Patents

Literature

38 results about "Capacity efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiply effective capacity by efficiency to arrive at actual capacity rate. Given an effective capacity of 60 and an efficiency of 66 percent, for instance, multiply 60 by .66 to obtain an actual capacity rate of 40 television sets per hour.

Method and device for predicting battery life

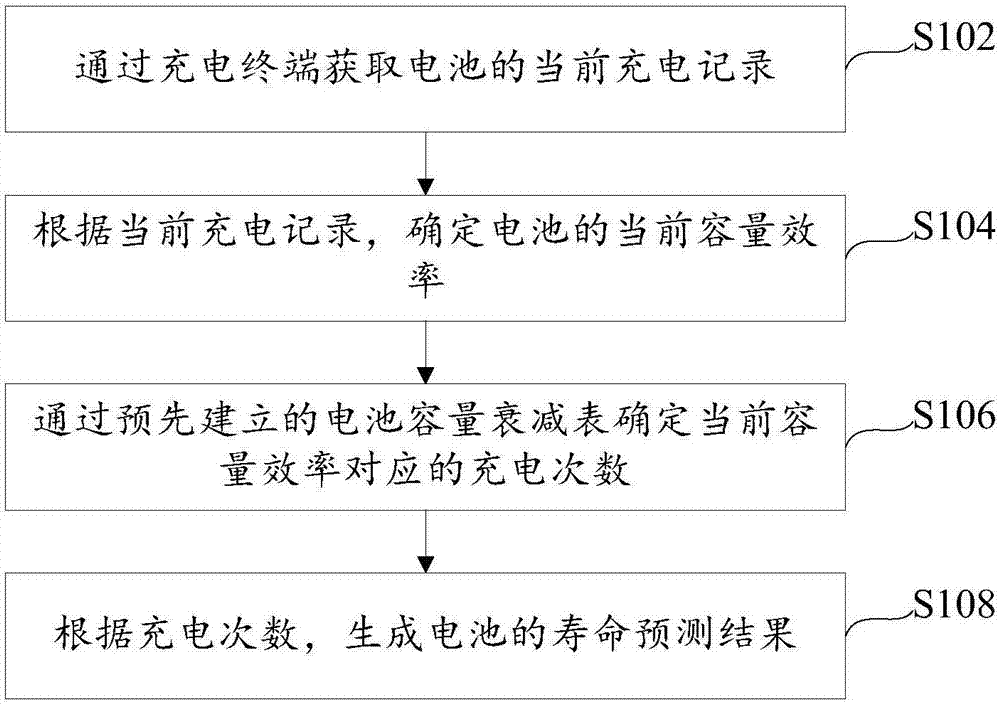

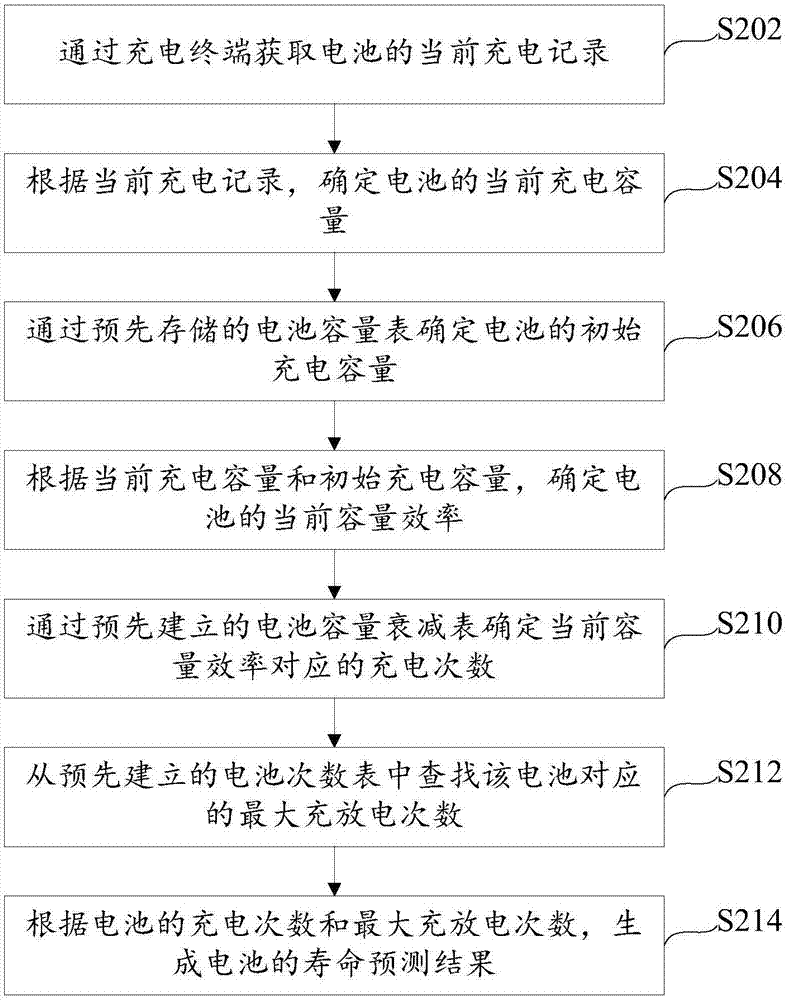

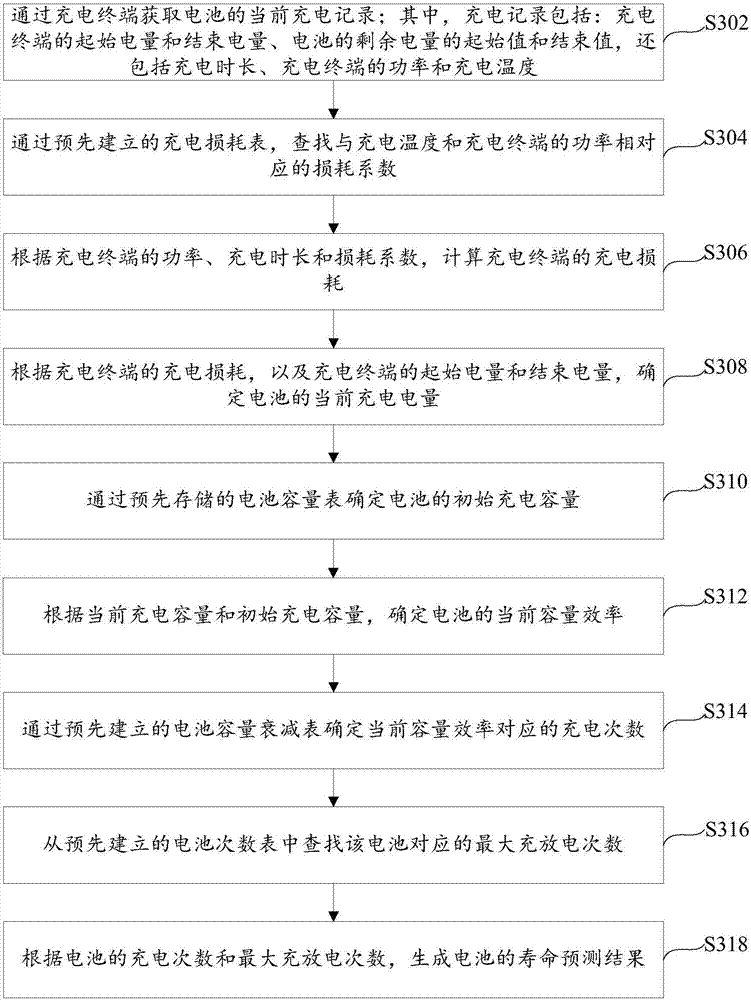

The present invention provides a method and device for predicting a battery life, relating to the technical field of battery detection. The method is executed by a server which is in communication connection with a charging terminal. The method comprises a step of obtaining a current charging record of a battery through the charging terminal, wherein the charging record comprises starting power and ending power of the charging terminal and a starting value and an ending value of the remaining power of the battery, a step of determining a current capacity efficiency of the battery according to the current charging record, a step of determining a charging number of times corresponding to the current capacity efficiency through a pre-established battery capacity attenuation table, wherein the battery capacity attenuation table records a corresponding relation between capacity efficiency and a charging number of times, and a step of generating a life prediction result of the battery according to the charging number of times. The above battery life prediction mode is simple and convenient and has low cost, and a user can conveniently and clearly understand the service life of the battery after charging the battery.

