Composite positive electrode sheet with rapid heating function, and cell and battery using the same

A composite positive electrode and positive electrode sheet technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low heating film heating efficiency, poor heating consistency, complex assembly, etc., and achieve simple structure, small changes, simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

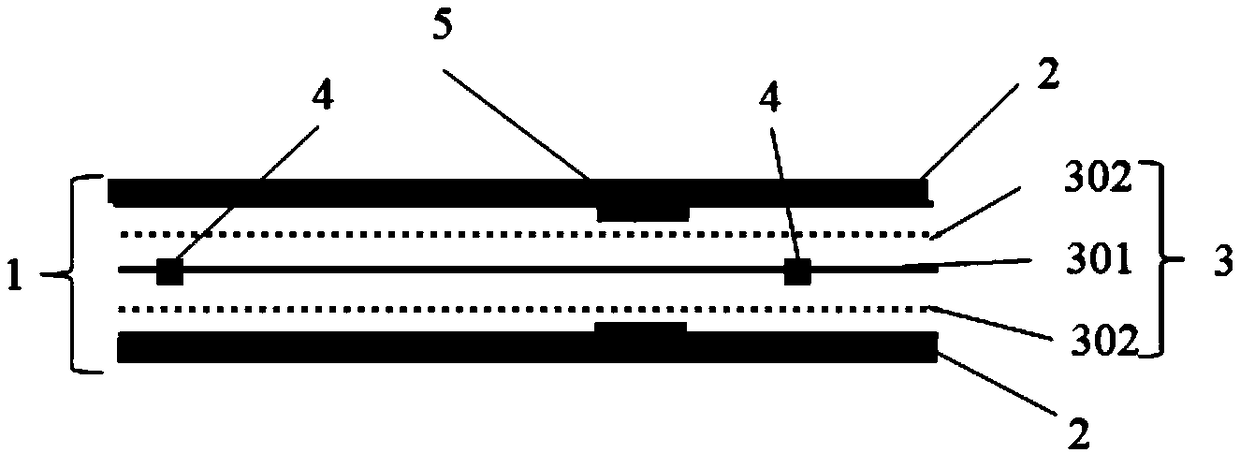

Embodiment 1

[0050] This embodiment provides a composite positive pole piece 1, the composite positive pole piece 1 includes two positive pole pieces 2, a thermal resistance sandwich structure 3 is arranged between the two positive pole pieces 2, and the thermal resistance sandwich structure 3 includes two A layer of diaphragm 302 and a layer of thermal resistance sheet 301 placed between the two layers of diaphragm 302, the thermal resistance sheet 301 is provided with two tabs 4 of the thermal resistance sheet at a certain distance. Wherein, the positive electrode sheet 2 is a single-sided positive electrode sheet, and the slurry layer of the single-sided positive electrode sheet faces the interior of the composite positive electrode sheet 1 .

[0051] It can be seen from the above structure that the thermal resistance sheet 301 is separated from the two positive electrode sheets 2 by the diaphragm 302 .

[0052] The composite positive pole piece of this embodiment is connected to the lu...

Embodiment 2

[0056] Except that the positive electrode sheet 2 is replaced by a double-sided positive electrode sheet, other structures are the same as in Embodiment 1.

[0057] The composite positive pole piece of this embodiment is connected to the lug of the heat resistance plate through a built-in power supply or an external power supply, and can generate heat after being energized, achieving the purpose of rapid heating from the level of the pole piece.

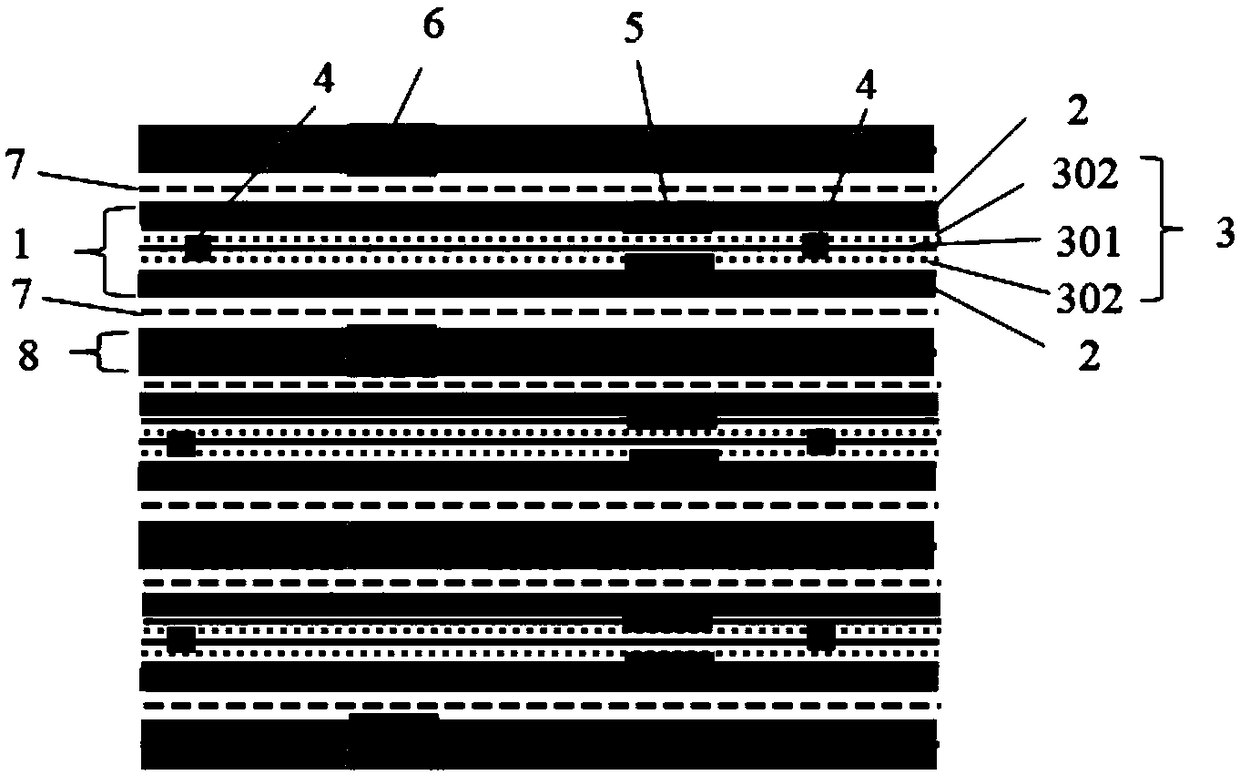

Embodiment 3

[0059] This implementation provides a battery cell, including a positive electrode, a separator, and a negative electrode. The positive electrode and the negative electrode are located on both sides of the separator. , separator, composite positive electrode sheet, separator, negative electrode, separator, composite positive electrode sheet, separator, negative electrode... Place the above-mentioned parts in order, and then wind them to obtain a bare cell.

[0060] Set the positive pole lug and the negative pole lug on the positive pole and the negative pole respectively, connect the positive pole lug and the negative pole lug to the top cover respectively, lead the thermal resistance plate lug to the outside of the cell, control the heating and sealing through the external circuit control strategy Finally, the electrolyte is injected and assembled into a battery cell.

[0061] The composite positive pole piece of this embodiment generates heat through the external circuit, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com