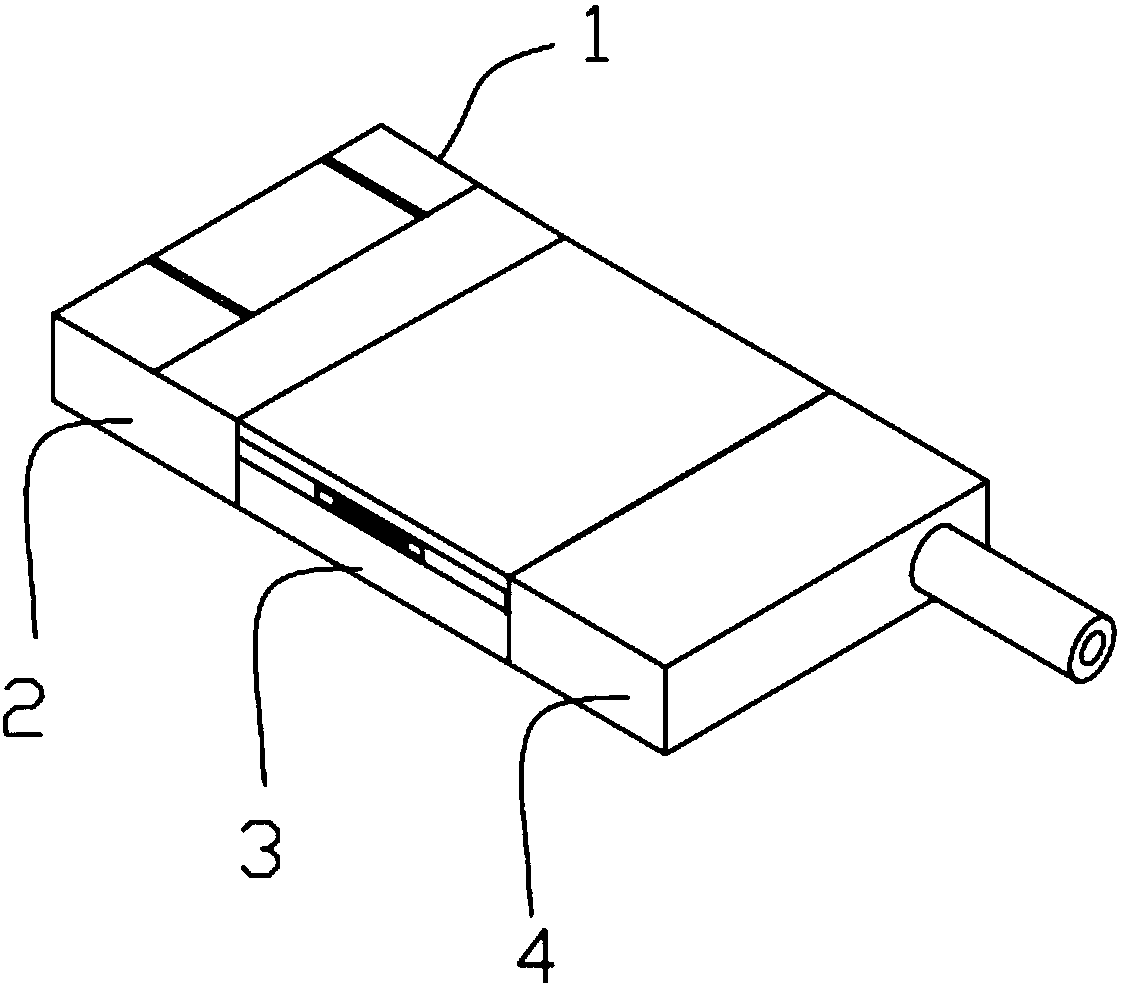

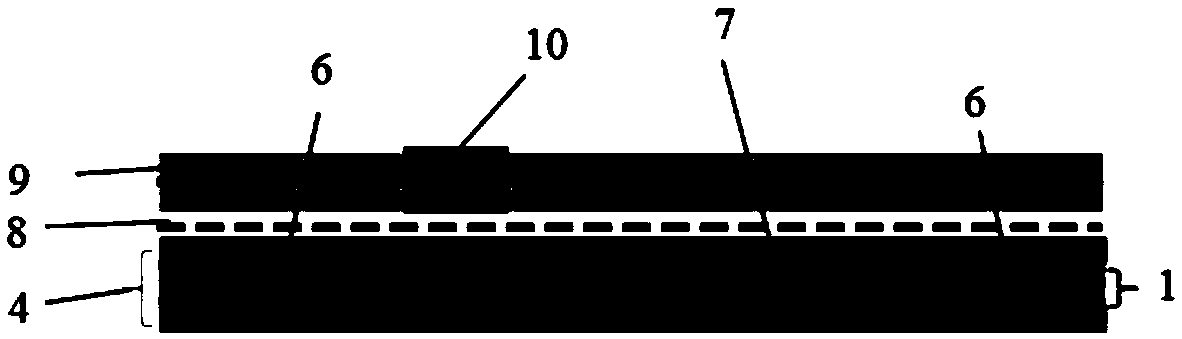

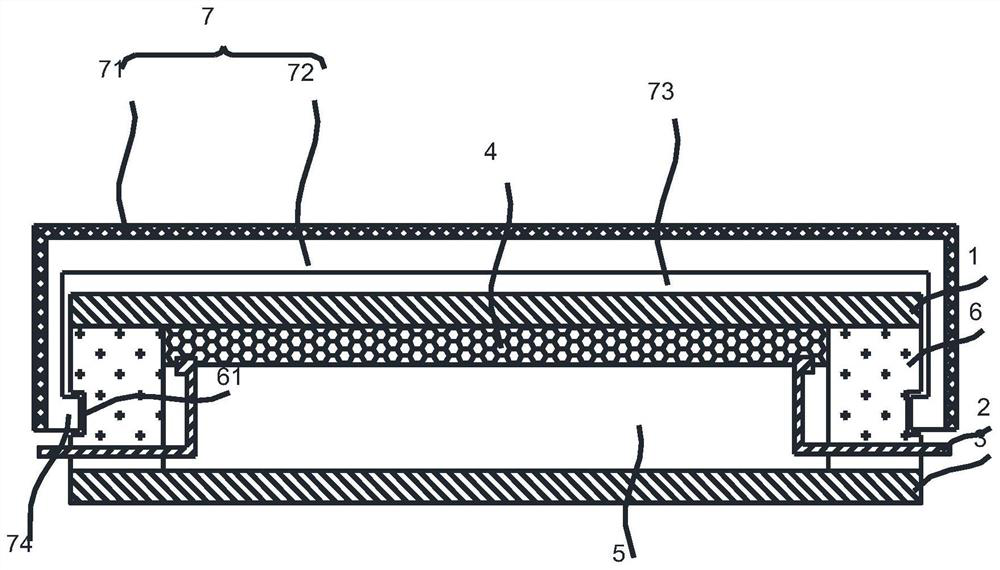

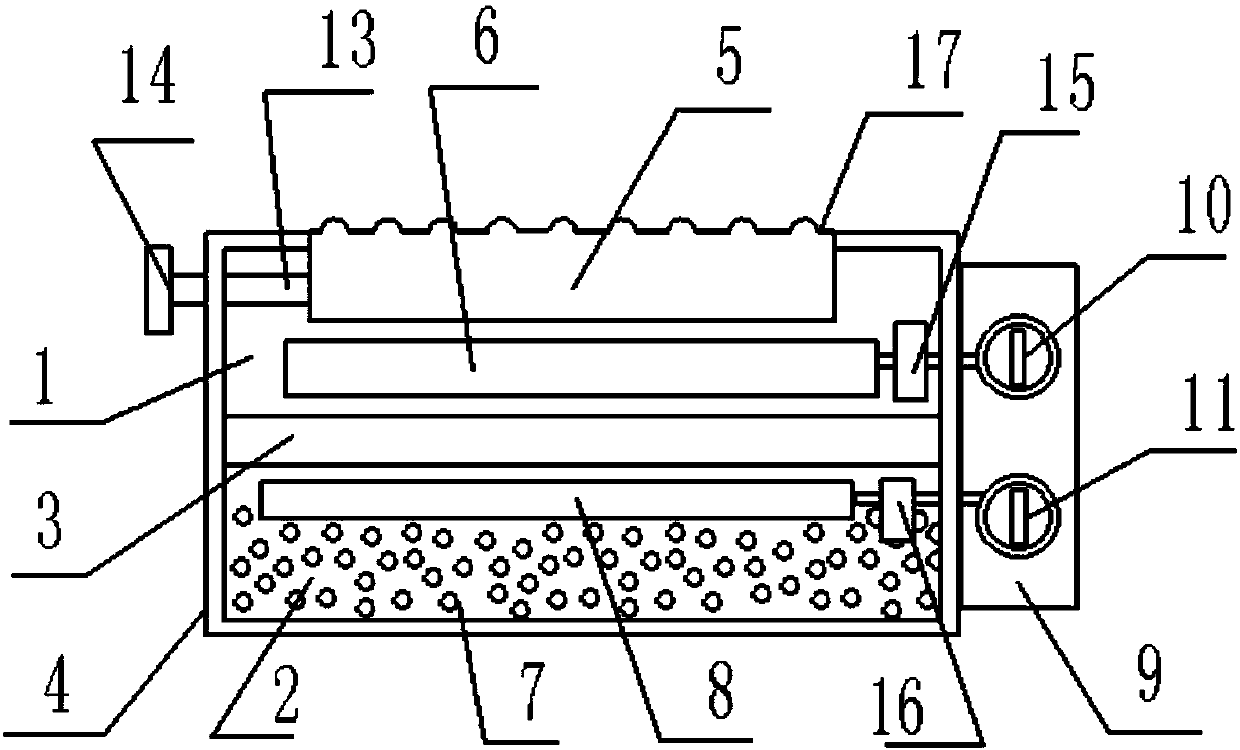

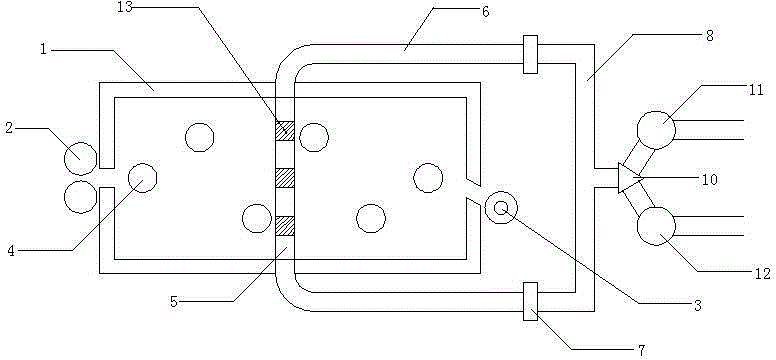

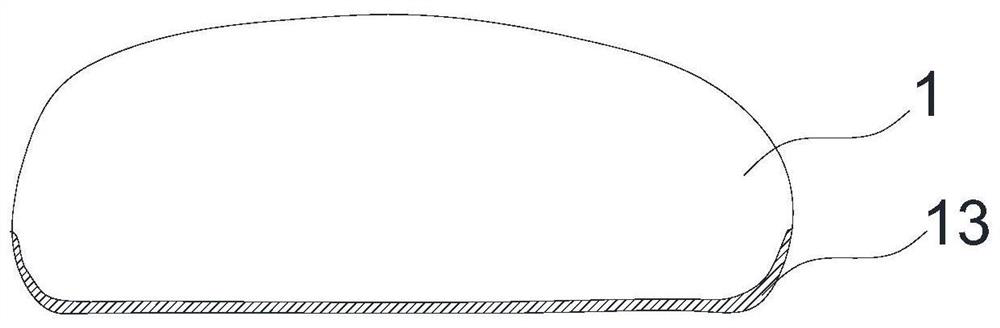

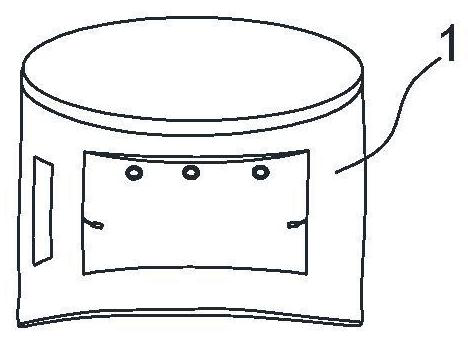

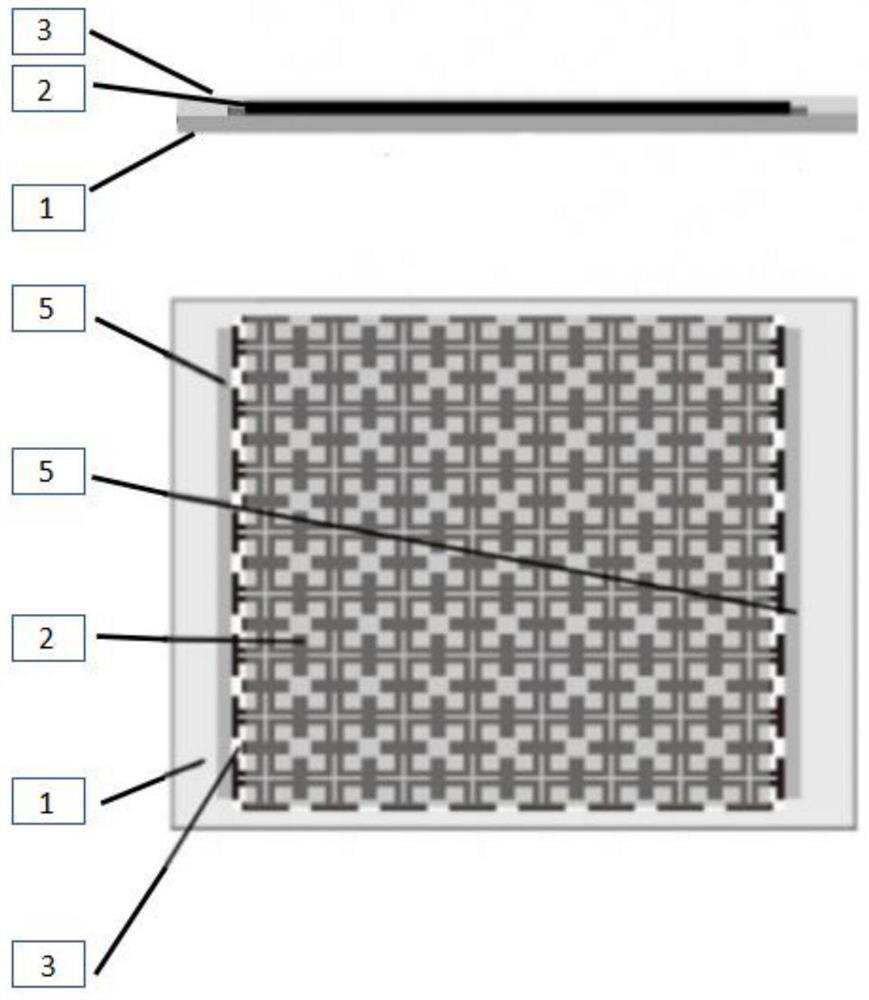

Battery self-heating and heat preserving device

ActiveCN110299580AFix Heating ProblemsEfficient self-preheating and heat preservationSecondary cellsPower batteryJoule

The invention discloses a battery self-heating and heat preserving device. The battery self-heating and heat preserving device comprises a power battery monomer, a heating diaphragm, an aerogel shell,a temperature sensor and a switching circuit. The outer surface of the power battery monomer is coated with the heating diaphragm. The outer surface of the heating diaphragm is coated with the aerogel shell. The temperature sensor is arranged on the power battery monomer, and the temperature sensor is arranged between the power battery monomer and the heating diaphragm. The temperature sensor andthe switching circuit are connected by a signal line. Every two of the power battery monomer, the heating diaphragm and the switching circuit are connected with each other. The switching circuit is used to connect the power battery monomer and the heating diaphragm to form a heating hoop. The heating diaphragm is used to generate heat by the Joule heat effect and heat the power battery monomer bythe heat conduction effect. By adopting the battery self-heating and heat preserving device provided by the invention, batteries can be efficiently self-preheated and kept warm under low temperatureconditions, and the charging and discharging performance of batteries can be enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Thin-sheet type heated-noncombustible device

InactiveCN108185525AEfficient heatingHeating fastTobacco devicesElectromagnetic inductionEngineering

The invention provides a thin-sheet type heated-noncombustible device, which comprises a main body, wherein the main body is represented as a flat plate, and the main body comprises a battery component area, a control area, a heating area and a smoke flowing area; a battery component is arranged in the battery component area; the battery component is connected to the control area; the control areais connected to the heating area; the heating area is provided with a gas inlet and a gas outlet; the gas inlet communicates with the external side; a smoke channel is arranged in the smoke flowing area; the gas outlet communicates with the smoke channel; the heating area is designed as at least one electromagnetic induction heating device or at least one resistance-type heating device or a combination of the electromagnetic induction heating device and the resistance-type heating device; the heating area further comprises a heating cavity; the heating cavity is represented as a flat plate; and a thin-sheet type tobacco is arranged in the heating cavity. The device can achieve efficient and rapid heating of the thin-sheet type tobacco; the device is constant in heat generating, uniform inheating and easy to control; and in addition, the device can prevent dry burning.

Owner:SHENZHEN INNOKIN ELECTRONICS TECH CO LTD

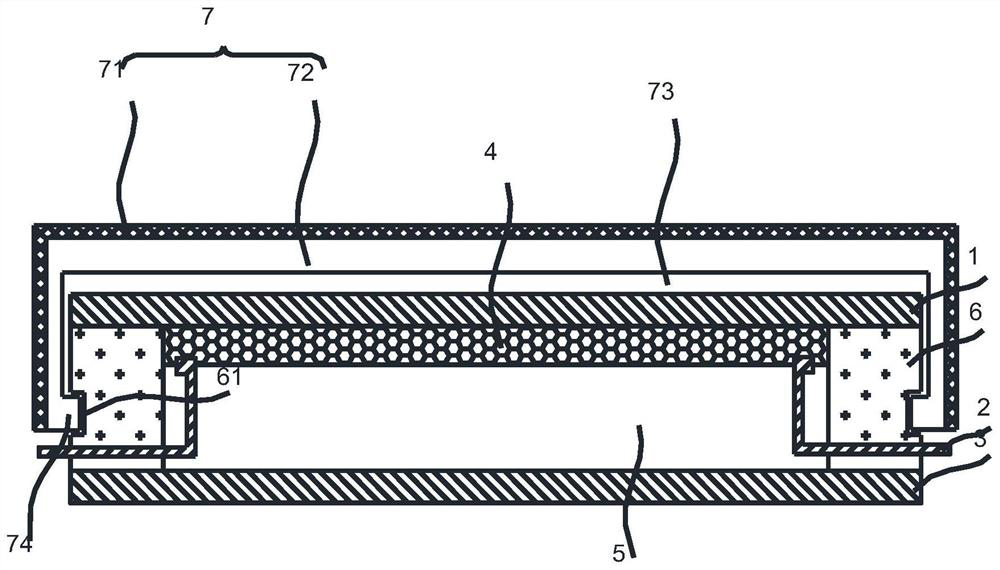

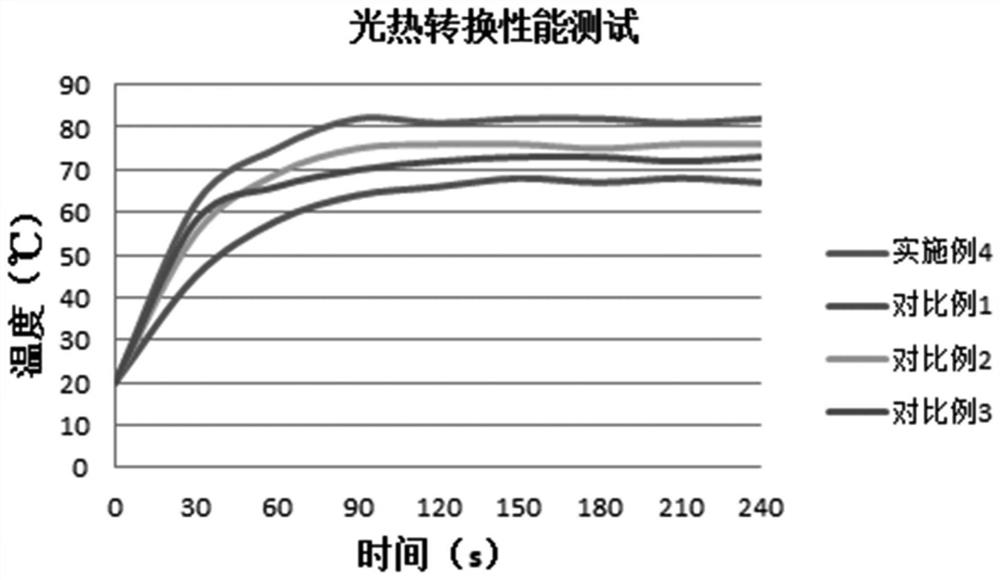

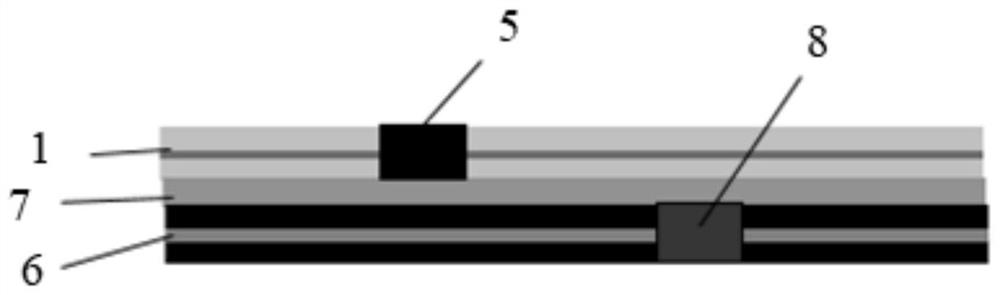

Non-layered molybdenum nanosheetgraphene-based heating film

InactiveCN112020160APrevent leakageRealize diversified heat production functionsMaterial nanotechnologyOhmic-resistance heatingFiberGraphene

The invention provides a non-layered molybdenum nanosheetgraphene-based heating film, which comprises a first transparent insulating layer, an electrode, a second transparent insulating layer and a non-layered molybdenum nanosheetgraphene-based fiber membrane, wherein the first transparent insulating layer covers one surface of the non-layered molybdenum nanosheetgraphene-based fiber membrane, thesecond transparent insulating layer covers the other surface of the non-layered molybdenum nanosheetgraphene-based fiber membrane, one end of the electrode is electrically connected with the non-layered molybdenum nanosheetgraphene-based fiber membrane, and the other end of the electrode extends out of the first transparent insulating layer or the second transparent insulating layer. According tothe non-layered molybdenum nanosheetgraphene-based heating film disclosed by the invention, by virtue of high-efficiency photo-thermal conversion efficiency and electro-thermal conversion efficiencyof the non-layered molybdenum nanosheetgraphene-based fiber film, electro-thermal and photo-thermal diversified heat production functions are realized.