Owner:WANBANG CHARGING EQUIP CO LTD +1

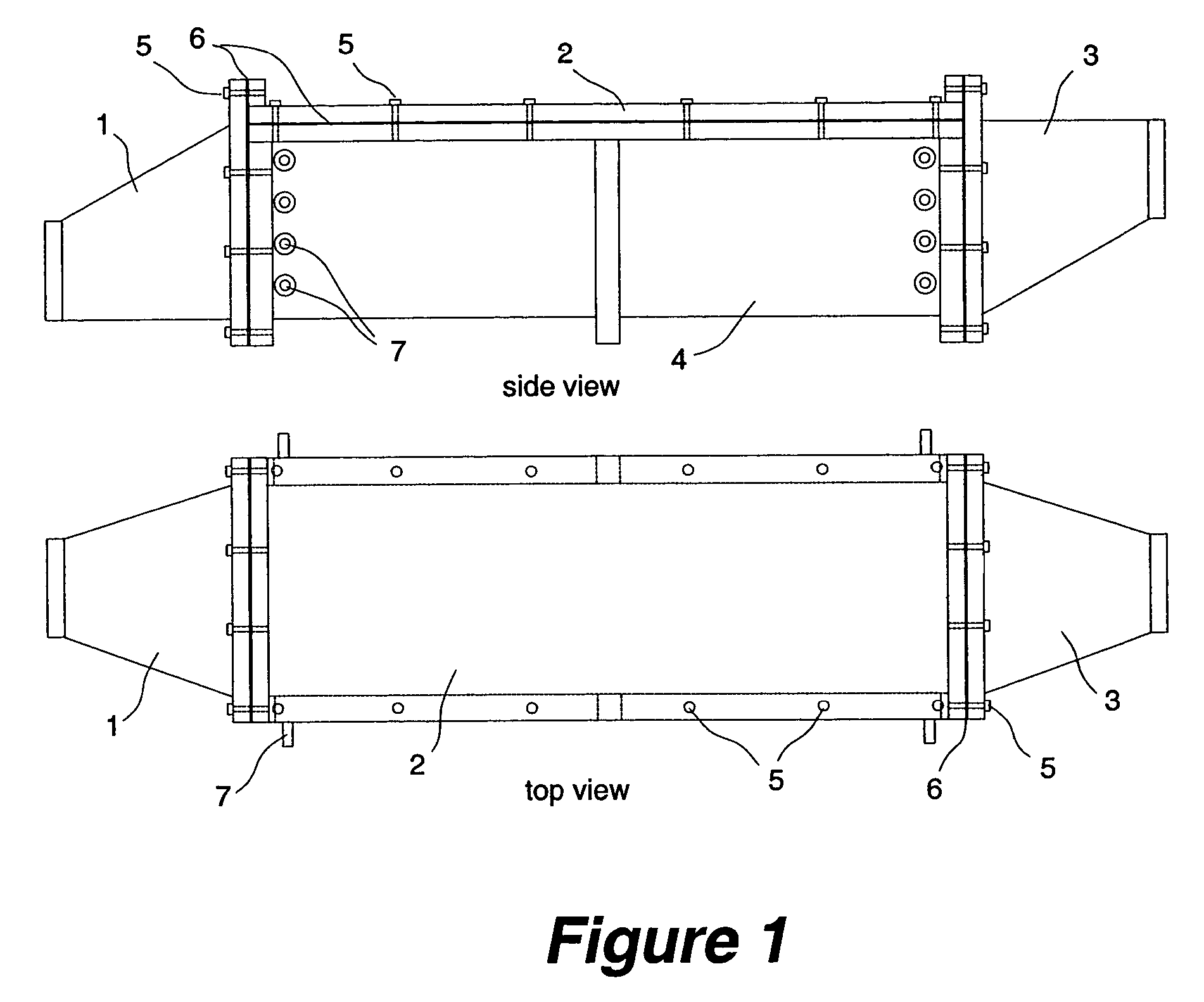

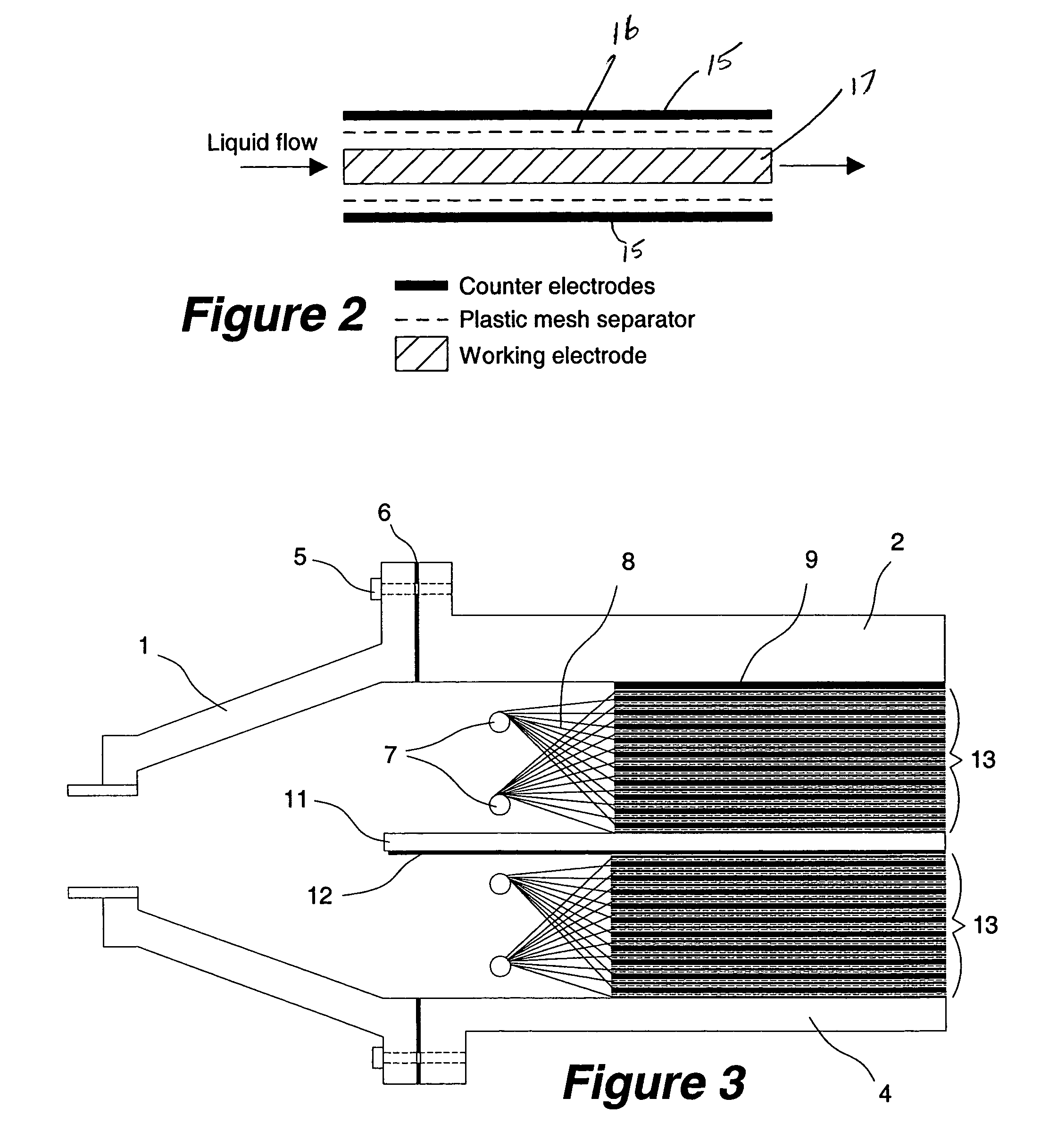

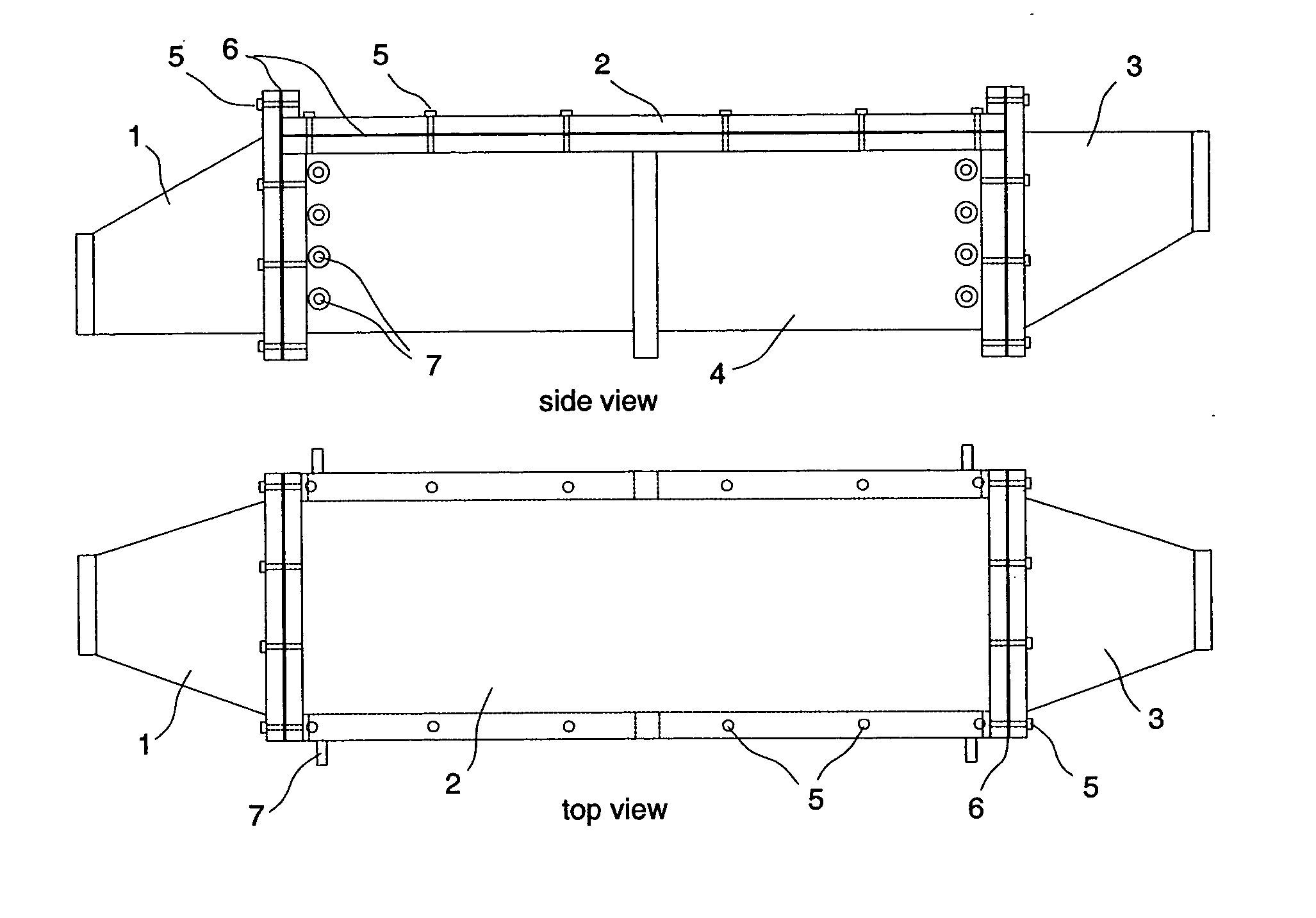

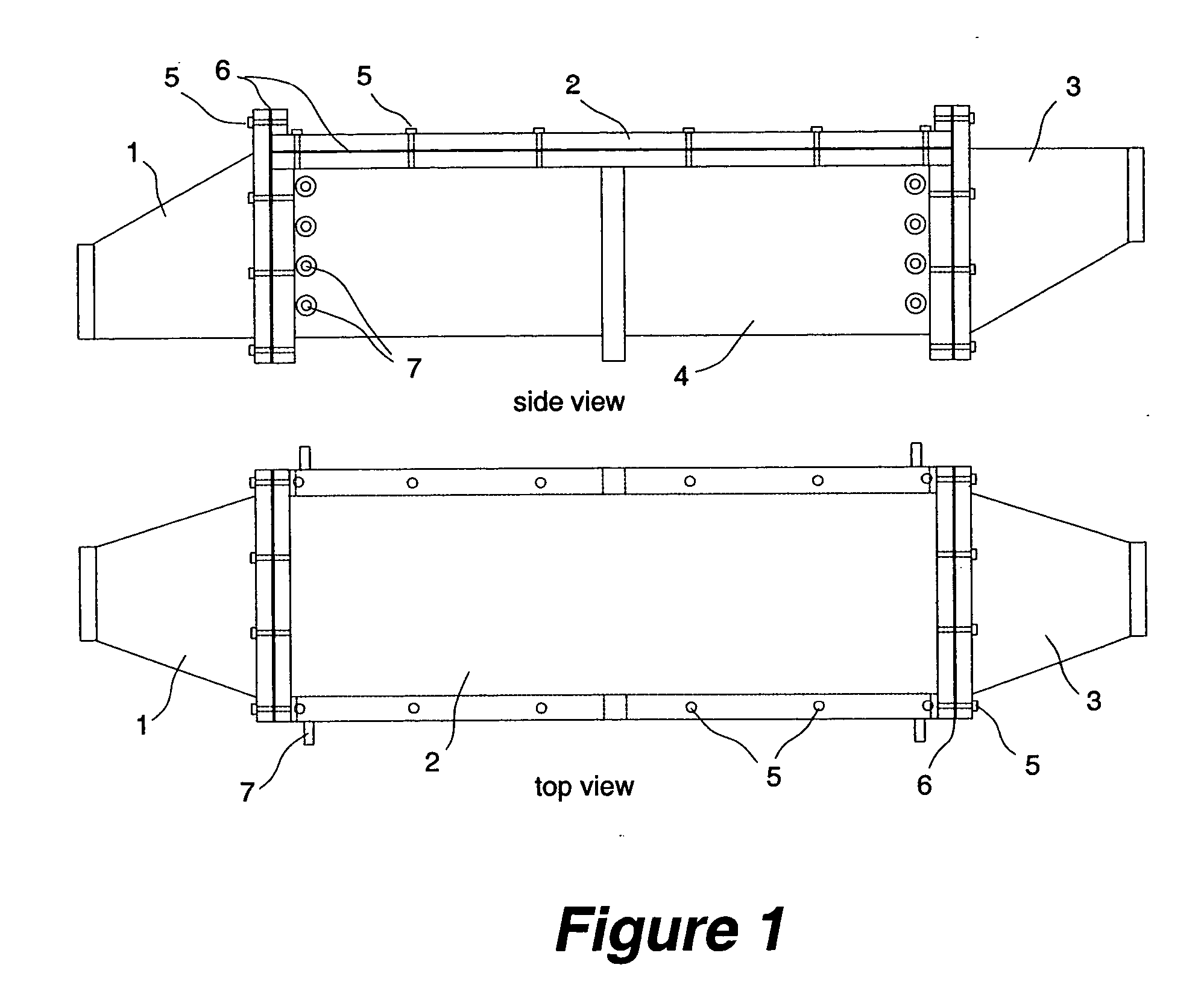

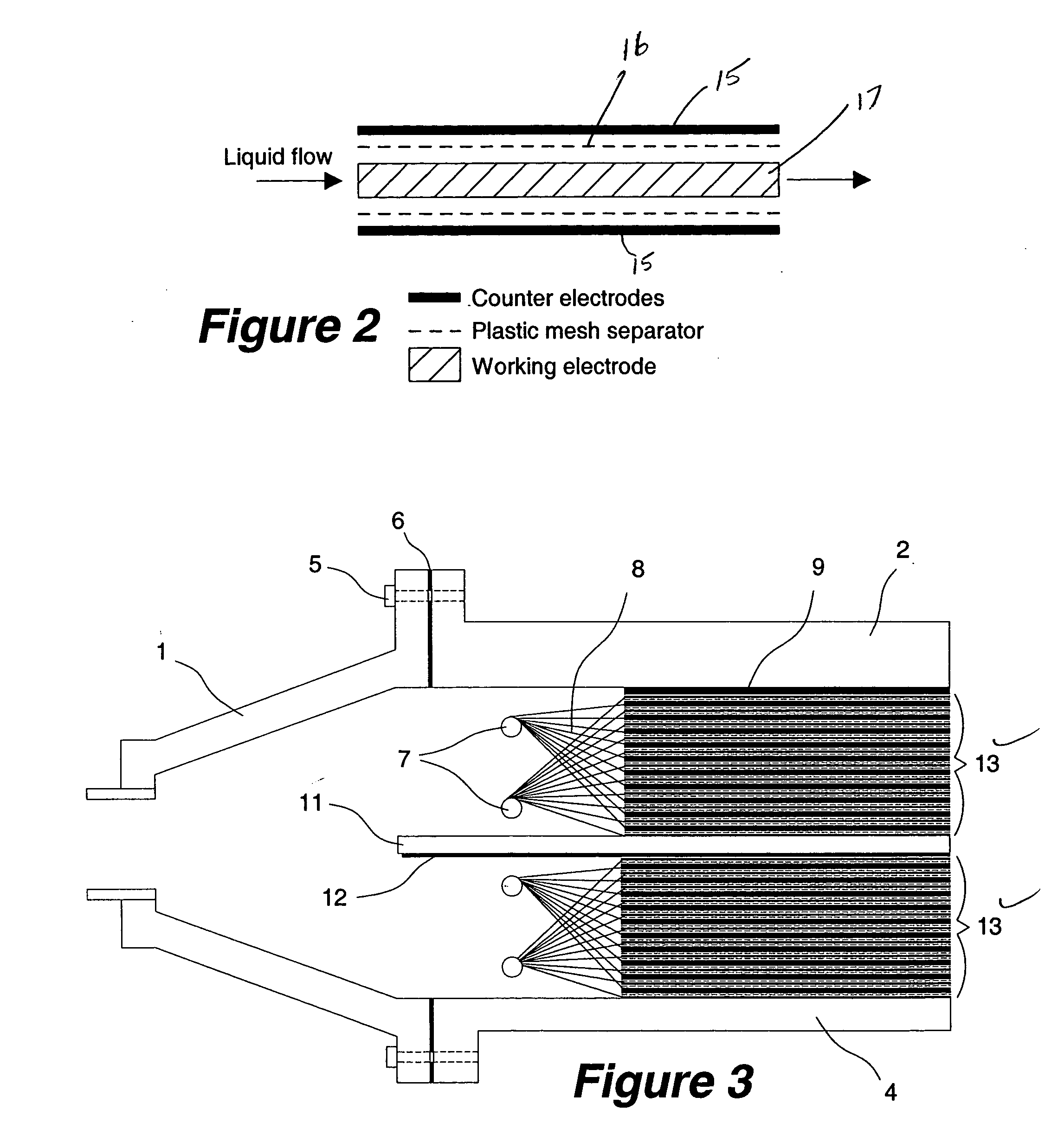

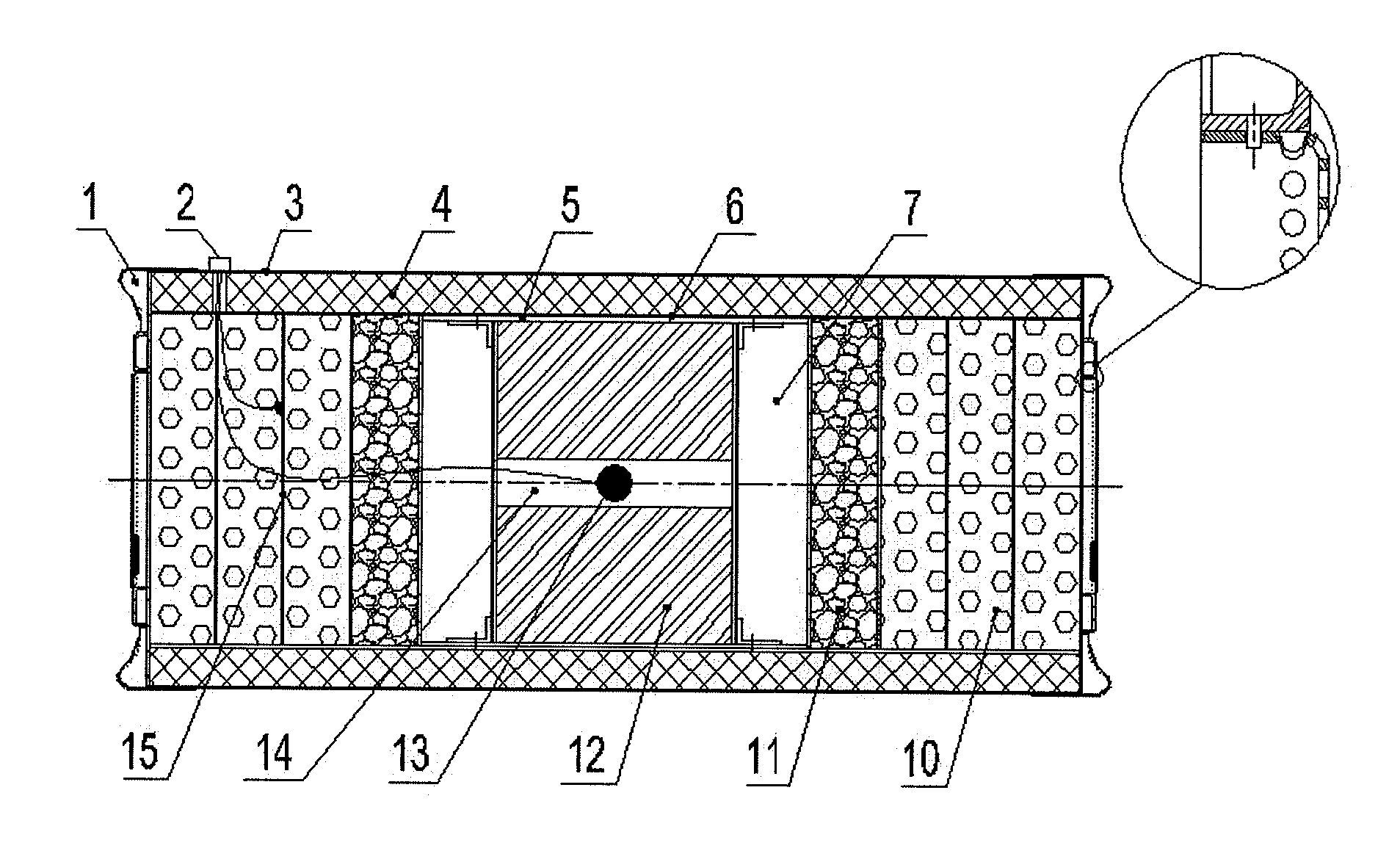

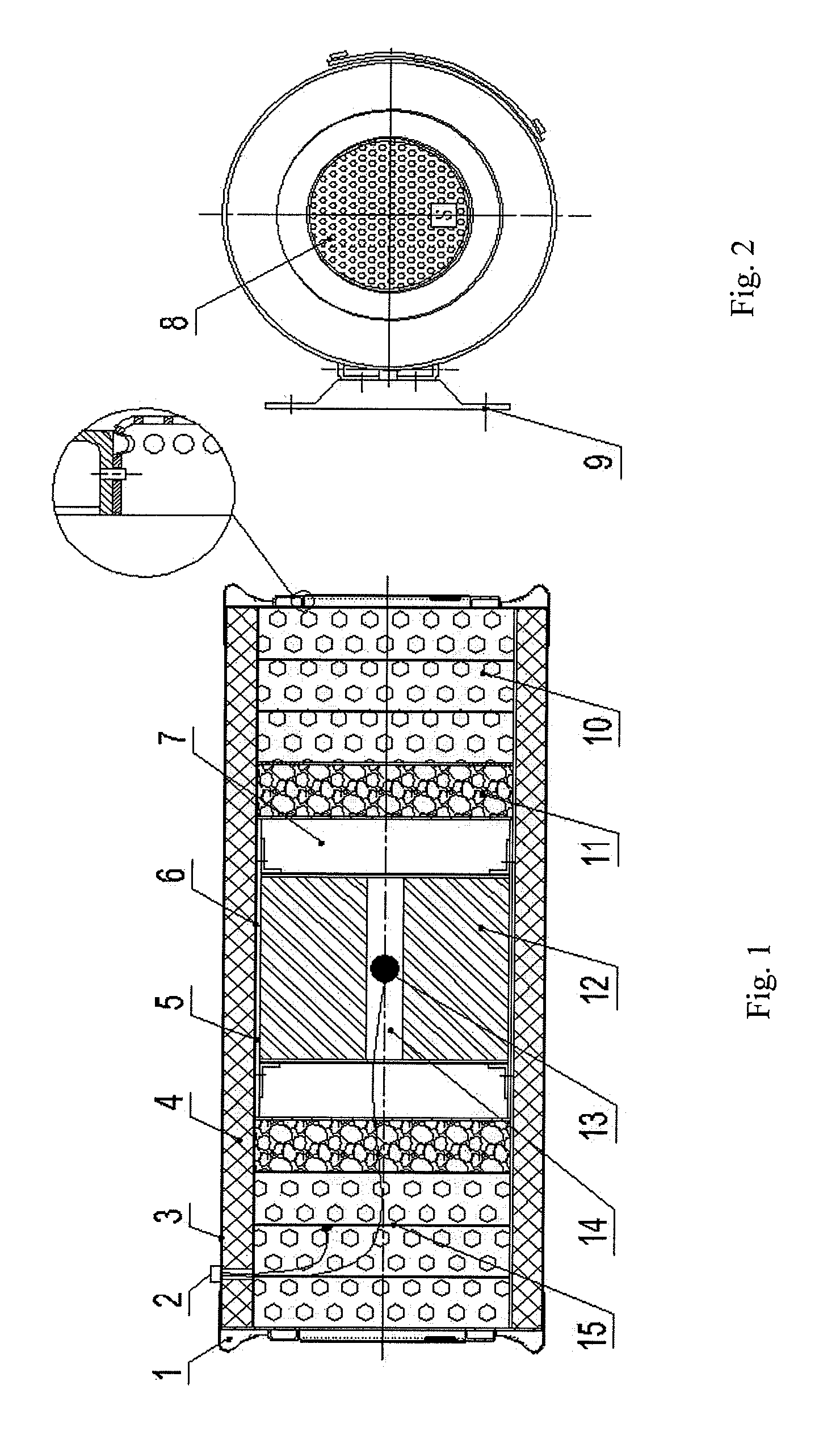

High volumetric efficiency electrochemical cell design for treatment of low concentrations of contaminants in low conductivity water

InactiveUS7232507B2Reduce conductivityCellsWater contaminantsElectrical batteryVolumetric efficiency

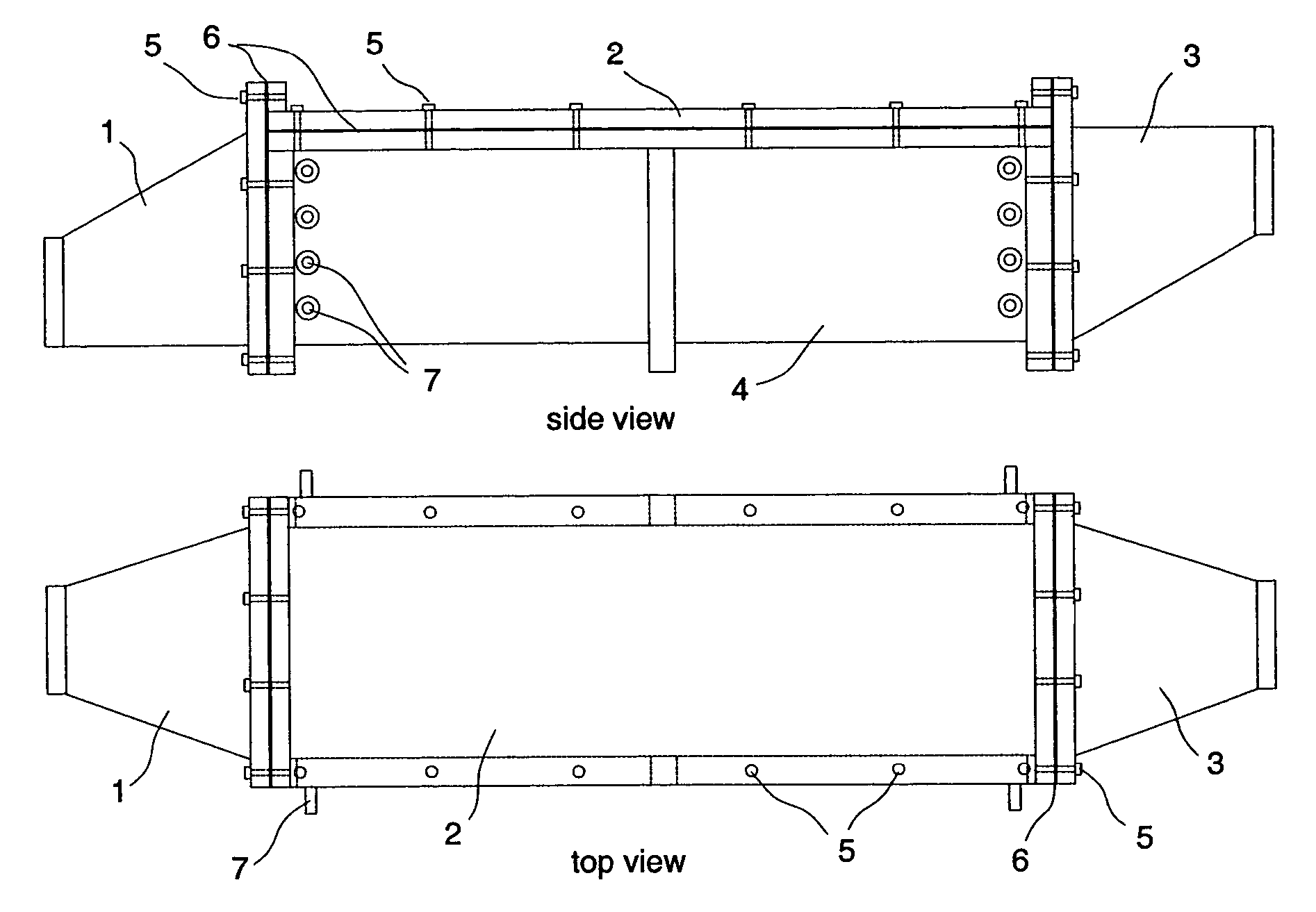

An electrochemical cell design is disclosed for the particular application of the electrochemical treatment of contaminants in water. The cell is designed to allow the treatment of low concentrations of contaminants in low conductivity water efficiently, and to be simple to fabricate. The design incorporates tapered inlet and outlet fluid flow manifolds so that the cell pressure drop will be almost entirely due to fluid contacting the electrodes, thus maximising the effective use of the system pump power. A short anode to cathode distance and thin working electrodes are used to minimise resistive electrical power losses. The parallel slacked arrangement of the electrodes and the smooth inlet and outlet designs leads to relatively even distributions of current density and mass transfer resulting in maximal utilisation of the entire active electrode surface area. The electrodes are connected internally in parallel in monopolar stack modules, and the modules are then connected externally in series, with insulating baffles to minimise current by-pass problems. This provides a simple cell construction (a minimum number of simple insulating baffles) while still simplifying the cell wiring and reducing the cell current demand (allowing lighter wiring to be used).

Owner:NAT RES COUNCIL OF CANADA

High volumetric efficiency electrochemical cell design for treatment of low concentrations of contaminants in low conductivity water

An electrochemical cell design is disclosed for the particular application of the electrochemical treatment of contaminants in water. The cell is designed to allow the treatment of low concentrations of contaminants in low conductivity water efficiently, and to be simple to fabricate. The design incorporates tapered inlet and outlet fluid flow manifolds so that the cell pressure drop will be almost entirely due to fluid contacting the electrodes, thus maximising the effective use of the system pump power. A short anode to cathode distance and thin working electrodes are used to minimise resistive electrical power losses. The parallel slacked arrangement of the electrodes and the smooth inlet and outlet designs leads to relatively even distributions of current density and mass transfer resulting in maximal utilisation of the entire active electrode surface area. The electrodes are connected internally in parallel in monopolar stack modules, and the modules are then connected externally in series, with insulating baffles to minimise current by-pass problems. This provides a simple cell construction (a minimum number of simple insulating baffles) while still simplifying the cell wiring and reducing the cell current demand (allowing lighter wiring to be used).

