Large-scale guiding tank for electric heaters of fused salt storage tank

An electric heater and a guide box technology, applied in the field of chemical machinery, can solve the problems such as the temperature of the bottom of the tank cannot reach the temperature required for commissioning, the temperature difference between the tank wall and the bottom of the tank exceeds the allowable value, and the temperature of the bottom of the tank is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

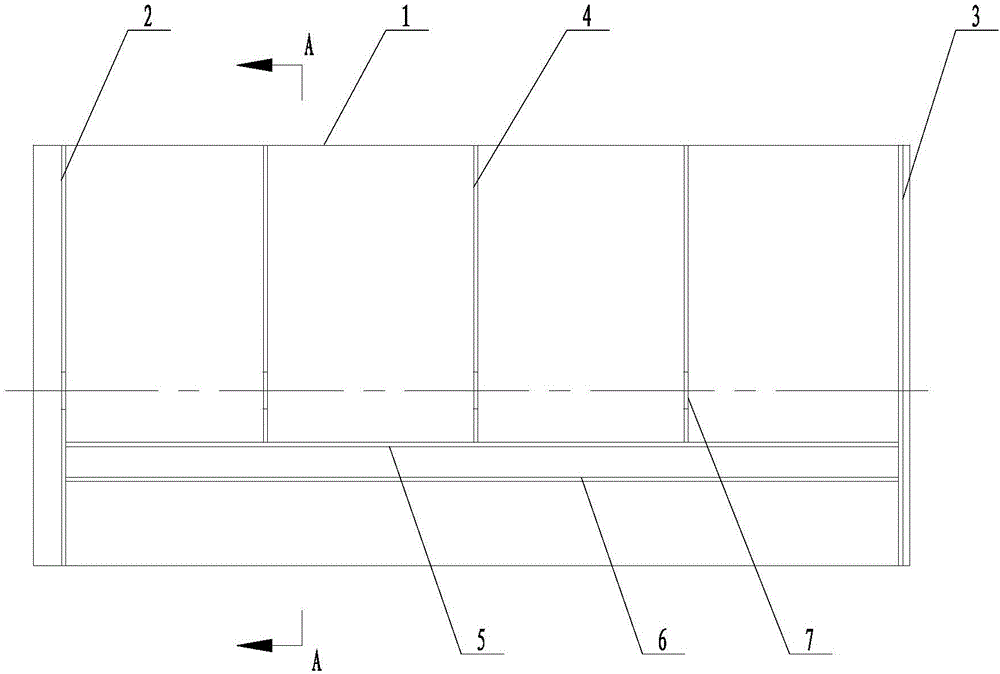

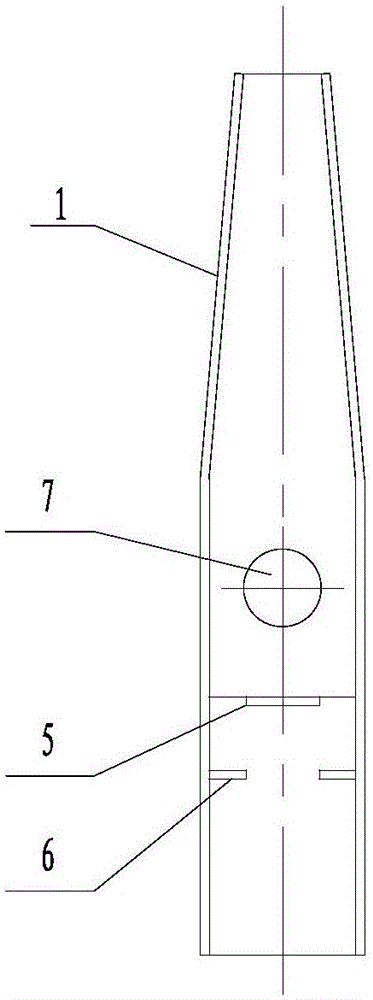

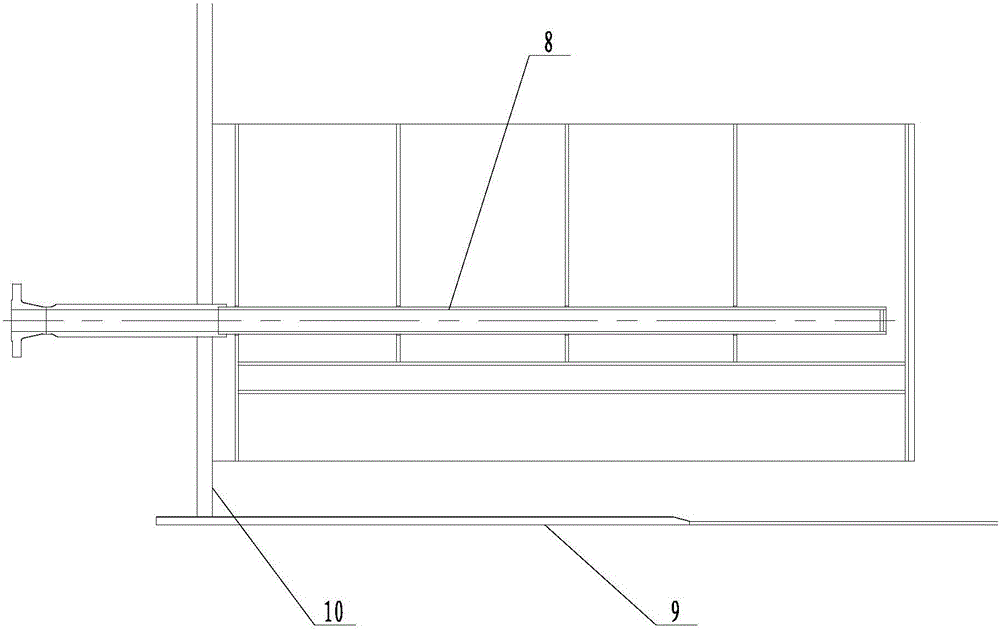

[0023] Such as Figure 1 ~ Figure 3 As shown, the large-scale molten salt storage tank electric heater diversion box according to the present invention includes two side plates 1, and support plates 4 are vertically distributed between the two side plates 1, and the front and rear ends of the side plates 1 are respectively provided with front ends The plate 2 and the rear end plate 3, the front end plate 2 and the rear end plate 3 are all fixed between the two side plates 1, and a horizontal baffle Ⅰ5 and two horizontal baffles Ⅱ6 are arranged longitudinally between the two side plates 1, and the horizontal baffles Plate Ⅰ5 is located above the horizontal baffle plate Ⅱ6, and the horizontal baffle plate Ⅰ5 is welded with the front end plate 2, the rear end plate 3 and the support plate 4 respectively, and the horizontal baffle plate Ⅱ6 is welded with the side plates 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com