Owner:北京康烯科技创新研究有限公司

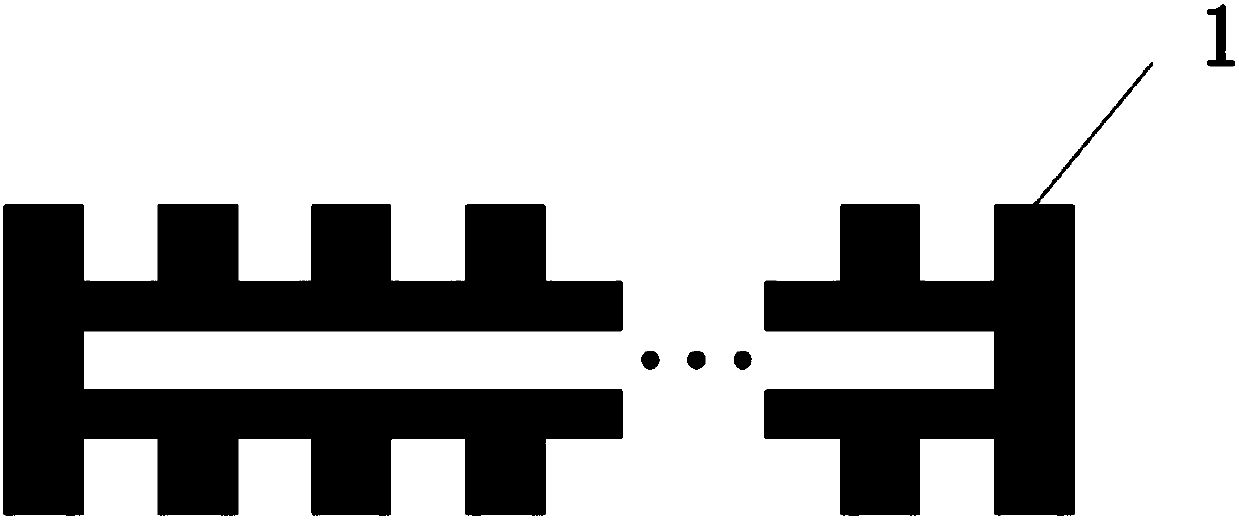

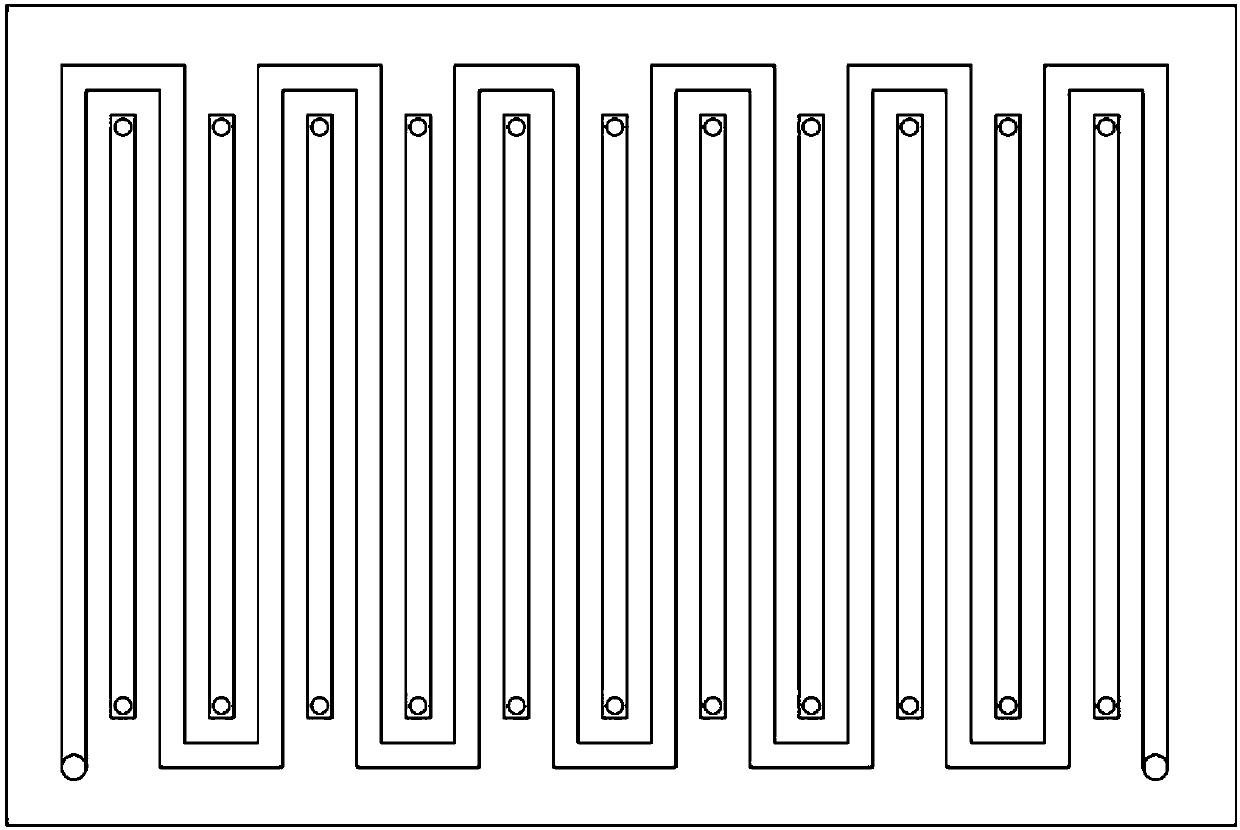

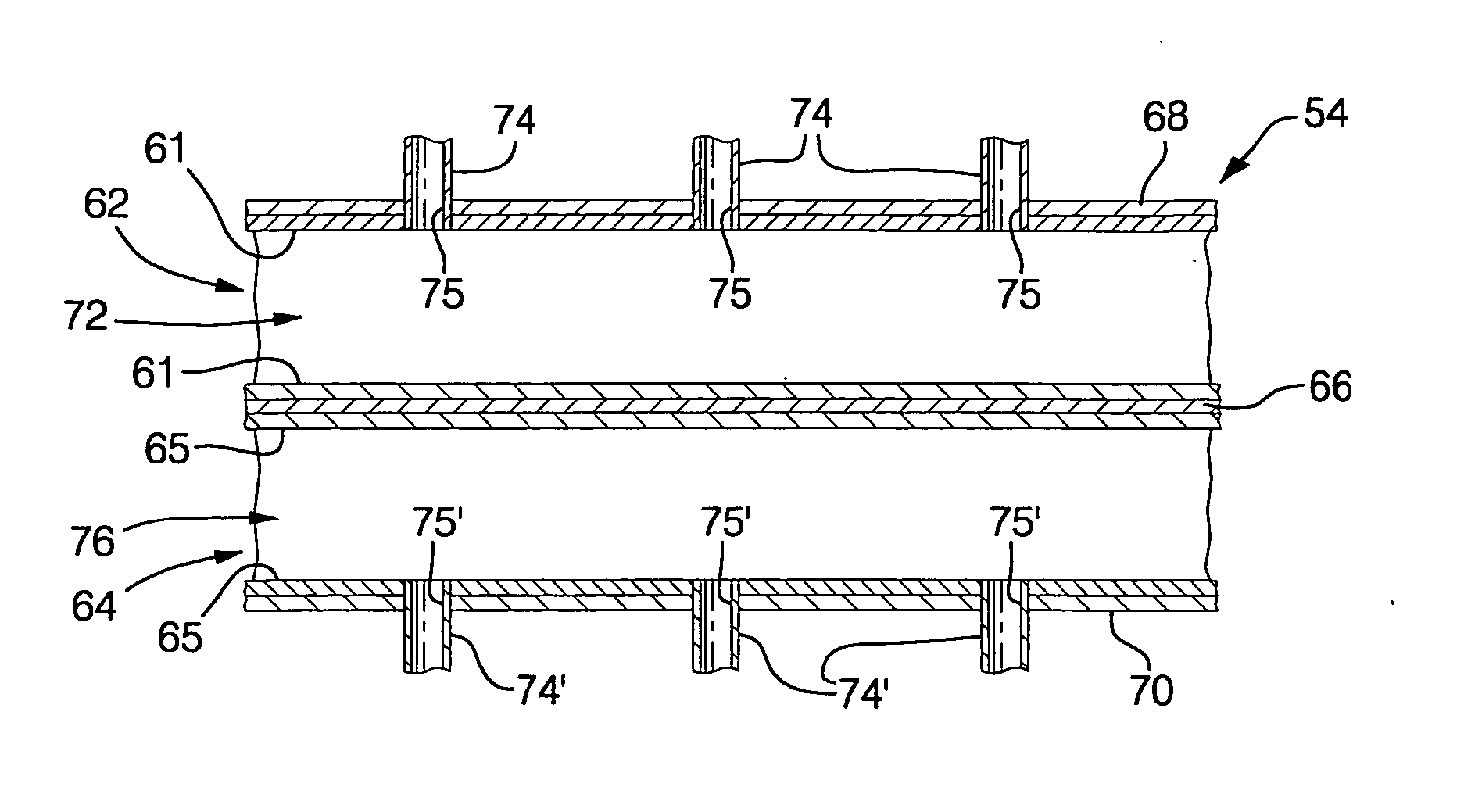

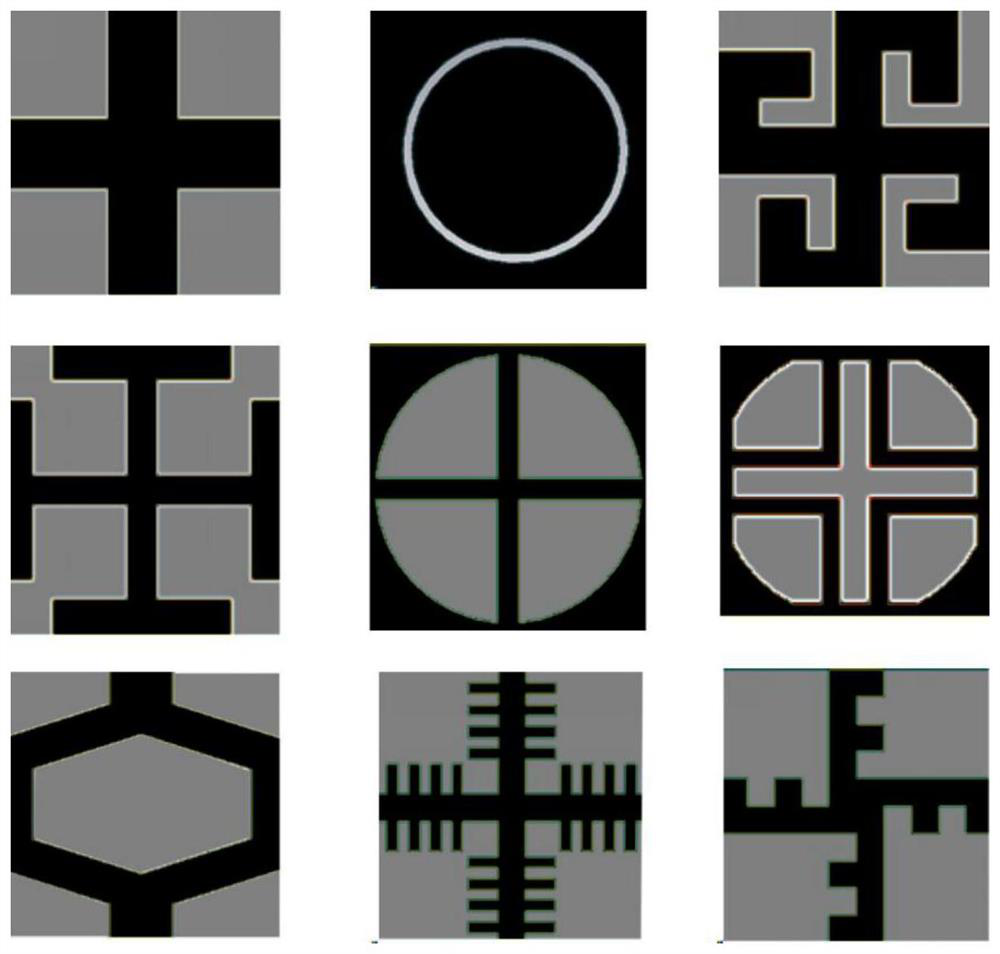

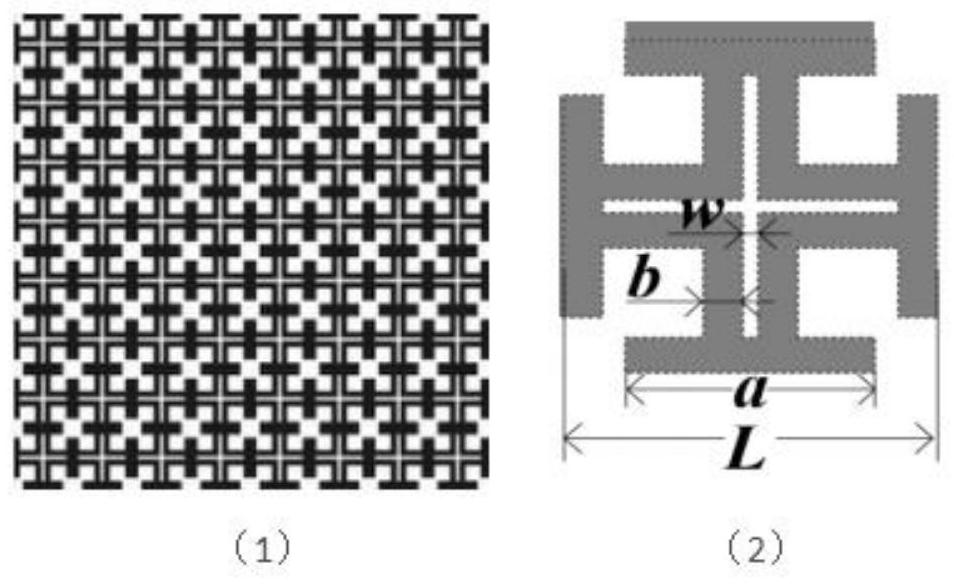

Flow field structure of fuel cell or redox flow cell pole plate

InactiveCN109921080AUniform dischargeUniform heat generationRegenerative fuel cellsFlow cellFuel cells

The invention discloses a flow field structure of a fuel cell or redox flow cell pole plate. A proton exchange membrane cell comprises two end plates and a unit cell arranged between two end plates; the unit cell comprises a bipolar plate and a membrane electrode; the bipolar plate comprises an anode flow field structure and a cathode flow field structure; the redox flow cell comprises two end plates and a unit cell set arranged between two end plates; the unit cell set comprises an electrode material, a diaphragm and the bipolar plate; the bipolar plate comprises a positive flow field structure and a negative flow field structure. Compared with the conventional flow field structure, the flow field structure can enable the fluid distribution of the cathode and anode to be more uniform, thereby enabling the reflection in the electrode to be more uniform.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

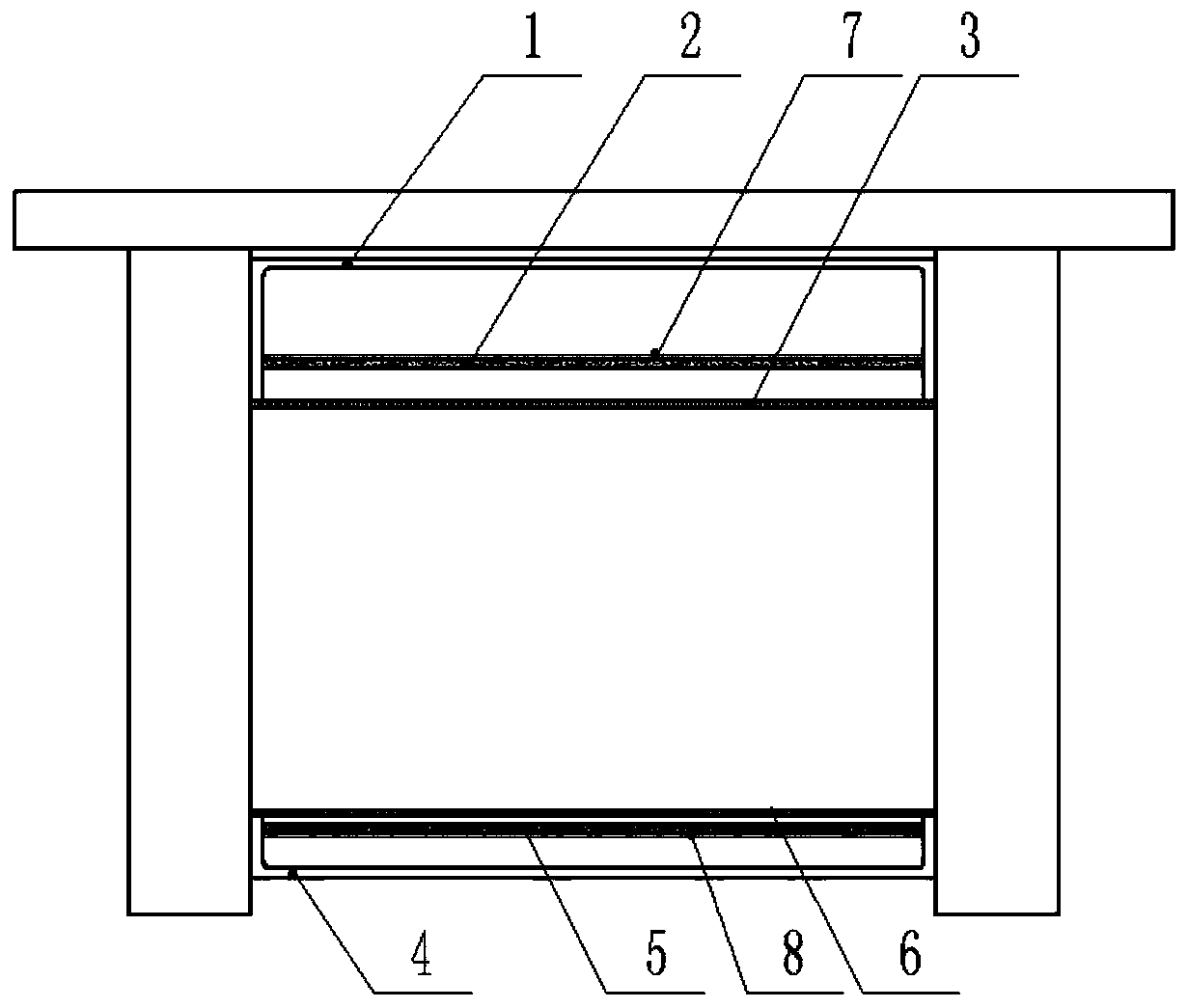

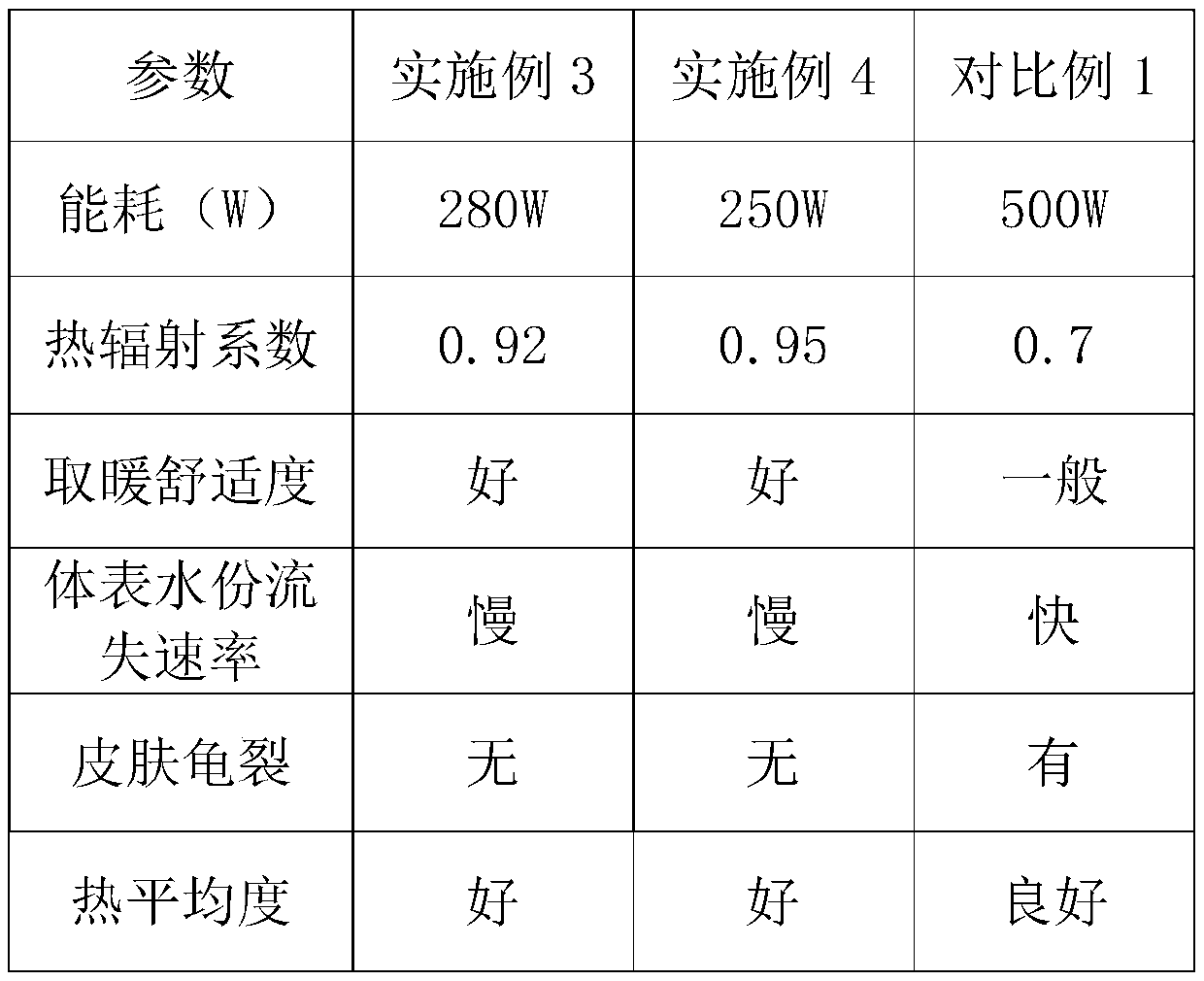

Electric heating table with graphene heating glass

ActiveCN110388686AImprove fracture toughnessHigh breaking strengthHeating fuelLighting and heating apparatusElectricityMiddle infrared

The invention discloses an electric heating table with graphene heating glass. The table comprises first graphene heating glass, a first protective cover and a protective heat radiating plate, a lowerheating device comprises second graphene heating glass, a second protective cover and a heat conducting insulating plate, the first graphene heating glass is fixedly arranged in the first protectivecover, the protective heat radiating plate is arranged at the opening of the first protective cover, the second graphene heating glass is arranged in the second protective cover, and the heat conducting insulating plate is fixed at the opening of the second protective cover. According to the table, a small quantity of near infrared rays and middle infrared rays generated in the graphene heating glass directly act on the protective heat radiating plate and the heat conducting insulating plate, the near infrared rays and the middle infrared rays are filtered by the protective heat radiating plate and the heat conducting insulating plate and transmitted out in a far infrared rays manner, so that the near infrared rays and the middle infrared rays are prevented from directly acting on human body skin; and the depth of the far infrared rays penetrating tissue is smaller than 2 mm, when the depth of the far infrared rays penetrating the skin tissue is about 2 mm, the feeling of a human bodyis most comfortable, so that the low-temperature burn is avoided.