Owner:NAT RES COUNCIL OF CANADA

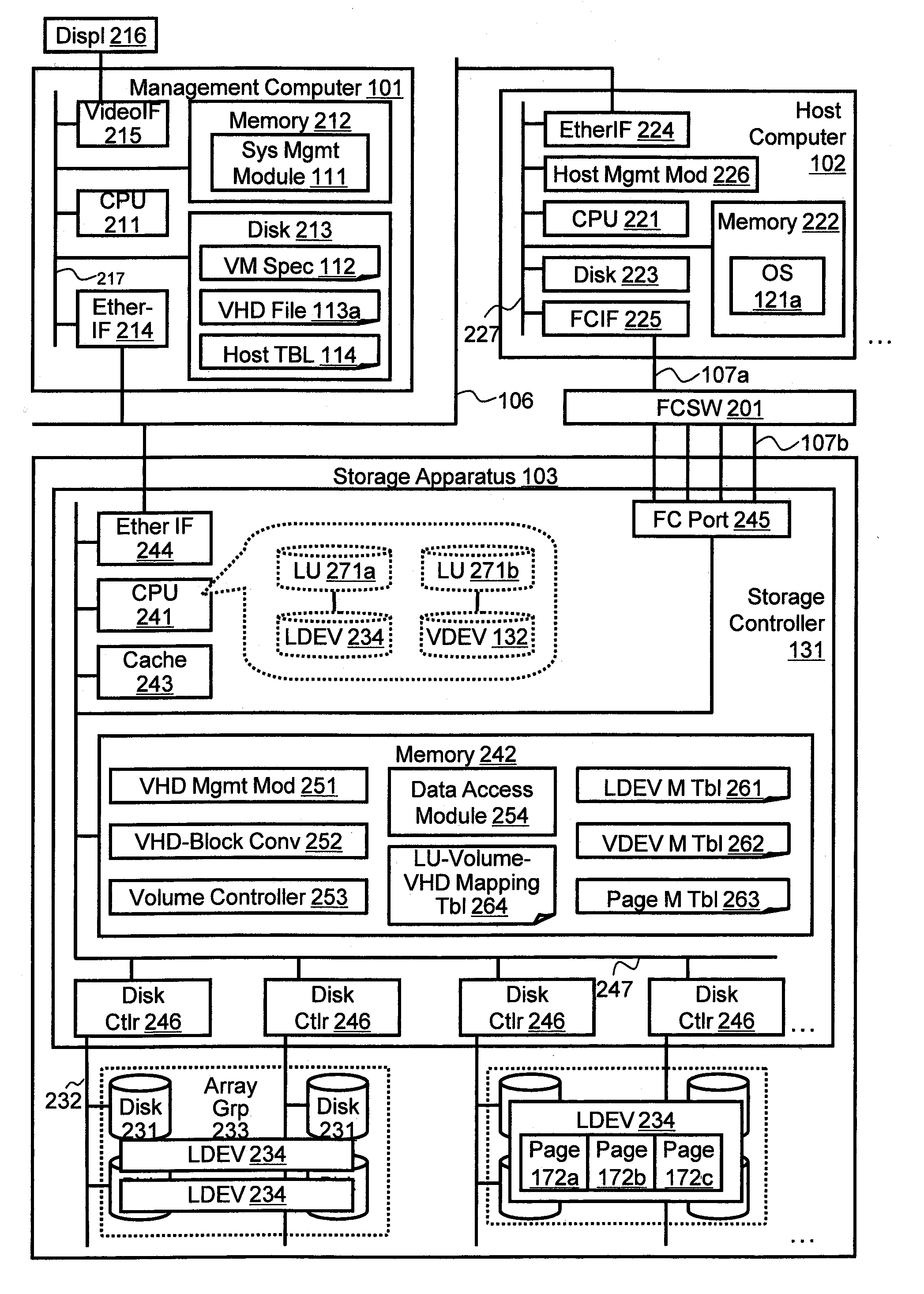

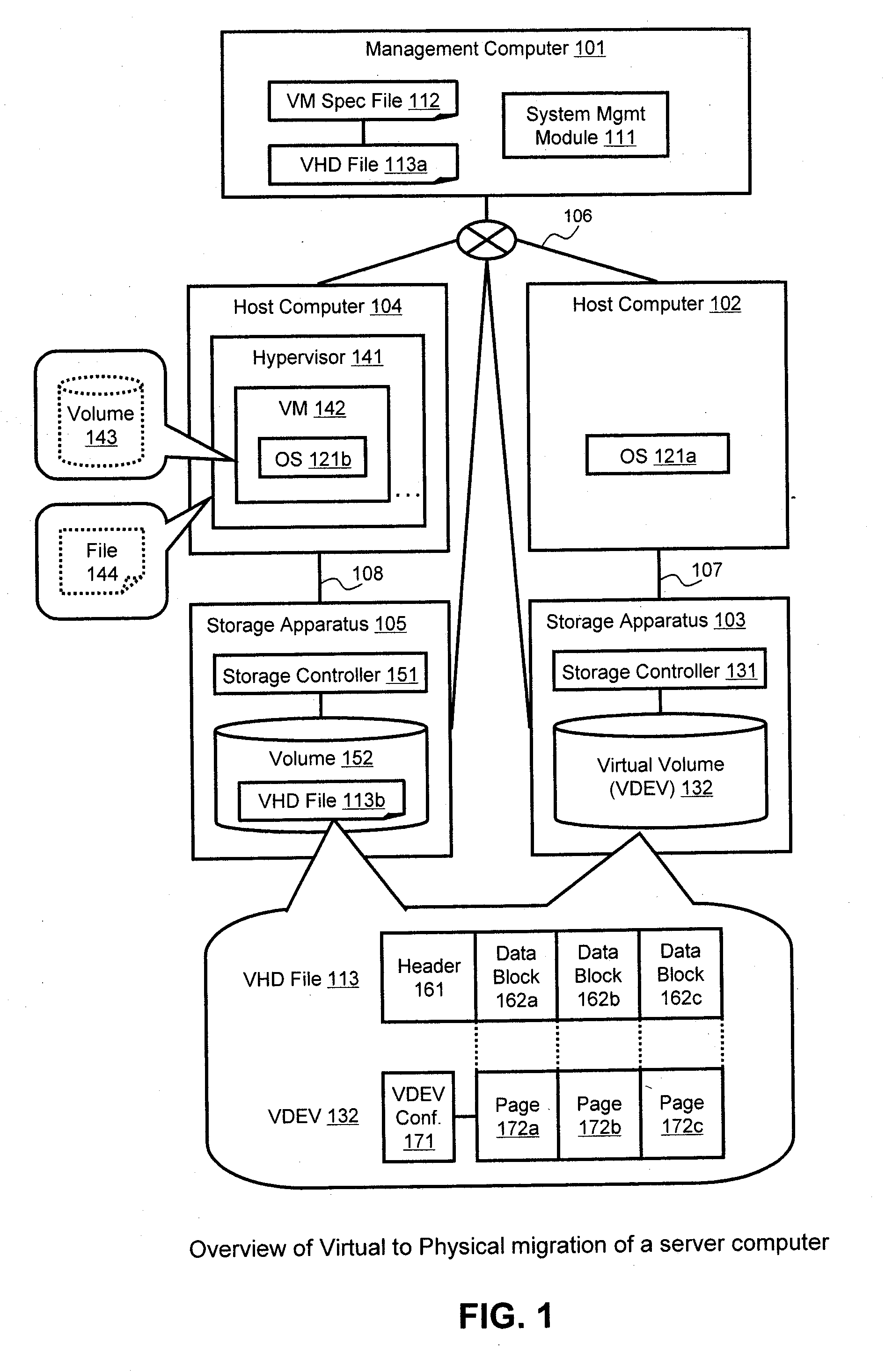

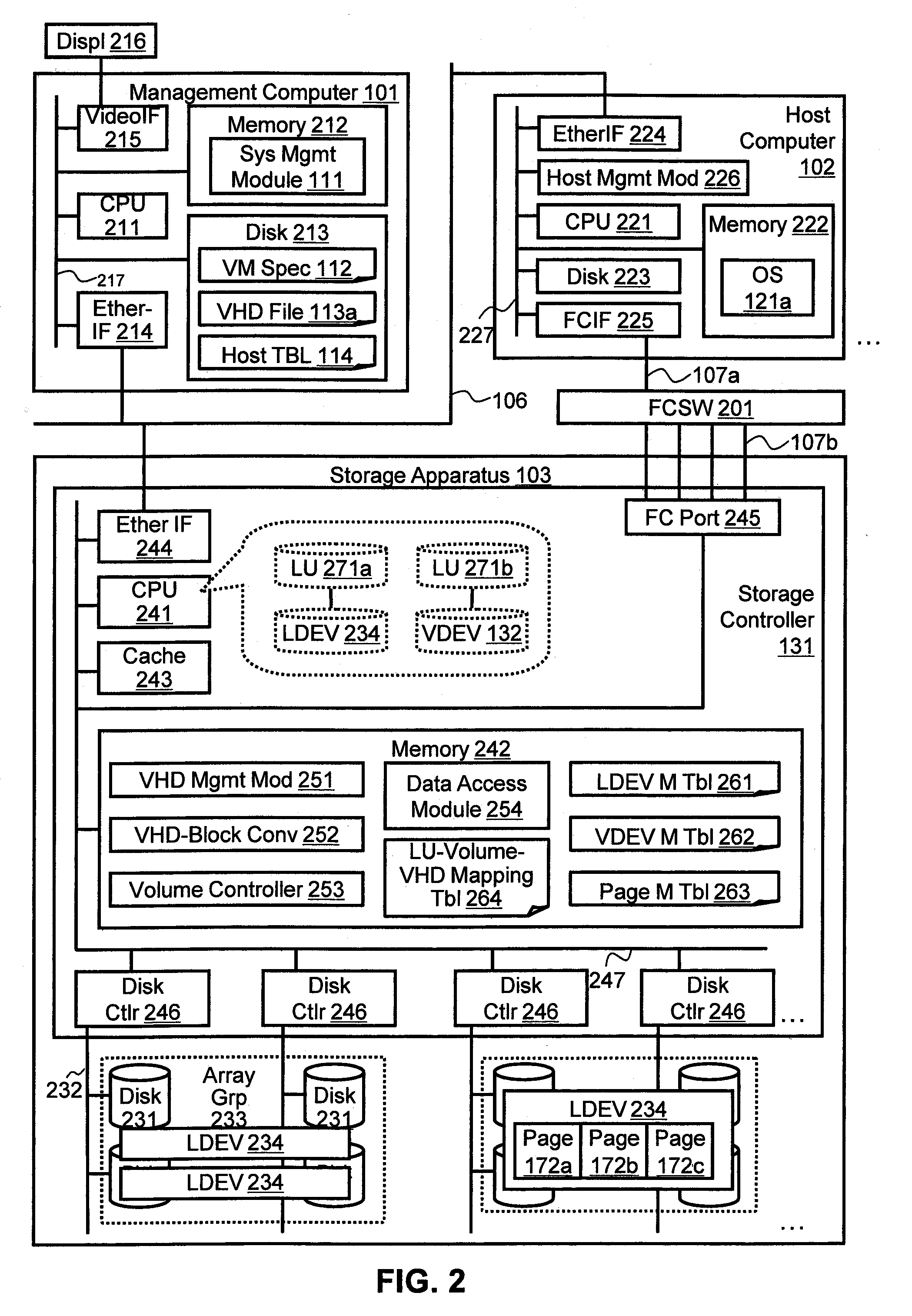

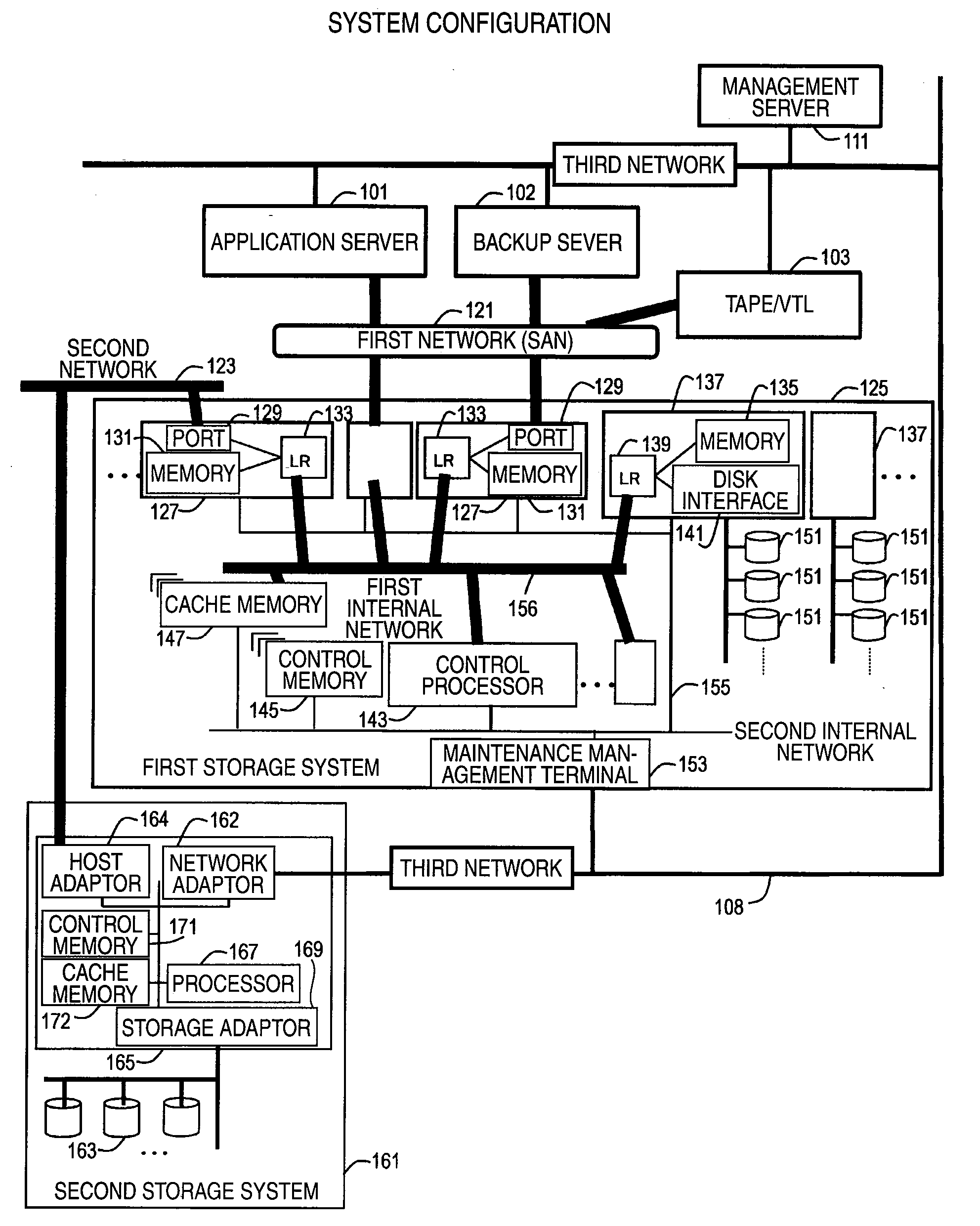

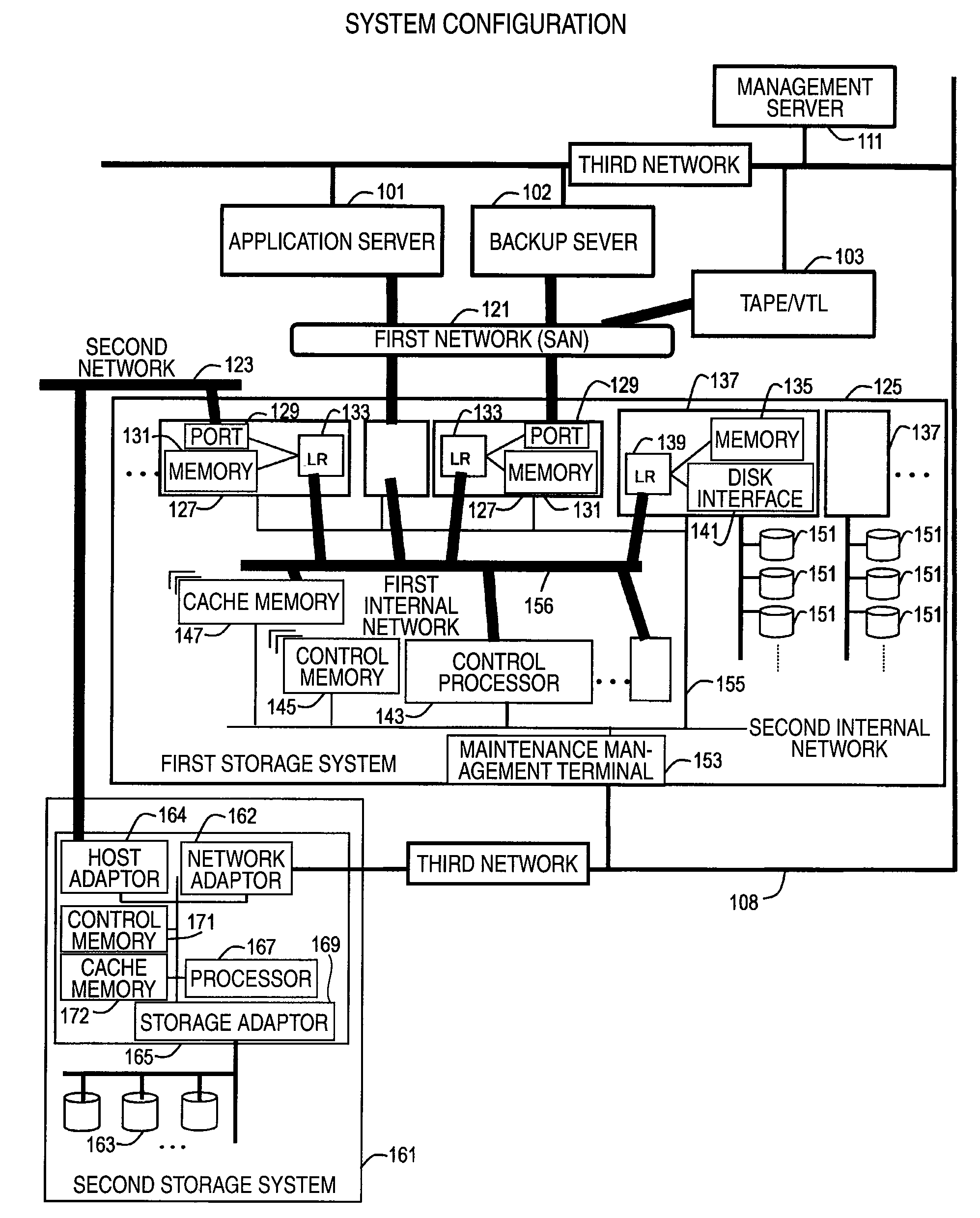

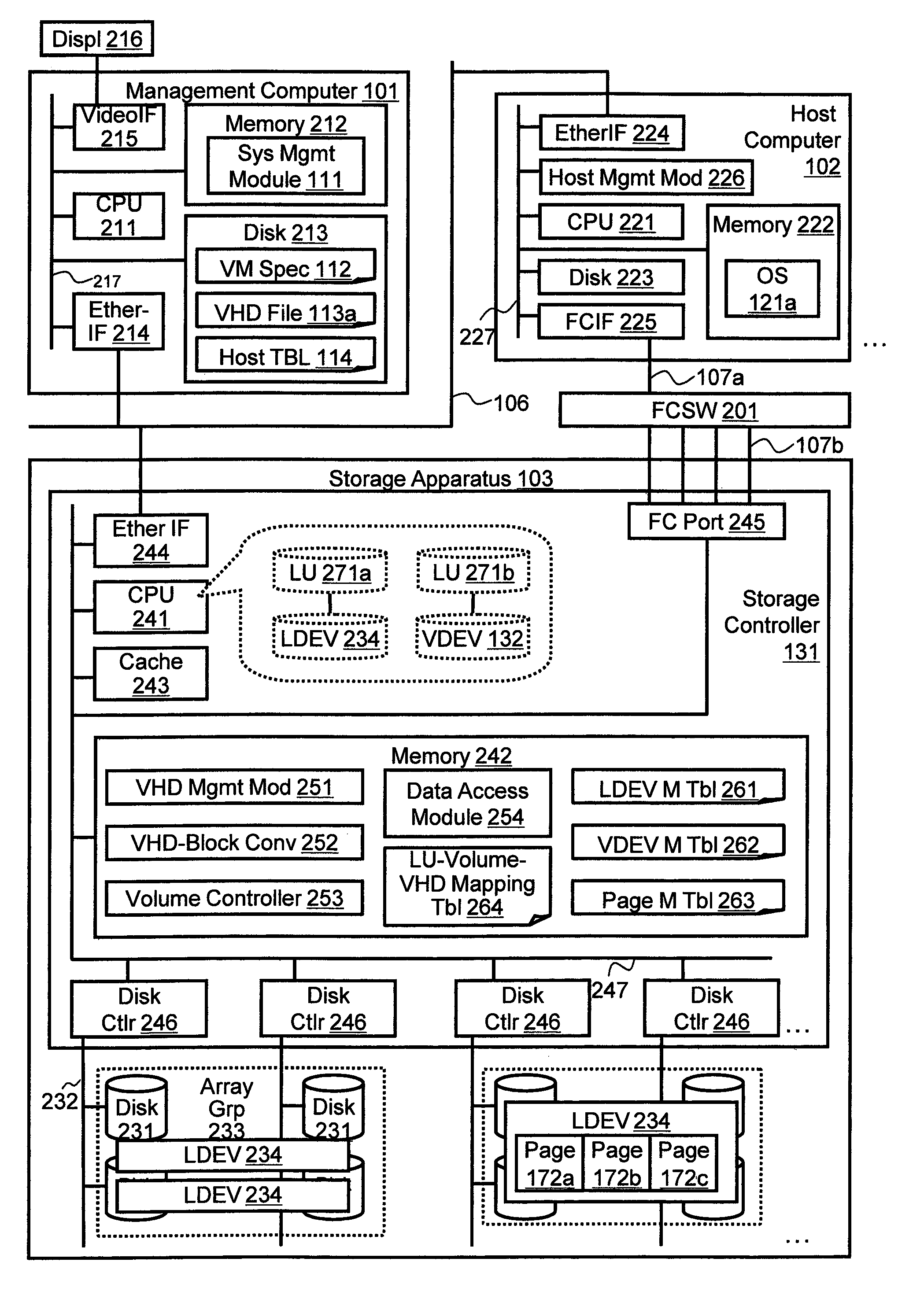

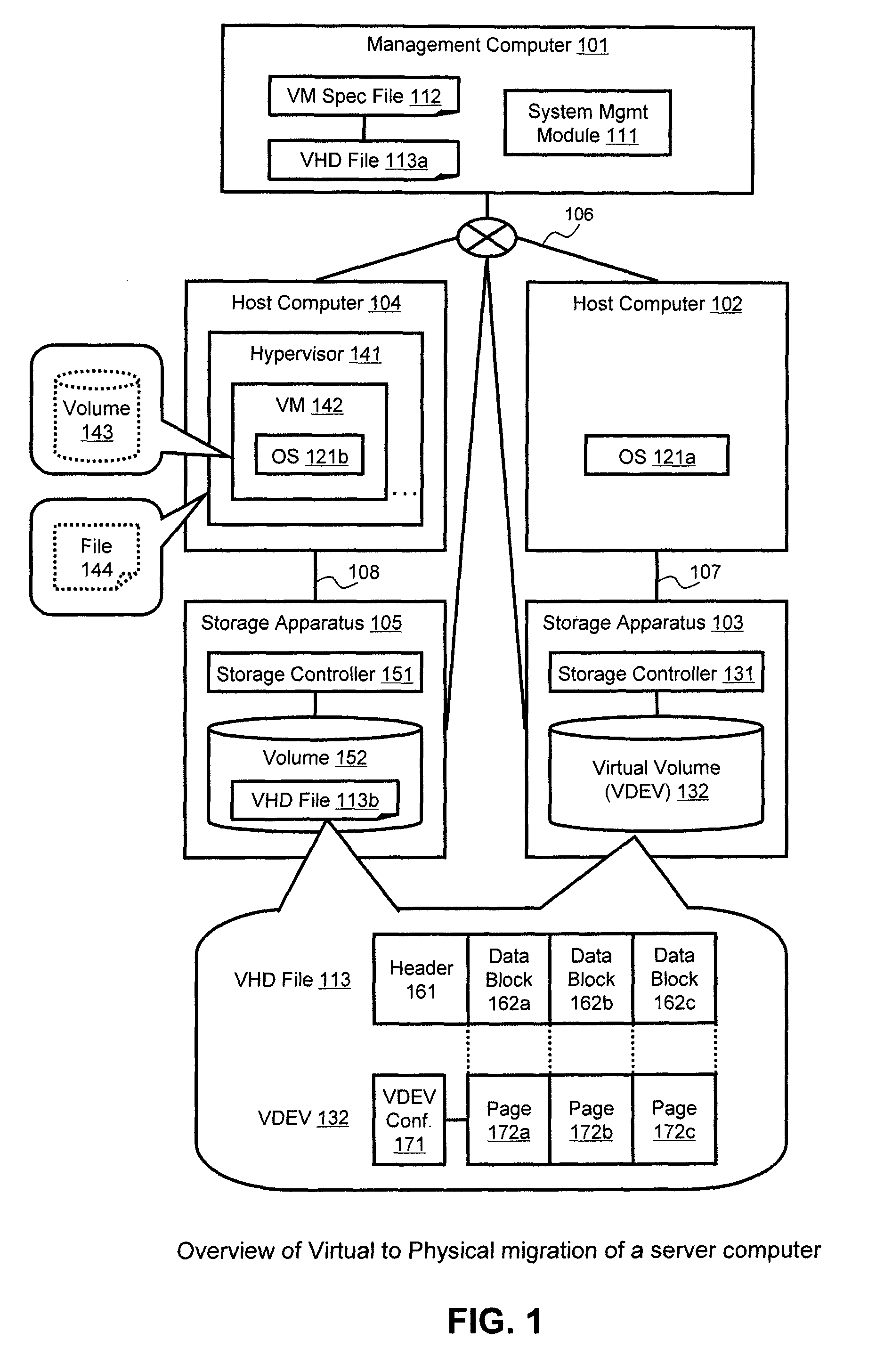

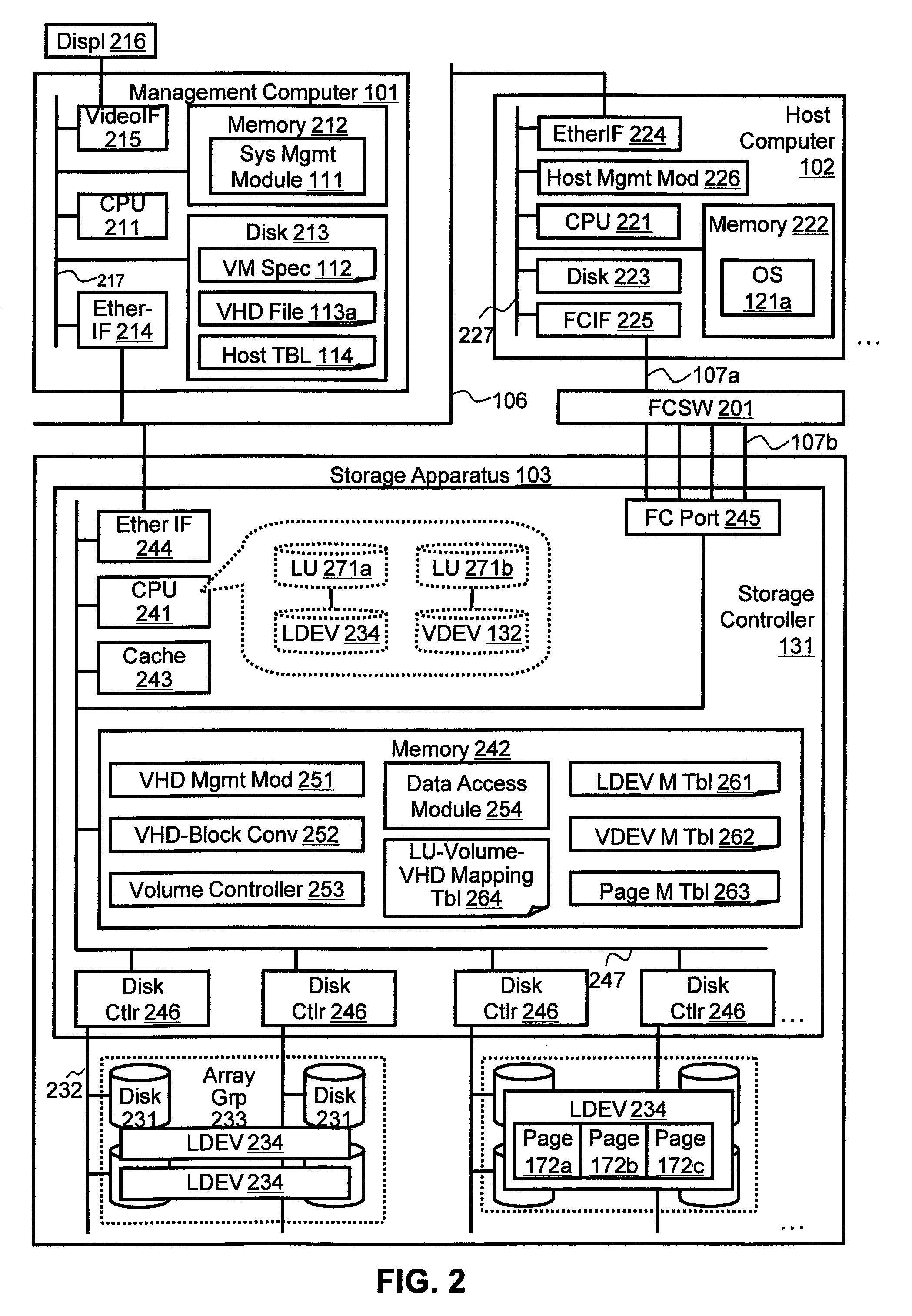

Method and apparatus for deploying virtual hard disk to storage system

InactiveUS20100250630A1Maximizing capacity efficiencyMaximizing data access performanceDigital data processing detailsMemory adressing/allocation/relocationUnit sizeFile system

Exemplary embodiments of the invention provide a solution to deploy a virtual hard disk (VHD) to virtual device with maximizing capacity efficiency and data access performance by making the allocation unit size of virtual device the same as that of the VHD. In one embodiment, a method of deploying a VHD file to a storage apparatus comprises checking a block size of the VHD file received by the storage apparatus based on a header of the VHD file; creating a virtual volume to provide a page size which is same size as the block size of the VHD file; and performing one of (A) copying contents of the VHD file to the created virtual volume by allocating one page of the created virtual volume for each block of the VHD file; or (B) formatting the created virtual volume with a virtual volume file system, and copying the VHD file to the formatted virtual volume.

Owner:HITACHI LTD

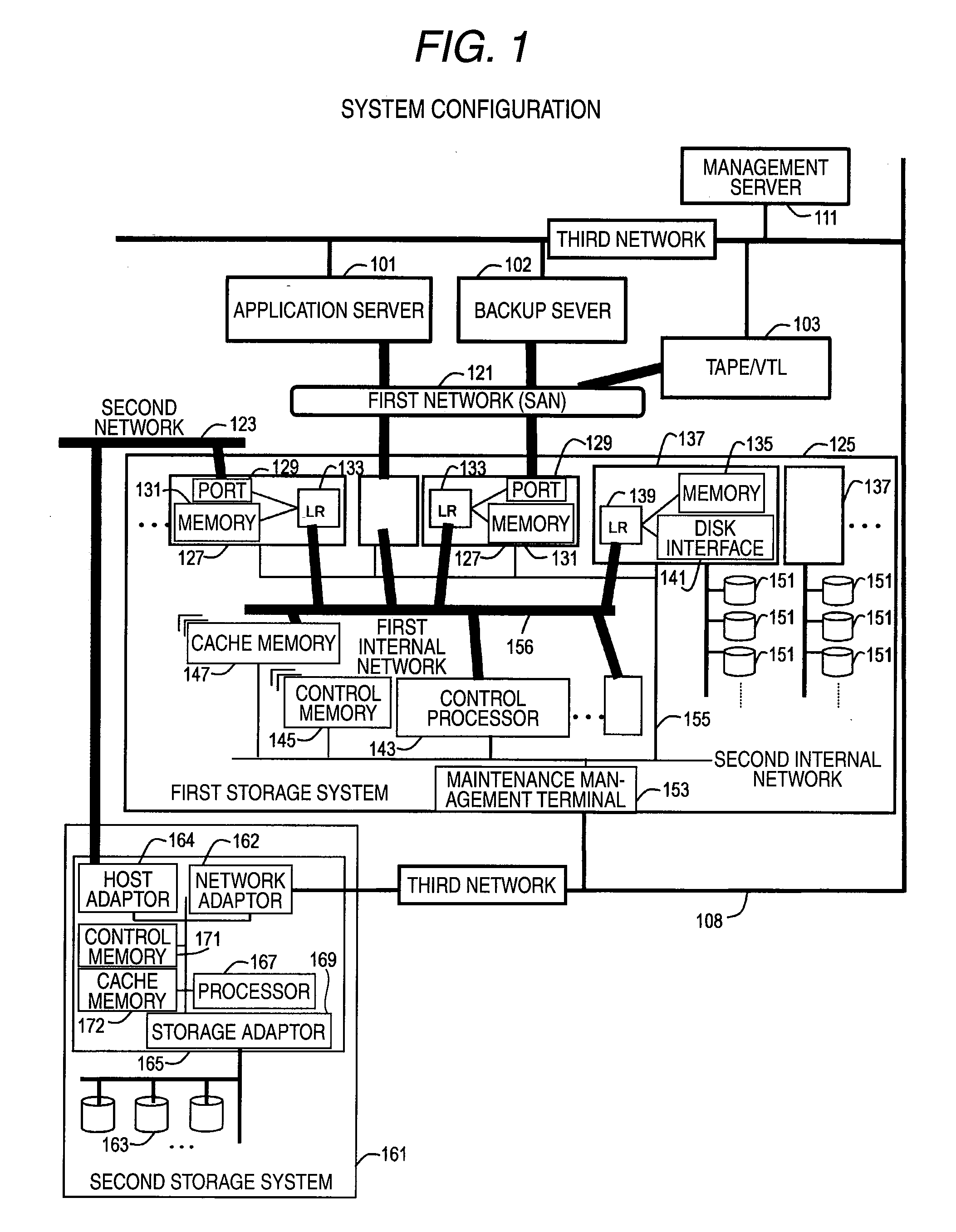

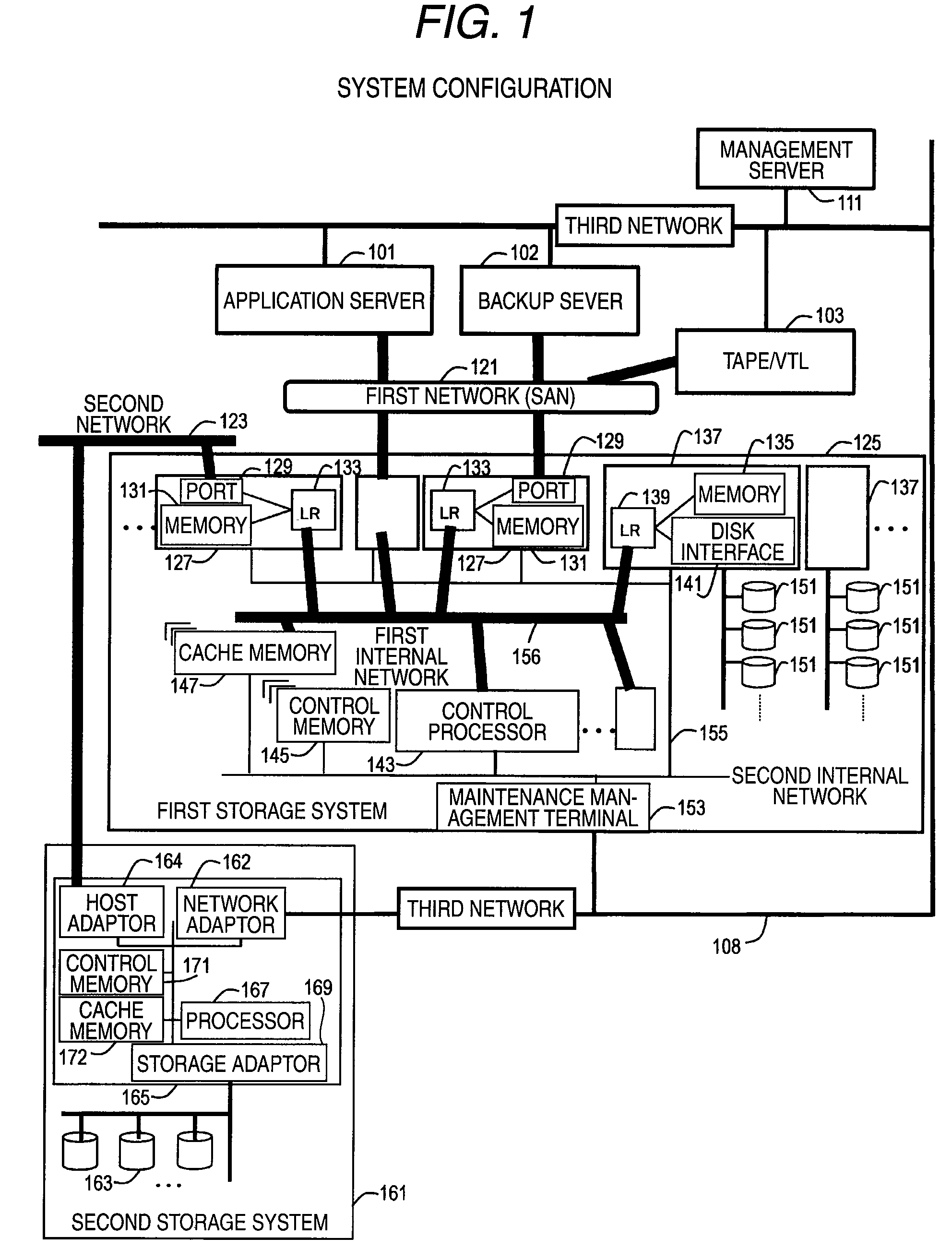

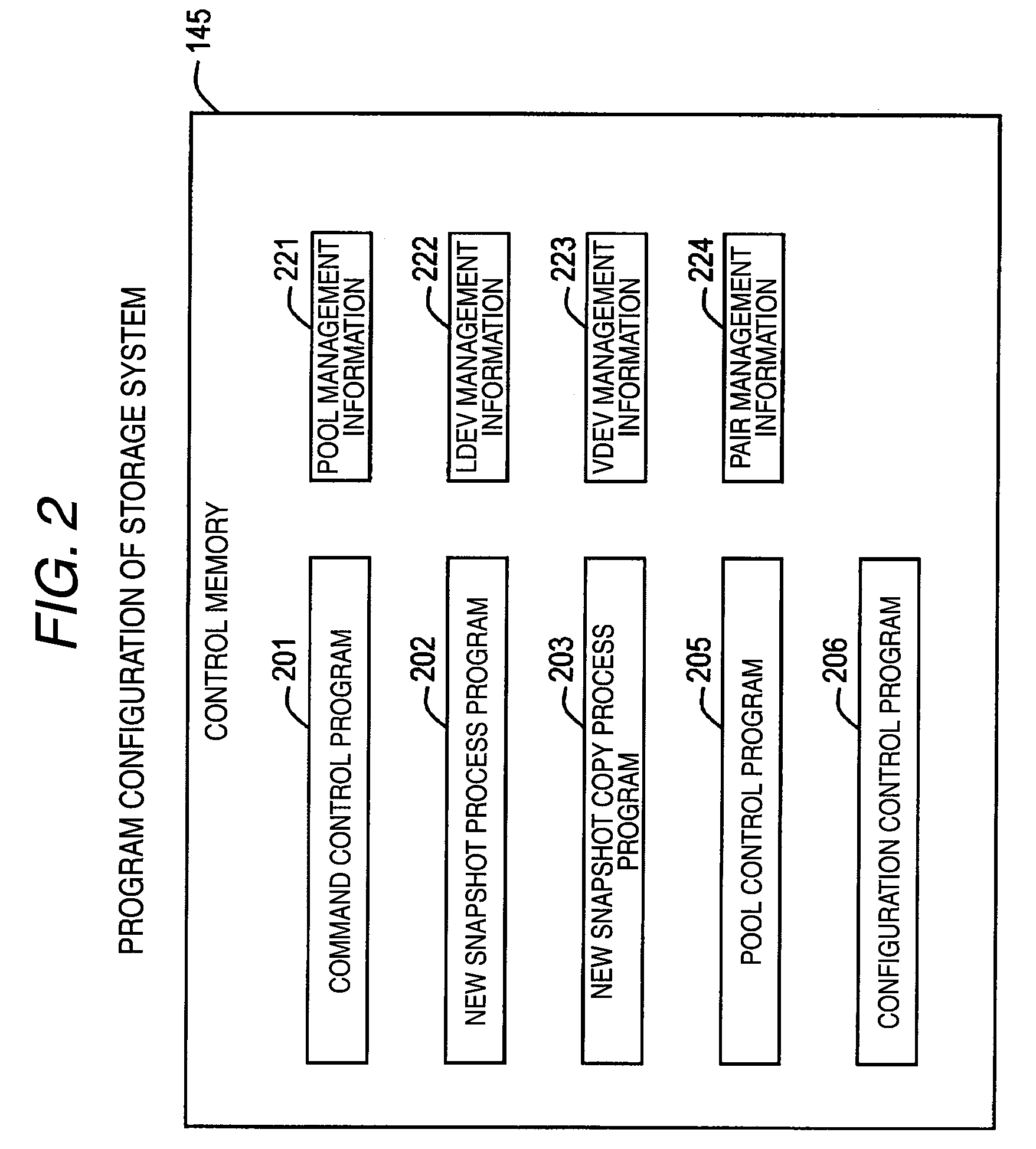

Storage system and method implementing online volume and snapshot with performance/failure independence and high capacity efficiency

InactiveUS20100131727A1Improve capacity efficiencyMemory loss protectionError detection/correctionFirst generationData storing

A storage system for storage of data written from a computer, and when a write request of data to a first logical volume is received, the data on request is stored into the first logical volume. When a first-generation snapshot creation request is received, the data stored in the first logical volume at the time of receiving the first-generation snapshot creation request is written into a pool region as data corresponding to a first-generation snapshot, and when a second-generation snapshot creation request is received, any portion of the data updated after the first-generation snapshot creation request is received but before the second-generation snapshot creation request is issued is read from the first logical volume for writing into the pool region. Such a storage system favorably implements snapshot backup with no dependency with a positive volume in terms of performance and failure, and with high capacity efficiency.

Owner:HITACHI LTD

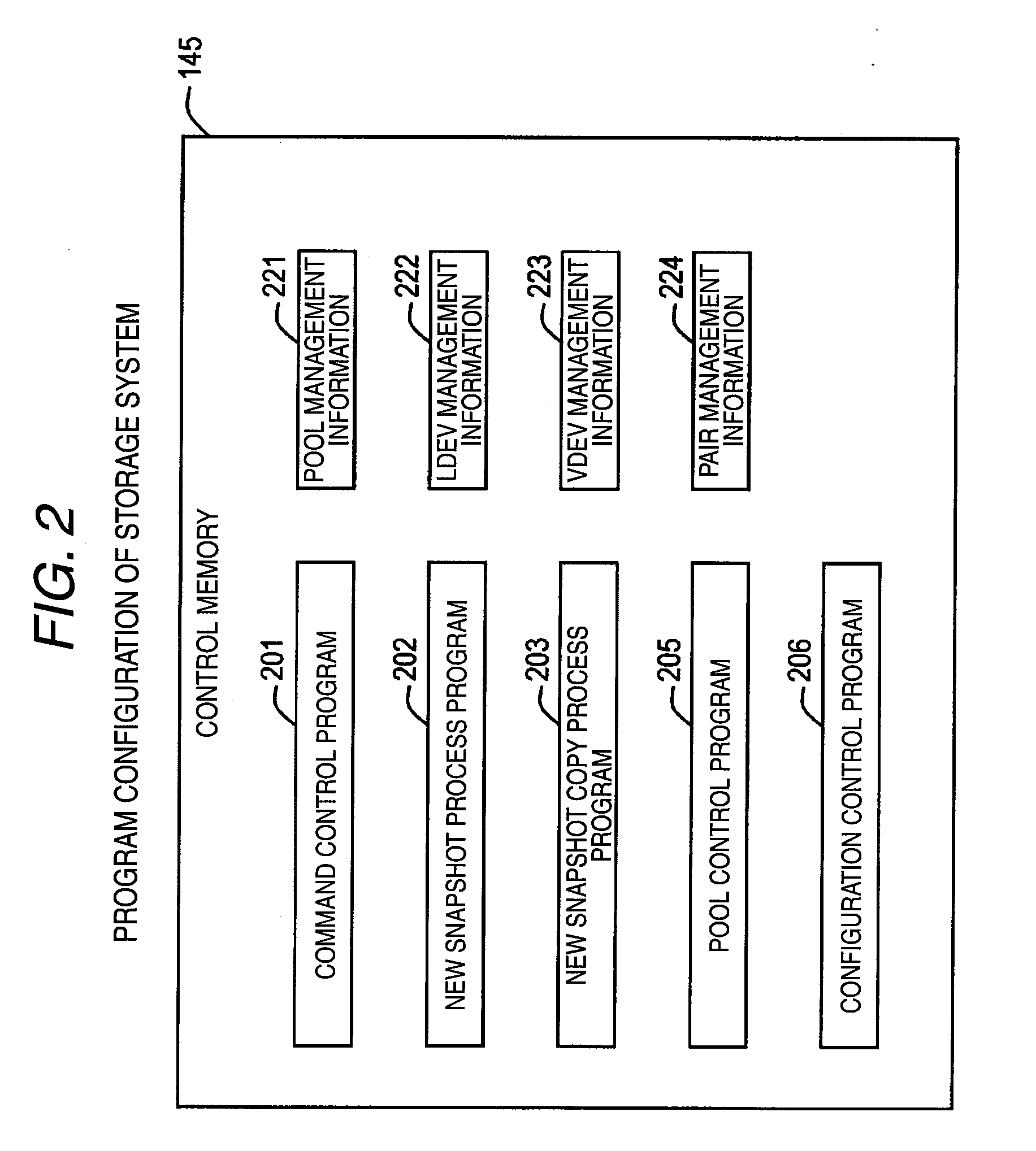

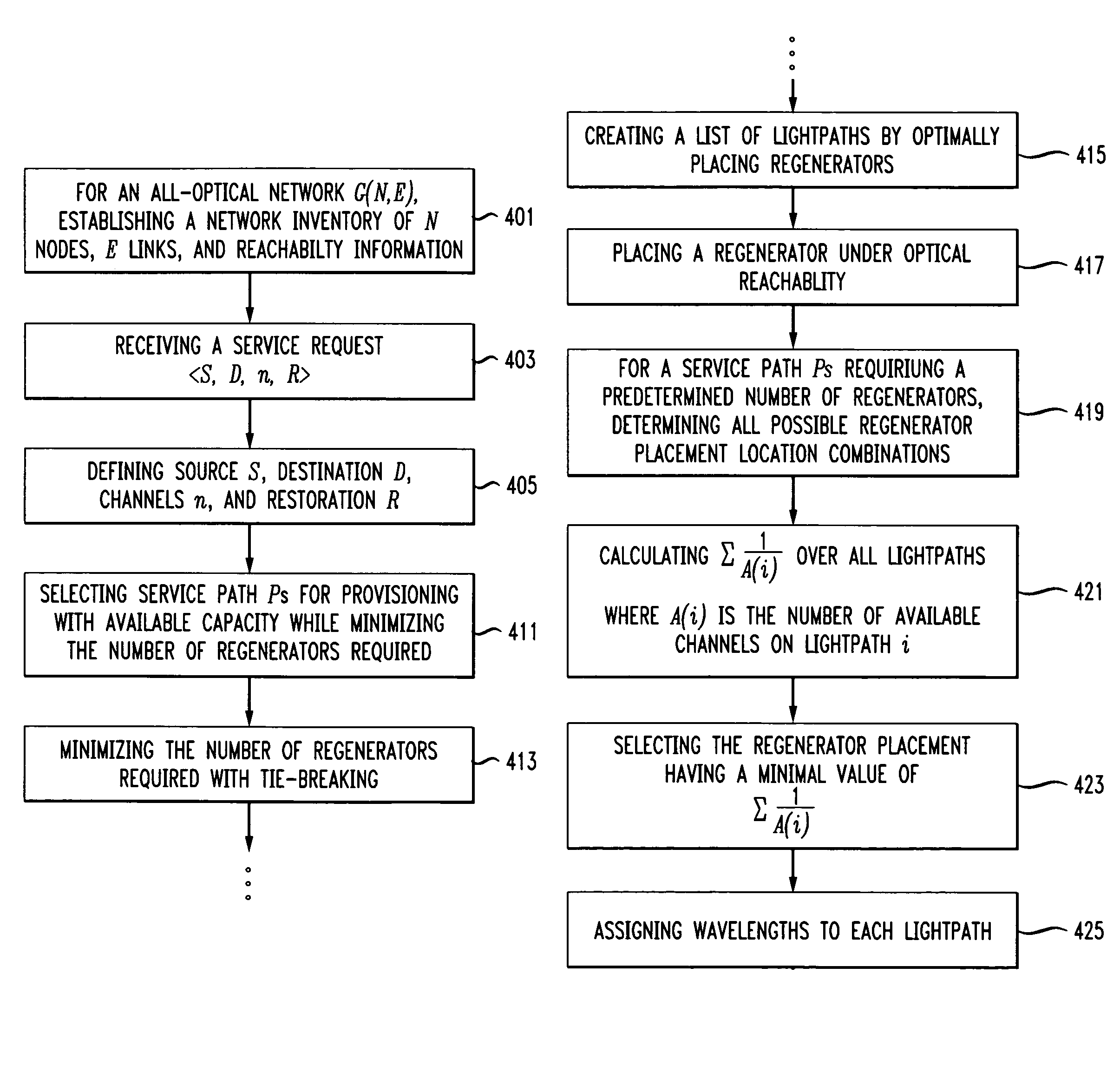

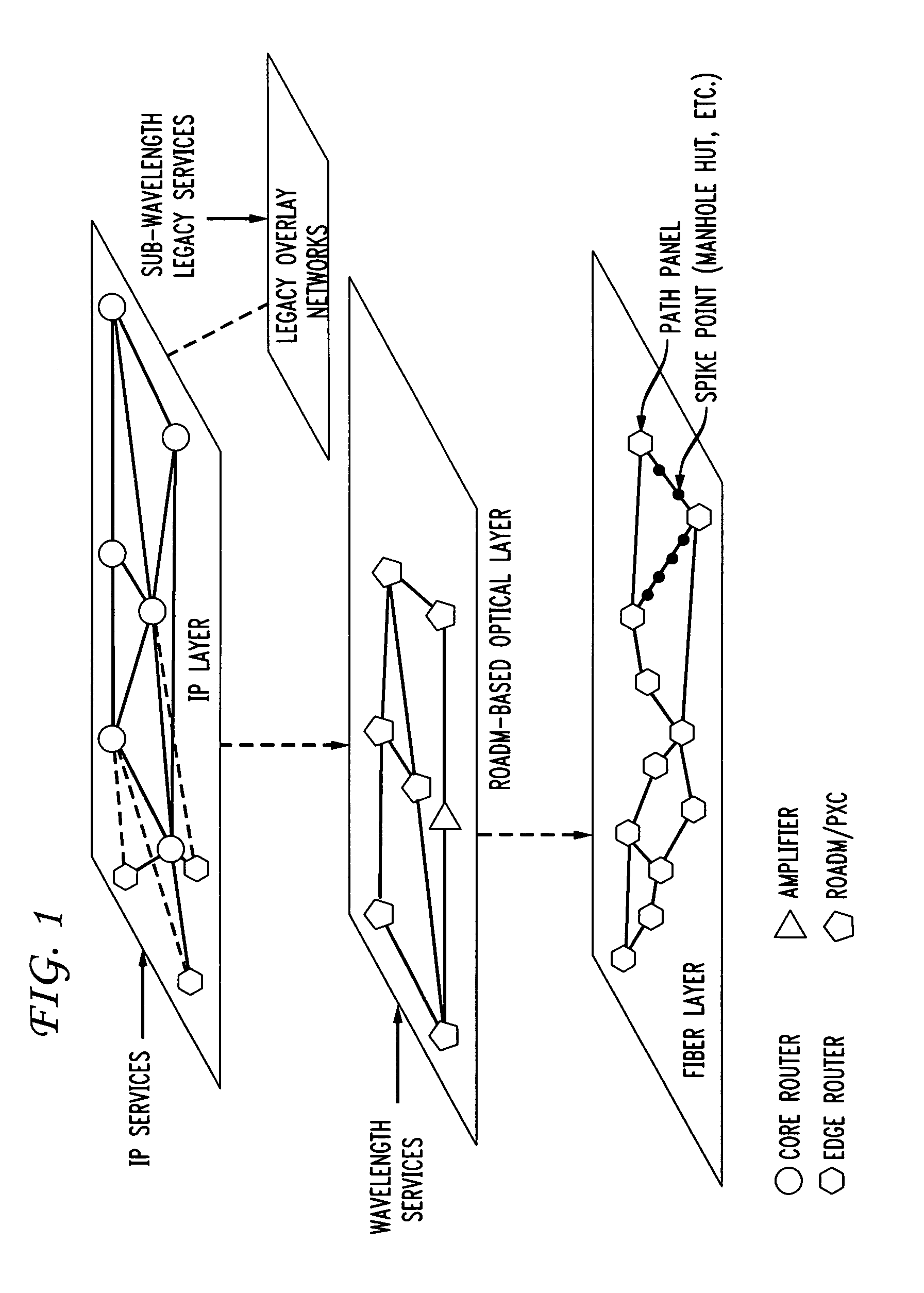

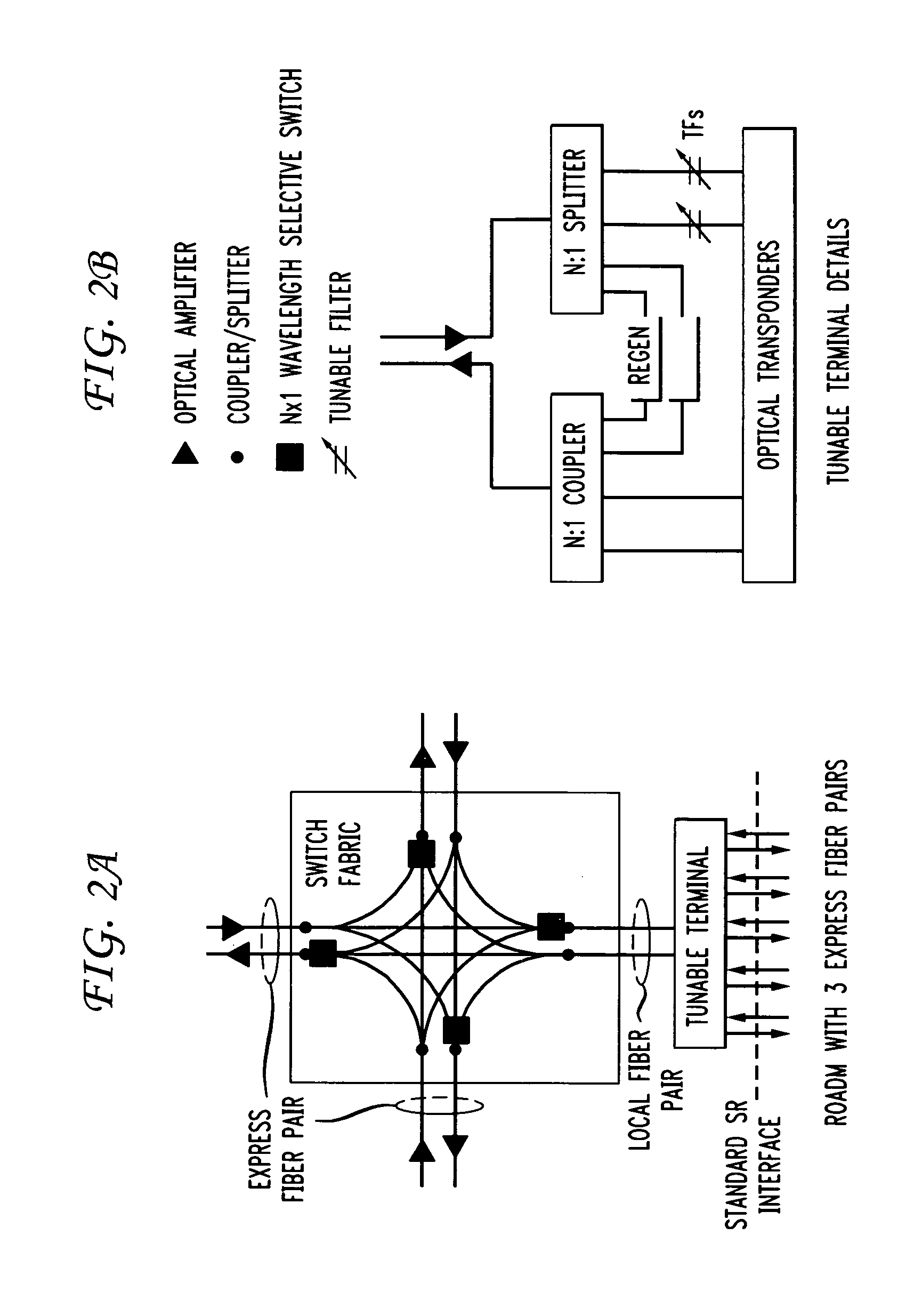

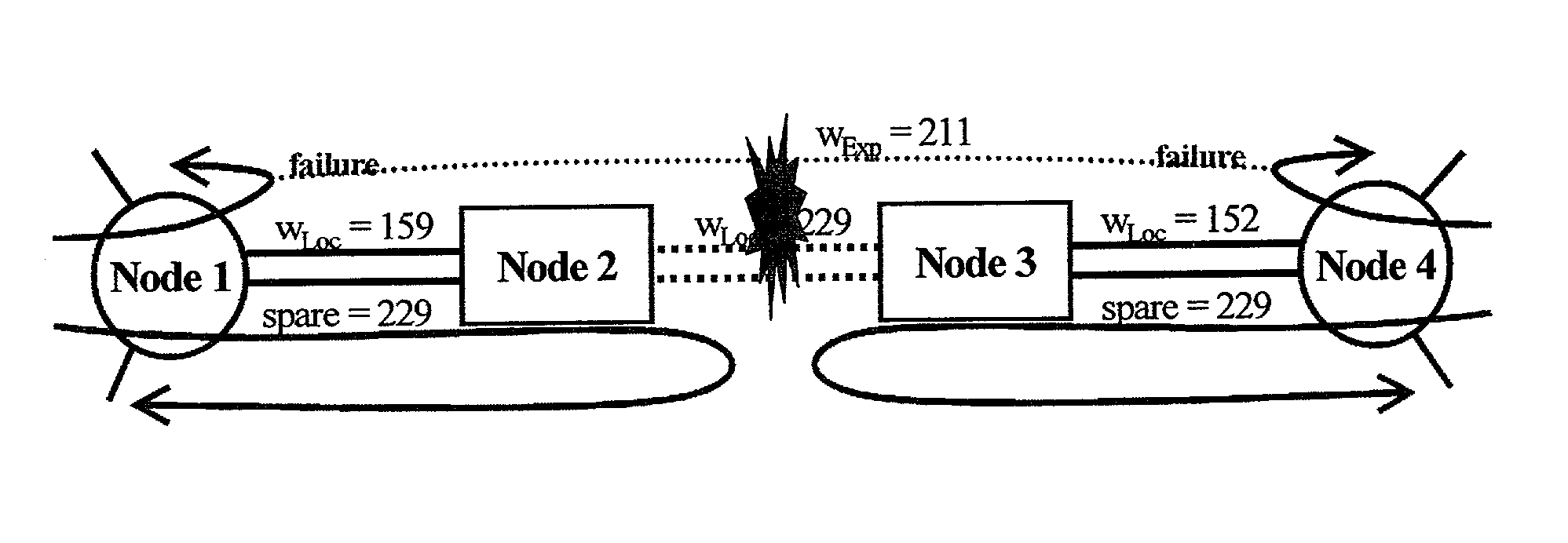

Shared mesh restoration with pre-configured standby lightpaths

ActiveUS8150257B1Minimize the numberLaser detailsOptical multiplexCross connectionRestoration method

Systems and methods are described for restoring wavelength services in mesh networks using pre-configured, standby lightpaths. The standby lightpaths are pre-cross-connected lightpaths that provide connectivity between switching nodes having a fiber link of degree-2 or higher. The restoration method overcomes the problem of optical impairments for long haul connections, avoids wavelength power balancing delays, provides wavelength conversion for capacity efficiency, and allows sharing of links across nonsimultaneous failures.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