Owner:湖南步升取暖科技股份有限公司

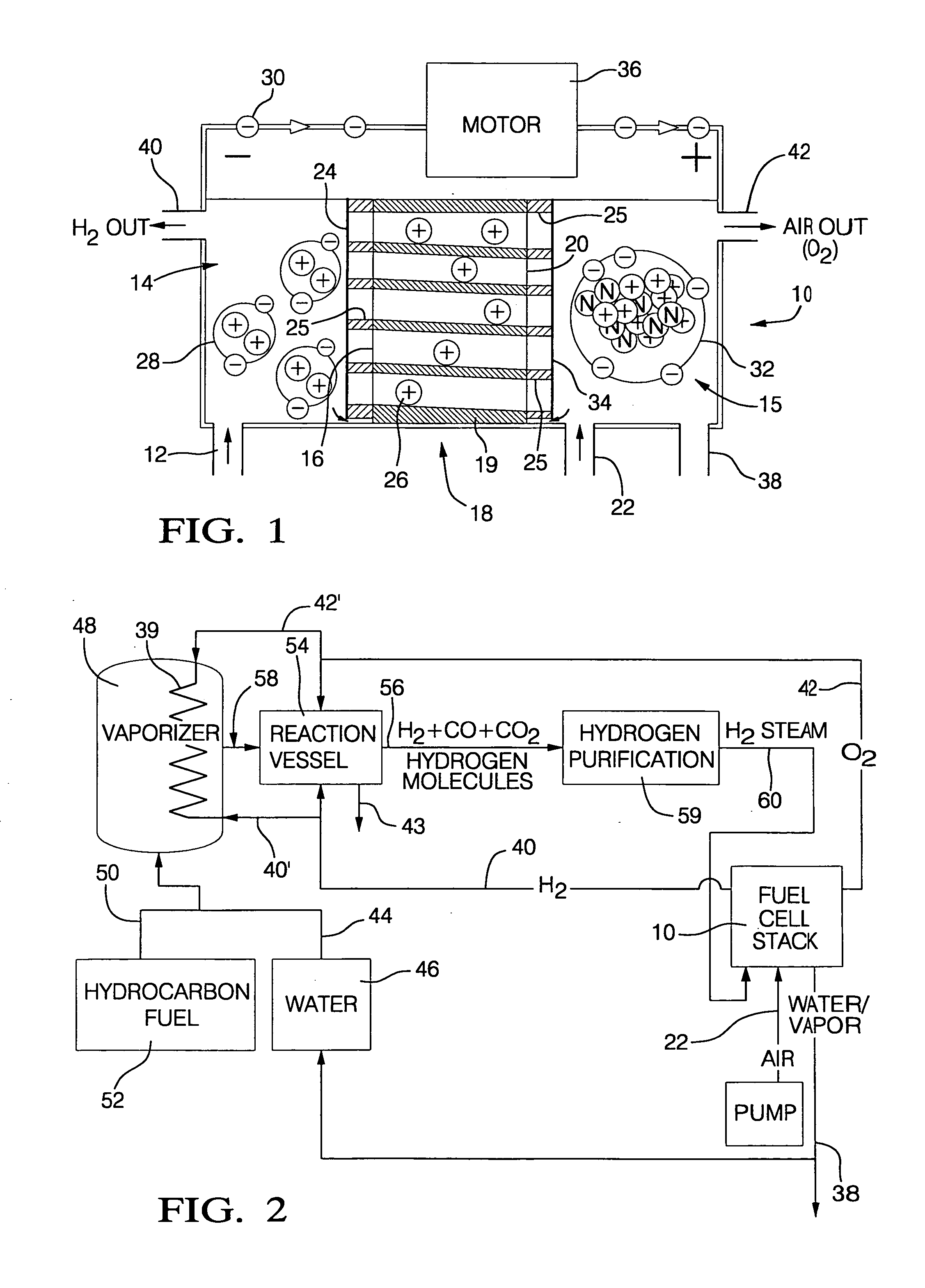

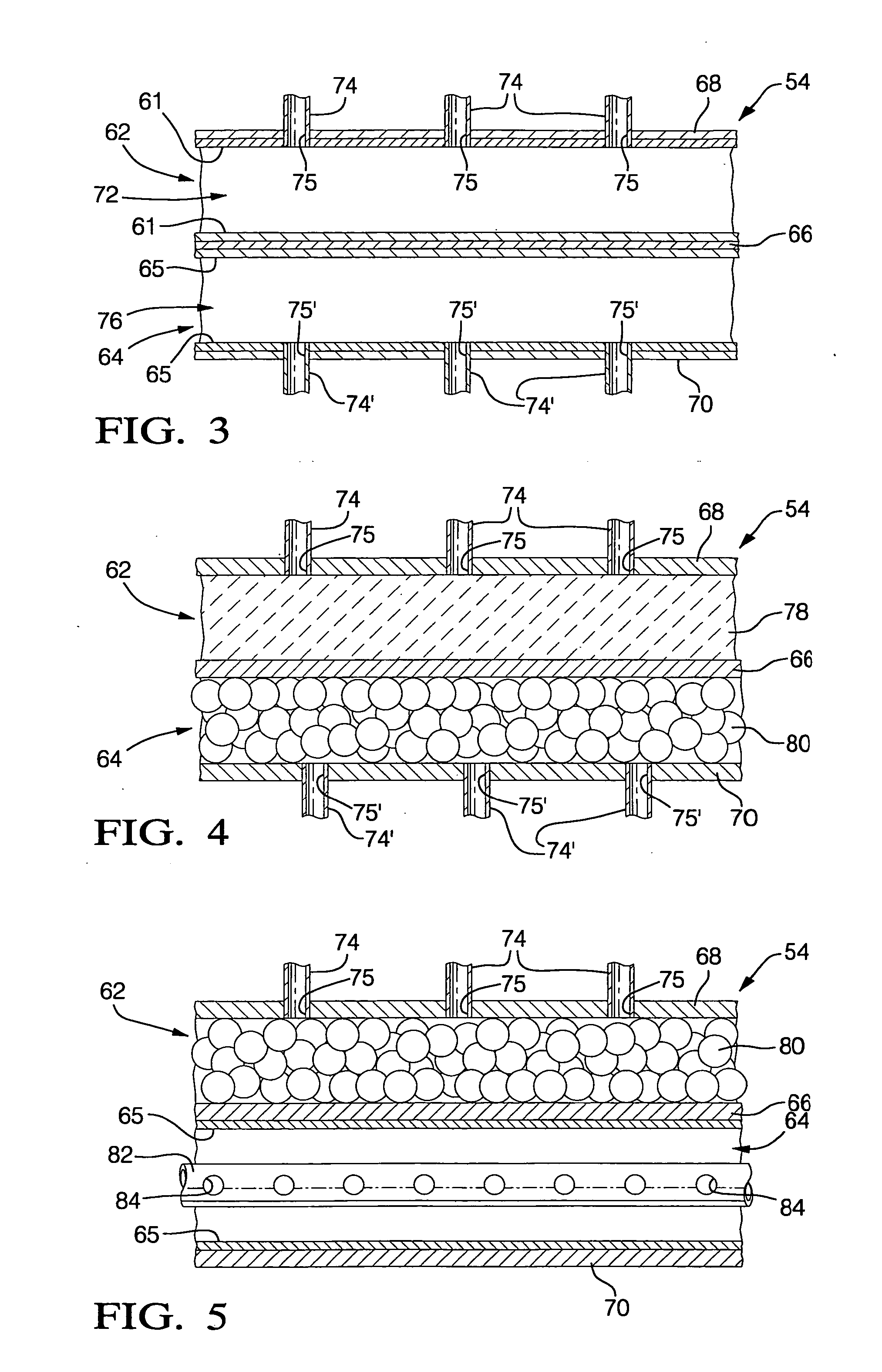

Multiple stage combustion process to maintain a controllable reformation temperature profile

InactiveUS20050048332A1Uniform exchangeUniform heat generationLaboratory glasswaresHydrogen/synthetic gas productionFuel cellsWorking fluid

A reaction vessel that integrates and balances an endothermic process with at least one exothermic process of the fuel cell system. Preferably the exothermic process is conducted in stages to provide more uniform and / or controllable heat generation and exchange, and to produce a uniform and / or controllable temperature profile in the endothermic reaction process. The invention allows for the elimination of the working fluid loop of prior art systems that had unsatisfactory response times at startup, and during transient conditions, and also added to the overall mass and volume of the fuel cell system.

Owner:GM GLOBAL TECH OPERATIONS LLC

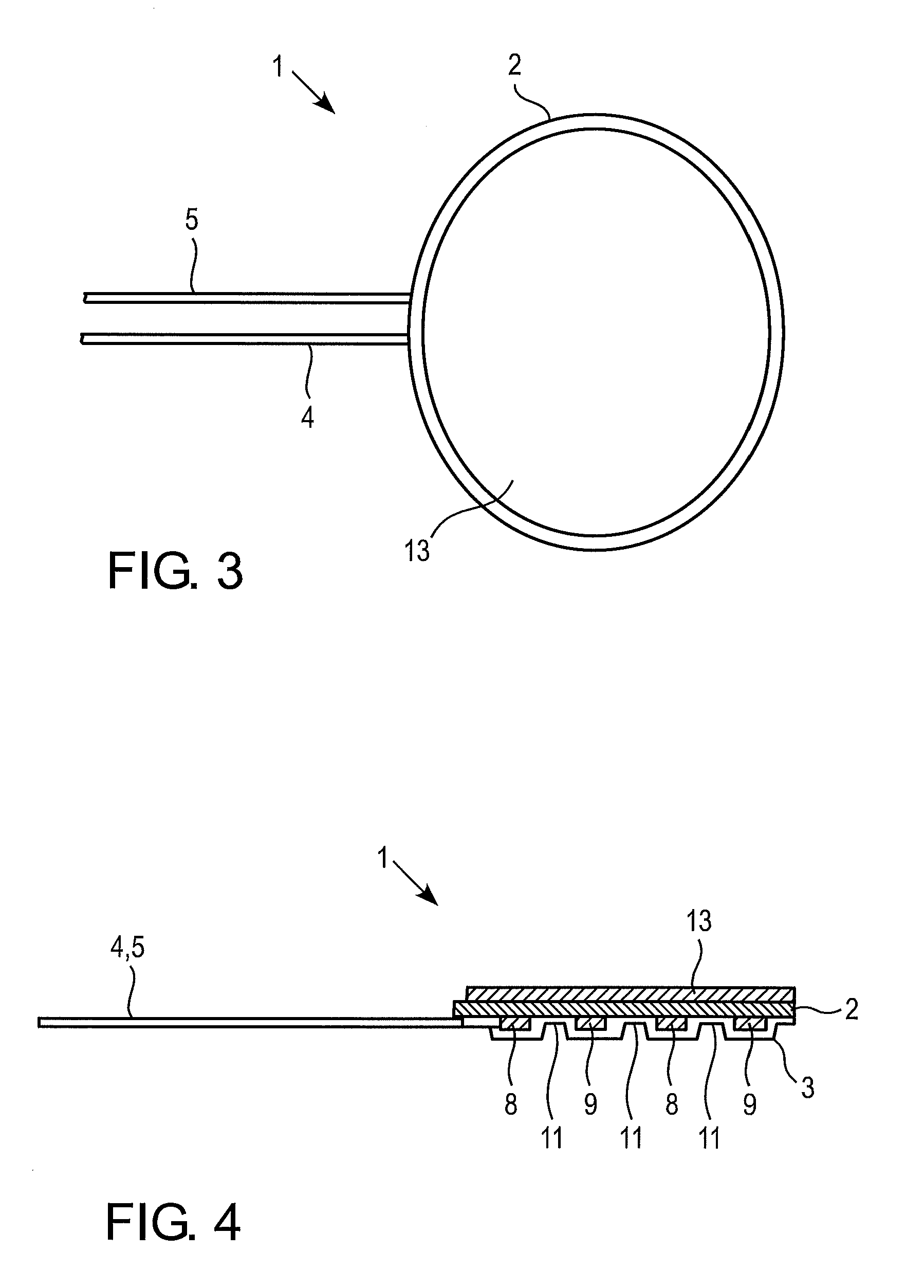

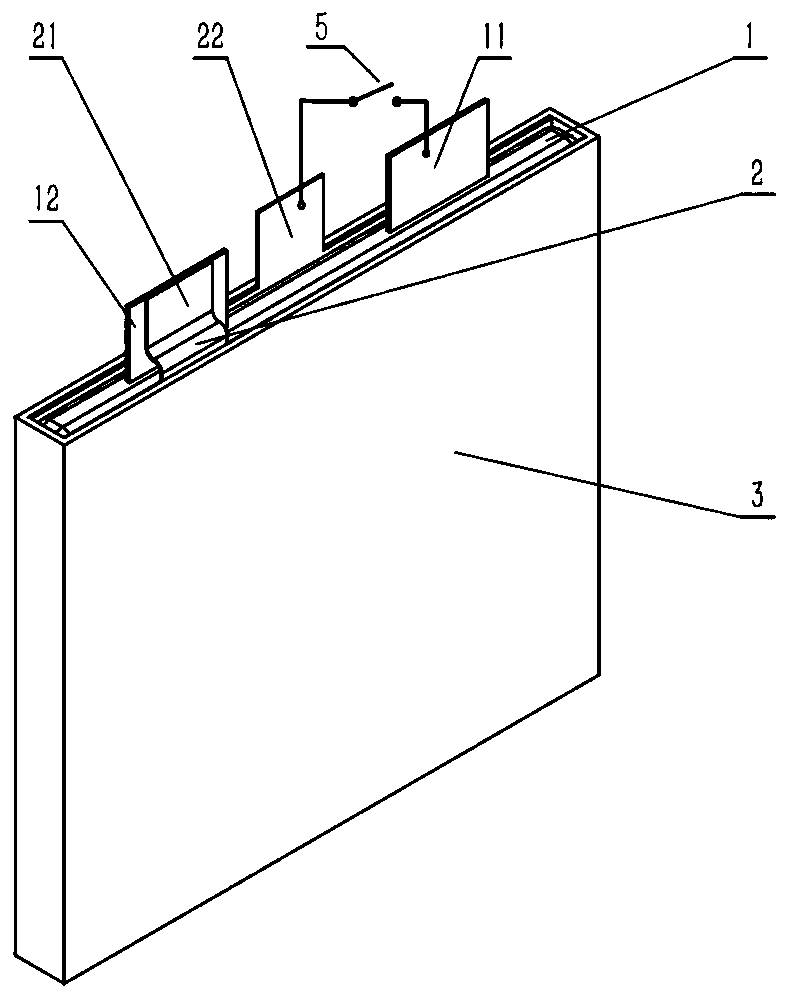

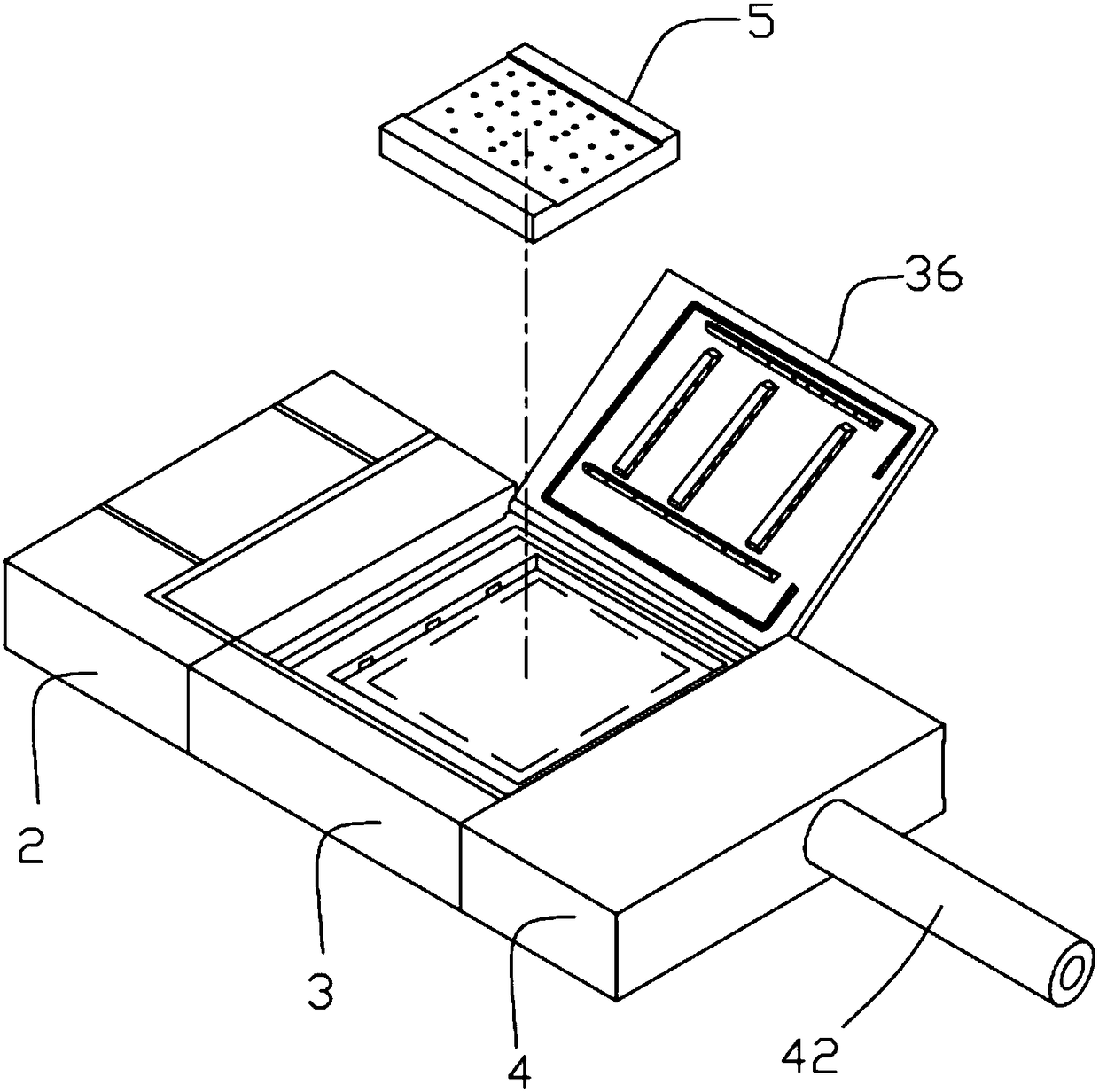

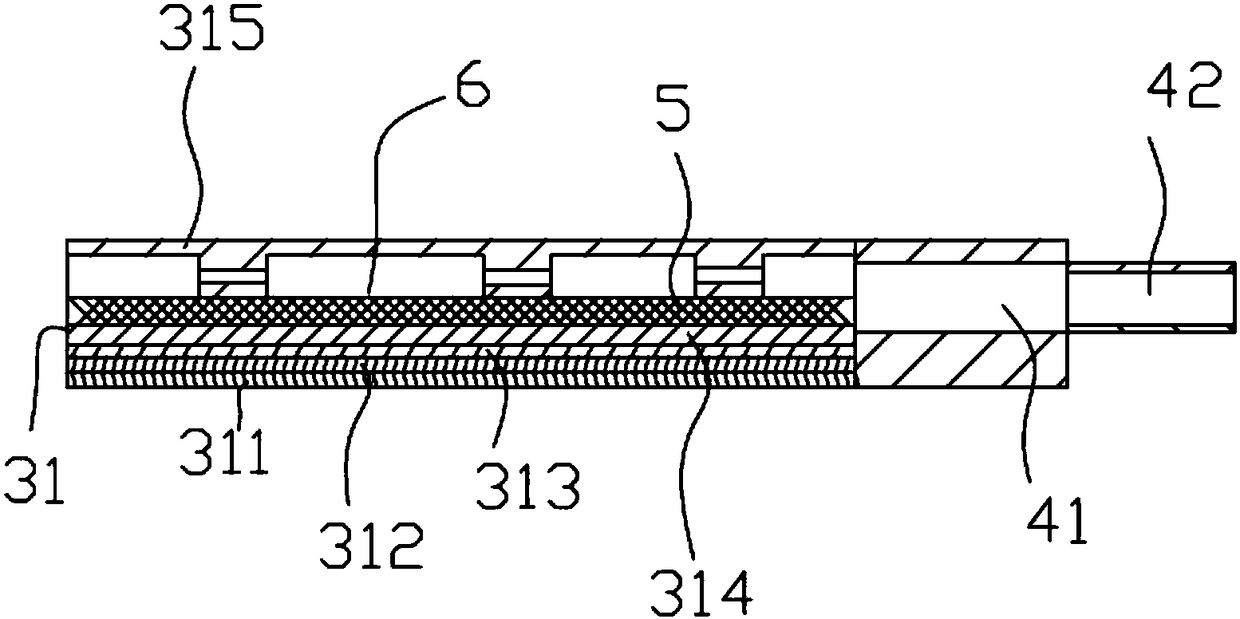

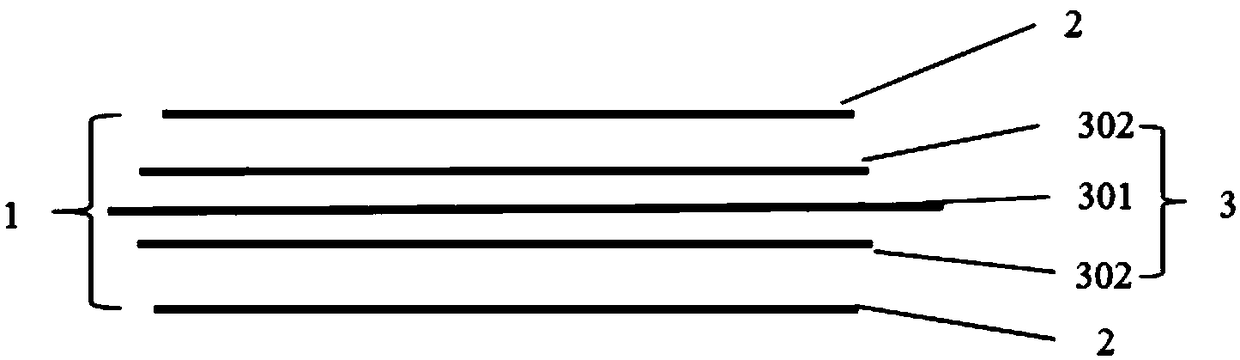

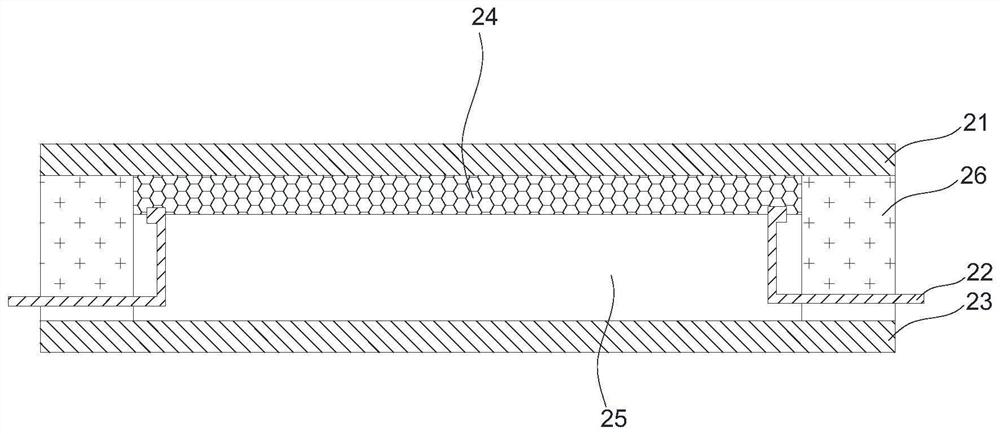

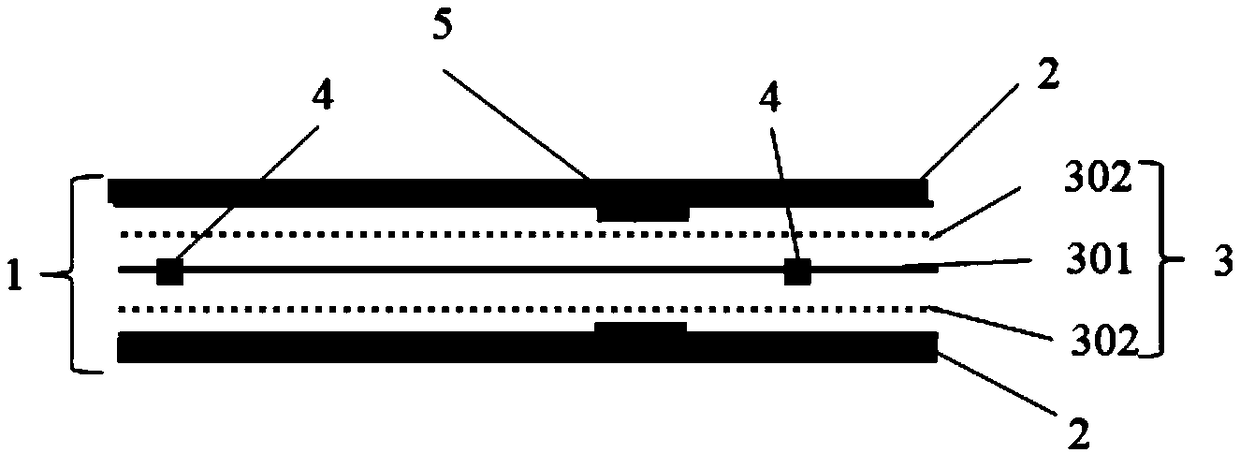

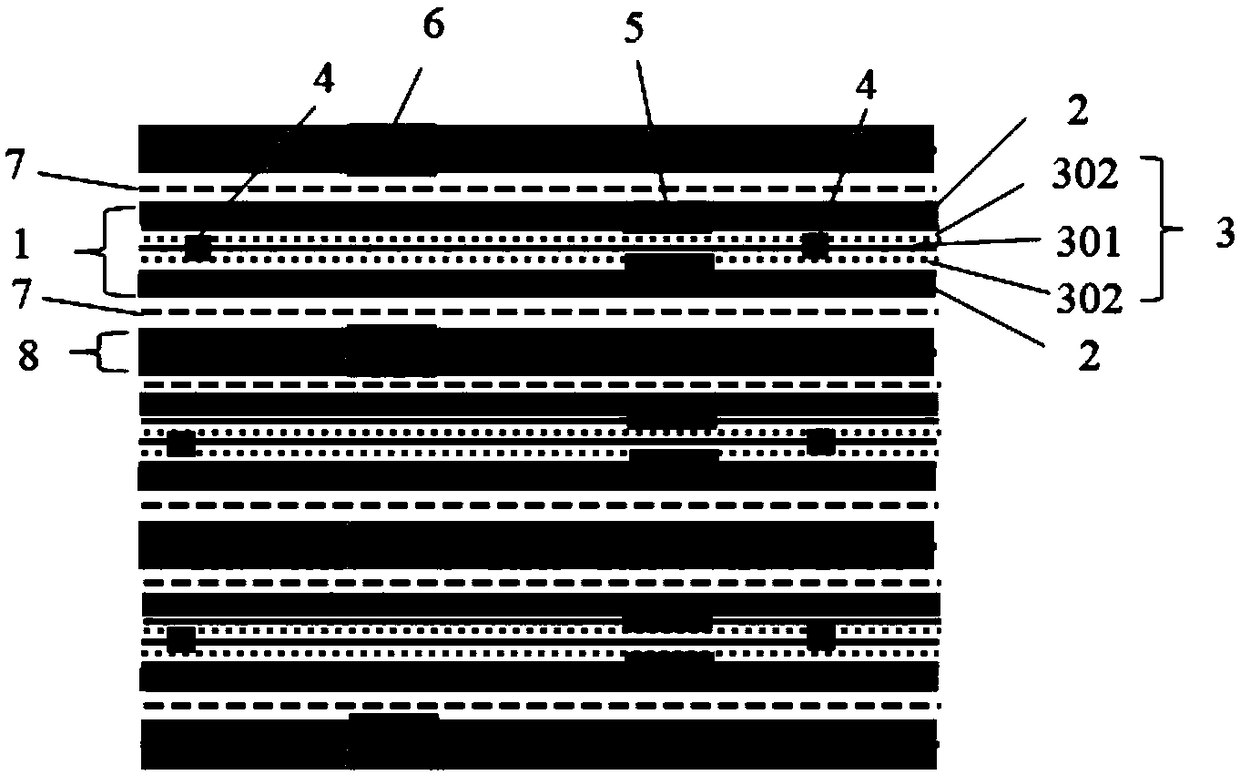

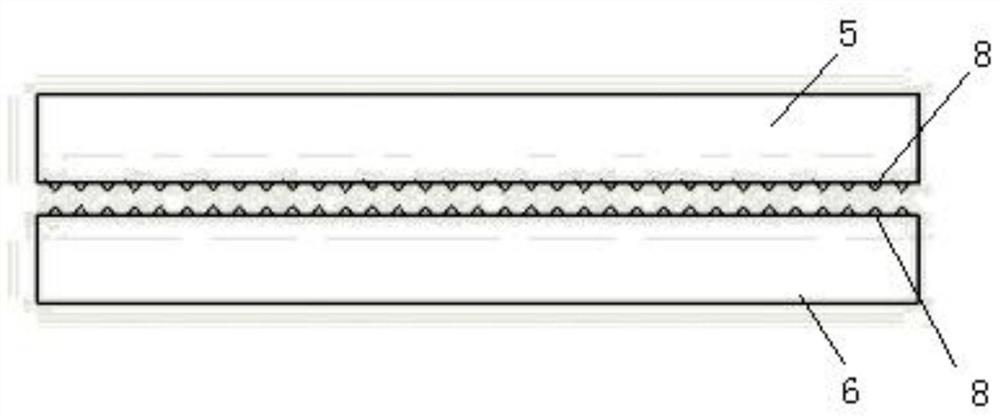

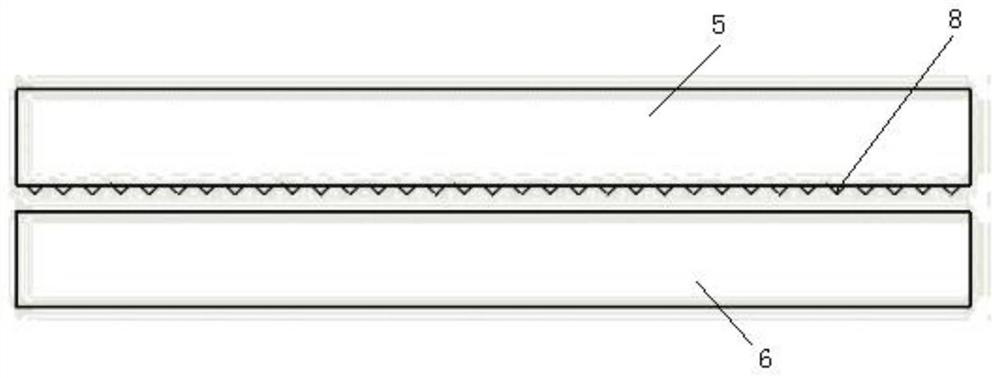

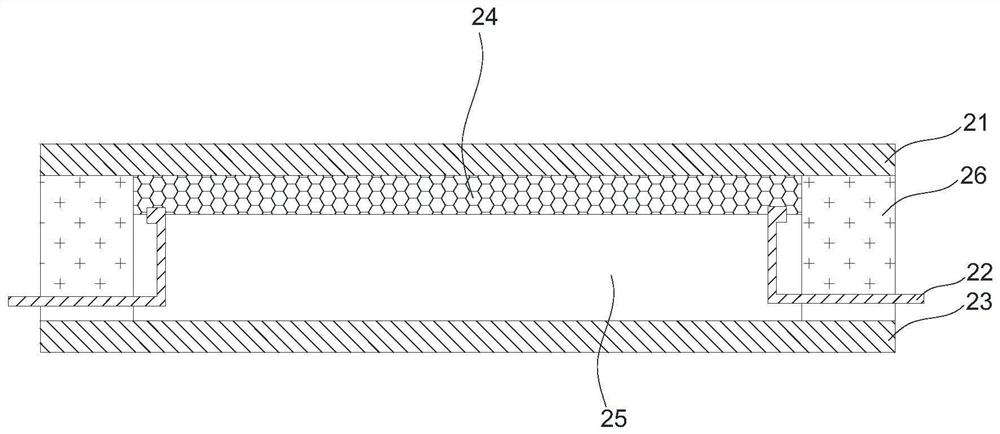

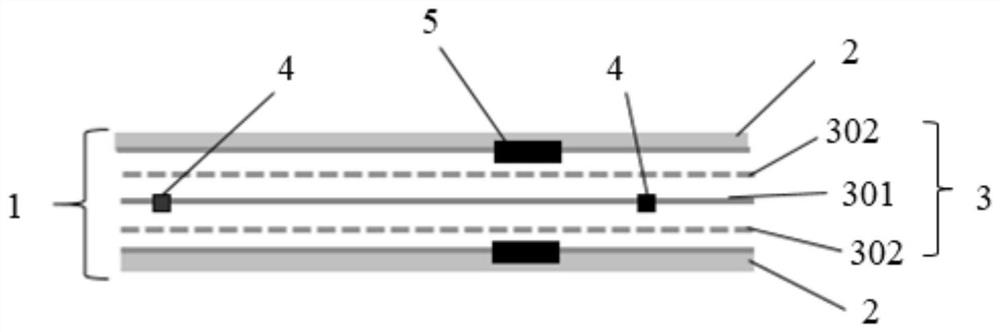

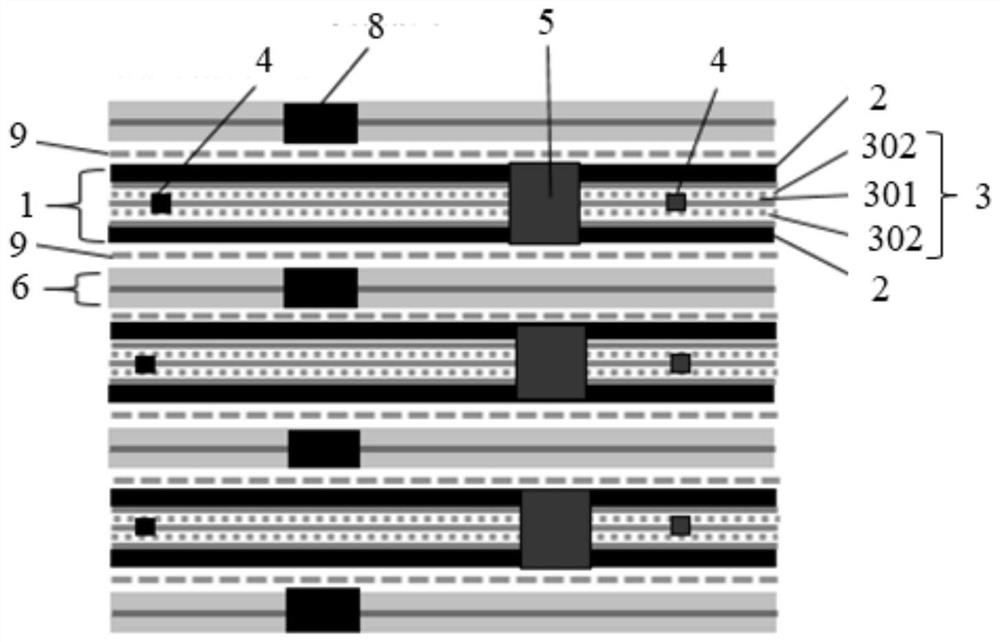

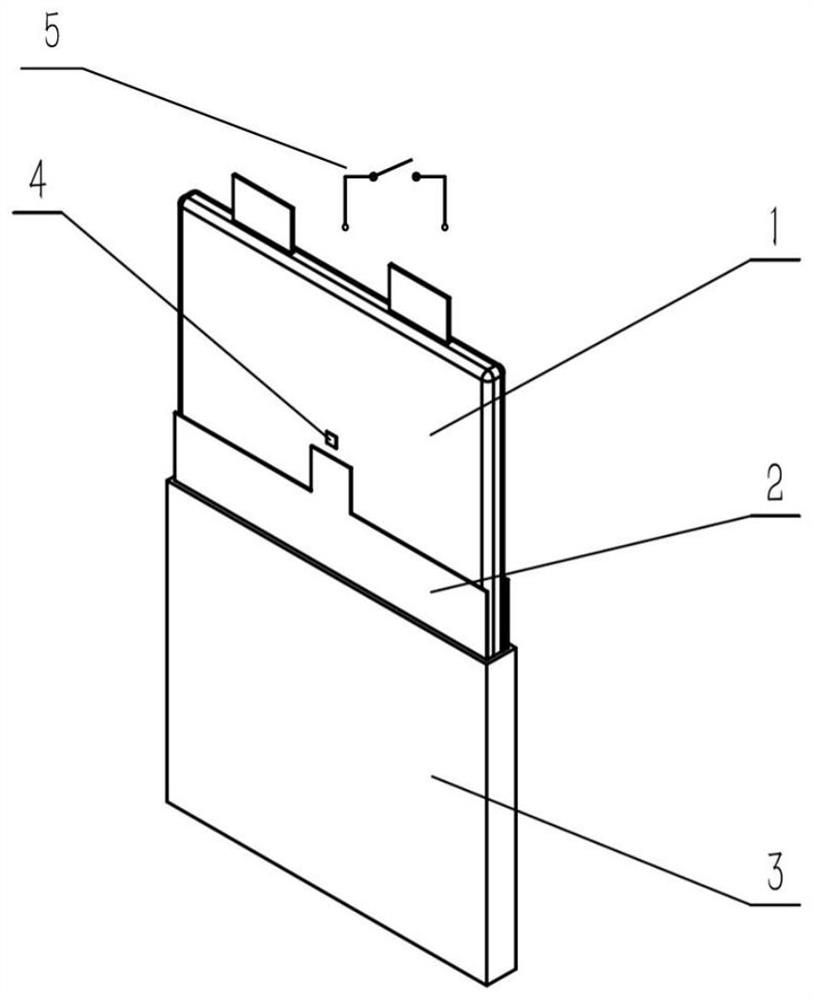

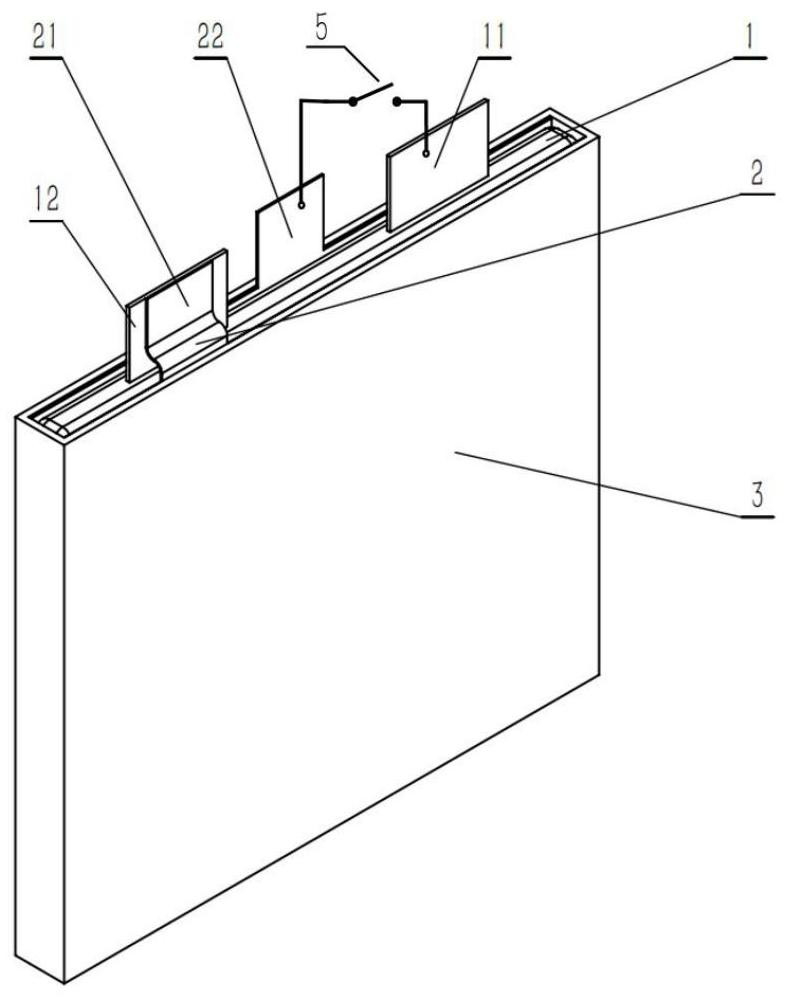

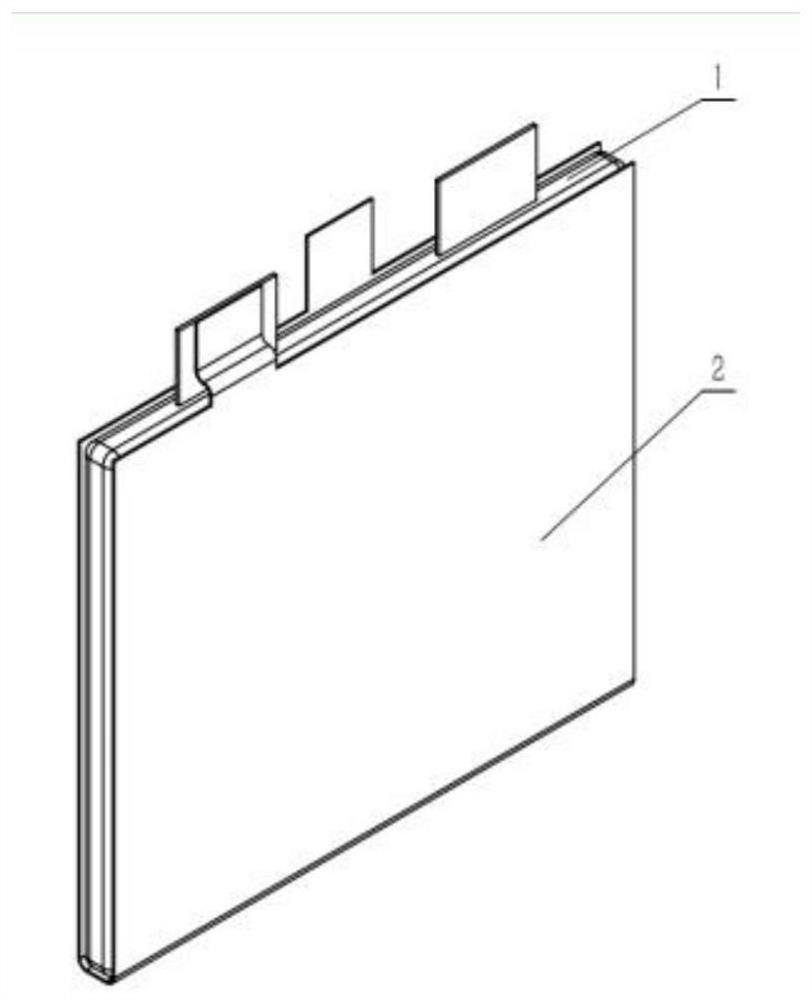

Heat-resistant composite foil with rapid heating function as well as battery cell and battery made of heat-resistant composite foil

ActiveCN109378556AQuickly and evenly increase the temperature of the battery cellGood discharge performanceSecondary cellsVoltageThermal efficiency

The invention discloses heat-resistant composite foil with a rapid heating function as well as a battery cell and a battery made of the heat-resistant composite foil. The heat-resistant composite foilcomprises two pieces of foil and at least one layer of heat-resistant sheet located between the two pieces of foil; the heat-resistant sheet is separated from the foil by an insulating layer; the adjacent heat-resistant sheets are separated by the insulating layer when more than two layers of heat-resistant sheets are provided; and the heat-resistant sheet is provided with at least one heat-resistant sheet lug. The heat-resistant composite foil disclosed by the invention is novel in structure; the heat-resistant sheet lug is connected with an external power source or an internal power source,so that the heat-resistant composite foil can be rapidly heated after the power source is electrified; due to the adoption of the heating way, the heat conducting speed is high, heat is uniformly generated inside the battery cell, a voltage window of the battery cell can be controlled better, most of the generated heat is capable of raising the temperature of a pole piece, and the heat efficiencyis high; in addition, the heat-resistant composite foil is capable of increasing the capacity and efficiency of the battery cell and improving the cycle performance of the battery cell.