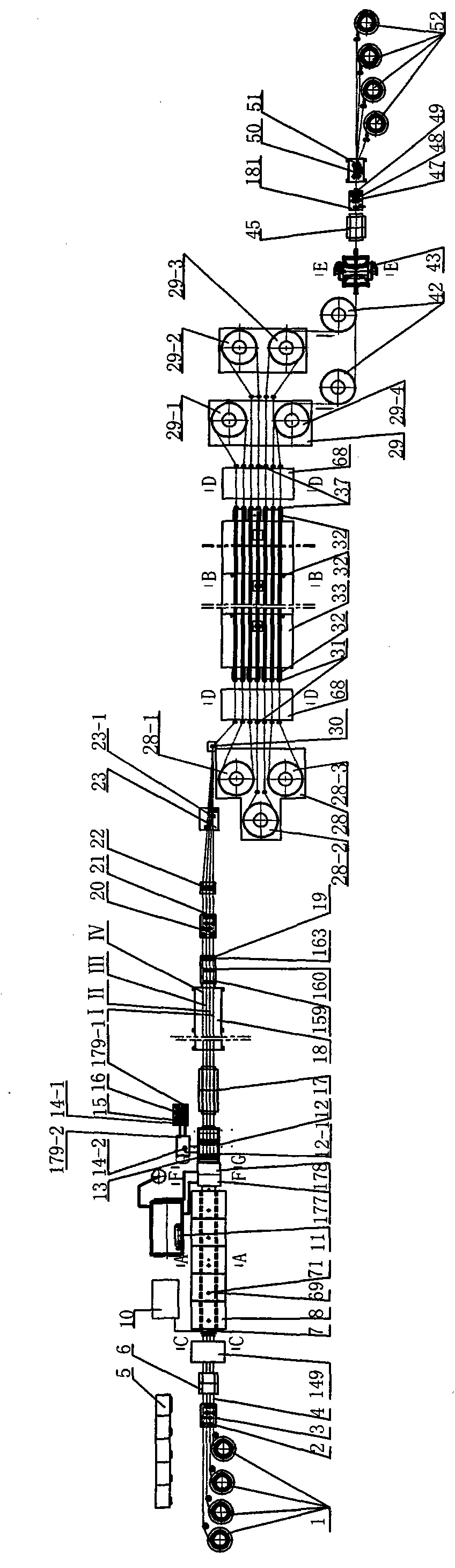

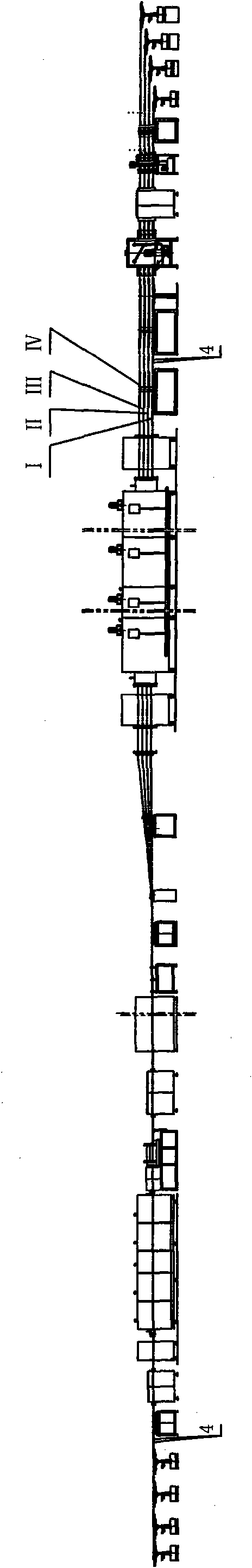

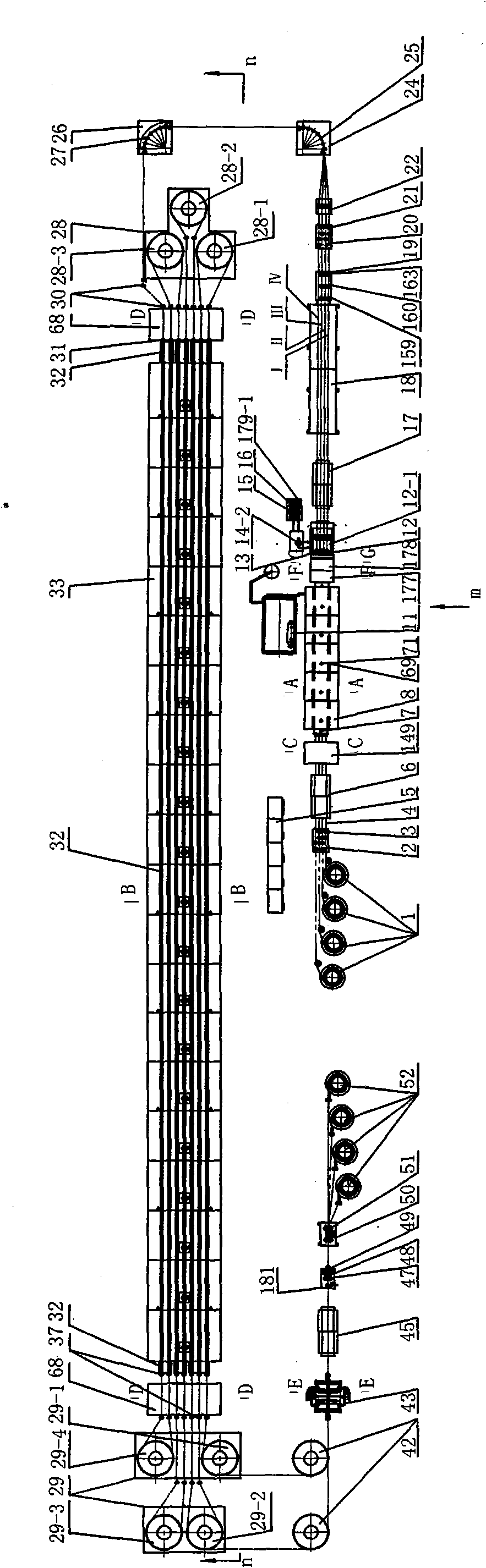

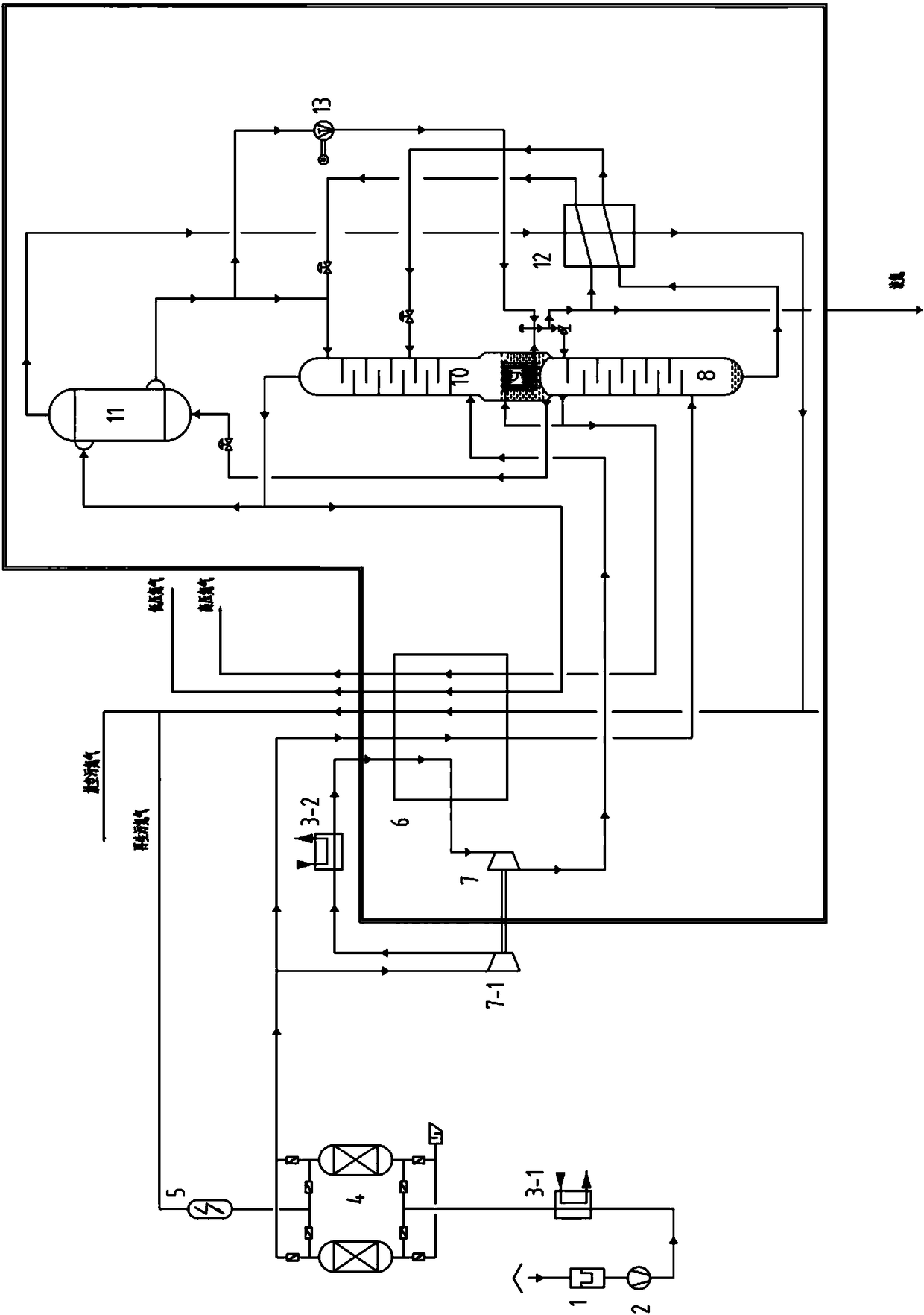

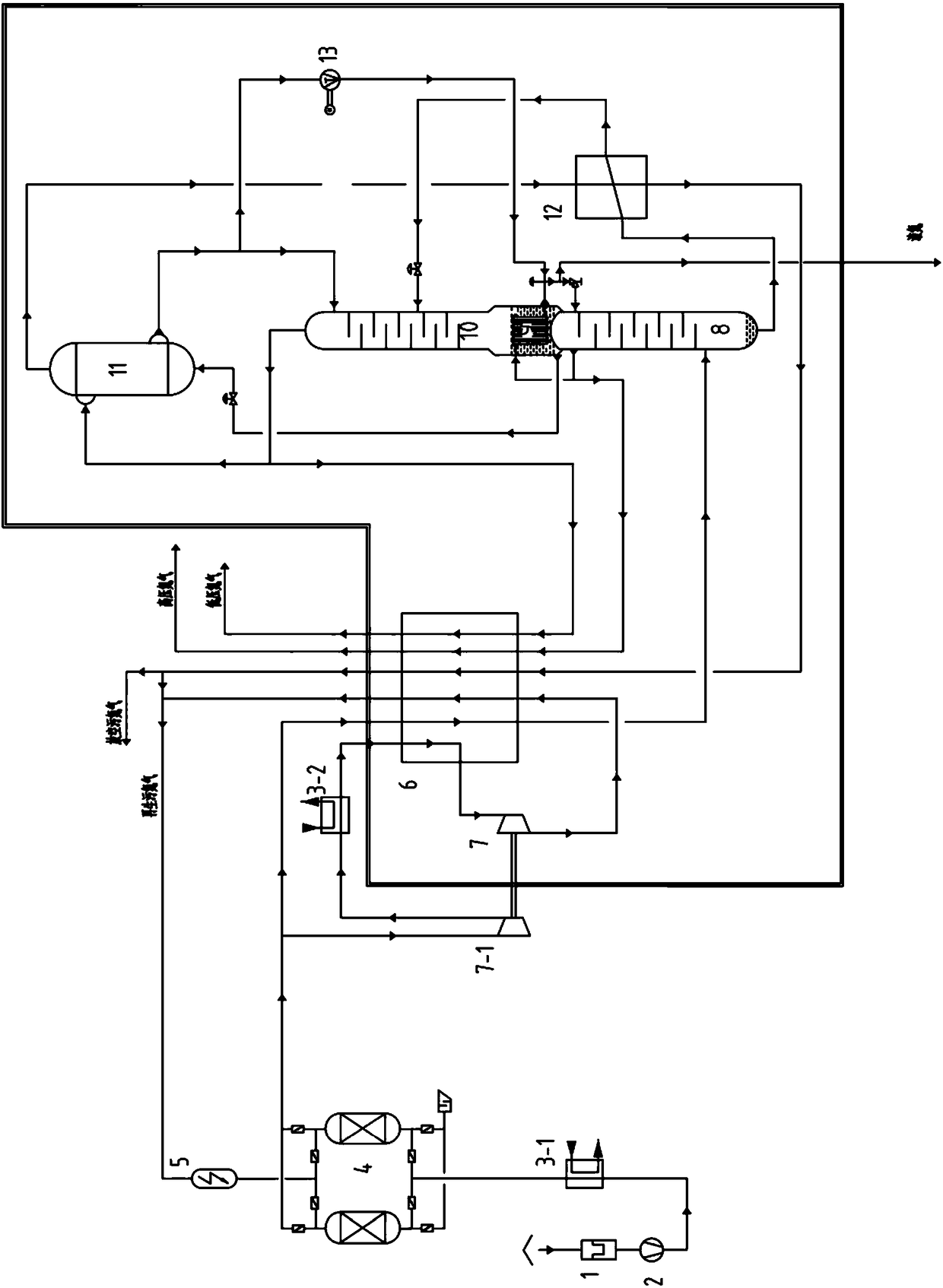

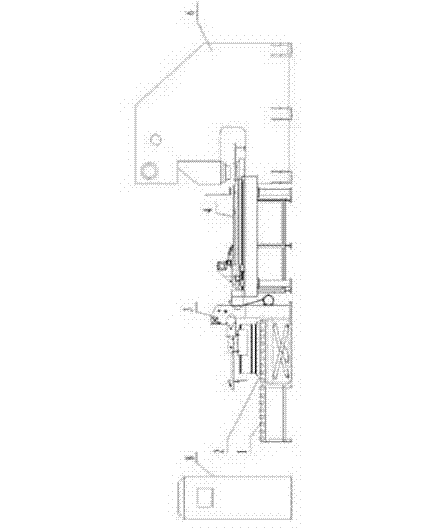

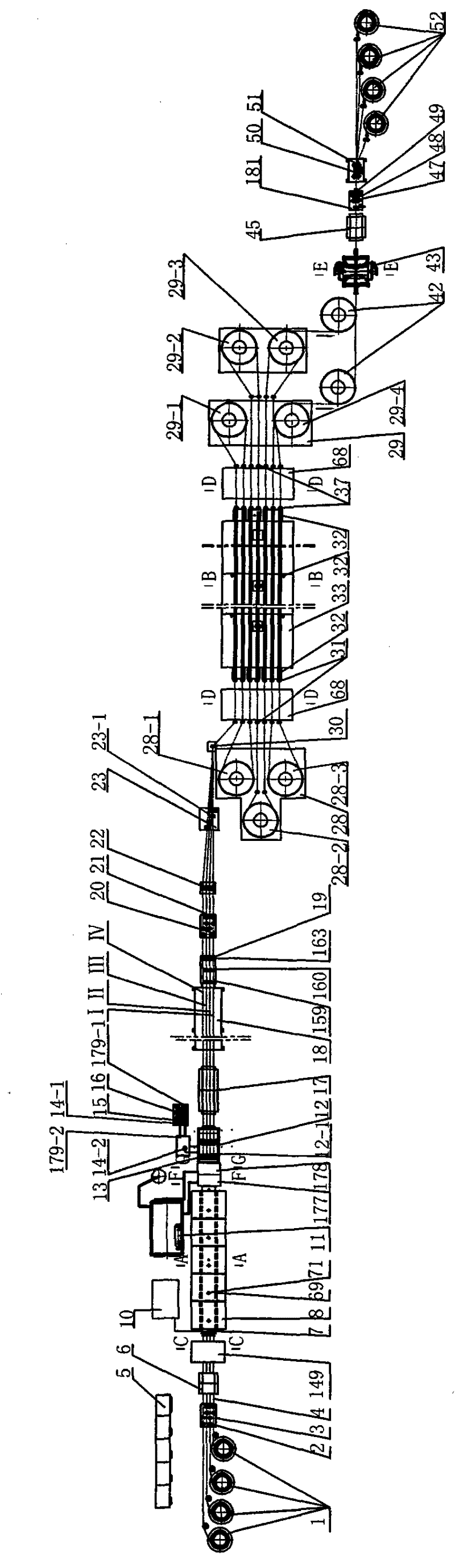

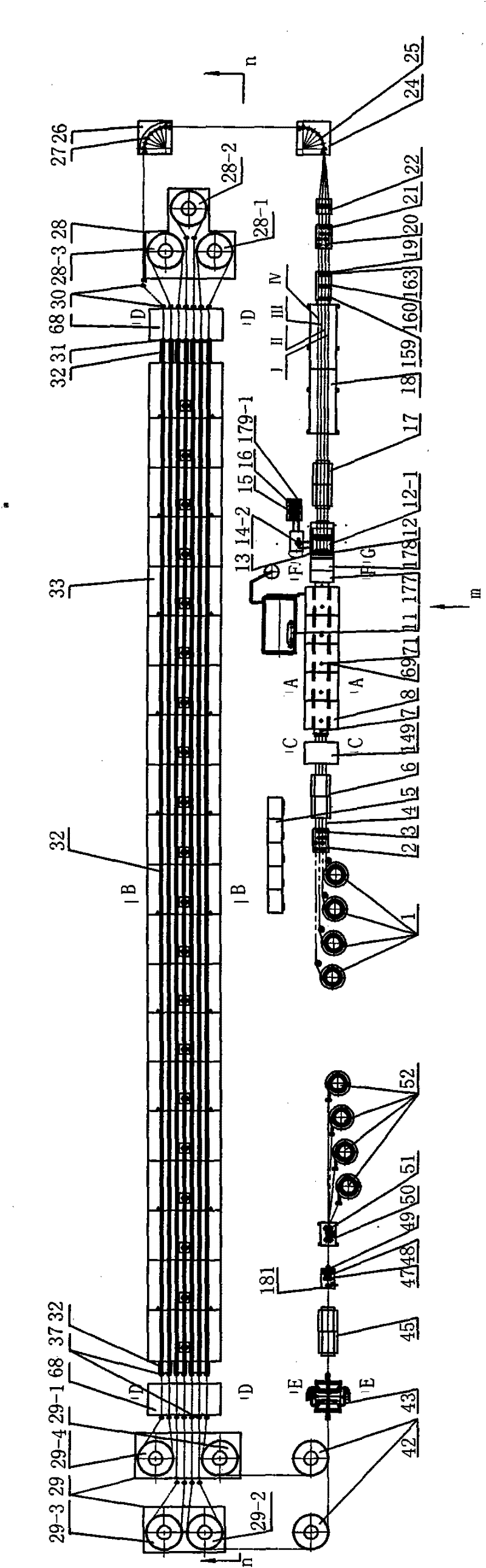

Multifunctional same-furnace multi-band bimetal strip saw blade heat treatment full-automatic production line and process thereof

ActiveCN101956056AIncrease work intensityImprove working environmentFurnace typesHeat treatment furnacesMulti bandQuenching

The invention discloses a multifunctional same-furnace multi-band bimetal strip saw blade heat treatment full-automatic production line and a process thereof, relating to a bimetal strip saw blade production line and a compound quenching process and solving the problems of difficult control of equipment and process parameters, difficult guarantee of product quality, incapability of producing multiple saw blades in various specifications at the same time, low equipment capacity efficiency, high production cost and energy wastes of water, power and gas at present. In the invention, equipment in all working procedures are integrated into one production line, all the working procedures of quenching, tempering, sand blasting, cleaning, baking, marking, oil coating, straightening and the like are completed on the same production line, the production of multiple saw blades in various specifications can be completed at the same time, and after the invention is applied, the total capacity can be improved by 5-8 times, the service life of the product can be improved by around 50%, and the production cost can be reduced by more than 40%. An on-ling dynamic rapid-tempering novel technology is adopted for tempering equipment and process, thus the saw blades travels faster on the production line to complete the whole process of tempering so that high capacity can be achieved for the saw blades.

Owner:曹玉贵

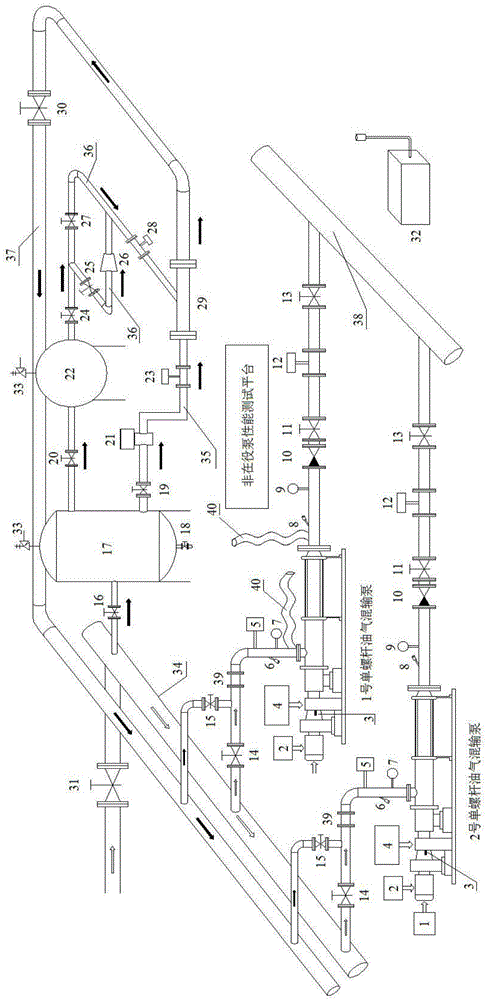

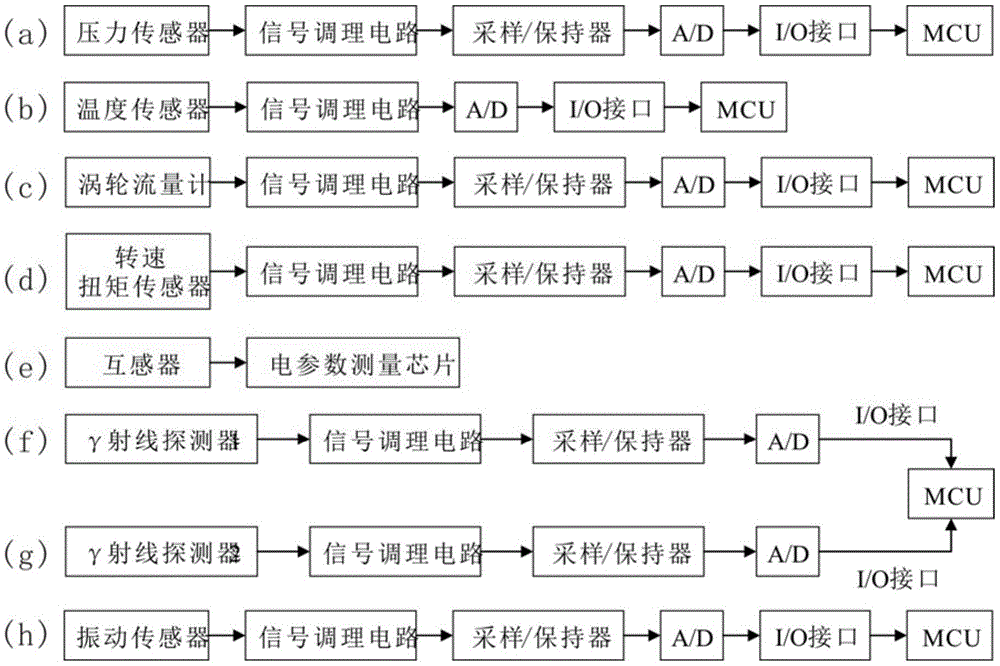

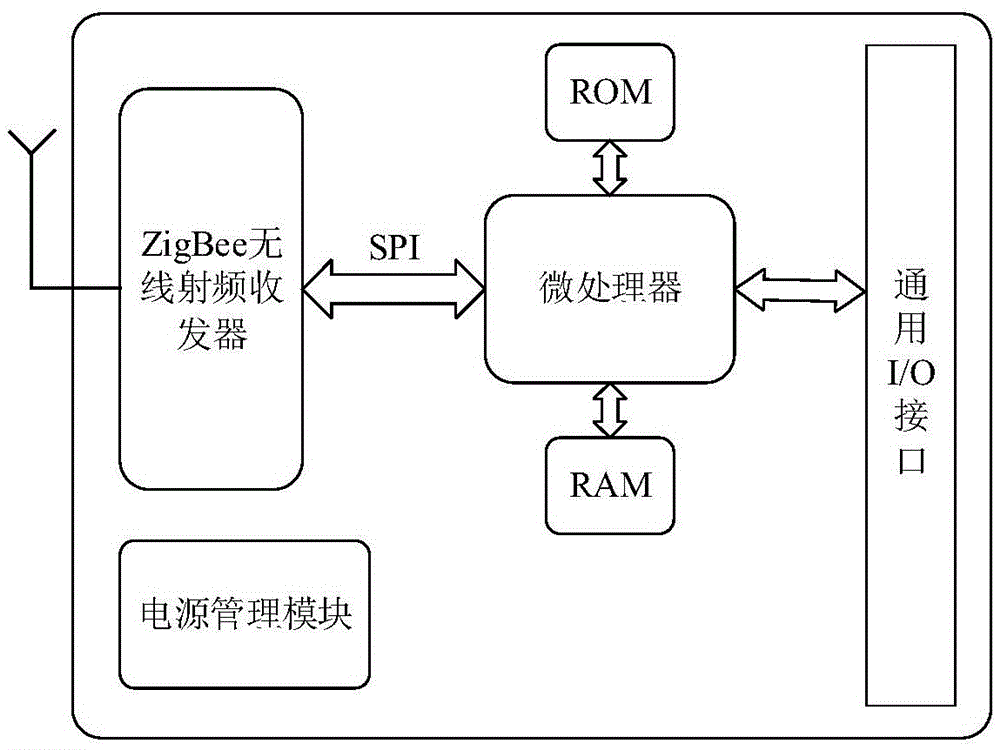

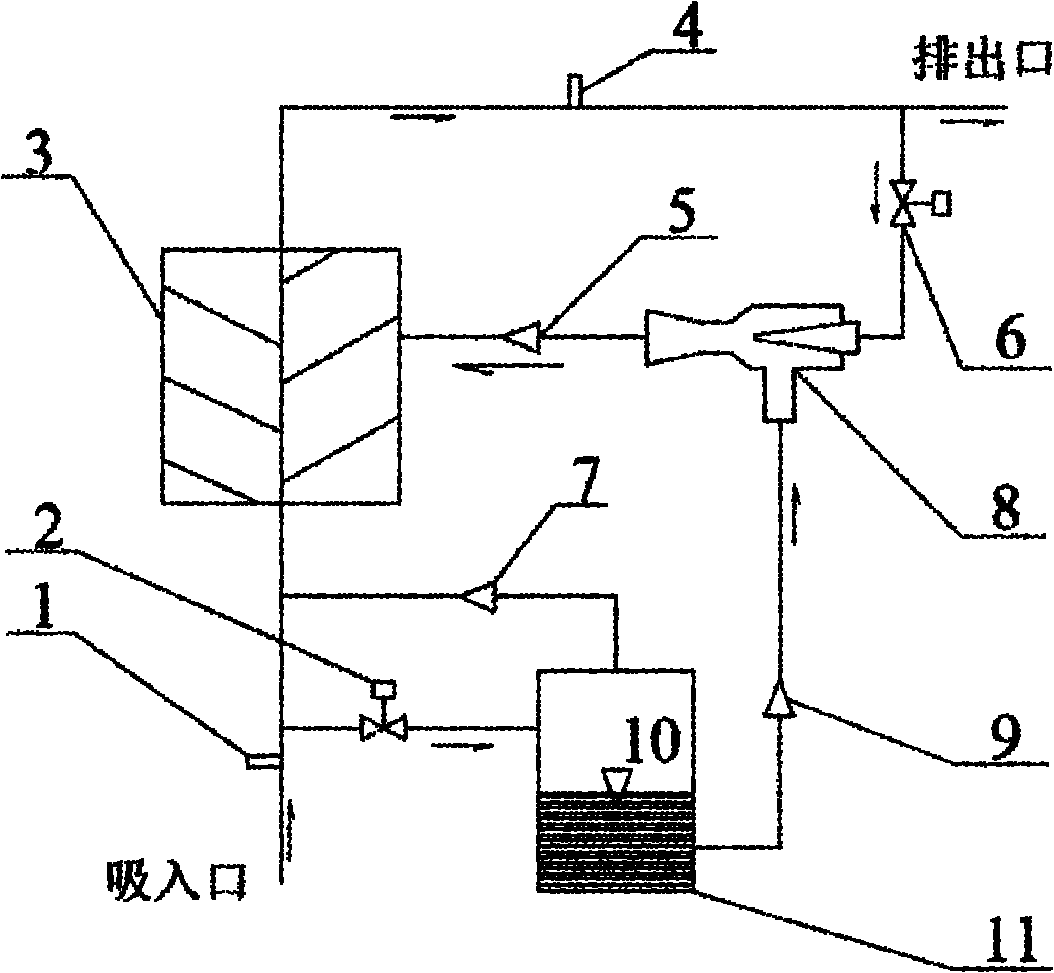

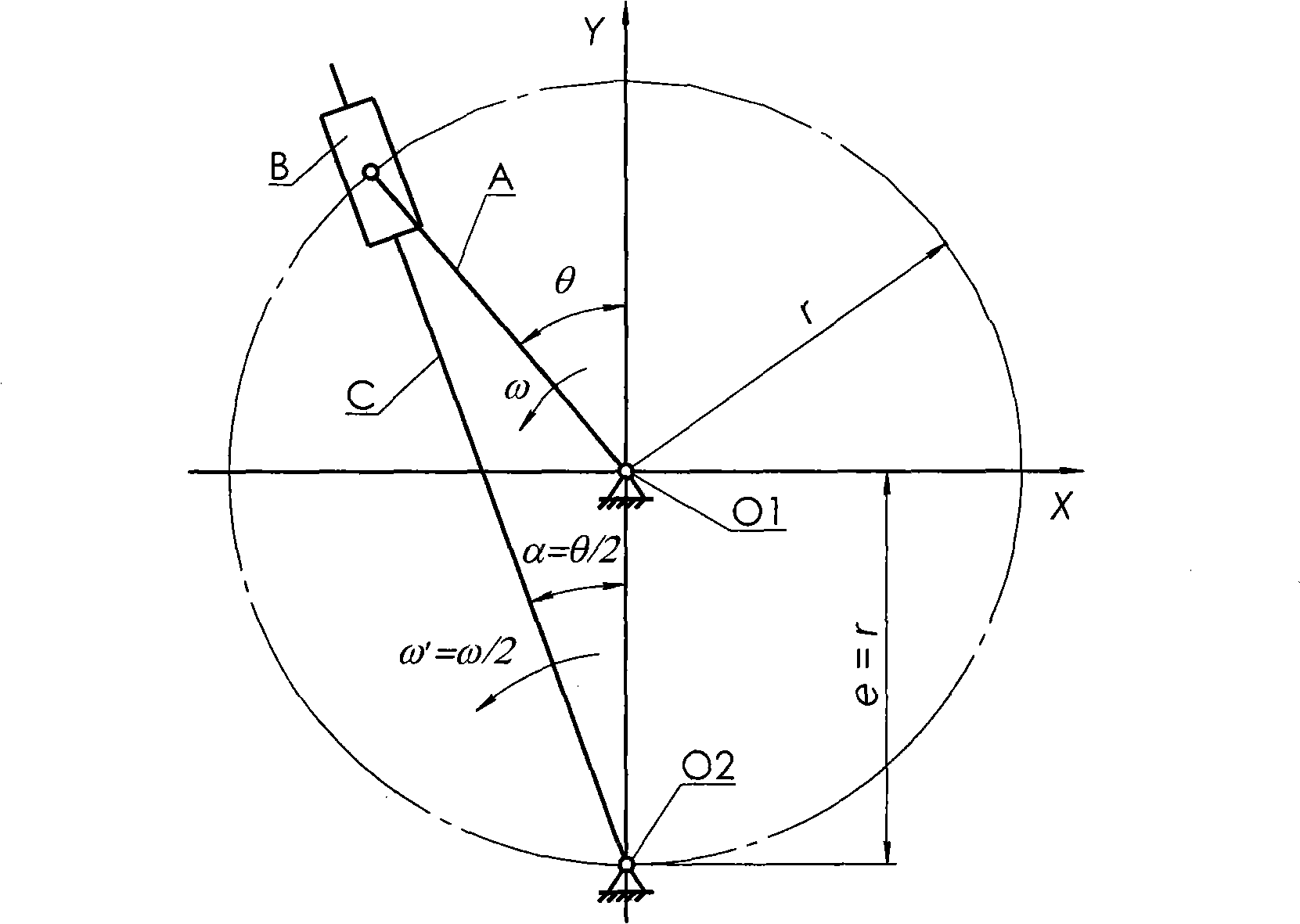

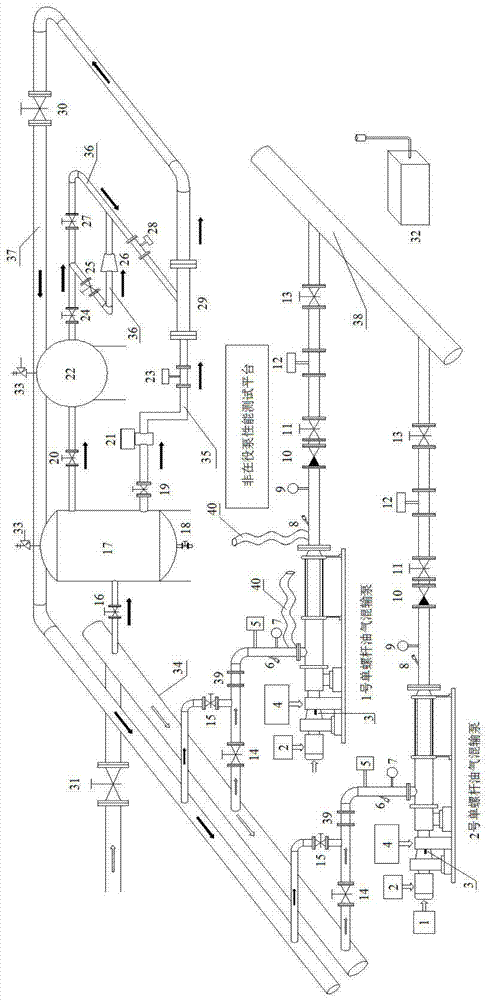

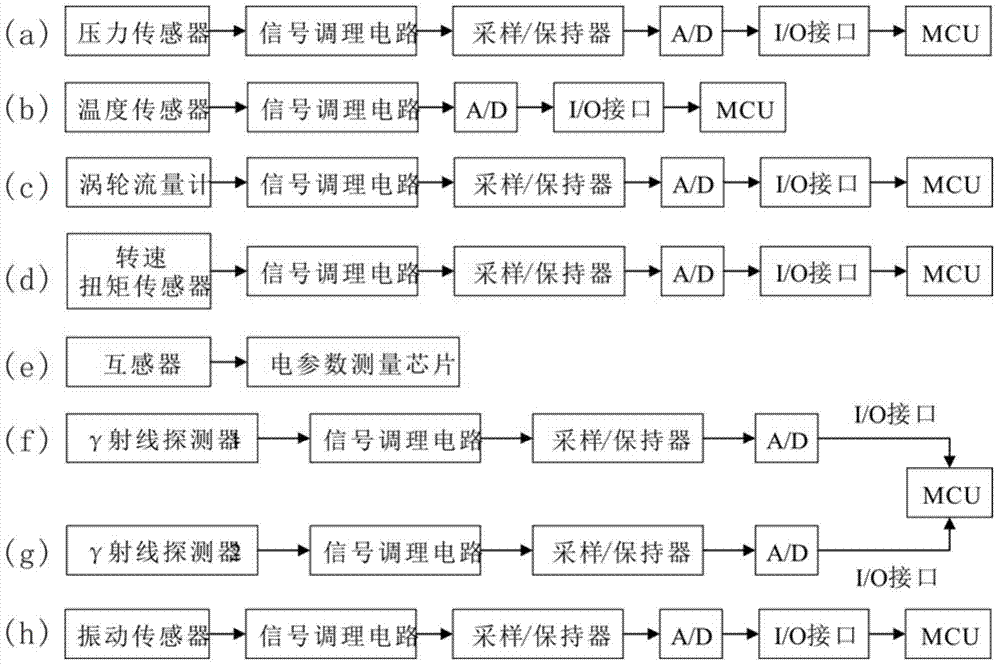

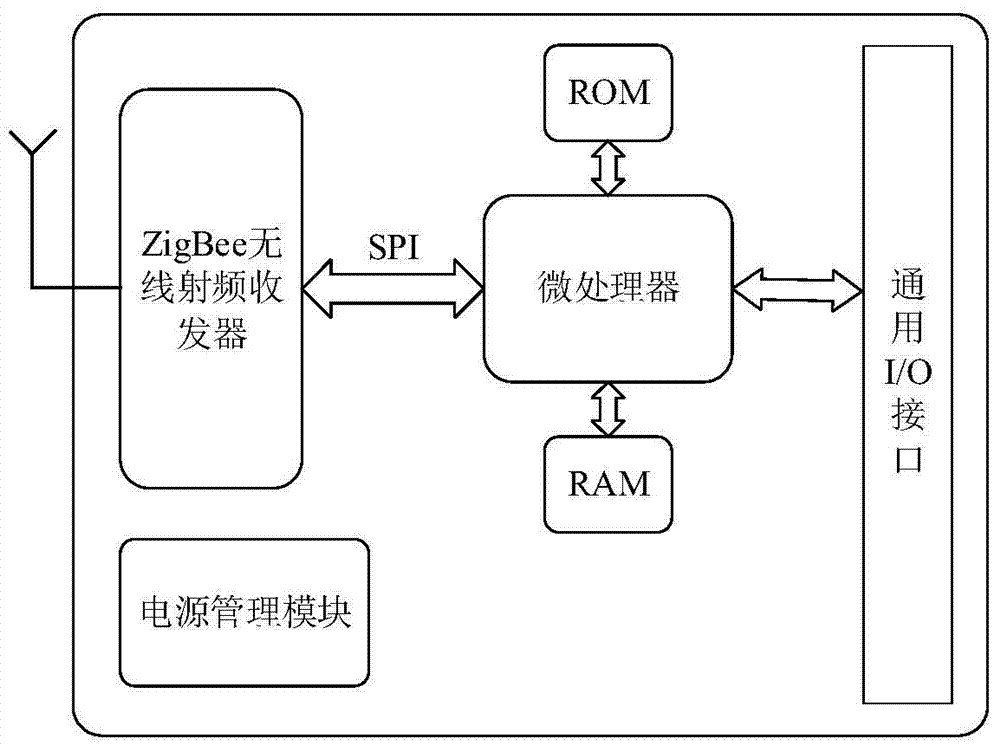

Device and method for diagnosing faults and testing performance of single-screw pump

InactiveCN105649978ARealize online monitoringImplement fault diagnosisPump componentsRotary piston pumpsEngineeringTest fixture

The invention provides a device and method for diagnosing faults and testing performance of a single-screw pump. The operation condition of the single-screw pump can be subjected to online monitoring, fault diagnosis and performance testing. Two work modes, namely, a normal production monitoring mode and a performance online testing mode are provided in the device. In the normal production monitoring mode, based on real-time monitoring on running parameters of the pump in the normal production process, the online monitoring of the operation condition of the pump is achieved; and online diagnosis of common faults of the pump can be completed by means of online detected data, and a maintaining strategy is made on the basis. In the pump performance testing mode, pump performance testing of an in-service single-screw pump / an out-of-service single-screw pump under a common operating condition / extreme operating condition can be achieved, the pump capacity efficiency, the shaft power, the lift, the overall efficiency and other performance parameters can be calculated under different operating conditions, and a performance curve is drawn and stored on the basis.