Owner:CONTEMPORARY AMPEREX TECH CO

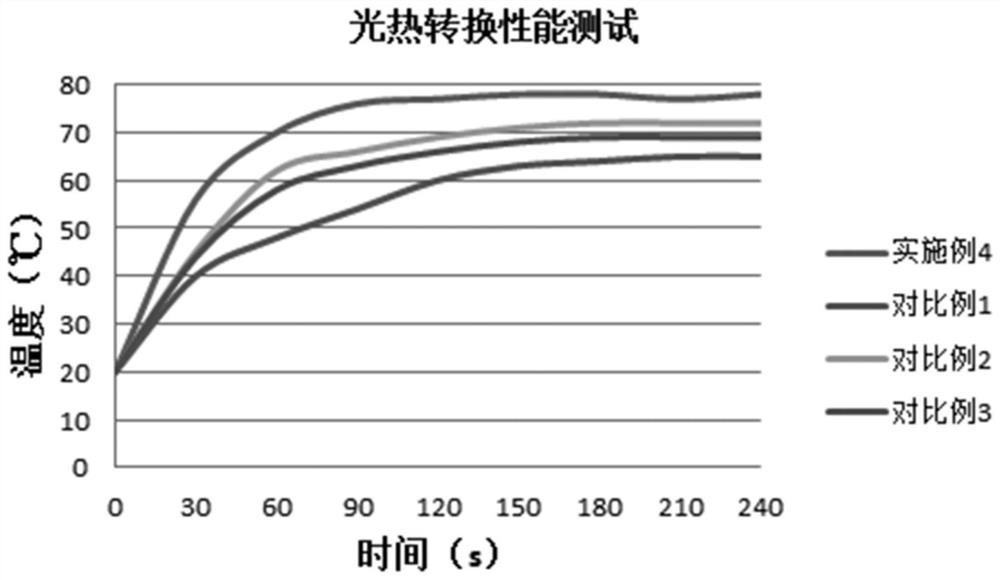

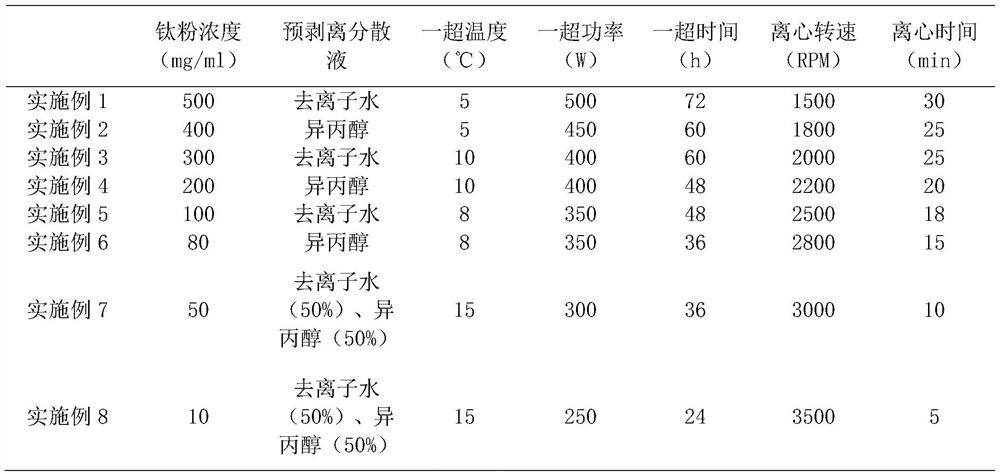

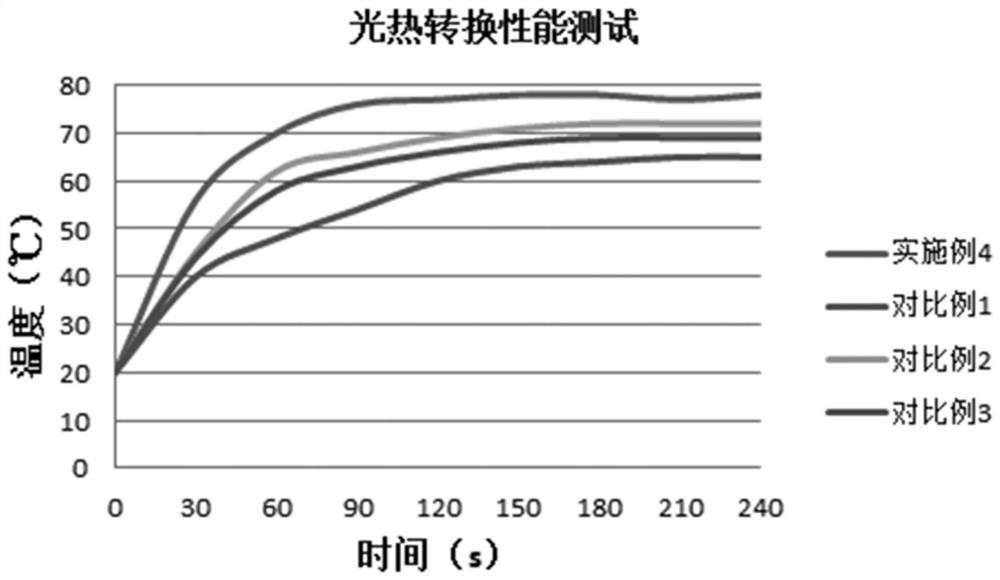

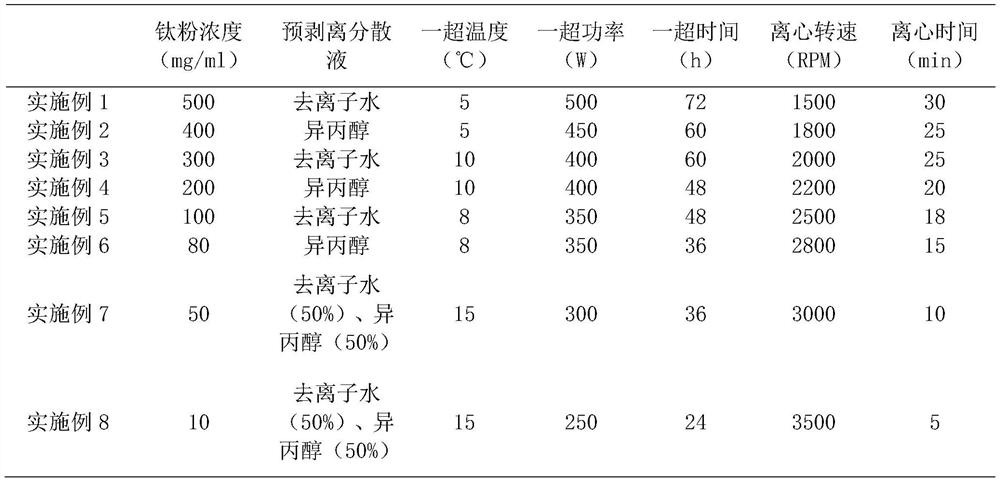

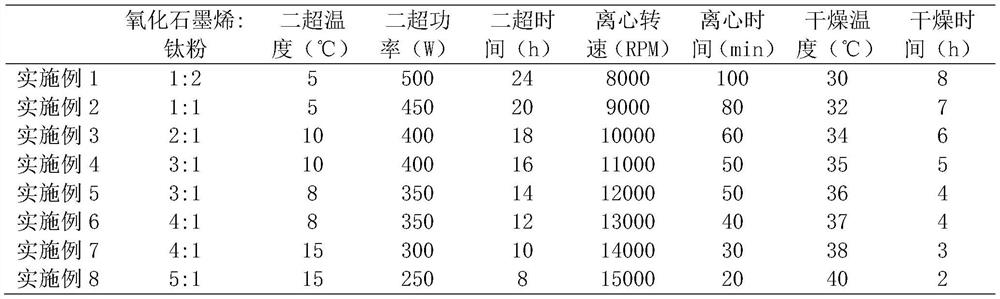

Titanium nanosheet/graphene-based heating film

InactiveCN112004274APrevent leakageRealize diversified heat production functionsMaterial nanotechnologyOhmic-resistance heatingFiberGraphite

The invention provides a titanium nanosheet / graphene-based heating film which comprises a first transparent insulating layer, an electrode, a second transparent insulating layer and a titanium nanosheet / graphene-based fiber membrane, wherein the first transparent insulating layer covers one surface of the titanium nanosheet / graphene-based fiber membrane; the second transparent insulating layer covers the other surface of the titanium nanosheet / graphene-based fiber membrane, one end of the electrode is electrically connected with the titanium nanosheet / graphene-based fiber membrane, and the other end of the electrode extends out of the first transparent insulating layer or the second transparent insulating layer. According to the titanium nanosheet / graphene-based heating film, by means of the efficient photo-thermal conversion efficiency and electro-thermal conversion efficiency of the titanium nanosheet / graphene-based fiber film, the electro-thermal and photo-thermal diversified heat production functions are achieved.

Owner:北京康烯科技创新研究有限公司

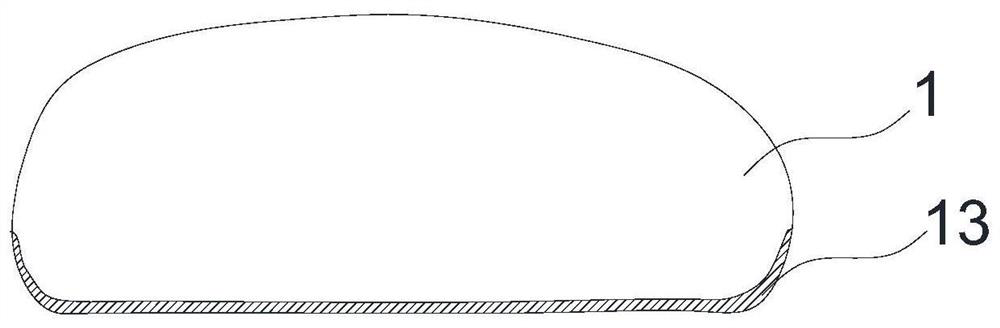

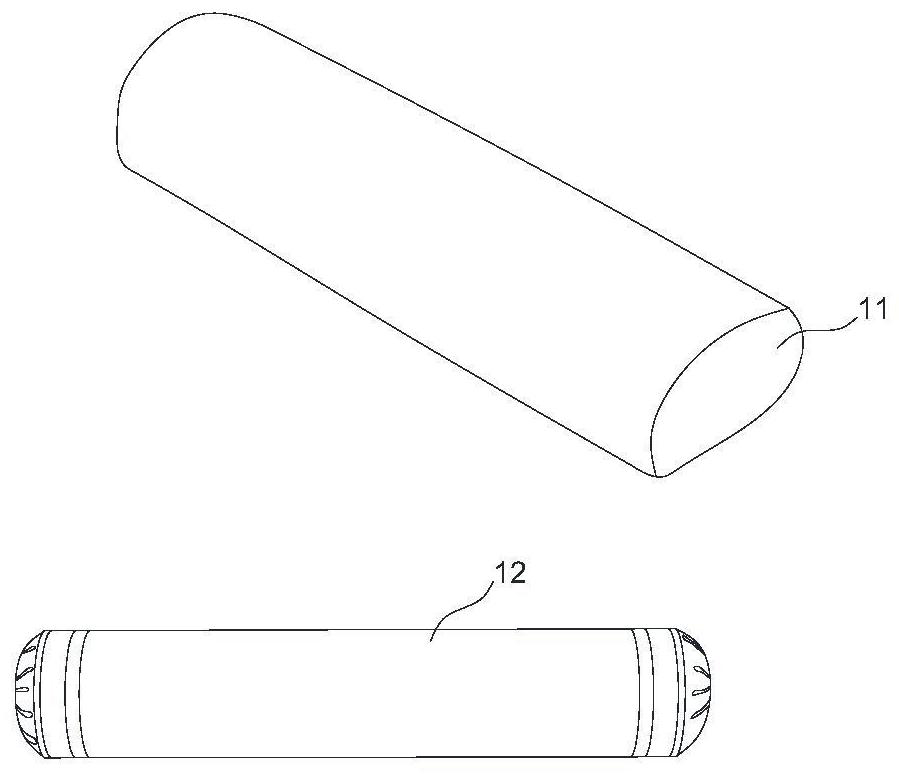

Palladium nanosheet/graphene-based hot compress medicine pillow

InactiveCN112021893AImprove heat production efficiencyLarge specific heat capacityPillowsFilament/thread formingAntibiosisFiber

The invention provides a palladium nanosheet / graphene-based hot compress medicine pillow, which comprises a pillowcase and a pillow inner, the pillowcase comprises a flexible contact layer and a palladium nanosheet / graphene-based heating film, the flexible contact layer is arranged on the outer side of the pillowcase, the palladium nanosheet / graphene-based heating film is arranged on the inner side of the pillowcase, and the flexible contact layer covers the palladium nanosheet / graphene-based heating film; the pillow inner comprises a flexible containing bag and heat storage gel, and the heatstorage gel is contained in the flexible containing bag. According to the palladium nanosheet / graphene-based hot compress medicine pillow, by means of the efficient electrothermal conversion efficiency, the high infrared normal emissivity, the antibacterial function and the good flexibility and elasticity of the palladium nanosheet / graphene-based fiber membrane, the medicine pillow can act on epidermis for antibiosis, release of medicine active ingredients is promoted, the high infrared normal emissivity can also play a role in promoting blood circulation, relaxing pores, improving the epidermal absorption effect and the like.

Owner:北京康烯科技创新研究有限公司

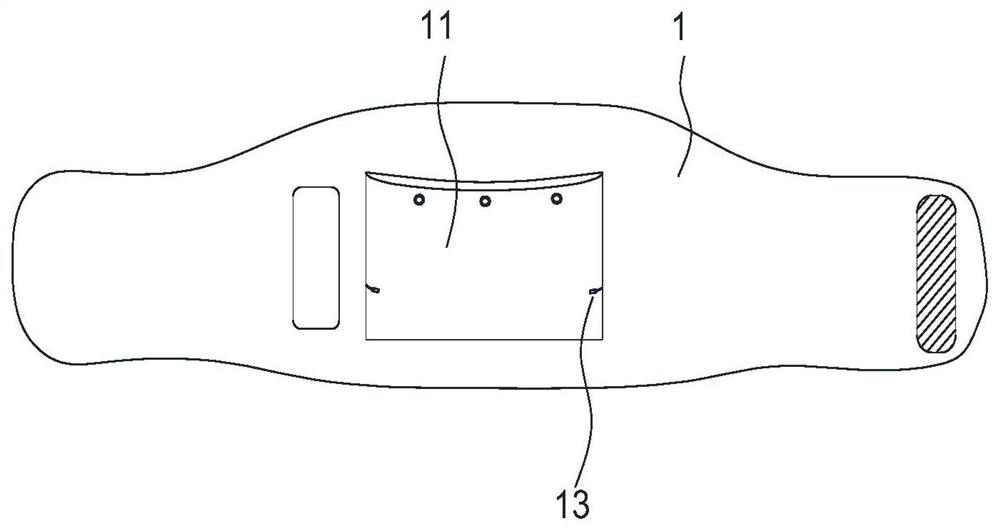

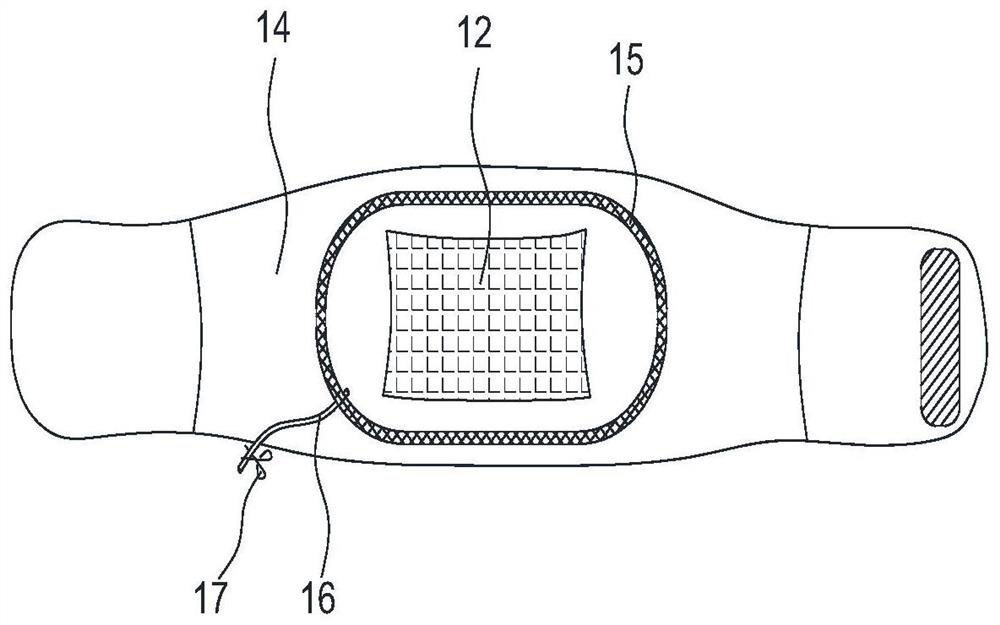

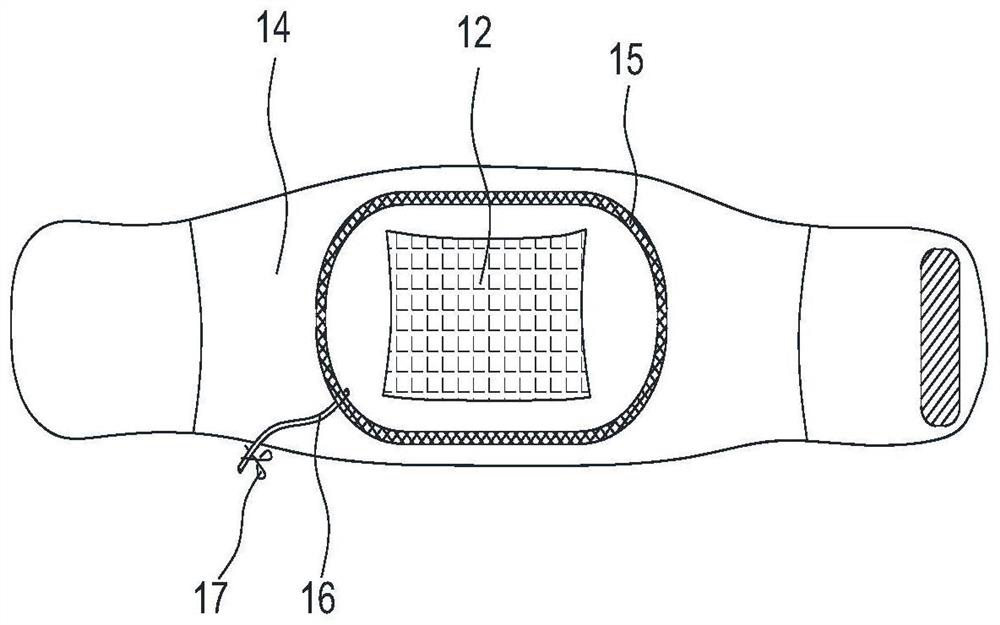

Cold and hot compress bag for medical treatment

InactiveCN107822769AChange temperatureMeet actual needsTherapeutic coolingTherapeutic heatingEngineeringStructural stability