Owner:SOUTHWEST PETROLEUM UNIV

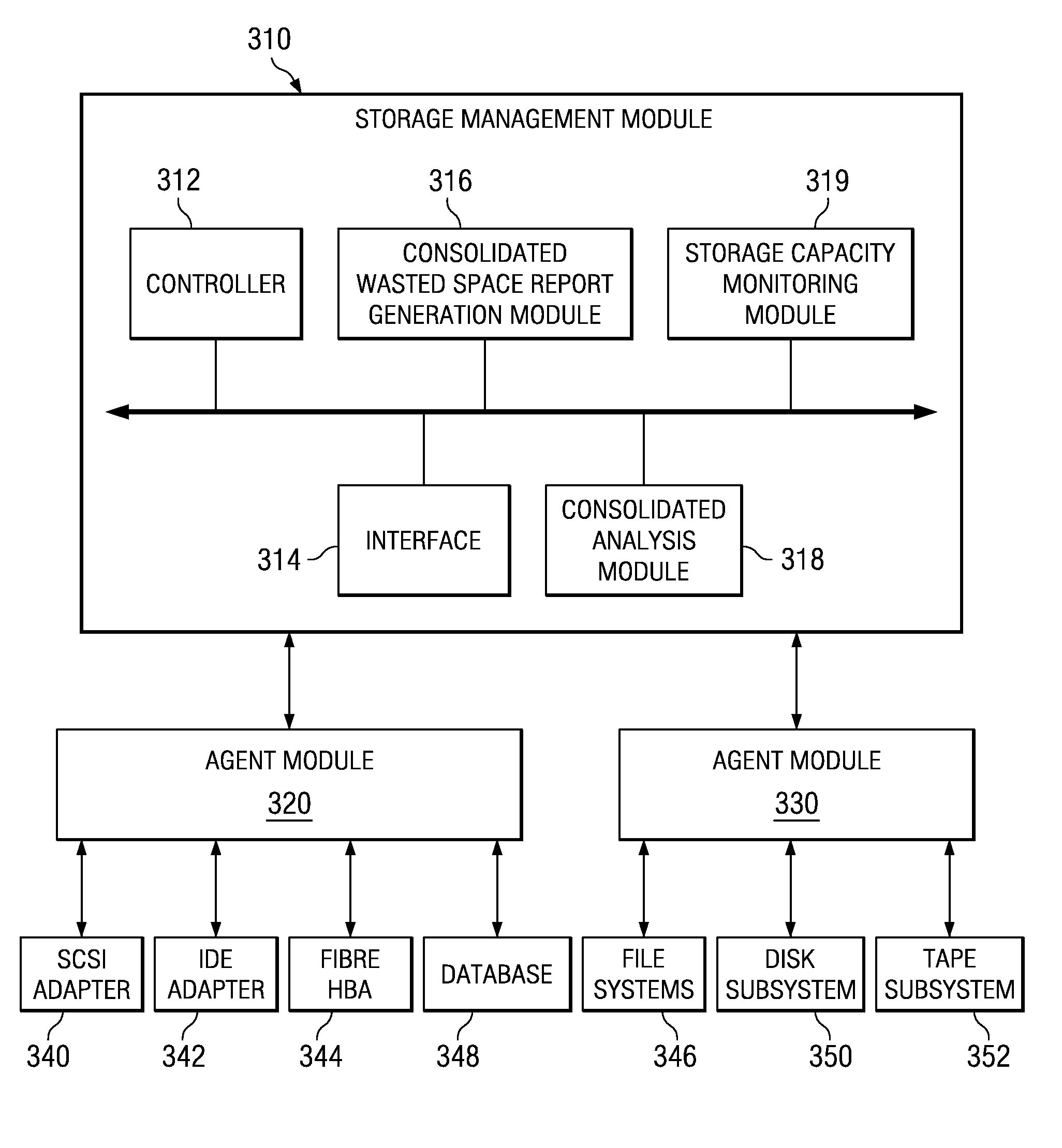

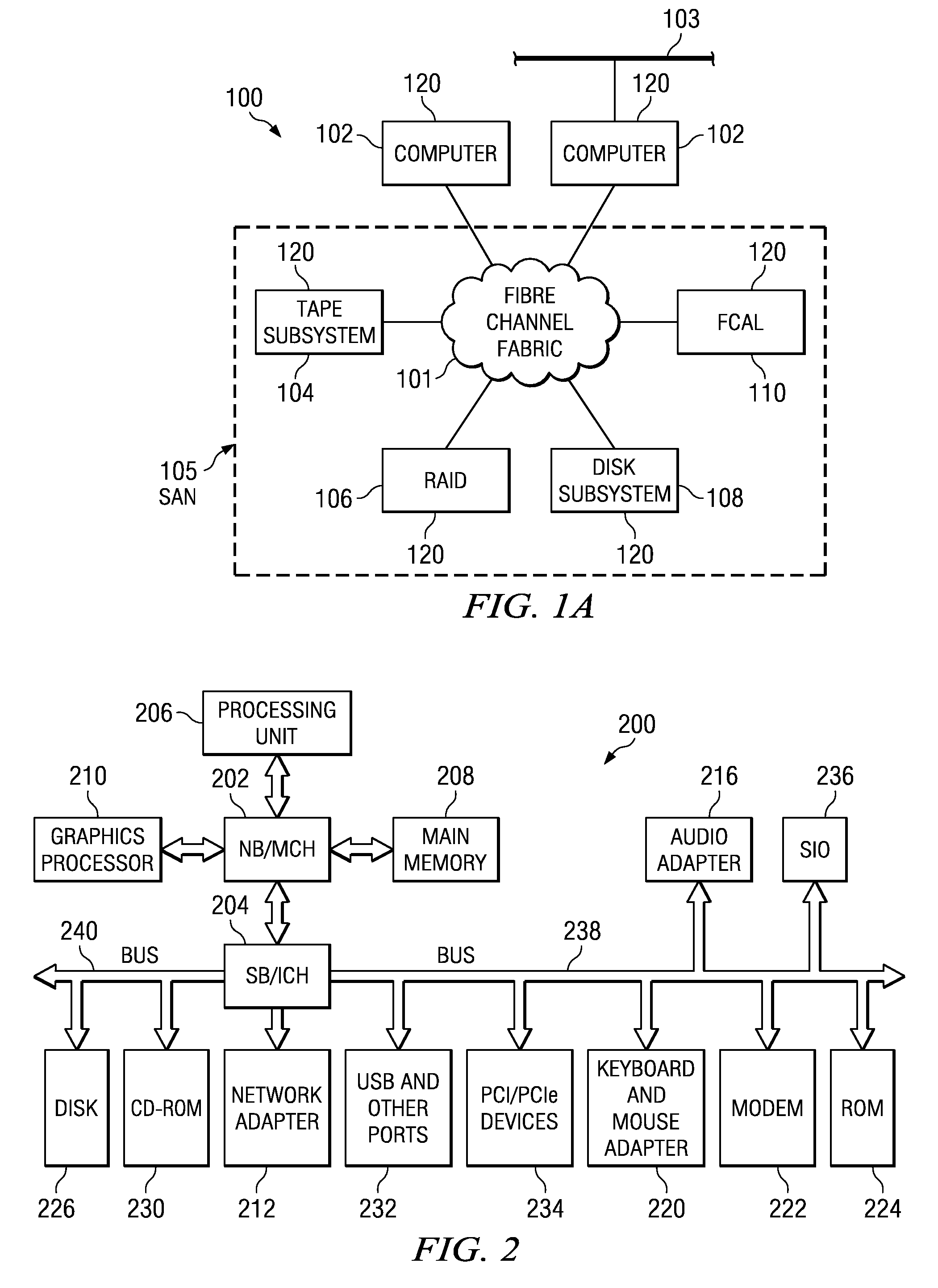

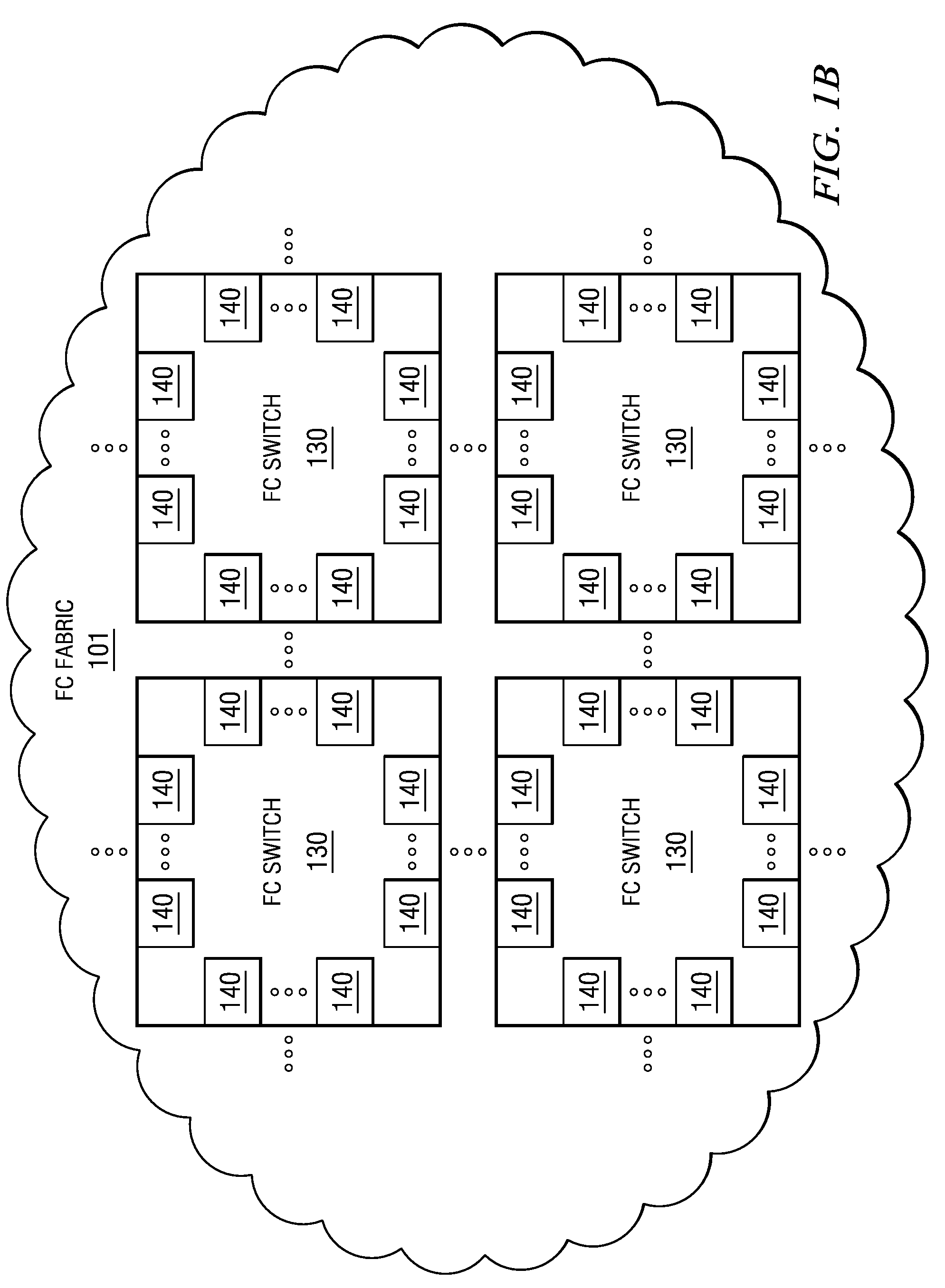

Correlated Analysis of Wasted Space and Capacity Efficiency in Complex Storage Infrastructures

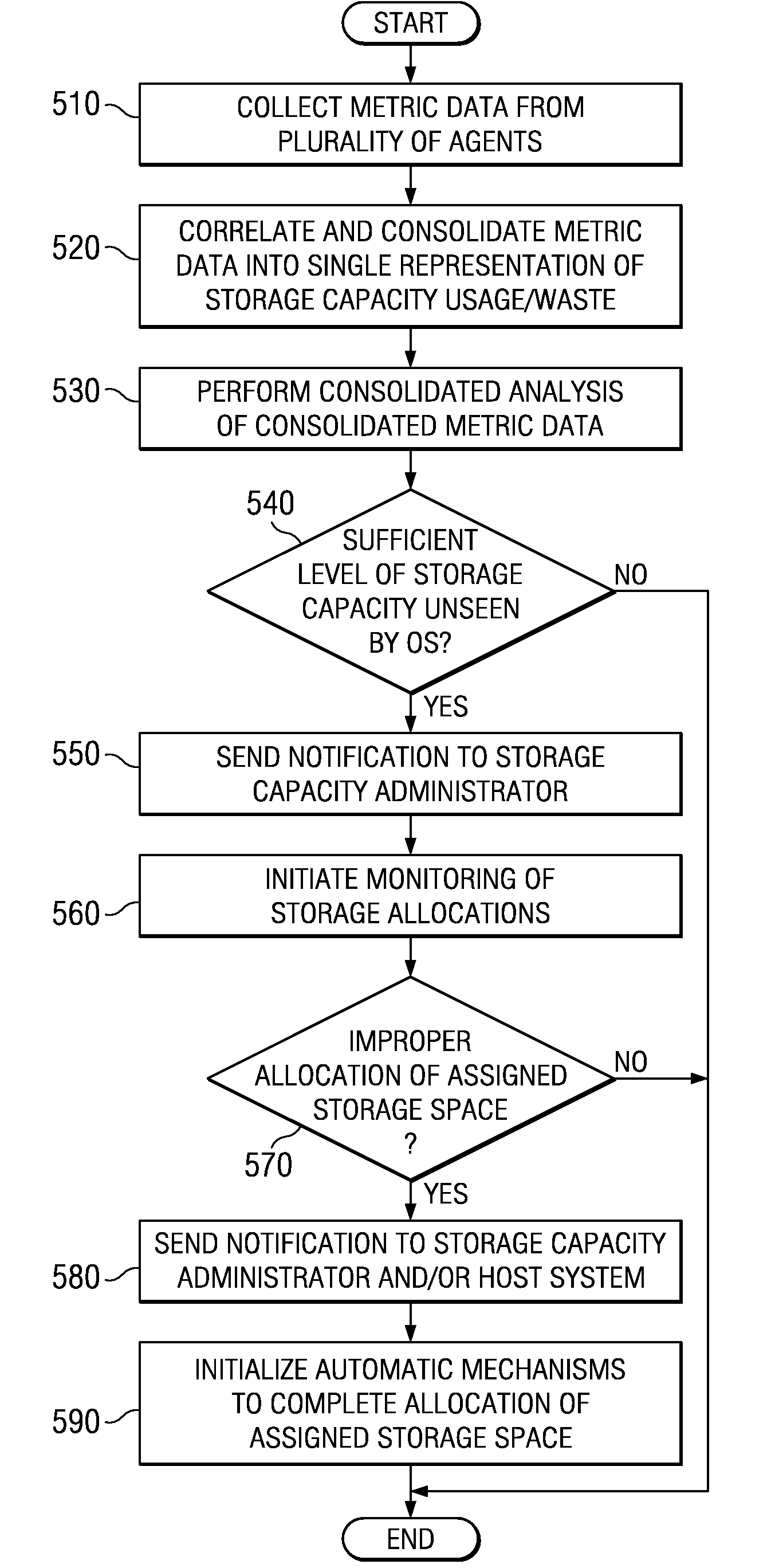

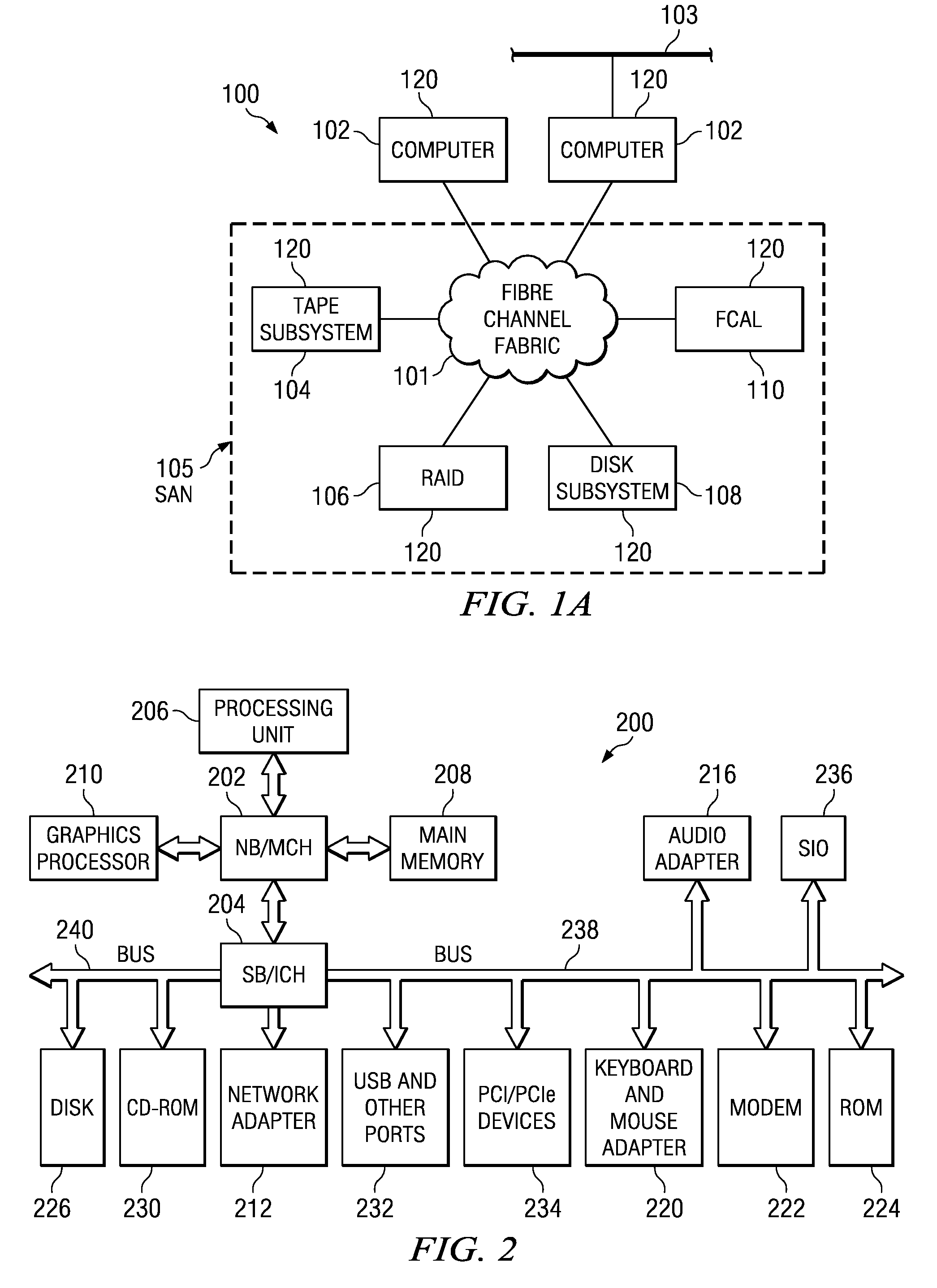

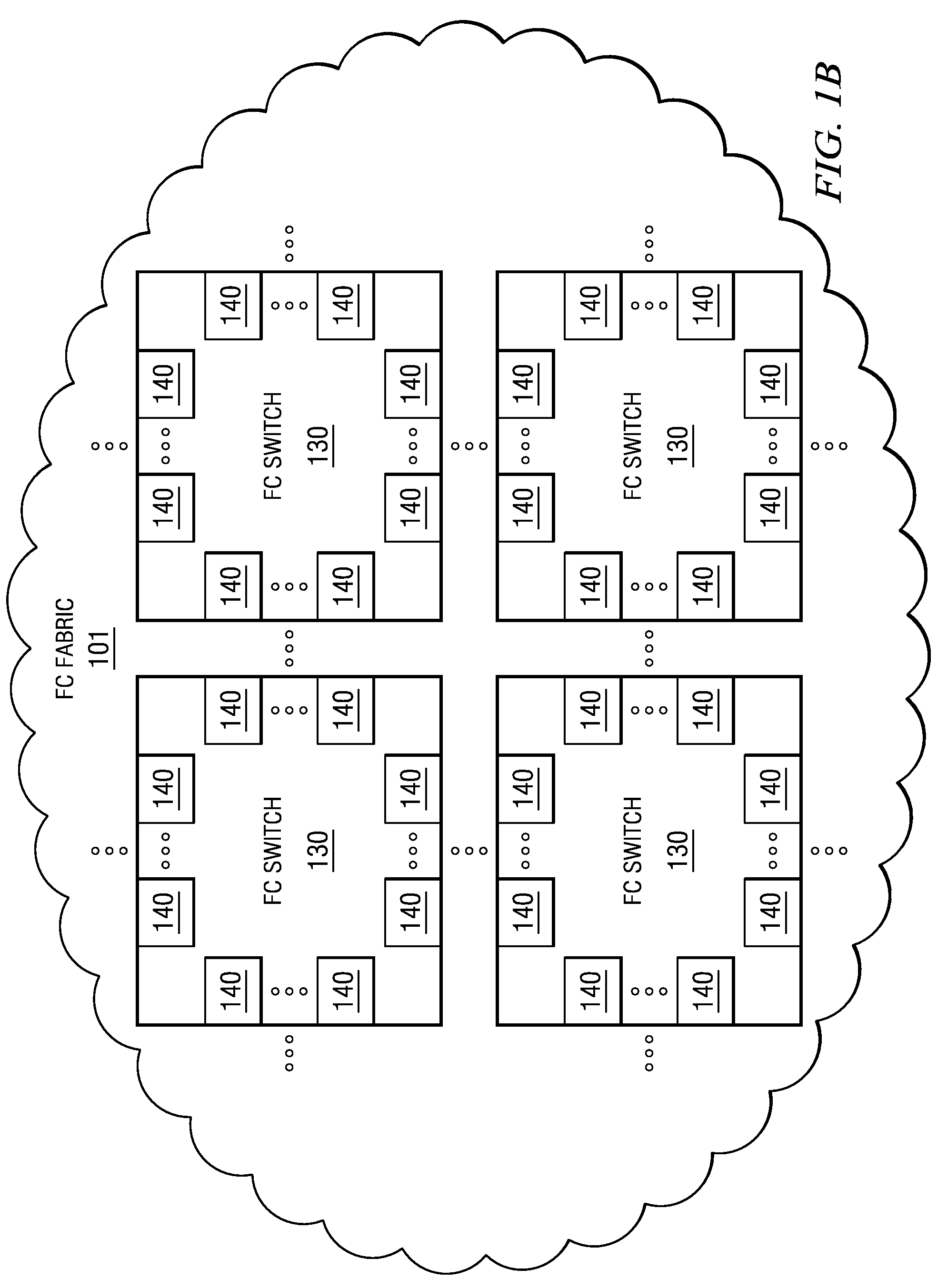

ActiveUS20080301204A1Special data processing applicationsMemory systemsCorrelation analysisOperating system

A system and method for correlated analysis of wasted space and capacity efficiency in complex storage infrastructures are provided. The system and method of the illustrative embodiments bring together wasted space data from all areas and components of the storage infrastructure into a single set of reports correlating information from these various sources in the storage infrastructure. In addition, correlated analysis of this collected information is performed with regard to wasted space. Logical storage devices of the storage infrastructure which are unused by host systems may be identified and appropriate corrective actions may be automatically taken. Moreover, automated recommendations and other automated corrective actions may be taken based upon the correlated analysis of the correlated data collected from the various components of the storage infrastructure.

Owner:HUAWEI TECH CO LTD

Pure nitrogen preparation device and process

PendingCN108061428ALow oxygenPrevent overheating problems during heatingSolidificationLiquefactionStart timeAir compressor

The invention discloses a pure nitrogen preparation device. The device comprises a filter, a turbine air compressor, an air pre-cooling unit, alternatively used molecular sieve adsorbers, an electricheater, a supercharged aftercooler, a main heat exchanger, an expansion machine, a first rectifying tower, a second rectifying tower, a first condensation evaporator, a second condensation evaporator,a subcooler, a liquid nitrogen pump and a cold box. According to the device, the cold flow needed by the device is prepared through expansion of pressured air, the air enters the second rectifying tower to participate in rectification after being expanded to a certain pressure, the extraction rate is high, and the energy consumption is low; or the air is expanded to the normal pressure, the pressure ratio is high, the refrigerating capacity efficiency is high, the refrigerating capacity is large, the starting time of the device can be shortened, the electricity consumption is saved, the extraction rate is higher, the energy consumption is lower, the high-pressure nitrogen is discharged out of the cold box after being reheated, the dirty nitrogen in the mixed part is used for air regeneration of alternatively used molecular sieve adsorbers, the oxygen content in the regenerated dirty nitrogen is reduced, and the service life of the electric heater is effectively prolonged.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

Storage system and method implementing online volume and snapshot with performance/failure independence and high capacity efficiency

InactiveUS8316203B2Improve capacity efficiencyError detection/correctionMemory systemsFirst generationData storing

A storage system for storage of data written from a computer, and when a write request of data to a first logical volume is received, the data on request is stored into the first logical volume. When a first-generation snapshot creation request is received, the data stored in the first logical volume at the time of receiving the first-generation snapshot creation request is written into a pool region as data corresponding to a first-generation snapshot, and when a second-generation snapshot creation request is received, any portion of the data updated after the first-generation snapshot creation request is received but before the second-generation snapshot creation request is issued is read from the first logical volume for writing into the pool region. Such a storage system favorably implements snapshot backup with no dependency with a positive volume in terms of performance and failure, and with high capacity efficiency.

Owner:HITACHI LTD

Bi-directional horizontal spraying aerosol fire-extinguishing apparatus

InactiveUS20100065285A1Apparatus be installedThe method is simple and safeFire rescueEngineeringMechanical engineering

A new bi-directional horizontal spraying aerosol fire-extinguishing apparatus is disclosed, which comprises a shell structure, an aerosol generator including an aerosol generating agent and disposed inside the shell structure, and a control unit for initiating the aerosol generator. The bi-directional horizontal spraying aerosol fire-extinguishing apparatus of the present invention is characterized in that both ends of the shell structure or of the aerosol generator are respectively provided with an aerosol exhaust passage. The advantages of the present apparatus are in that it can reduce the spraying time of the aerosol extinguishing agent in the case of ensuring the fire-suppression efficiency, and increase the charge capacity of the fire-extinguishing apparatus, so that the capacity efficiency of the present apparatus is totally increased, and the present apparatus is easy and safe to be installed and does not occupy the useful space.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

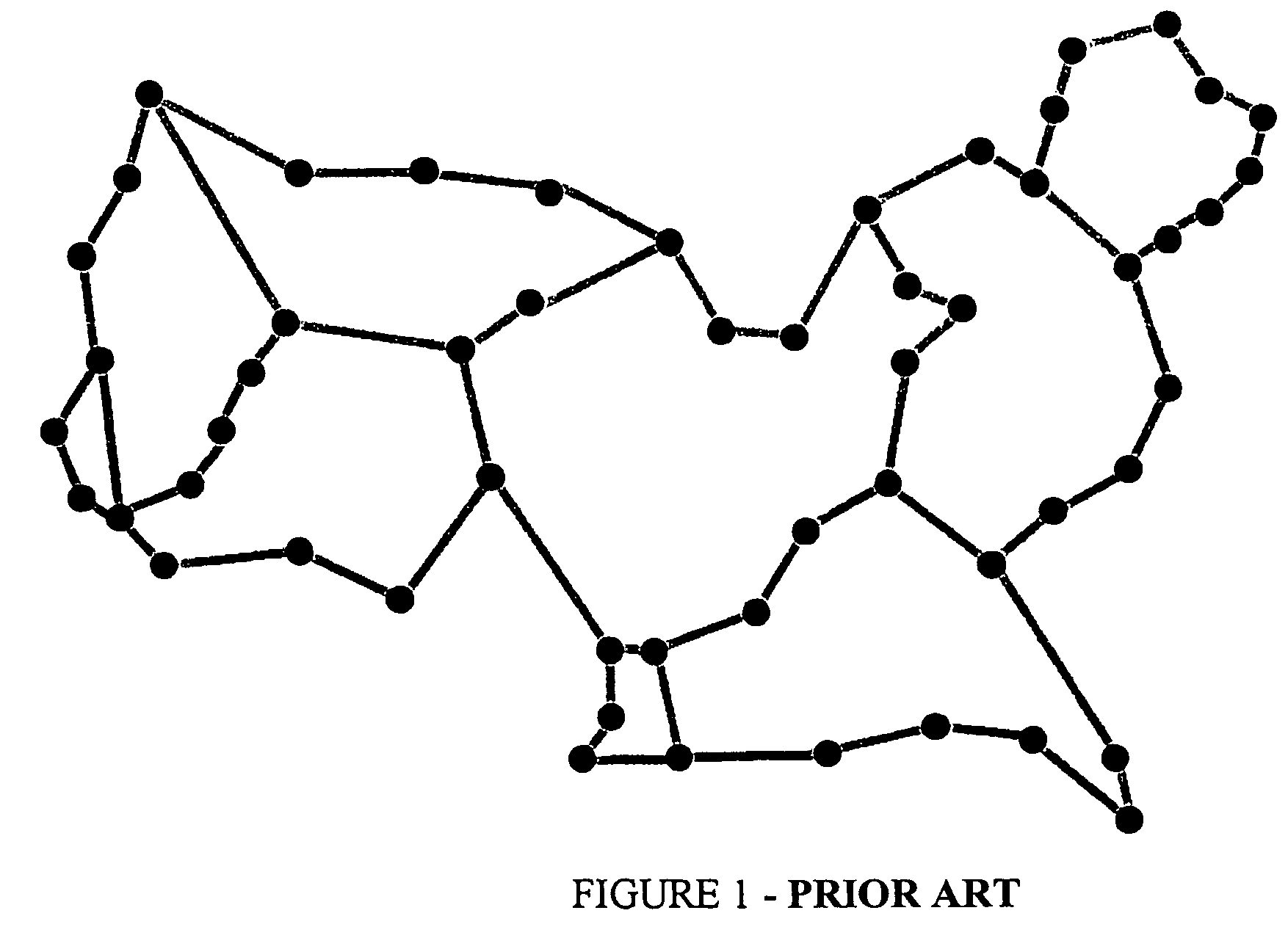

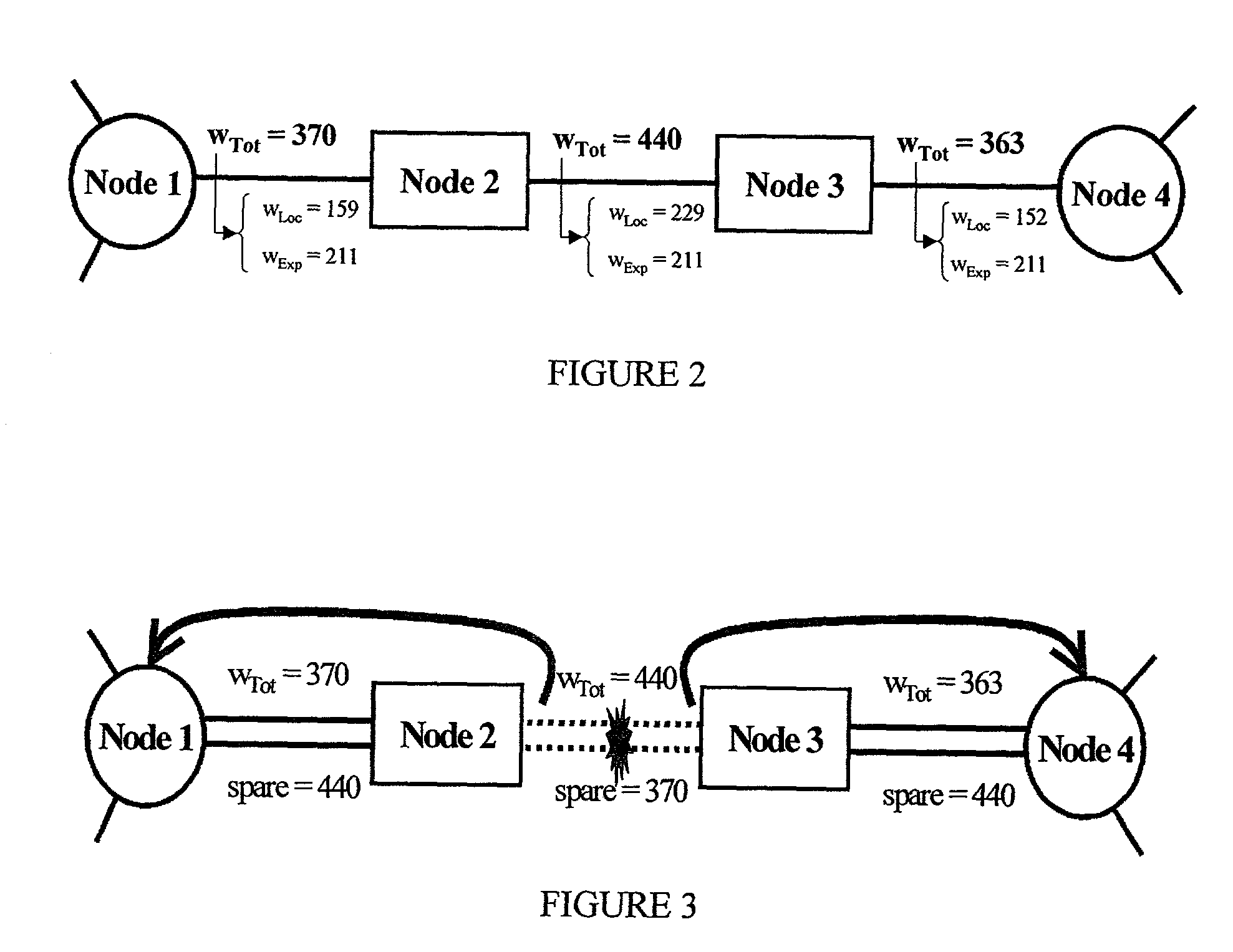

Design of a meta-mesh of chain sub-networks

InactiveUS7719962B2Great advantageLow costMultiplex system selection arrangementsError preventionNODALCross connection

A method to increase the capacity efficiency of span-restorable mesh networking on sparse facility graphs. The new approach views the network as a “meta-mesh of chain sub-networks”. This makes the prospect of WDM mesh networking more economically viable than with previous mesh-based design where the average nodal degree is low. The meta-mesh graph is a homeomorphism of the complete network in which edges are either direct spans or chains of degree-2 nodes. The main advantage is that loop-back type spare capacity is provided only for the working demands that originate or terminate in a chain, not for the entire flow that crosses chains. The latter “express” flows are entirely mesh-protected within the meta-mesh graph which is of higher average degree and hence efficiency for mesh restoration, than the network as a whole. Nodal equipment savings also arise from the grooming of express lightpaths onto the logical chain-bypass span. Only the meta-mesh nodes need optical cross-connect functionality. Other sites use OADMs and / or glassthroughs. The resultant designs comprise a special class of restorable network that is intermediate between pure span restoration and path restoration. Most of the efficiency of path restoration is achieved, but with a span restoration mechanism which is more localized and potentially faster and simpler than path restoration. The concept lends itself to implementation with OADMs having a passive waveband pass-through feature to support the logical chain bypass spans for express lightpaths.

Owner:TELECOMM RES LAB AN ALBERTA CORP

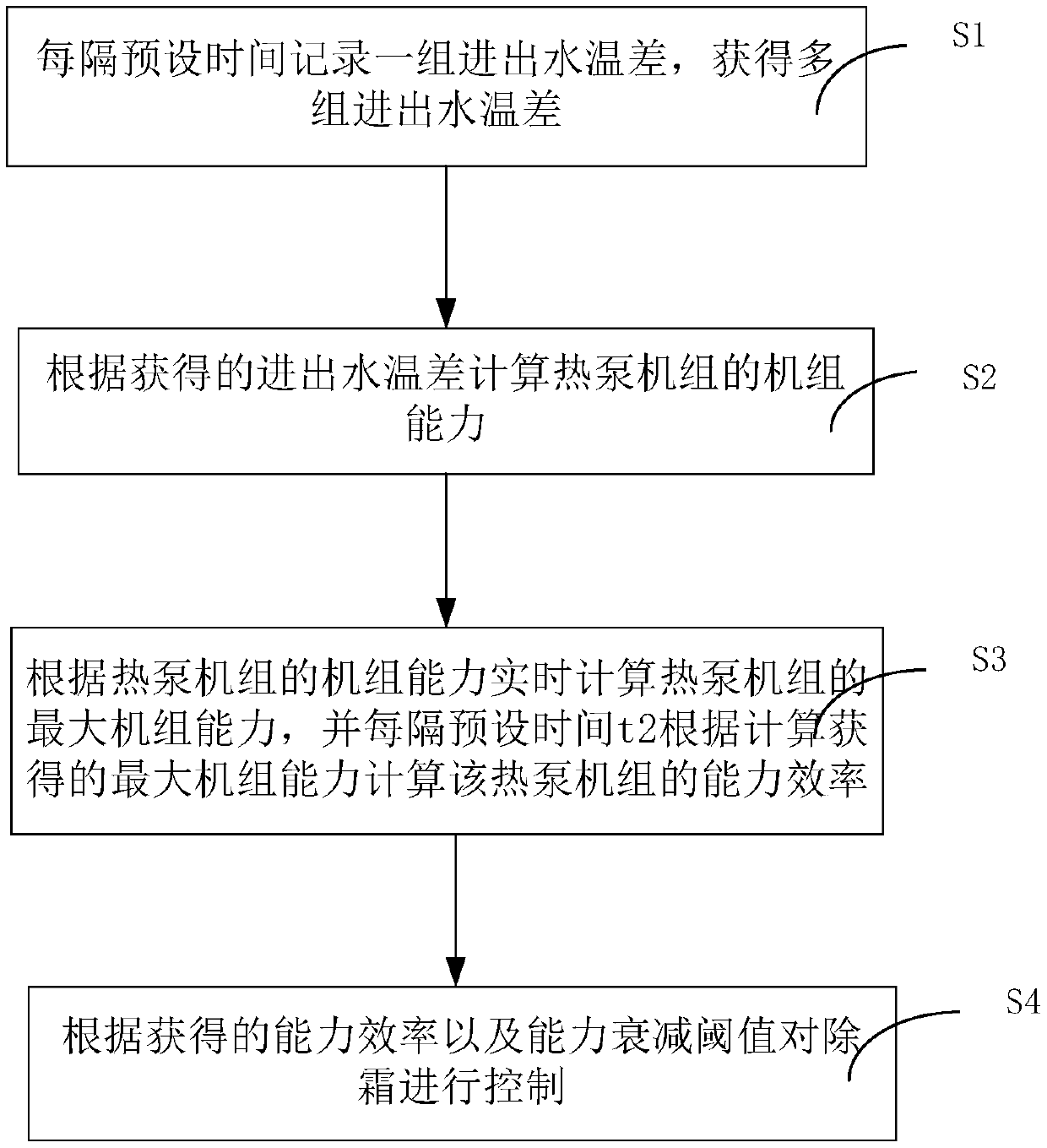

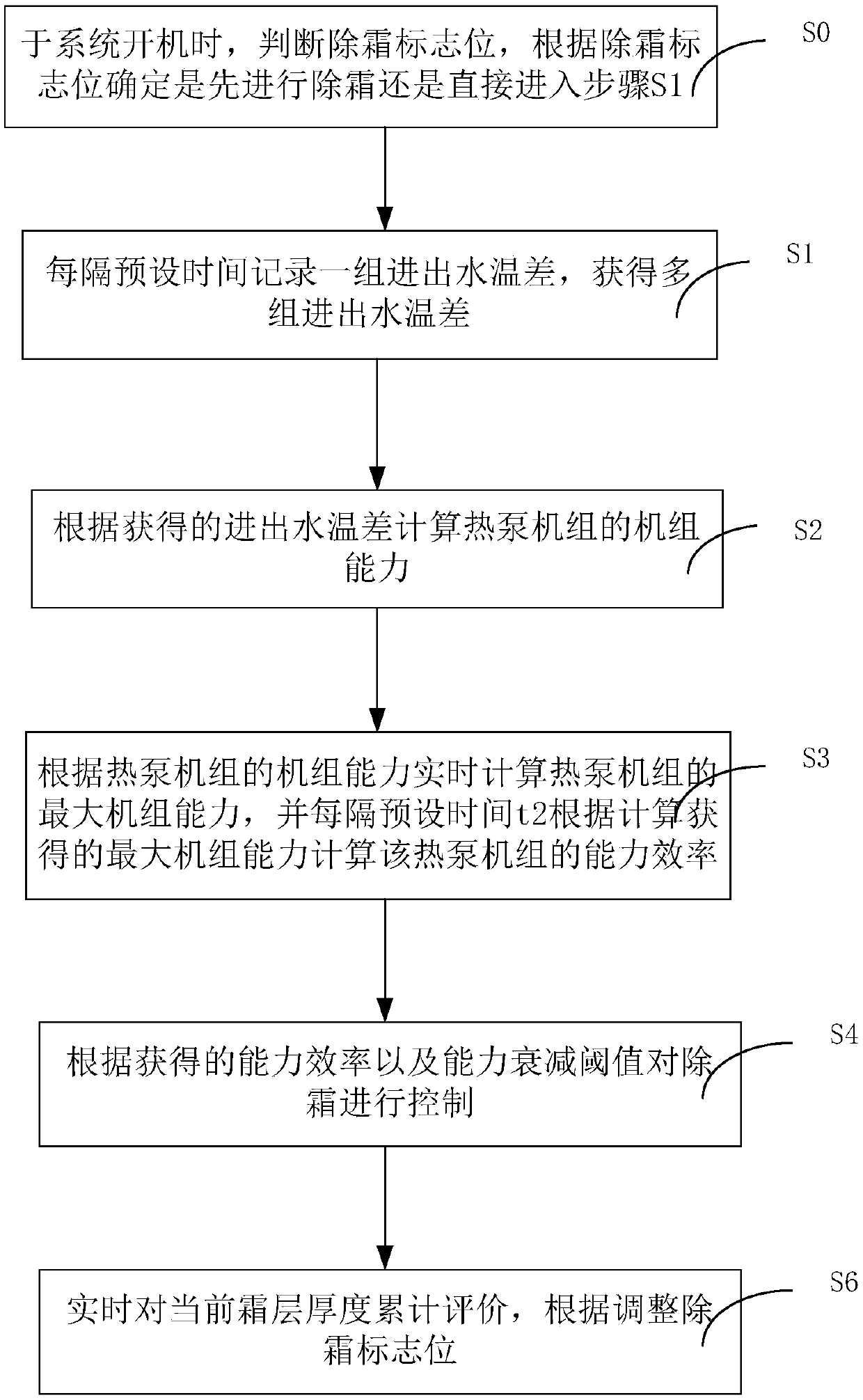

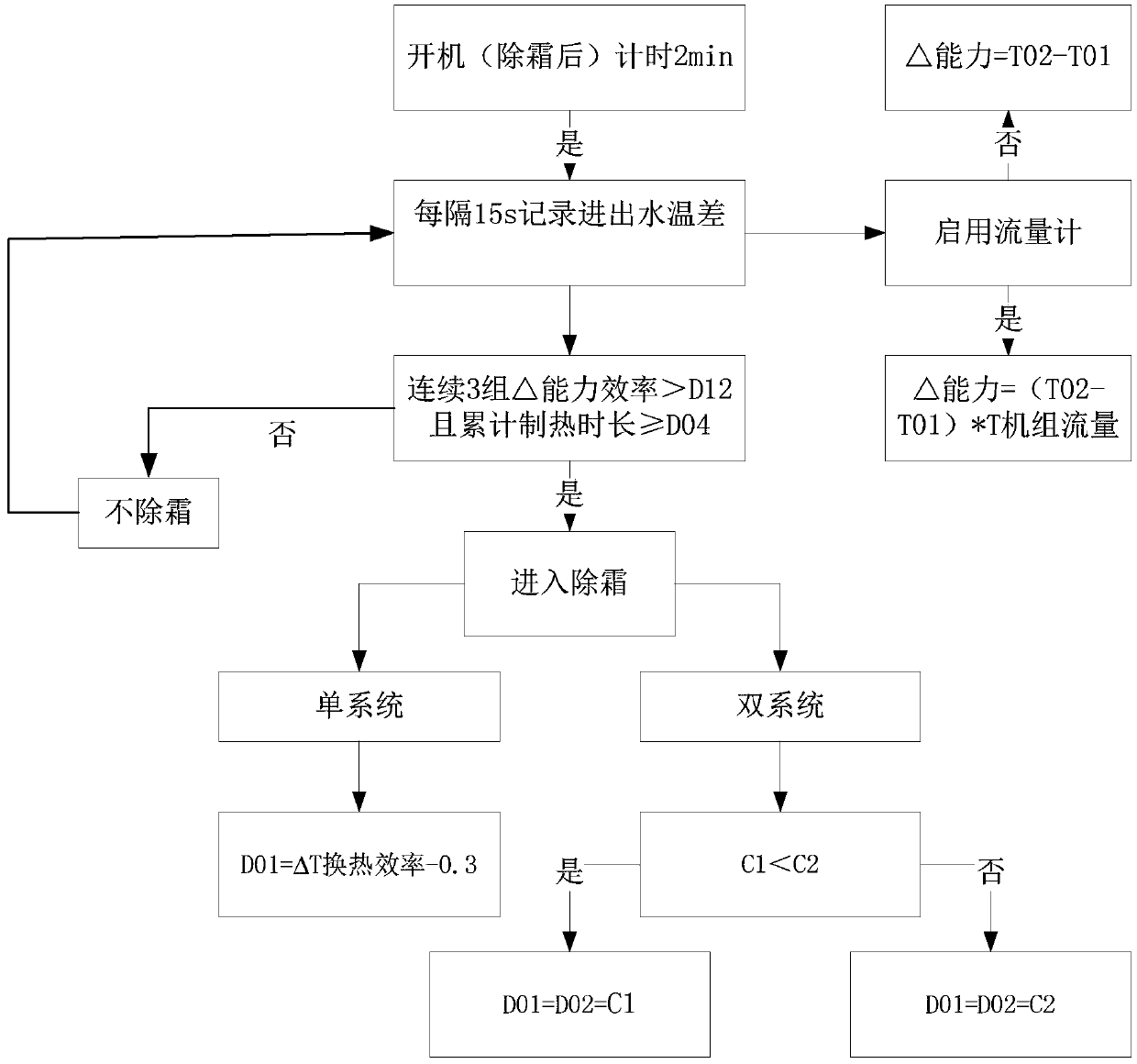

Defrosting control method and system for heat pump unit

ActiveCN109668356AImprove performanceReal-time adjustment of defrost thresholdCorrosion preventionRefrigeration safety arrangementUltrasound attenuationProcess engineering

The invention discloses a defrosting control method and system for a heat pump unit. The defrosting control method comprises the following steps that S1, a set of water inlet and outlet water temperature difference is recorded every preset time t1, and a plurality of groups of water inlet and outlet temperature difference delta t water i are obtained; S2, the unit capacity delta capability of theheat pump unit is calculated according to the obtained water inlet and outlet temperature difference; S3, the maximum unit capacity max (delta capacity) of the heat pump unit is calculated in real time according to the unit capacity delta capability of the heat pump unit, and the maximum unit capacity max (delta capacity) obtained according to calculation is calculated every preset time t2, and the capacity efficiency delta capability efficiency of the heat pump unit is calculated; and S4, a defrosting program is determined according to the obtained capability efficiency delta capability efficiency and the capacity attenuation threshold value, and defrosting control is carried out. According to the defrosting control method and system for the heat pump unit, the optimal unit performance ofthe heat pump unit can be guaranteed while accurate defrosting is met.

Owner:GUANGDONG PHNIX ECO ENERGY SOLUTION

Correlated analysis of wasted space and capacity efficiency in complex storage infrastructures

ActiveUS7680991B2Memory systemsInput/output processes for data processingCorrelation analysisOperating system

A system and method for correlated analysis of wasted space and capacity efficiency in complex storage infrastructures are provided. The system and method of the illustrative embodiments bring together wasted space data from all areas and components of the storage infrastructure into a single set of reports correlating information from these various sources in the storage infrastructure. In addition, correlated analysis of this collected information is performed with regard to wasted space. Logical storage devices of the storage infrastructure which are unused by host systems may be identified and appropriate corrective actions may be automatically taken. Moreover, automated recommendations and other automated corrective actions may be taken based upon the correlated analysis of the correlated data collected from the various components of the storage infrastructure.

Owner:HUAWEI TECH CO LTD

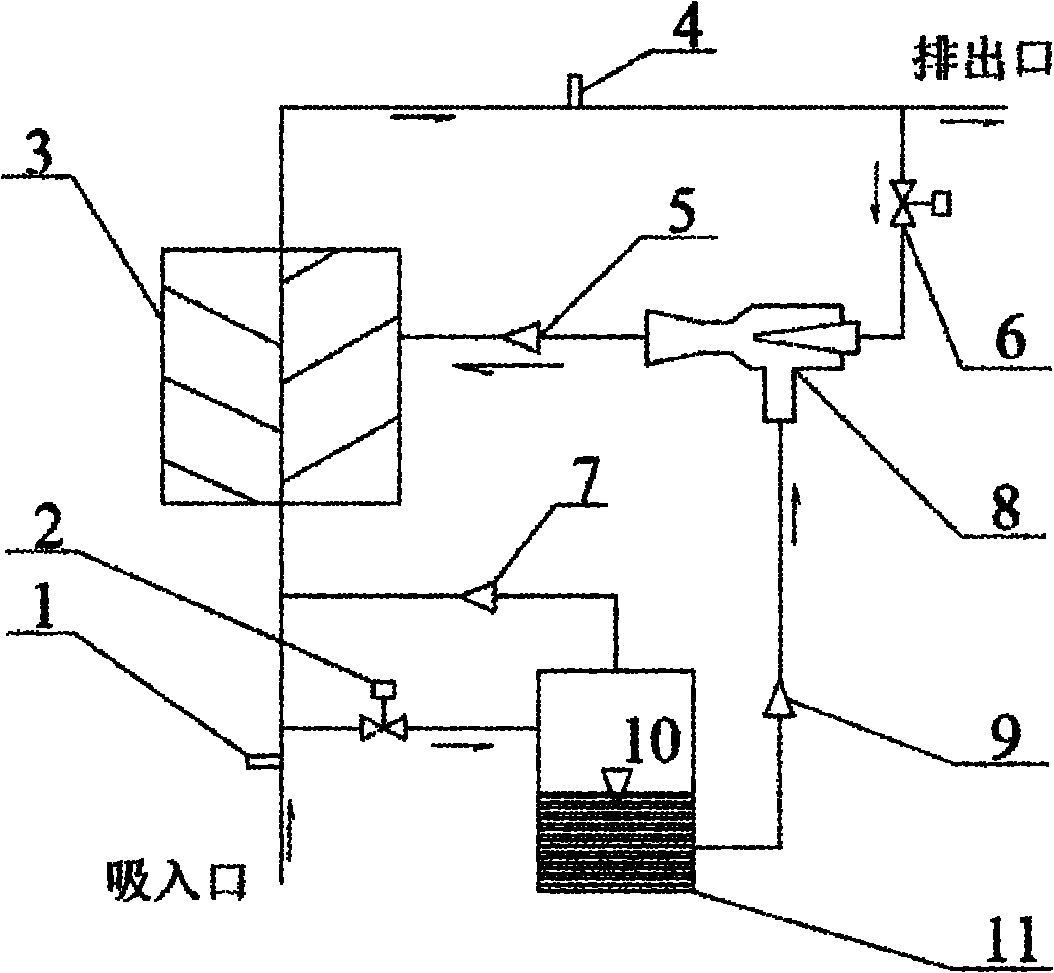

Two-screw multiphase pump device suitable for working condition with high air void

InactiveCN102062088AIncrease pressureImprove efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringElectromagnetic valve

The invention relates to a two-screw multiphase pump device suitable for a working condition with a high air void, comprising a two-screw multiphase pump. An inlet temperature sensor and a gas-liquid separation and liquid reservoir are mounted on an inlet pipeline of the two-screw multiphase pump. The inlet and the outlet of the gas-liquid separation and liquid reservoir are respectively provided with a liquid reservoir inlet electromagnetic valve and a liquid reservoir outlet one-way valve, an outlet pipeline of the two-screw multiphase pump is provided with an outlet temperature sensor and an ejector inlet electromagnetic valve which is connected with an ejector inlet, an outlet pipeline at the lower part of the gas-liquid separation and liquid reservoir is connected with an inlet at the other side of the ejector through an ejector inlet one-way valve, and an ejector outlet is connected with a middle injection hole of the two-screw multiphase pump through an ejector outlet one-way valve. By adopting the ejector to eject liquid, the invention has the advantages of improving the middle pressure of the multiphase pump, moderating a pressure change curve, reducing leakage, improving the capacity efficiency and lowering the temperature of an exhaust.

Owner:XI AN JIAOTONG UNIV

Method and apparatus for deploying virtual hard disk to storage system

InactiveUS8397046B2Maximizing dataMaximize efficiencyDigital data processing detailsComputer security arrangementsUnit sizeFile system

Exemplary embodiments of the invention provide a solution to deploy a virtual hard disk (VHD) to virtual device with maximizing capacity efficiency and data access performance by making the allocation unit size of virtual device the same as that of the VHD. In one embodiment, a method of deploying a VHD file to a storage apparatus comprises checking a block size of the VHD file received by the storage apparatus based on a header of the VHD file; creating a virtual volume to provide a page size which is same size as the block size of the VHD file; and performing one of (A) copying contents of the VHD file to the created virtual volume by allocating one page of the created virtual volume for each block of the VHD file; or (B) formatting the created virtual volume with a virtual volume file system, and copying the VHD file to the formatted virtual volume.

Owner:HITACHI LTD

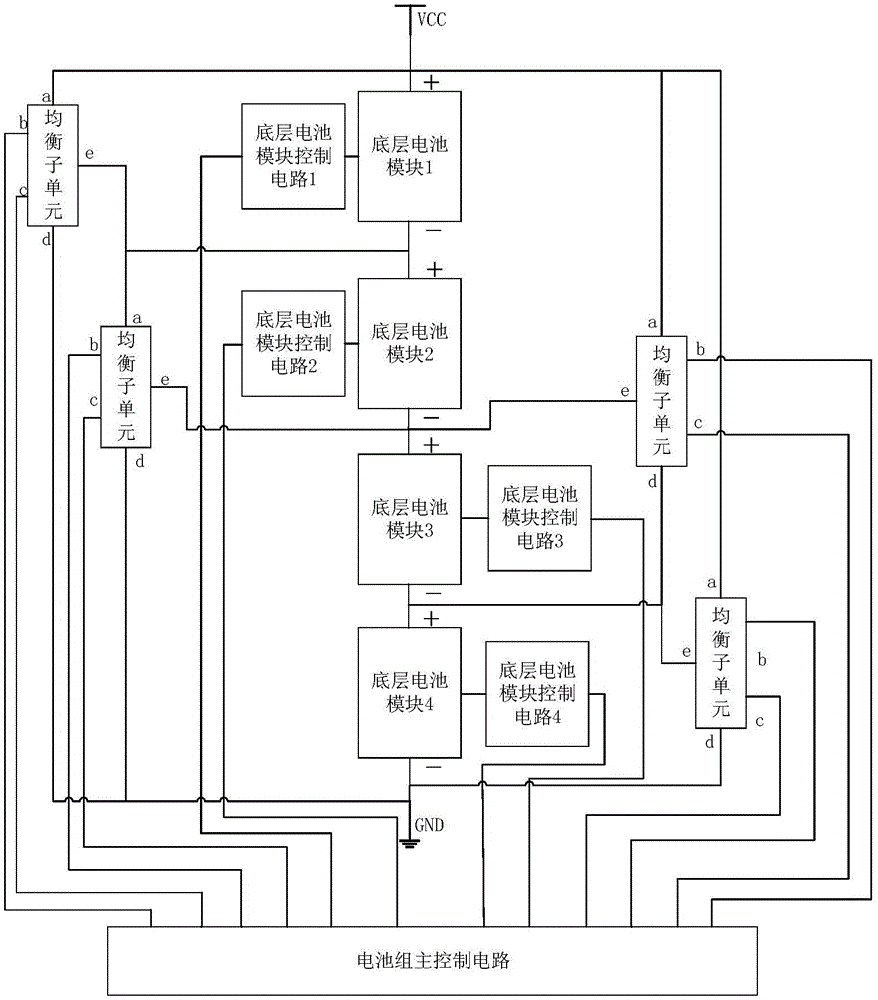

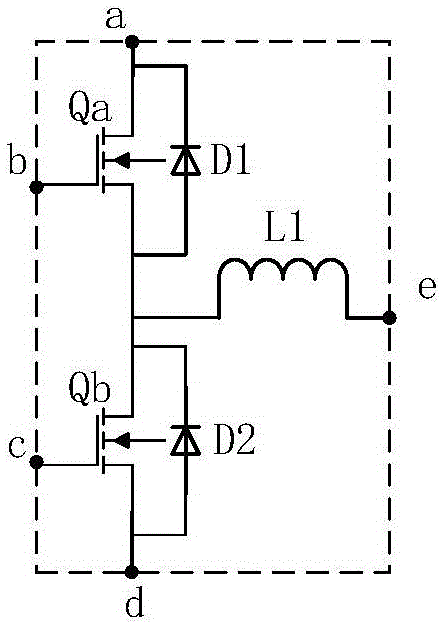

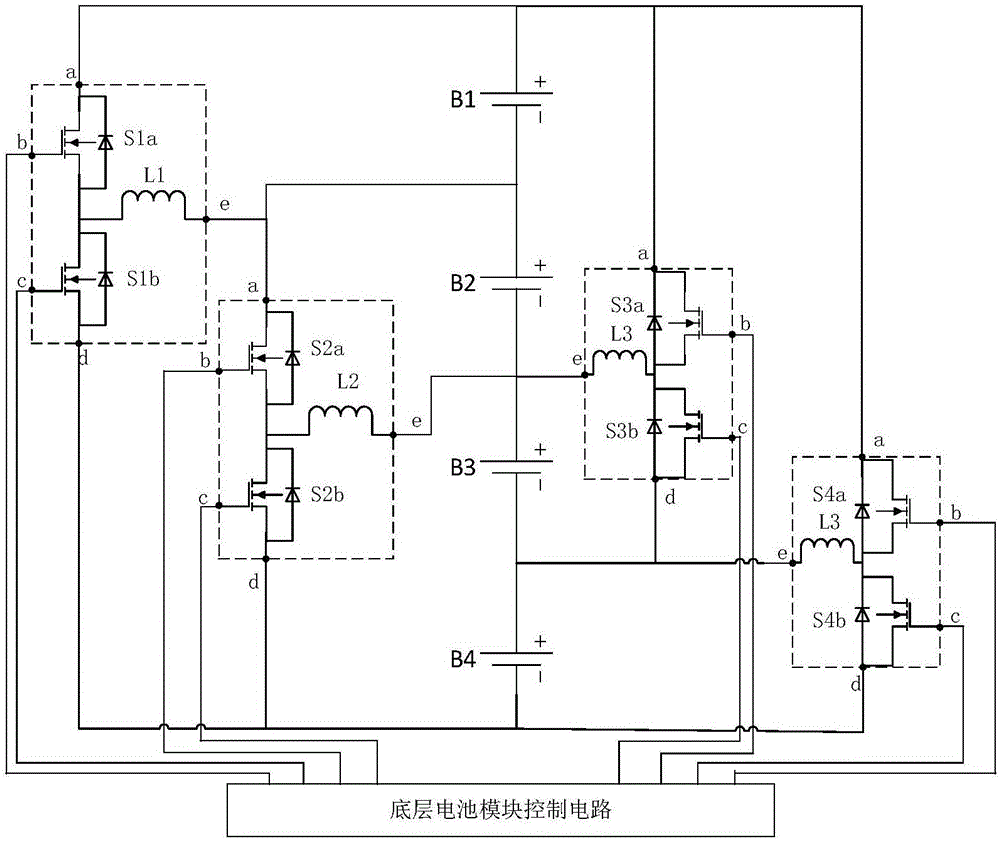

Layered battery pack balancing circuit

InactiveCN105162200AImprove performancePrevent overchargingBatteries circuit arrangementsElectric powerElectrical batteryDynamic balance

The invention discloses a layered battery pack balancing circuit, which comprises bottom battery module control circuits, a master control circuit of a battery pack and balancing sub-units, wherein the bottom battery module control circuits respectively control corresponding bottom battery modules, so that single batteries in the bottom battery modules achieve dynamic balance in the charging and discharging processes; and the master control circuit of the battery pack achieves electric quantity balance among various bottom battery modules in the series battery pack by outputting corresponding control signals to the balancing sub-units through the balancing sub-units. According to the layered battery pack balancing circuit, through mutual division and cooperation of the bottom battery module control circuits and the master control circuit of the battery pack, dynamic balance of the electric quantity of various single batteries in the charging and discharging process of the battery pack can be achieved; the short-board effect of the battery pack is cast off; the capacity efficiency of the battery pack is improved; the cycle life and the service life of the battery pack are prolonged; and the operation cost and the maintenance cost of a system are reduced. Therefore, the layered battery pack balancing circuit can be applicable to hybrid / pure electric vehicles, miniature electric cars or energy storage devices.