Owner:FOSHAN XUNYUAN MEDICAL EQUIP CO LTD

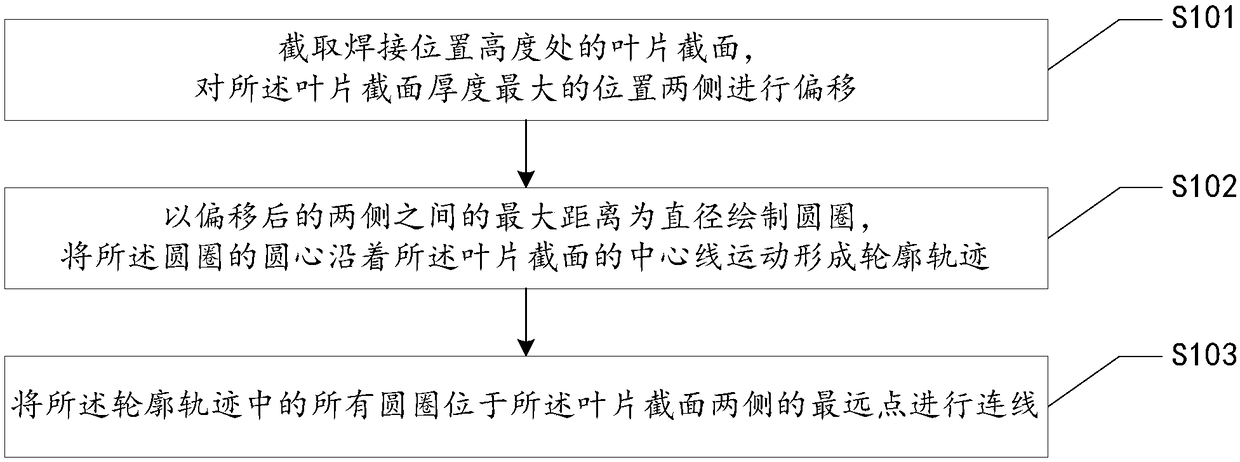

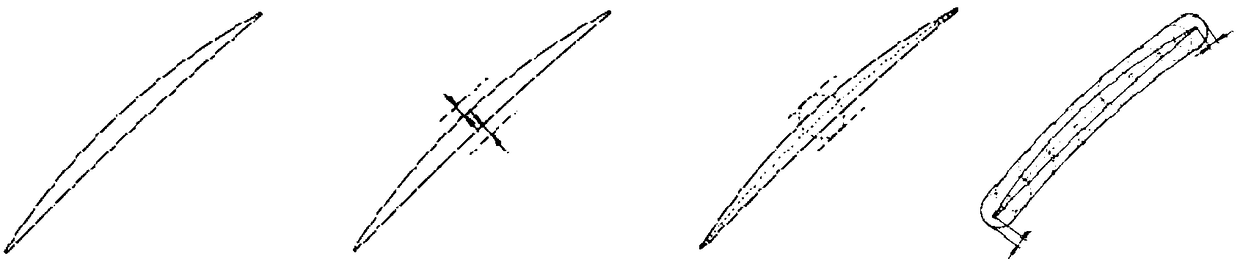

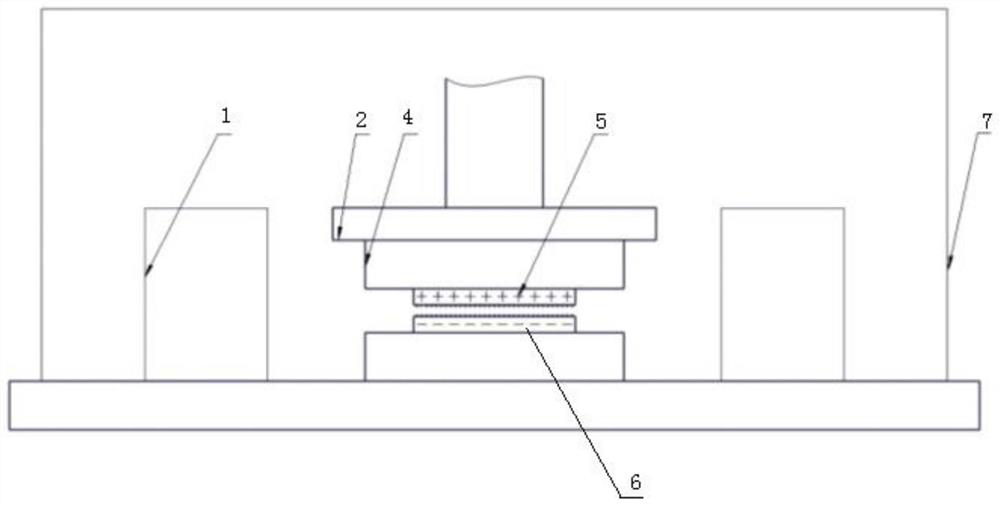

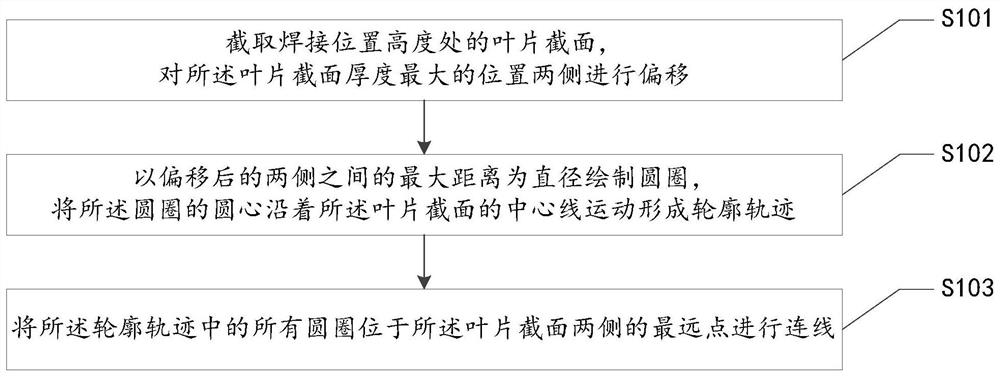

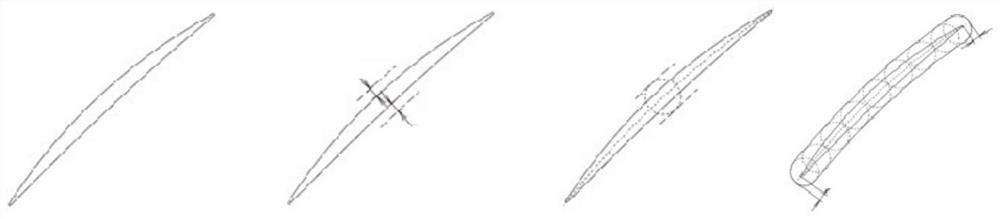

Quality control method and device for blade linear friction welding joint

ActiveCN109175673AUniform heat generationReduce wasteNon-electric welding apparatusLine segmentLarge distance

The invention discloses a quality control method for a blade linear friction welding joint. The method comprises the steps that the cross section of a blade at the height of a welding position; two sides of the position, which is the highest in thickness, of the cross section of the blade are displaced; a circle is drawn by taking the largest distance between the two sides after displacement as the diameter; the center of the circle is the middle spot of the largest distance segment between the two sides after displacement; the circle center of the circle moves along the central line of the cross section of the blade to form an outline trajectory; the farthest spots, located on two sides of the cross section of the blade, of all circles in the outline trajectory are connected; and the zonewhich is surrounded by the circles on the two ends of the cross section of the blade and two segments formed after connection is taken as the cross section zone of welding. The invention further discloses a blade linear friction welding joint quality control device. By adopting the quality control method and device, the problem that an unfused defect is prone to being formed at an angle part of atraditional rectangular or diamond cross section is overcome; the welding area of a component is effectively decreased, and the quality of the welding joint is ensured; and waste of precious metal isgreatly reduced.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Non-layered molybdenum nanosheet/graphene-based traditional Chinese medicine hot compress device

InactiveCN112006838AEasy to cleanPromote circulationMaterial nanotechnologyMedical devicesEngineeringGraphite

The invention provides a non-layered molybdenum nanosheet / graphene-based traditional Chinese medicine hot compress device. The device is characterized by comprising a hot compress sleeve and a non-layered molybdenum nanosheet / graphene-based heating film, a first accommodating bag is arranged on the outer side of the hot compress sleeve, the first accommodating bag is used for accommodating the non-layered molybdenum nanosheet / graphene-based heating film, a second accommodating bag is arranged on the inner side of the hot compress sleeve, and the second accommodating bag is used for accommodating a traditional Chinese medicine bag. According to the non-layered molybdenum nanosheet / graphene-based traditional Chinese medicine hot compress device, by means of the high-efficiency photo-thermalconversion efficiency and electro-thermal conversion efficiency of the non-layered molybdenum nanosheet / graphene-based heating film, the functions of electric heating and photo-thermal diversified heat production are achieved, and the device has the effects of being high in active ingredient absorption rate, stable in heat production and the like.

Owner:北京康烯科技创新研究有限公司

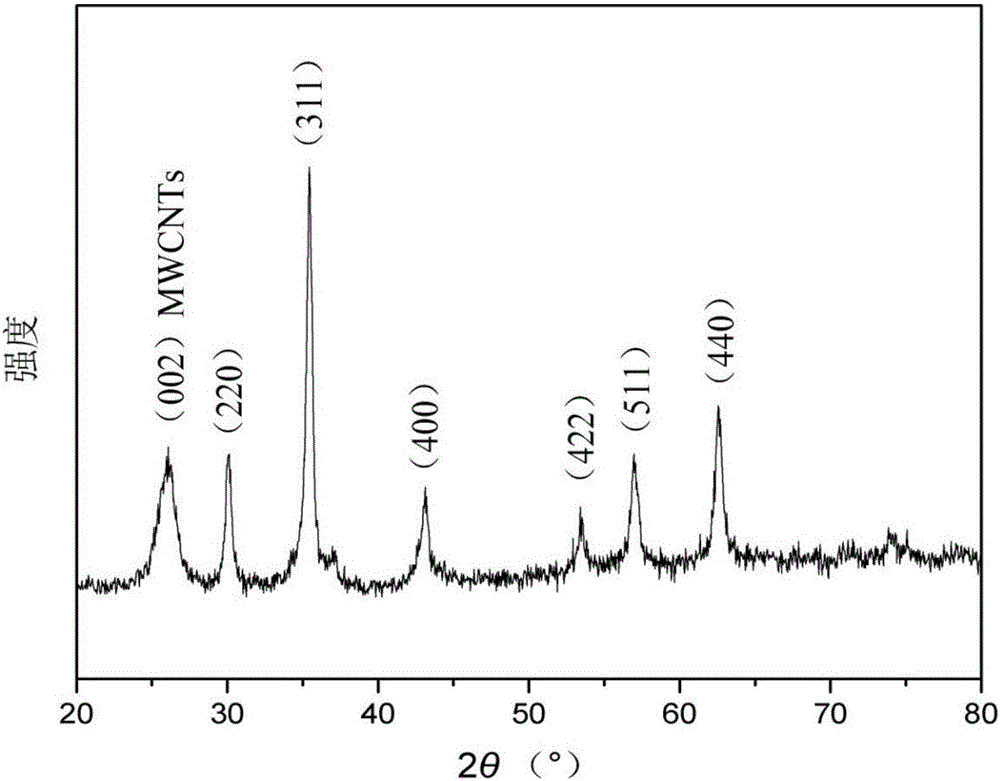

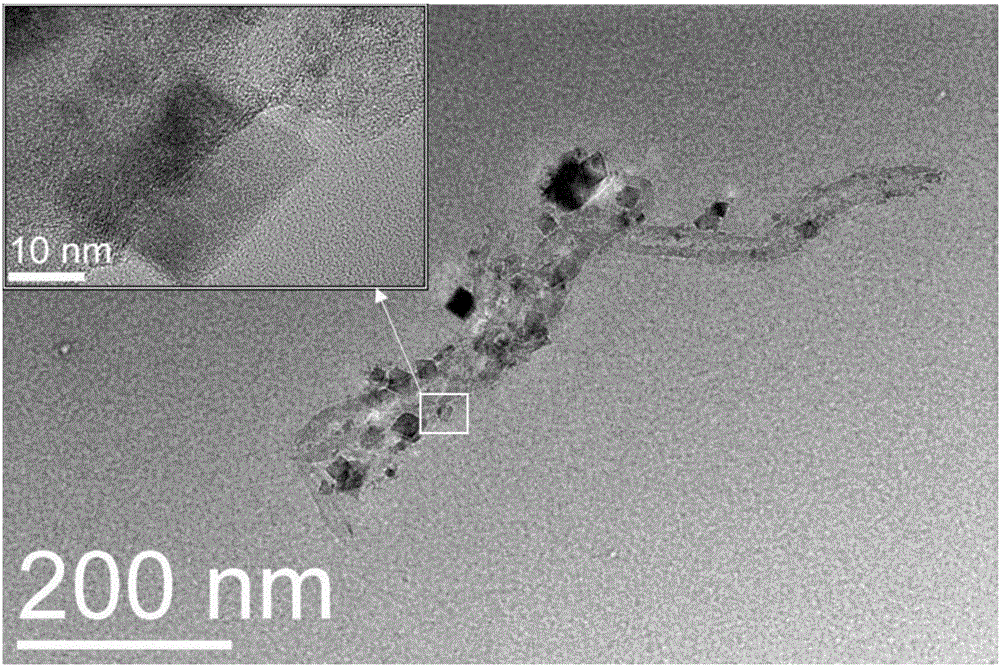

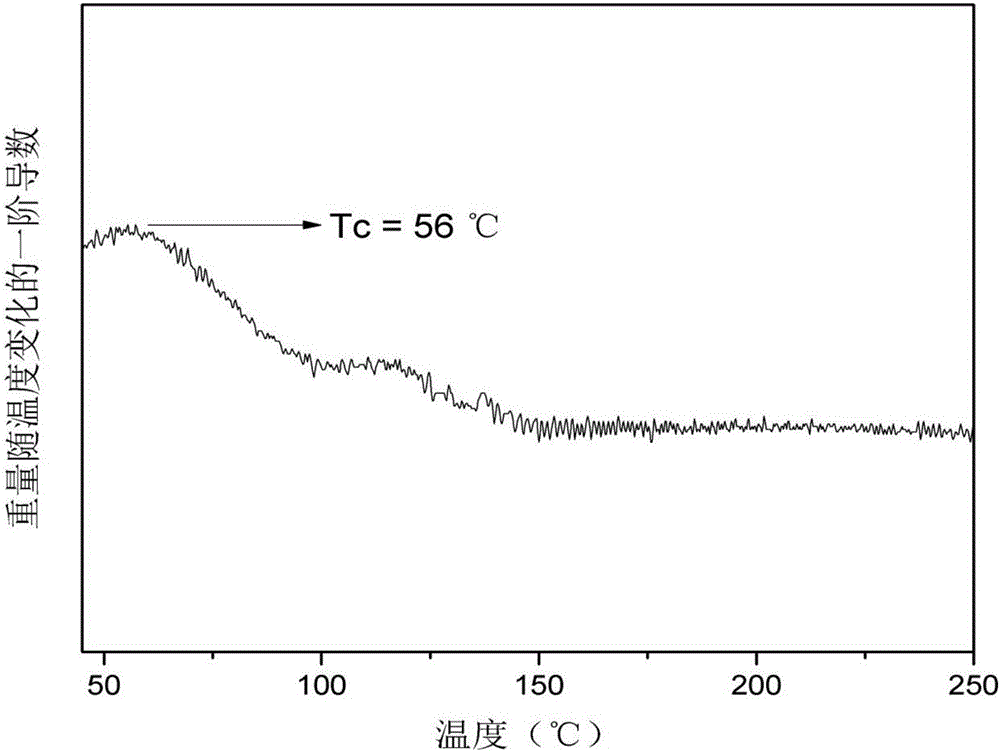

Preparation method of magnetic carbon nanotubes with low Curie temperature

ActiveCN105948020AImprove physical stabilityGood chemical stabilityMaterial nanotechnologyEnergy modified materialsDispersityMagnetite Nanoparticles

The invention belongs to the technical field of magnetic induction thermotherapy for tumors and provides a preparation method of magnetic carbon nanotubes with low Curie temperature. The preparation method comprises the following steps: 1) preparing a NaOH aqueous solution to serve as a precipitant; 2) dissolving CoCl2.6H2O, FeCl3.6H2O, CrCl3.6H2O, ZnCl2 and surface modified carbon nanotubes in deionized water to obtain a precursor solution; 3) adding the precipitant dropwise to the precursor solution to obtain a reaction liquid after stirring; 4) transferring the reaction liquid to an autoclave, sealing the autoclave, performing a reaction for 2-3 h and obtaining a black product through natural cooling; 5) washing and drying the black product to obtain the magnetic carbon nanotubes with low Curie temperature. According to the preparation method, the loading quantity of low-Curie-temperature magnetic nanoparticles on the carbon nanotubes is controlled by changing the proportion of initial raw materials, and the magnetic carbon nanotubes with different dispersity and heat production efficiency are obtained, have good dispersity and are applied to magnetic induction thermotherapy for the tumors.

Owner:DALIAN UNIV OF TECH

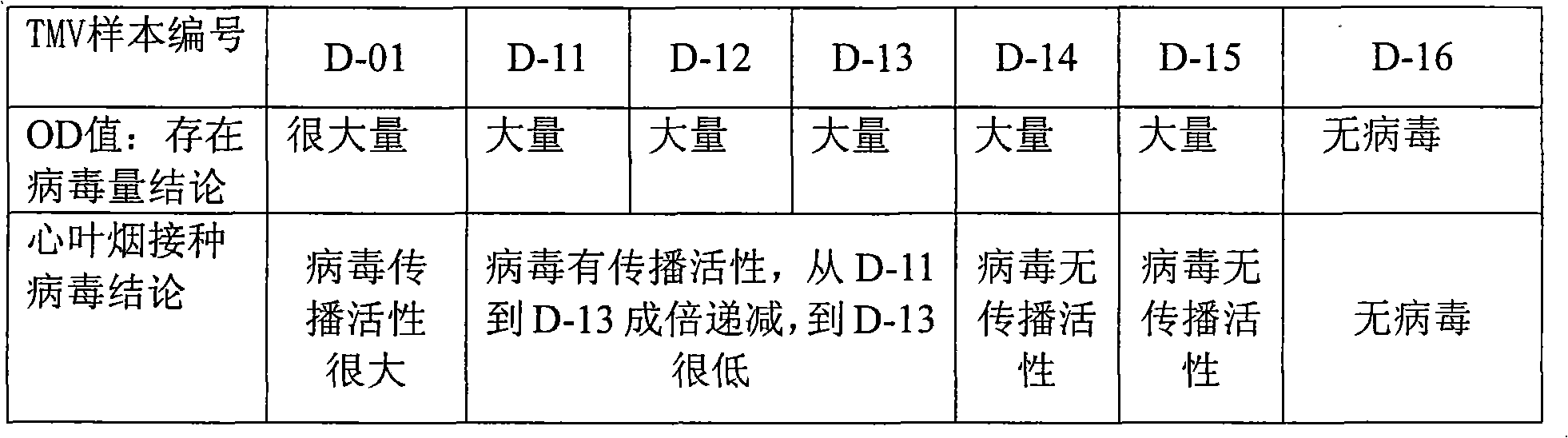

Application of microwave technology in control on disease and insect damage to tobacco

InactiveCN101889567AFast disinfectionReduce damageInsect catchers and killersRadiationNicotiana tabacumDisease

The invention relates to application of a microwave technology in control on disease and insect damage to tobacco. By using the microwave technology to control the disease and insect damage to tobacco, the invention can effectively control the disease and insect damage to tobacco, especially tobacco mosaic virus diseases, in the aspects of tobacco seedling raising, tobacco planting, tobacco baking and seasoning, tobacco planting soil, tobacco storage and the like, and achieves better disease and insect damage control effect. Besides, the invention can not generate pesticide residue and environmental pollution.

Owner:云南天禾地生物科技股份有限公司

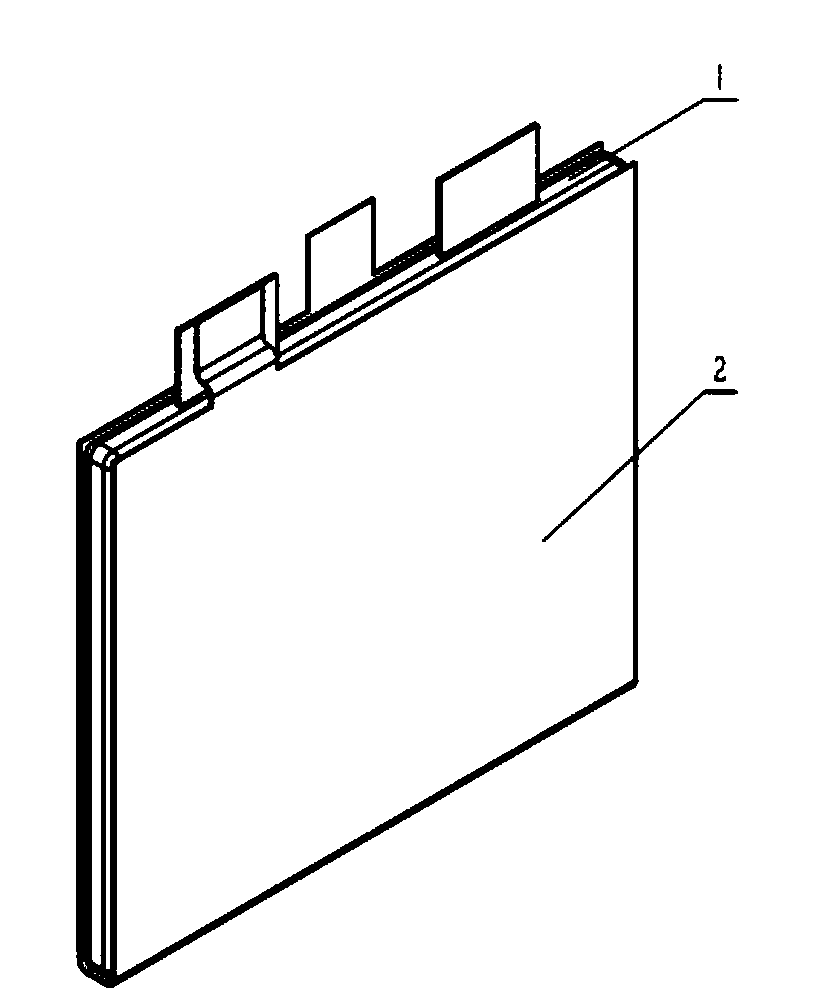

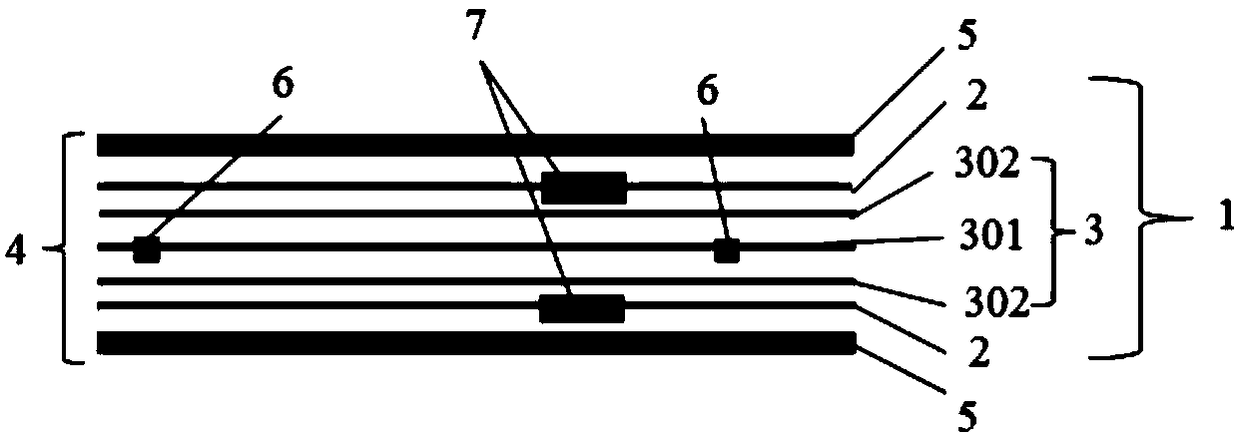

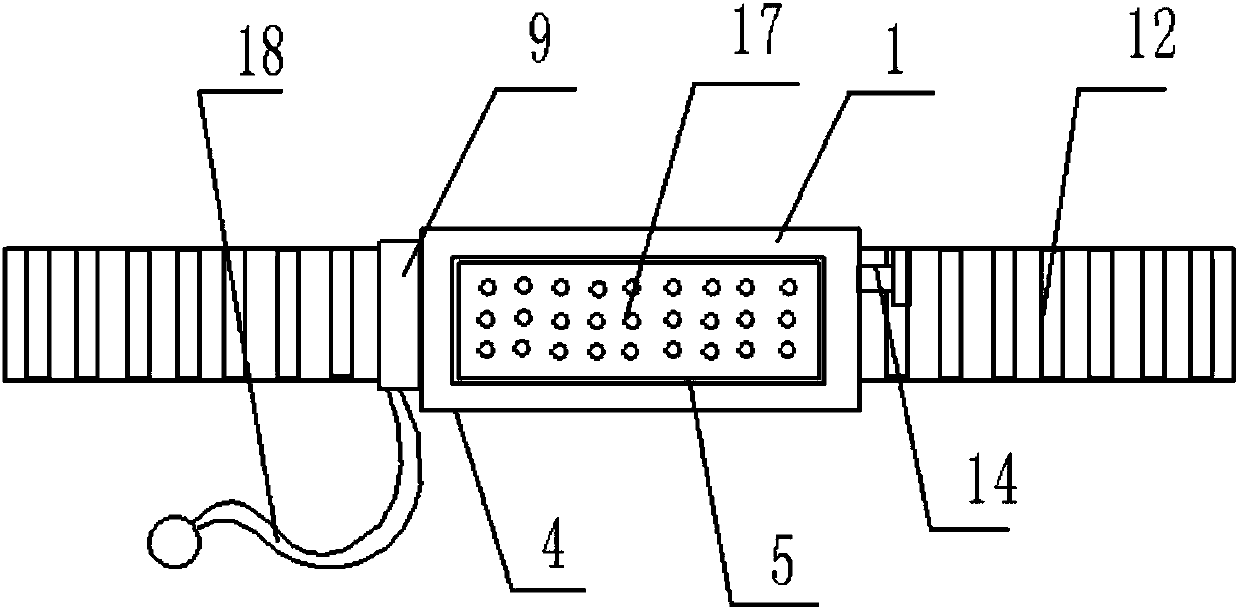

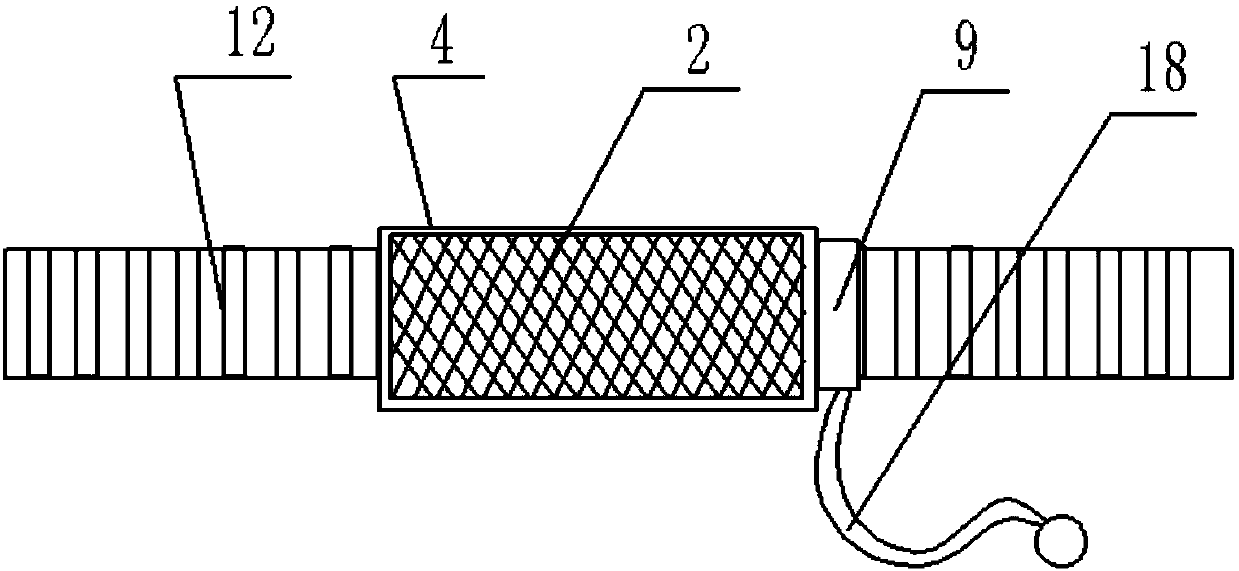

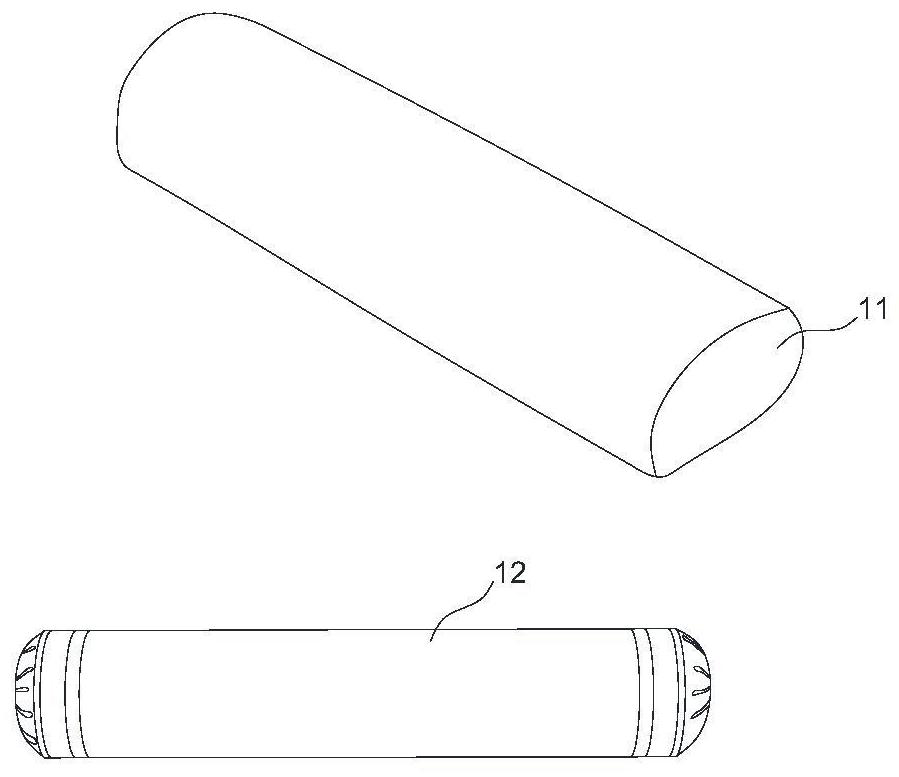

Composite positive electrode sheet with rapid heating function, and cell and battery using the same

ActiveCN109244598AFast and even temperatureIncrease temperatureSecondary cellsCapacity efficiencyEngineering

The invention discloses a composite positive electrode sheet with a rapid heating function, and a cell and a battery adopting the same. The composite positive electrode sheet comprises two positive electrode sheets and at least one layer of thermal resistance sheets, wherein the thermal resistance sheets and the positive electrode sheets are separated by a diaphragm; when the number of layers of the thermal resistance sheets is more than two, the adjacent thermal resistance sheets are separated by a diaphragm; and at least one thermal resistance sheet electrode lug is arranged on the thermal resistance sheets. The composite positive electrode sheet of the invention has novel structure, As that lug of the thermal resistor are connected with an external power supply or an internal power supply, This heating method has the advantages of fast heat conduction, uniform heat generation inside the cell, and better control of the cell voltage window. Most of the heat generated can accurately raise the temperature of the electrode plate, and the thermal efficiency is high. Moreover, the composite positive electrode plate can improve the capacity efficiency and cycle performance of the cell.

Owner:CONTEMPORARY AMPEREX TECH CO

Heat radiation type printing and dyeing drying device

InactiveCN104913614AExtended drying timeExtension of timeDrying machines with progressive movementsHeating arrangementCombustionPulp and paper industry

The invention provides a heat radiation type printing and dyeing drying device. The drying device comprises a box, a transmission mechanism and a drying mechanism; one end of the box is provided with a drying inlet, and the other end of the box is provided with a drying outlet; the transmission mechanism comprises inlet transmission rollers, an outlet wind-up roller and transmission rollers in the box, the inlet transmission rollers correspond to the drying inlet in position, the outlet wind-up roller corresponds to the drying outlet in position, and the transmission rollers are uniformly and rotationally connected in the box in a staggered mode; the drying mechanism comprises a radiation tube, combustion tubes, combustion nozzles and a gas leading pipe, the radiation tube penetrates through the box, the two ends of the radiation tube are connected with the combustion tubes, and one ends, away from the radiation tube, of the combustion tubes are sequentially connected with the combustion nozzles and the gas leading pipe. The heat radiation type printing and dyeing drying device has the advantages of being simple in structure, small in size, low in production cost, capable of using waste heat for drying and low in energy consumption, generating heat uniformly, ensuring the drying quality of cloth and reducing use cost.

Owner:JIANGSU SHUANGYING TEXTILE TECH

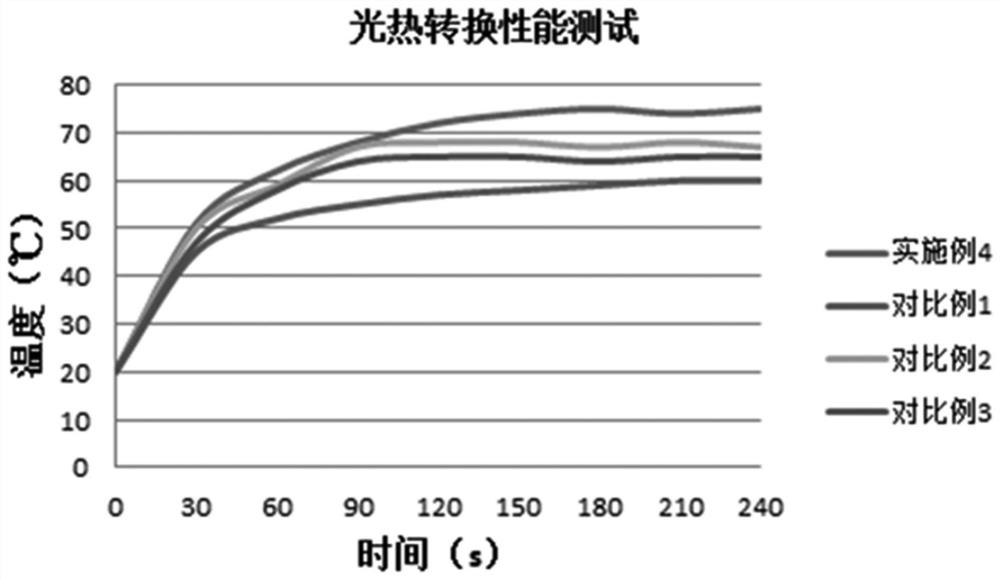

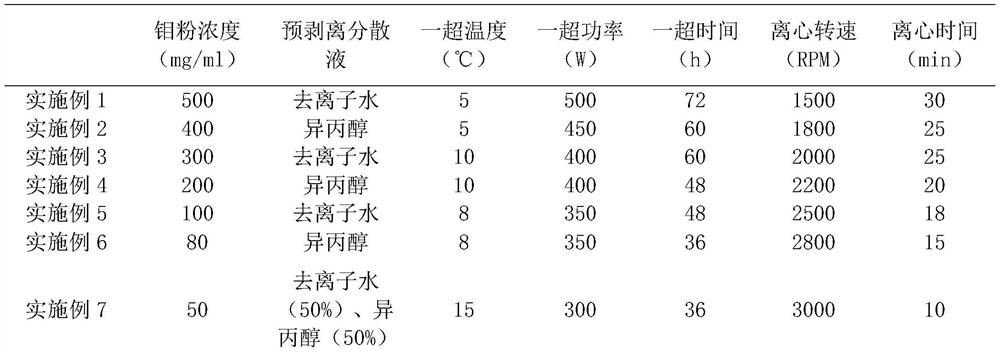

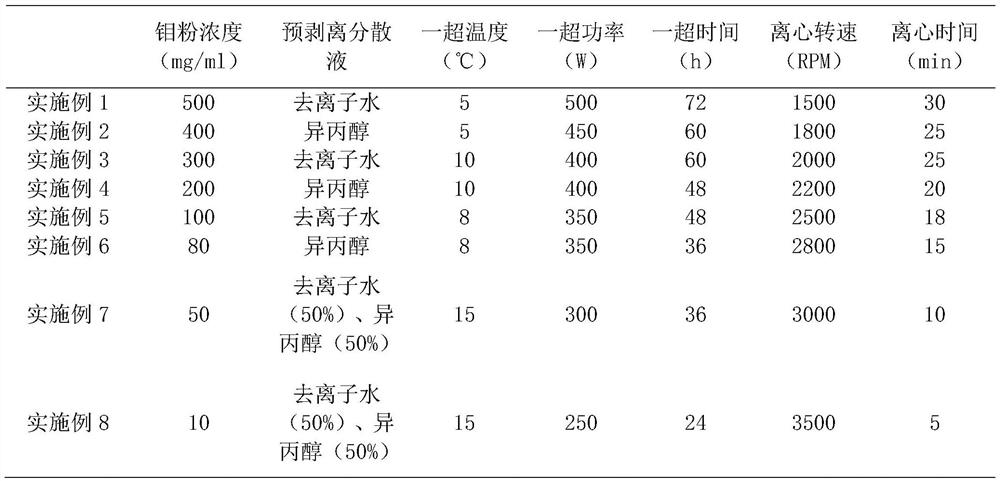

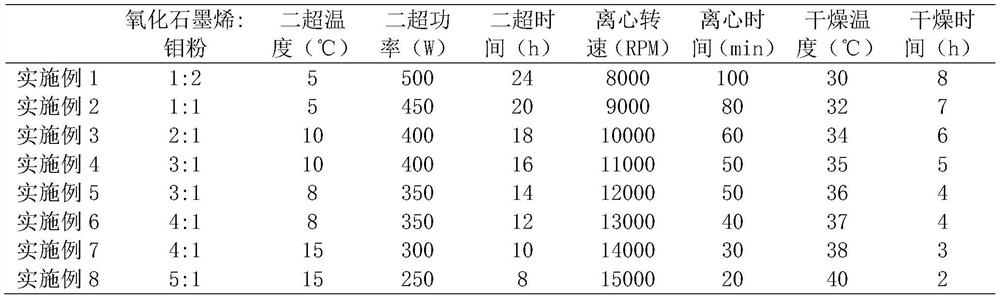

Non-layered molybdenum nanosheet/graphene-based fiber membrane and preparation method thereof

ActiveCN112030349AHigh porosityImprove flexibilityFilament forming substance formingNon-woven fabricsFiberGraphite oxide

The invention provides a preparation method of a non-layered molybdenum nanosheet / graphene-based fiber membrane. The preparation method comprises the following steps of preparing a pre-stripping dispersion solution of molybdenum powder, preparing a mixture of the molybdenum powder and graphene oxide, preparing a non-layered molybdenum nanosheet / graphene oxide dispersion solution and carrying out spinning and aftertreatment. According to the preparation method of the non-layered molybdenum nanosheet / graphene-based fiber membrane, the graphene oxide is added in the preparation process of a non-layered molybdenum nanosheet, the molybdenum powder can be assisted in being stripped into the non-layered molybdenum nanosheet, and the non-layered molybdenum nanosheet and the graphene oxide can be uniformly mixed. In the spinning process, the non-layered molybdenum nanosheet, graphene and the carbon black are further loaded onto a fiber, and the fiber has the advantages that the specific surfacearea is large, infrared radiation is strong, thermal conductivity is high, flexibility is good, and the bending-resistant effect is remarkable. The invention further provides the non-layered molybdenum nanosheet / graphene-based fiber membrane.

Owner:北京康烯科技创新研究有限公司

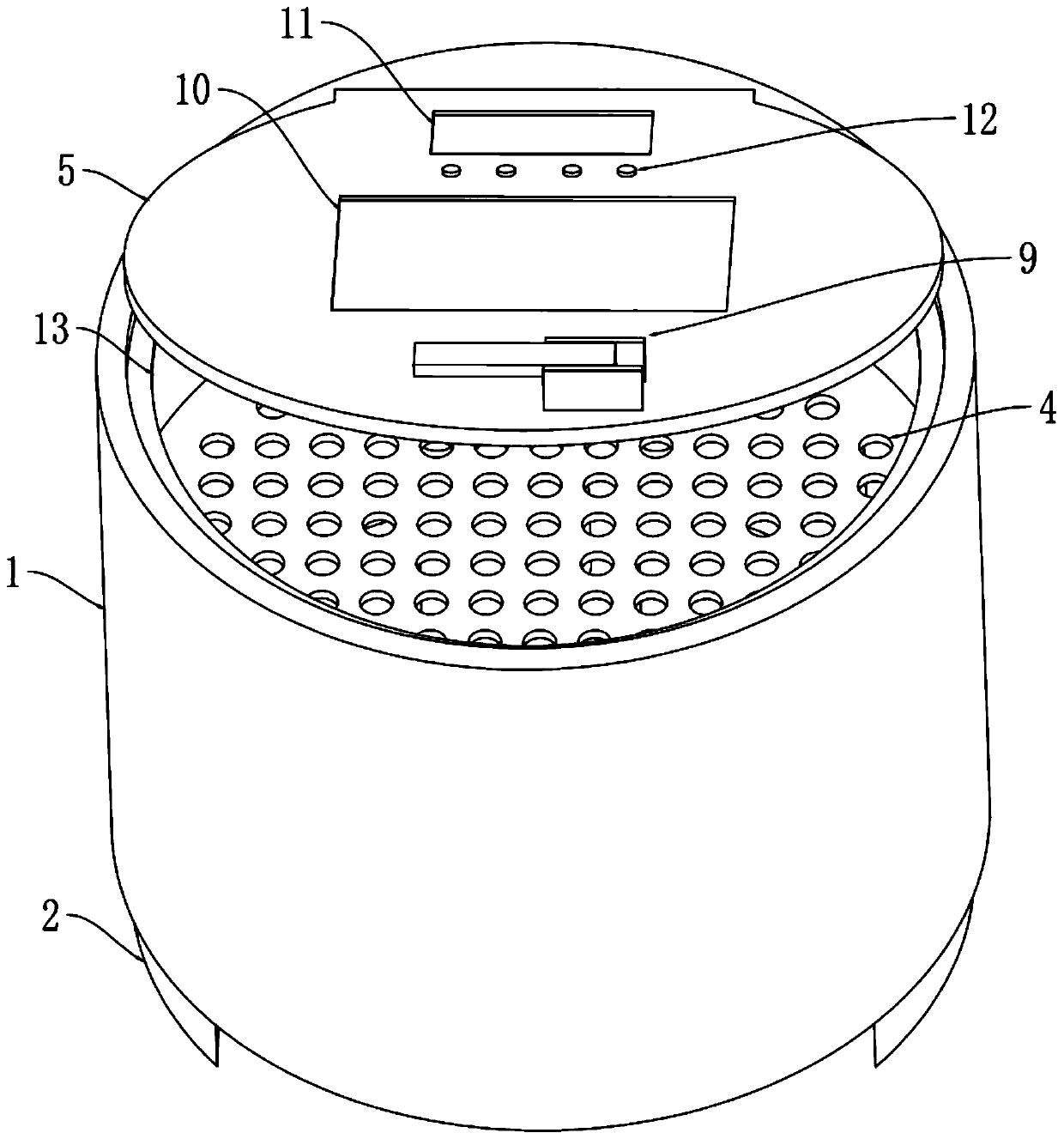

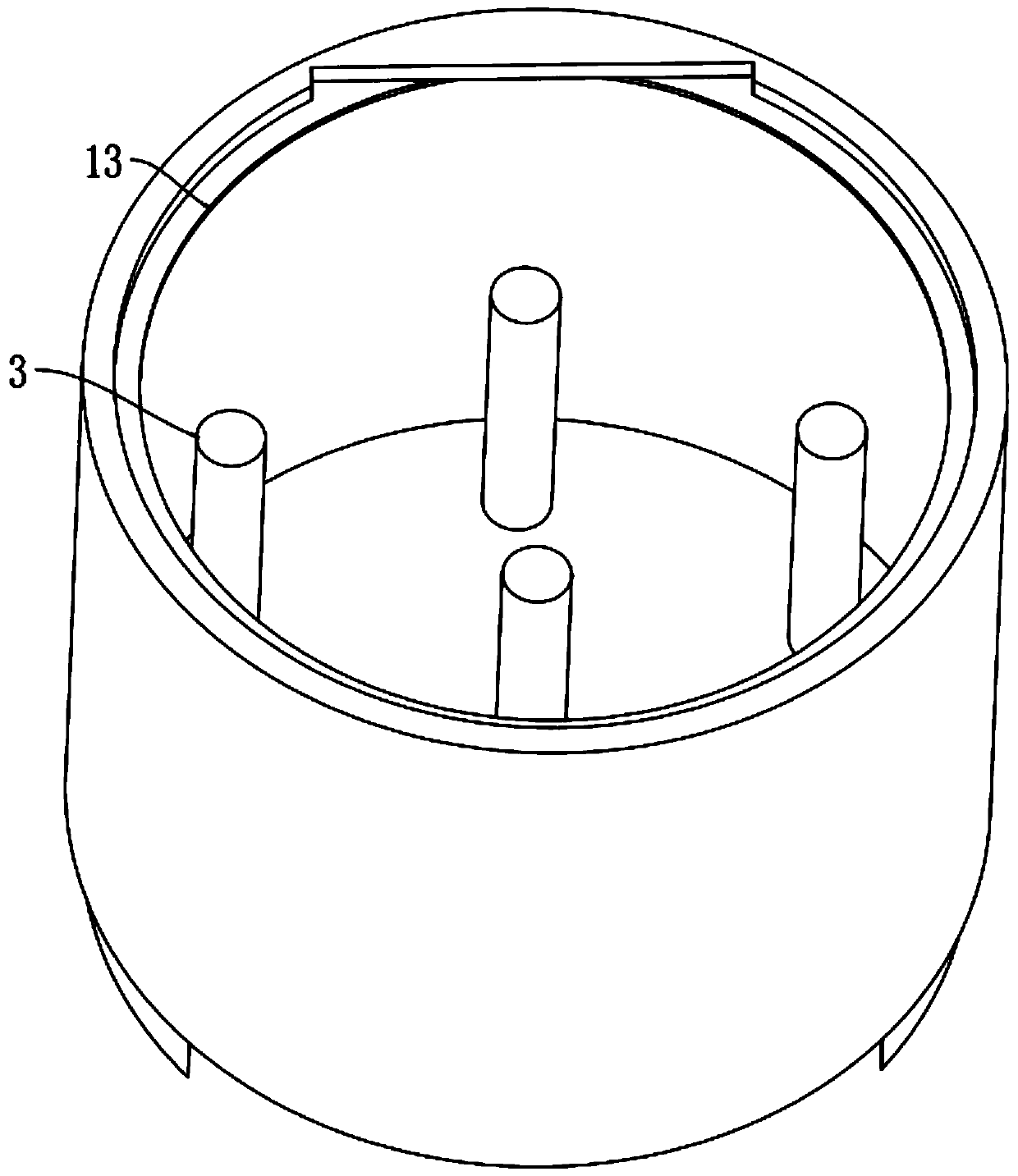

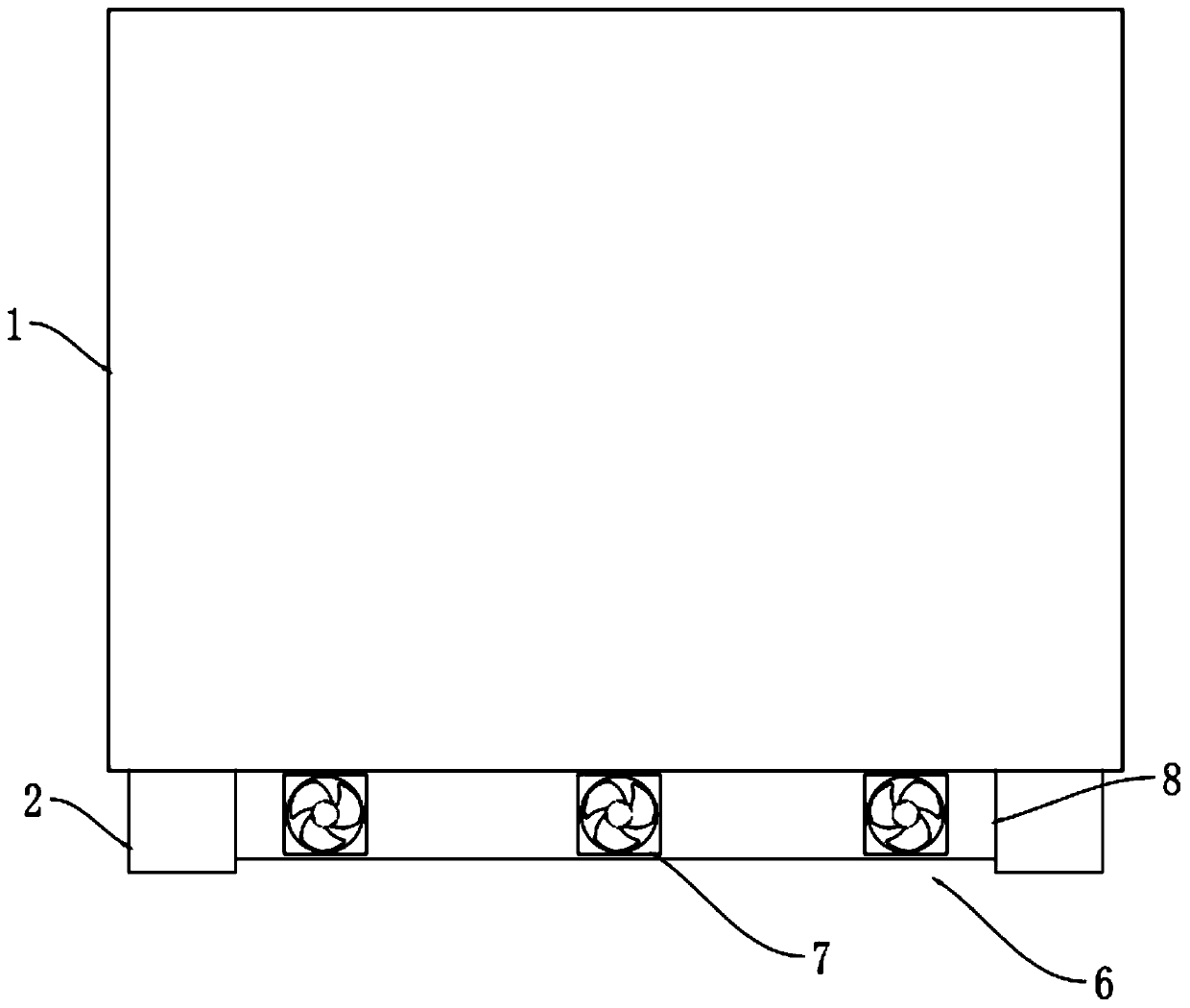

Vacuum drying oven

InactiveCN111520976ASimple structureReasonable designDrying solid materials without heatDrying chambers/containersHeater RodEngineering

The invention discloses a vacuum drying oven. The vacuum drying oven comprises a drying oven body, bases, electric heating rods, a supporting frame, a sealing cover and a heat accumulation preventingpart; the drying oven body is of a cylindrical hollow cavity structure with an opening in the upper end, the bases are symmetrically arranged at the bottom of the drying oven body, and the electric heating rods are arranged on the inner bottom wall of the drying oven body and are evenly distributed in a concentric circle mode; and the supporting frame is arranged in the drying oven body and arranged on the electric heating rods in a covering mode, the sealing cover is rotatably arranged at the opening in the upper wall of the drying oven body, and the heat accumulation preventing part is arranged on the bottom wall of the drying oven body and arranged between the bases. The invention belongs to the field of medical instruments, and particularly relates to the drying oven body with the cylindrical structure and the opening at the upper end, uniform heat is generated through the heating rods arranged in the concentric circle structure inside, and uniform distribution of heat is facilitated; and meanwhile, the bottom of the drying oven is subjected to forced convection heat exchange, and accelerated aging of the cable due to heat accumulation is prevented.

Owner:西安凯翔光电科技有限公司

Electric welding forming method for large-size amorphous alloys and bulk amorphous alloys

PendingCN113732478AGuaranteed heating temperatureUniform heat generationLaser beam welding apparatusNon-electric welding apparatusElectric heatingElectric discharge

The invention relates to the technical field of amorphous alloy connection, in particular to an electric discharge welding forming method and an electric heating welding forming method for large-size amorphous alloys. The electric discharge welding forming method comprises the following steps that S1, the first amorphous alloy and the second amorphous alloy are adopted, and tip microstructures are machined on to-be-welded interfaces; S2, the to-be-welded interface of the first amorphous alloy and the to-be-welded interface of the second amorphous alloy are made to be opposite, and a certain distance is reserved between the to-be-welded interface of the first amorphous alloy and the to-be-welded interface of the second amorphous alloy; S3, magnetic fields are applied to both the first amorphous alloy and the second amorphous alloy, and the first amorphous alloy and the second amorphous alloy are both connected to an electric discharge system; and S4, the electric discharge system is started, then the first amorphous alloy and the second amorphous alloy are driven to be pressed, and pressing pressure is applied till the first amorphous alloy and the second amorphous alloy are welded and formed. The electric discharge welding method has the advantages of being high in welding speed and high in welding quality, and the electric heating welding forming method improves the heating uniformity by increasing the magnetic field control and an auxiliary heating device.

Owner:GUANGDONG UNIV OF TECH

Method and device for quality control of blade linear friction welding joints

ActiveCN109175673BUniform heat generationGuarantee welding qualityNon-electric welding apparatusFriction weldingQuality control

The invention proposes a quality control method for linear friction welding joints of blades. The method includes: intercepting the blade section at the height of the welding position; offsetting the two sides of the position with the largest thickness of the blade section; The maximum distance is the diameter to draw a circle, and the center of the circle is the midpoint of the maximum distance line segment between the two sides after the offset; the center of the circle is moved along the centerline of the blade section to form a contour track; All circles are connected at the farthest points on both sides of the blade section, and the area enclosed by the two line segments after the connection and the circles at both ends of the blade section is the welded section area. The invention also provides a quality control device for blade linear friction welding joints. The invention overcomes the problem that the traditional rectangular and rhombus cross-sections tend to produce unwelded defects at the corners. Effectively reduce the welding area of components and ensure the quality of welded joints, and greatly reduce the waste of precious metals.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Titanium nanosheet/graphene-based hot compress drug pillow

InactiveCN111991137AHigh porosityImprove flexibilityPillowsMedical devicesPharmaceutical drugGraphene

The invention provides a titanium nanosheet / graphene-based hot compress drug pillow. The drug pillow comprises a pillow case and a pillow core, wherein the pillow case comprises a flexible contact layer and a titanium nanosheet / graphene-based heating film; the flexible contact layer is arranged outside the pillow case, the titanium nanosheet / graphene-based heating film is arranged inside the pillow case and covers the titanium nanosheet / graphene-based heating film; and the pillow core comprises a flexible containing bag and heat storage gel, and the heat storage gel is contained in the flexible containing bag. According to the titanium nano-sheet / graphene-based hot compress drug pillow, the titanium nano-sheet / graphene-based fiber film has the advantages of high electrothermal conversion efficiency, high infrared normal emissivity, antibacterial function and good flexibility and elasticity, and can act on epidermis to resist bacteria and promote release of active pharmaceutical ingredients; and the high infrared normal emissivity can also achieve functions of promoting blood circulation, opening pores, improving the absorption effect of epidermis and the like.

Owner:北京康烯科技创新研究有限公司

A kind of titanium nanosheet/graphene-based fiber film and preparation method thereof

ActiveCN111996666BHigh porosityImprove flexibilityMonocomponent synthetic polymer artificial filamentNon-woven fabricsFiberSpinning

Owner:北京康烯科技创新研究有限公司

Palladium nanosheet/graphene-based traditional Chinese medicine hot compress device

InactiveCN112022494AEasy to installEasy to cleanMaterial nanotechnologyTherapeutic coolingEngineeringGraphite

The invention provides a palladium nanosheet / graphene-based traditional Chinese medicine hot compress device. The palladium nanosheet / graphene-based traditional Chinese medicine hot compress device ischaracterized by comprising a hot compress sleeve and a palladium nanosheet / graphene-based heating film, wherein a first accommodating bag is arranged at the outer side of the hot compress sleeve, and is used for accommodating the palladium nanosheet / graphene-based heating film; and a second accommodating bag is arranged at the inner side of the hot compress sleeve, and is used for accommodatinga traditional Chinese medicine bag. The palladium nanosheet / graphene-based traditional Chinese medicine hot compress device provided by the invention realizes the photo-thermal and electro-thermal diversified heat production function through the efficient photo-thermal conversion efficiency and electro-thermal conversion efficiency of the palladium nanosheet / graphene-based heating film, and achieves the effects of high active ingredient absorption rate, heat production stability and the like.

Owner:北京康烯科技创新研究有限公司

Composite negative electrode sheet with rapid heating function, and cell and battery using same

Owner:CONTEMPORARY AMPEREX TECH CO

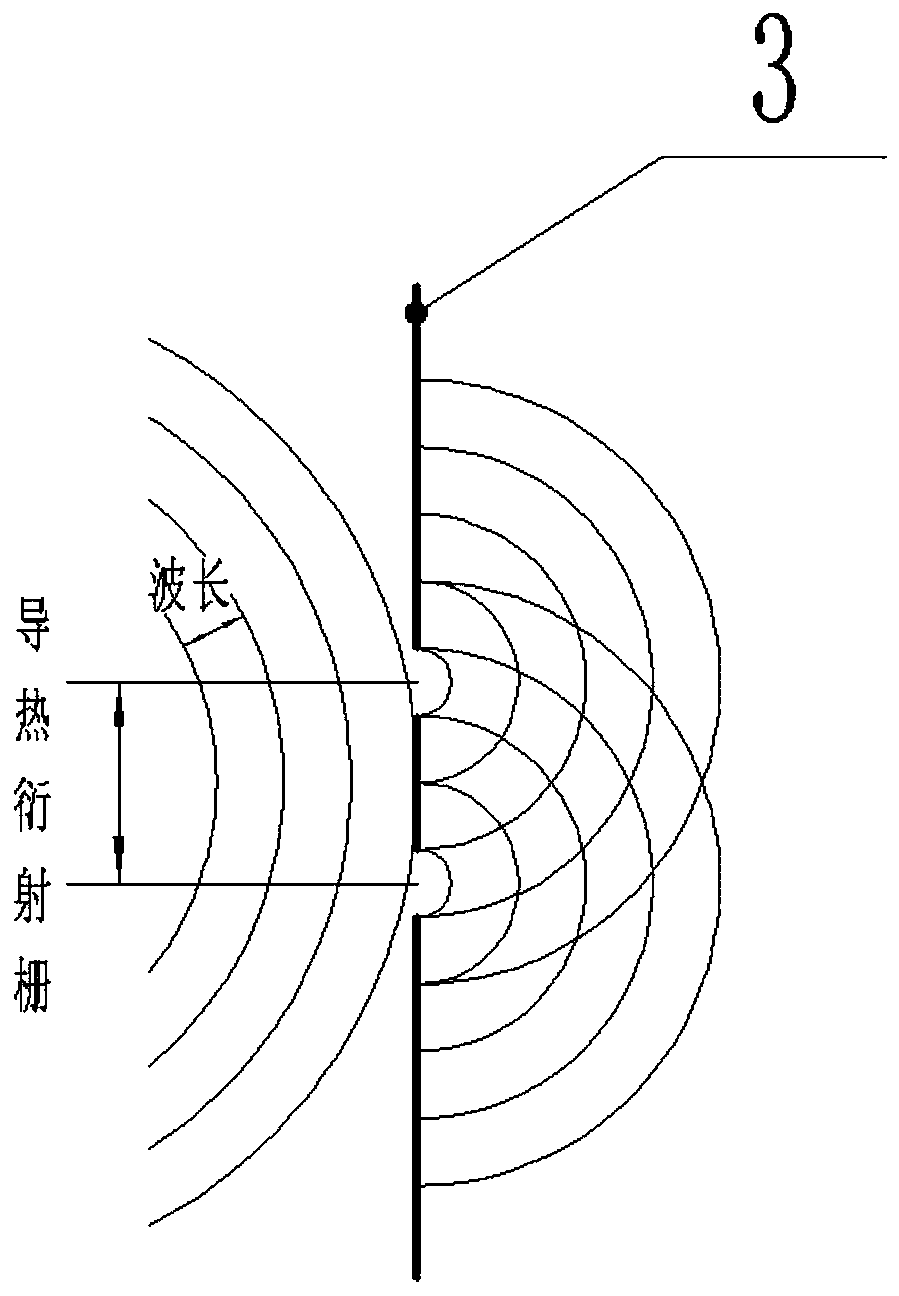

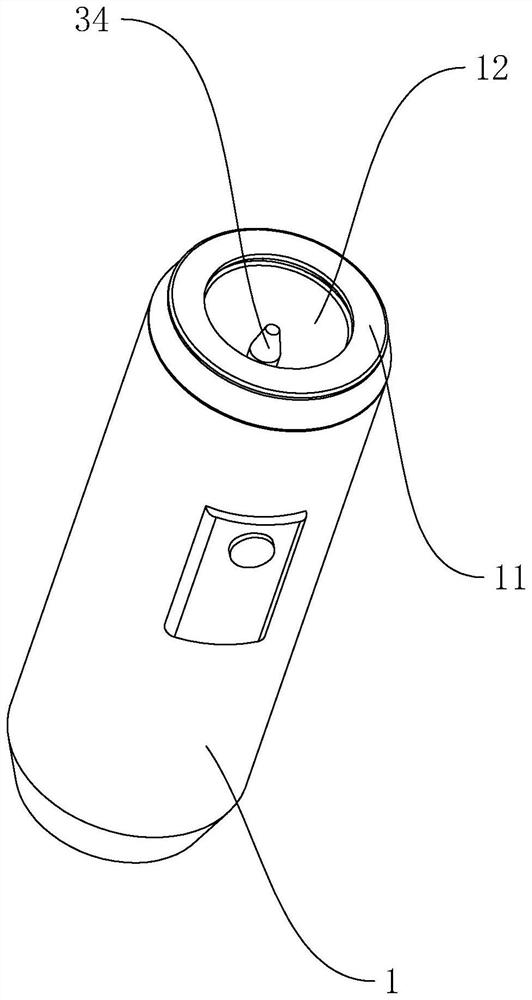

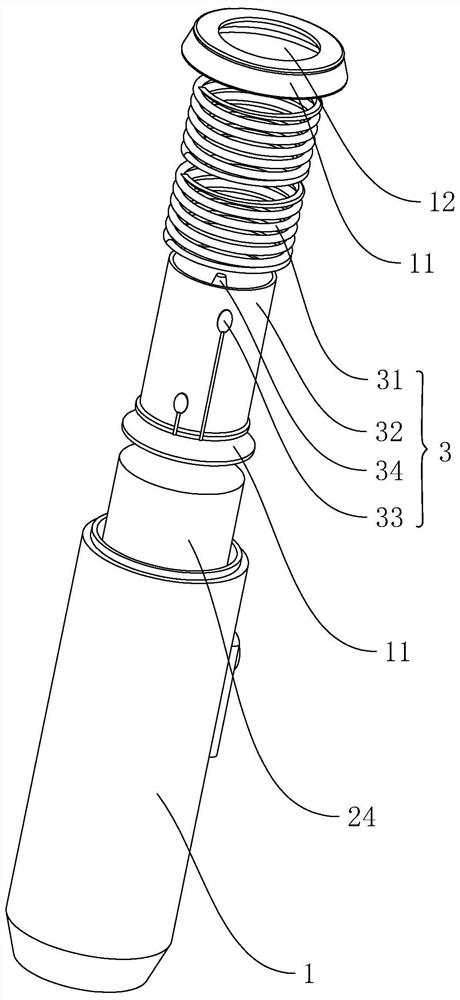

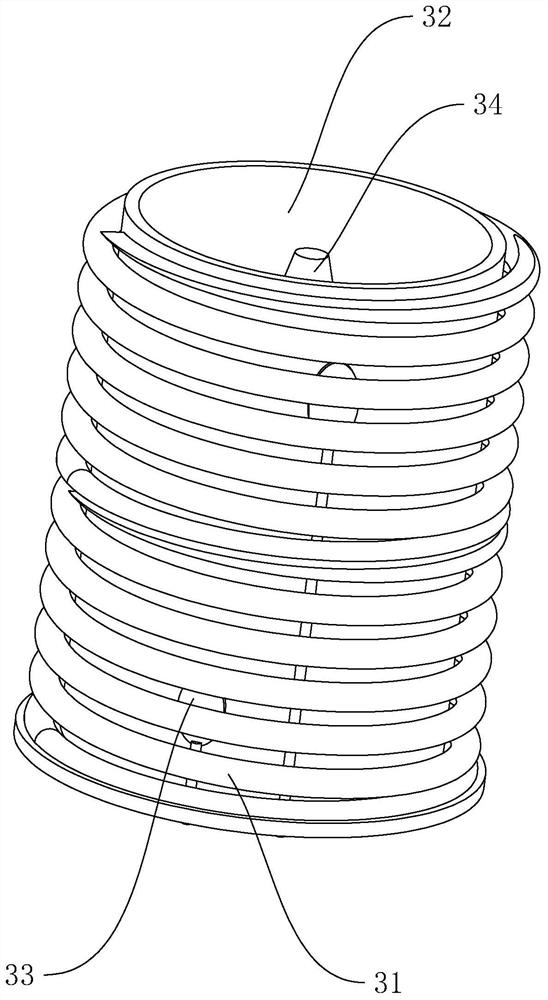

Electronic cigarette based on electromagnetic temperature control technology and control method thereof

The invention relates to an electronic cigarette based on an electromagnetic temperature control technology and a control method thereof. The electronic cigarette comprises a cigarette rod and further comprises a power supply device and an atomizer which are arranged in the cigarette rod. The atomizer comprises an induction coil connected with the power supply device and a metal heating tube arranged in the induction coil in a penetrating mode, wherein tobacco products are placed in the metal heating tube. The power supply device is used for outputting changing current to the induction coil. The electronic cigarette has the advantages that tobacco products are evenly heated, the taste is improved, and the use experience is improved.

Owner:SHENZHEN TIMEYAA ELECTRONIC TECH CO LTD

A kind of compatible stealth anti-icing material and its preparation method and application

ActiveCN113597032BAvoid getting lostReduce reflectivityMagnetic/electric field screeningConjugated diene hydrocarbon coatingsThermal breakTransmittance

Owner:BEIHANG UNIV

A battery self-heating and heat preservation device

ActiveCN110299580BFix Heating ProblemsEfficient self-preheating and heat preservationSecondary cellsPower batteryThermal insulation

The invention discloses a battery self-heating heat preservation device. The battery self-heating and heat preservation device includes: a power battery cell, a heating diaphragm, an airgel shell, a temperature sensor and a switch circuit; the outer surface of the power battery monomer is covered with a heating diaphragm; the outer surface of the heating diaphragm Covered with an airgel shell; the temperature sensor is set on the power battery unit, and the temperature sensor is set between the power battery unit and the heating diaphragm; the temperature sensor and the switch circuit are connected through the signal line; the power battery unit, the heating The diaphragm and the switch circuit are connected to each other in pairs. The switch circuit is used to connect the power battery unit and the heating diaphragm to form a heating circuit; for heating. The battery self-heating and heat preservation device provided by the present invention enables the battery to be efficiently self-preheated and heat-preserved under low temperature conditions, thereby improving the charging and discharging performance of the battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com