Owner:SOUTH CHINA UNIV OF TECH

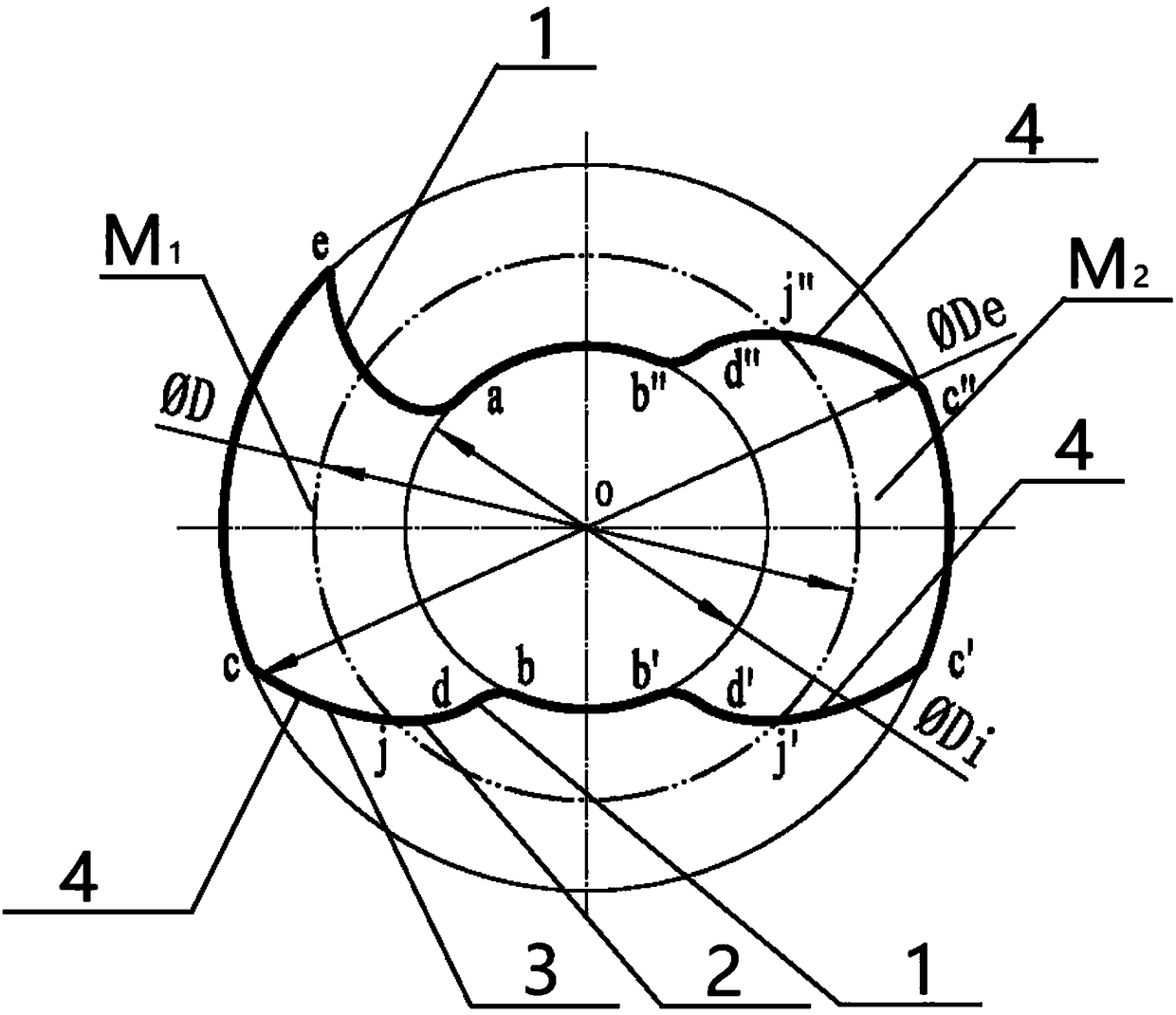

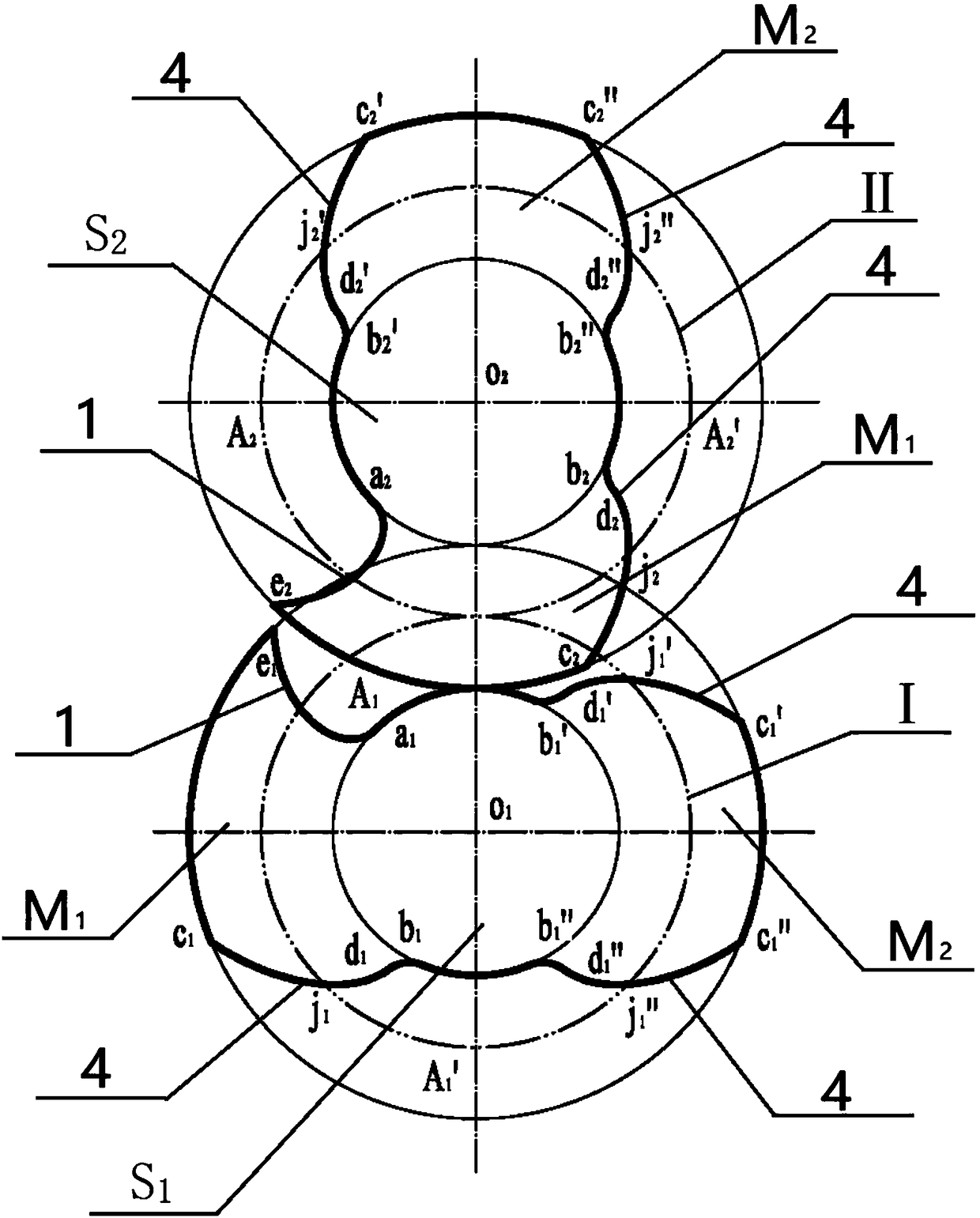

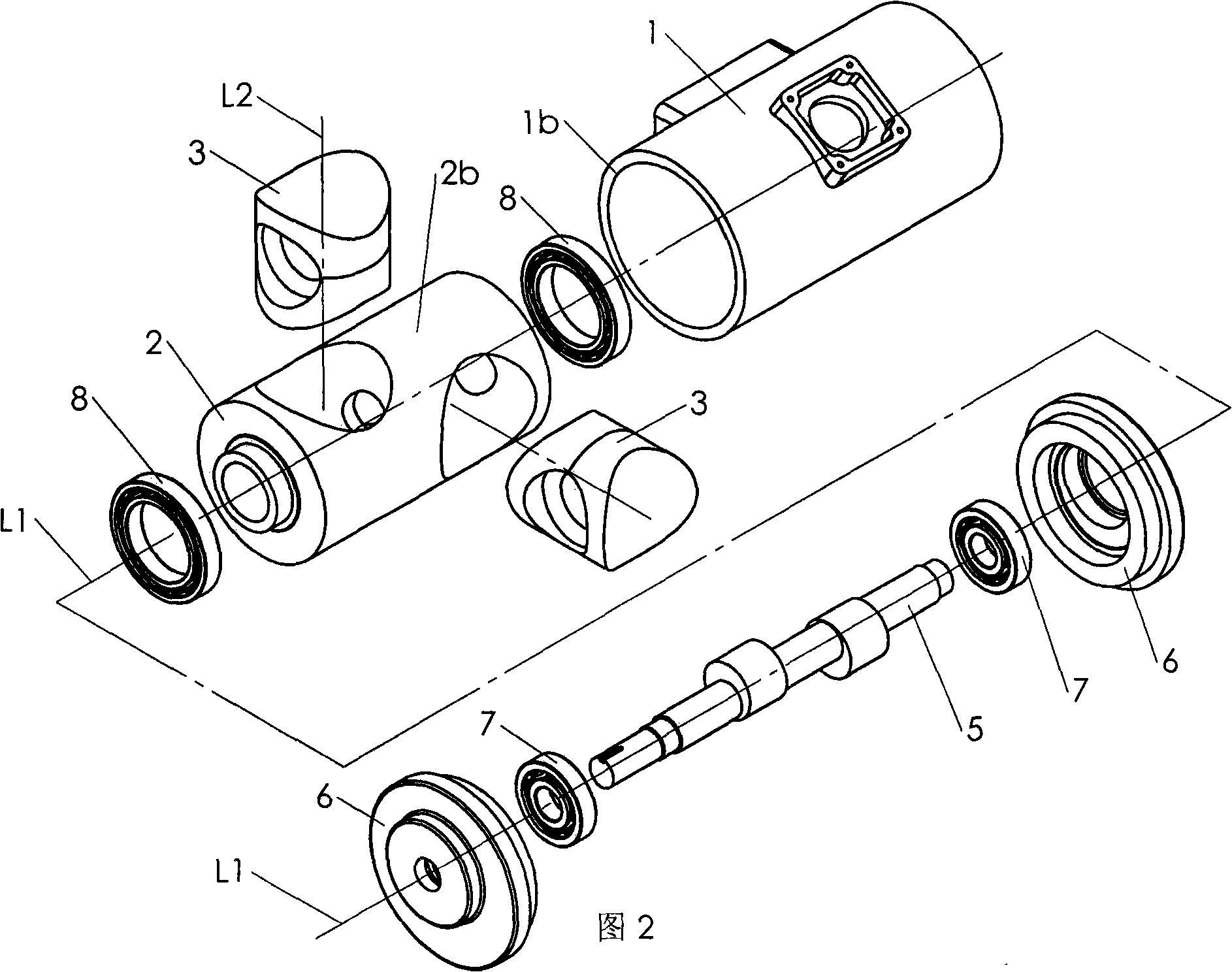

Double-end spiral screw rod and double-screw pump and dry vacuum screw pump adopting screw rod

ActiveCN108443145AEasy to operateImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesHigh pressureScrew pump

The invention provides a double-end asymmetrical tooth-shaped screw rod, and a double-screw pump and a dry vacuum screw pump designed and manufactured by adopting the screw rod. In the double-end screw rod, one tooth of the double-end screw rod is an asymmetric tooth, and the other tooth is a symmetric tooth; a tooth-shaped molded ling of a spiral surface of a sealing edge of the asymmetric toothis an extension outer swing line; a tooth-shaped molded line of a force transfer edge is Abao swing line; and tooth-shaped molded lines of tooth side spiral surfaces of the sealing edge and the forcetransfer edge of the symmetric tooth are Abao swing lines. The Abao swing lines consist of extension outer swing lines, Archimedes envelope lines and Archimedes lines. The screw rod with the tooth-shaped molded line is used for the double-screw pump, can achieve strict sealing, can guarantee a screw rotor to reach a dynamic unbalance quantity of zero (similar to zero), is suitable for high operation speed, guarantees use of the manufactured double-screw pump, is high in capacity efficiency under high pressure, and can guarantee stable and reliable operation of the double-screw pump under highrotating speed.

Owner:天津市道尔机械技术有限公司

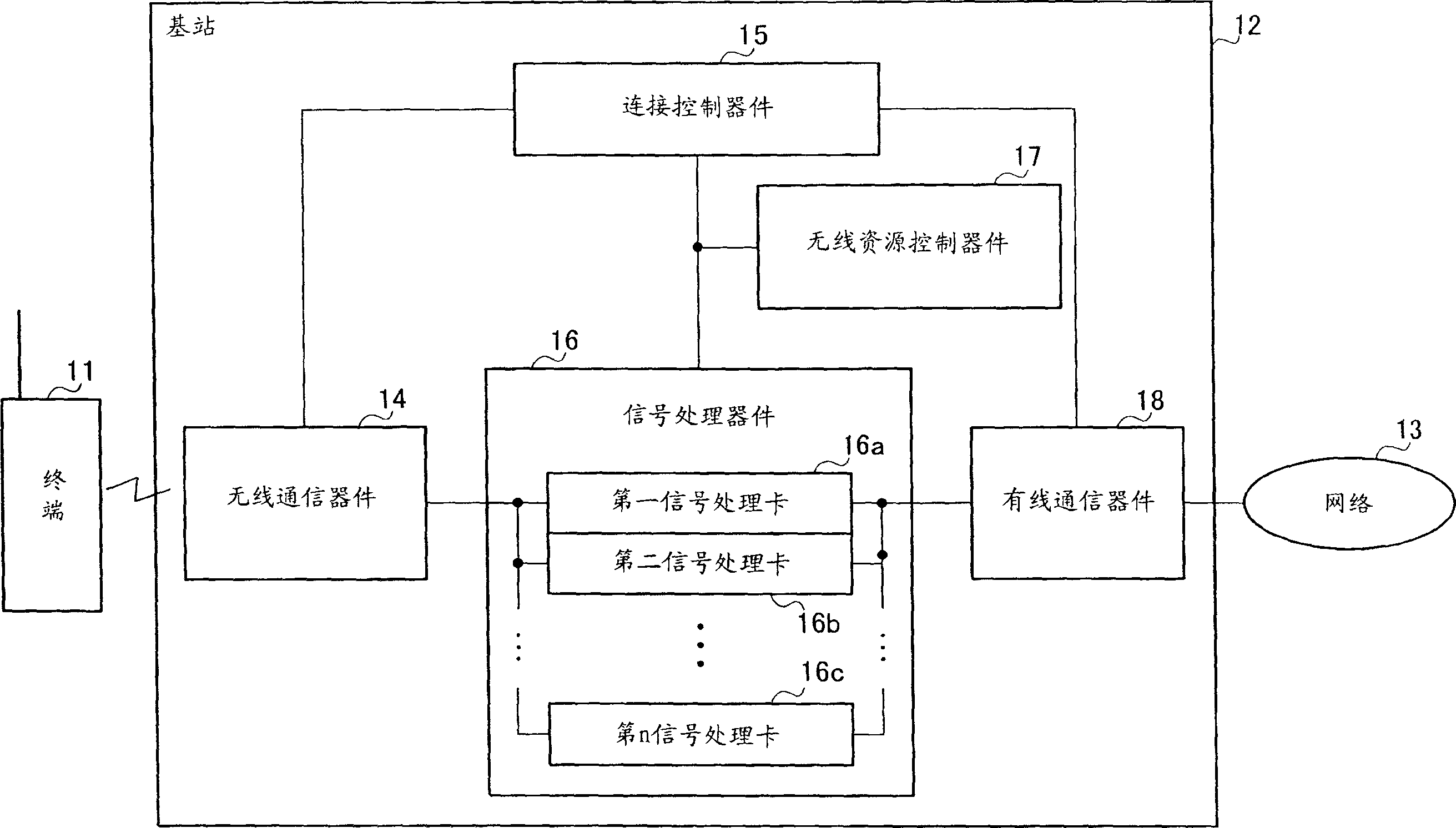

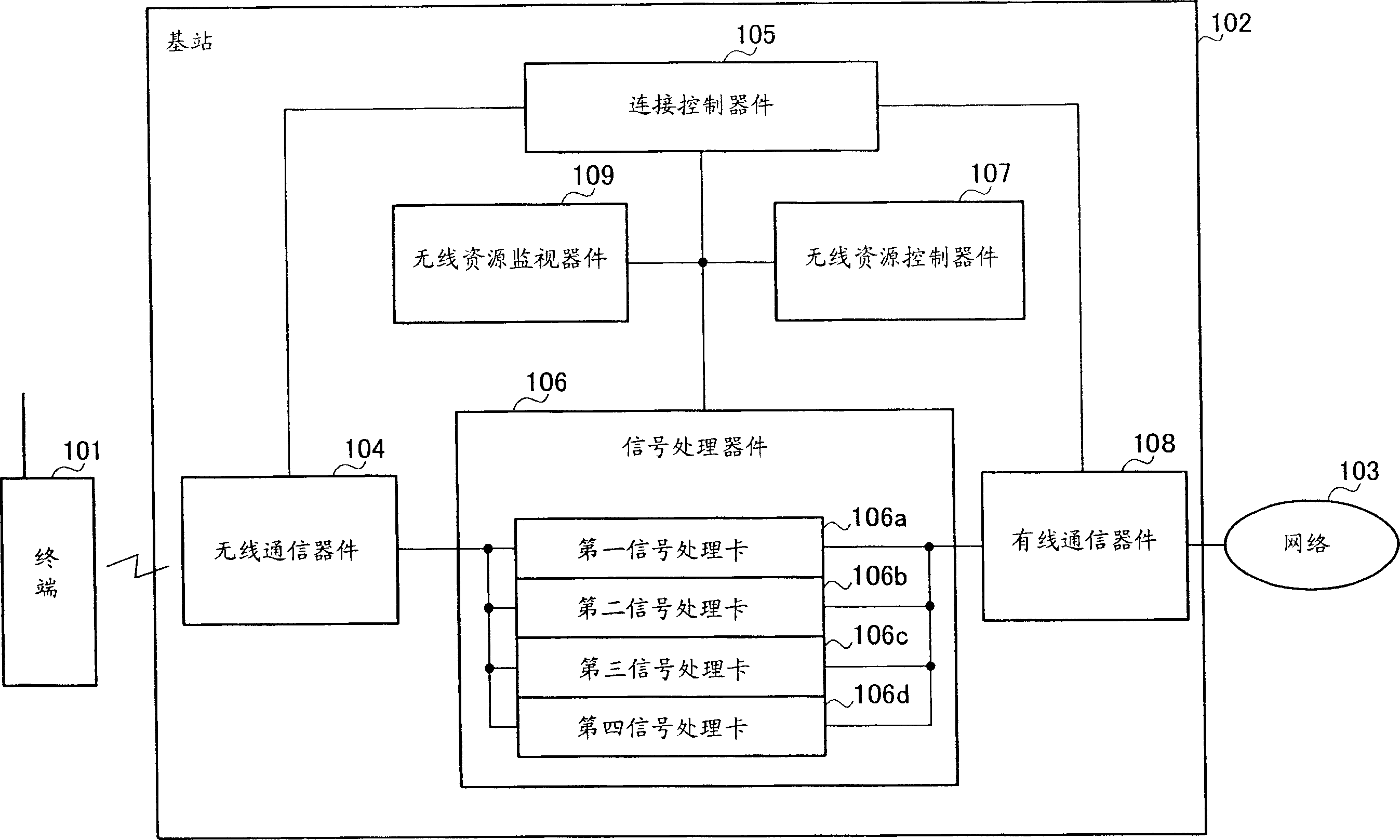

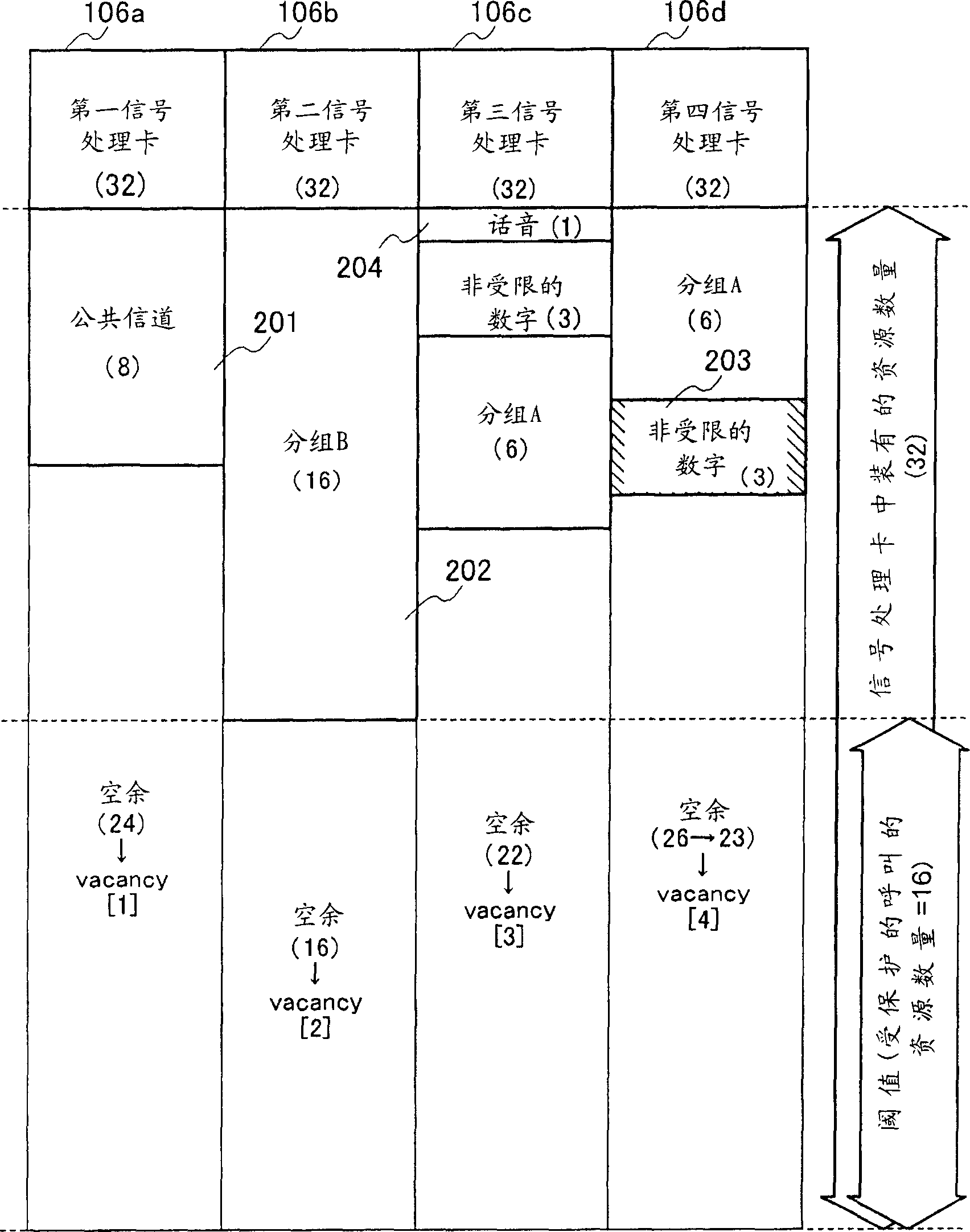

Radio base station resource allocation method and radio base station

InactiveCN1768541AImprove efficiencyConducive to loadNetwork traffic/resource managementNetwork planningDistribution methodLoad distribution

By allocating resources so as to minimize call losses, both capacity efficiency and load distribution improvements can be achieved. Set the calls to be protected and modify the resource allocation method according to the resource status of each card. Call distribution processing is performed as follows. When the traffic volume is low, load distribution is performed, and when the traffic volume is high, the resources of the high-usage cards are exhausted. Therefore, load distribution among signal processing cards can be obtained by efficiently using resources and minimizing call losses.

Owner:PANASONIC CORP

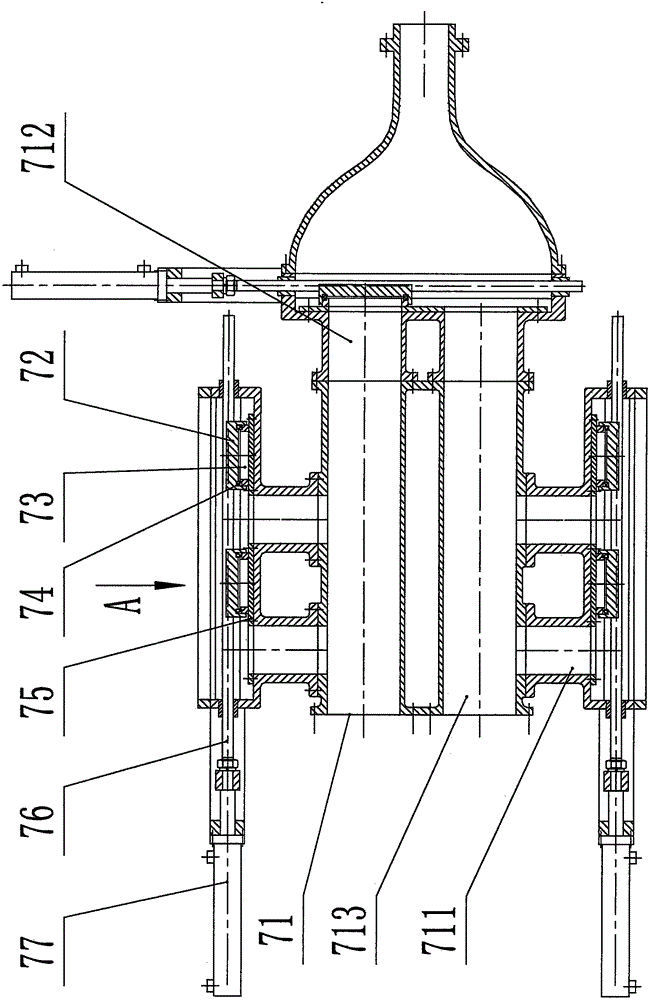

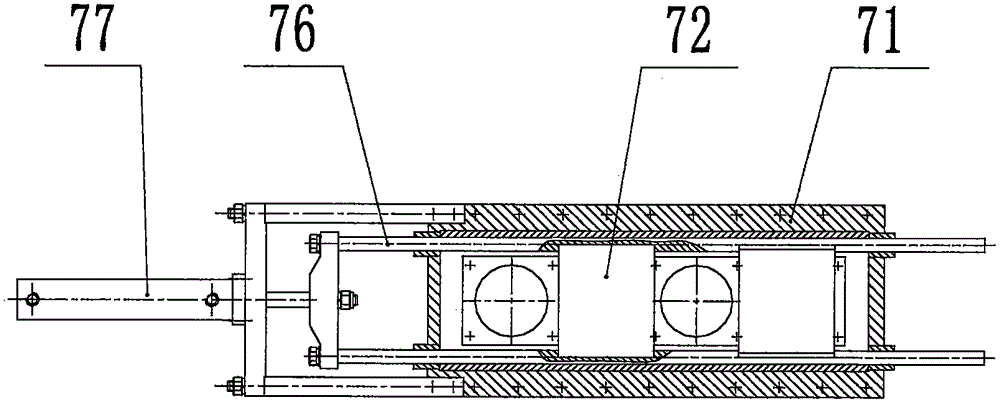

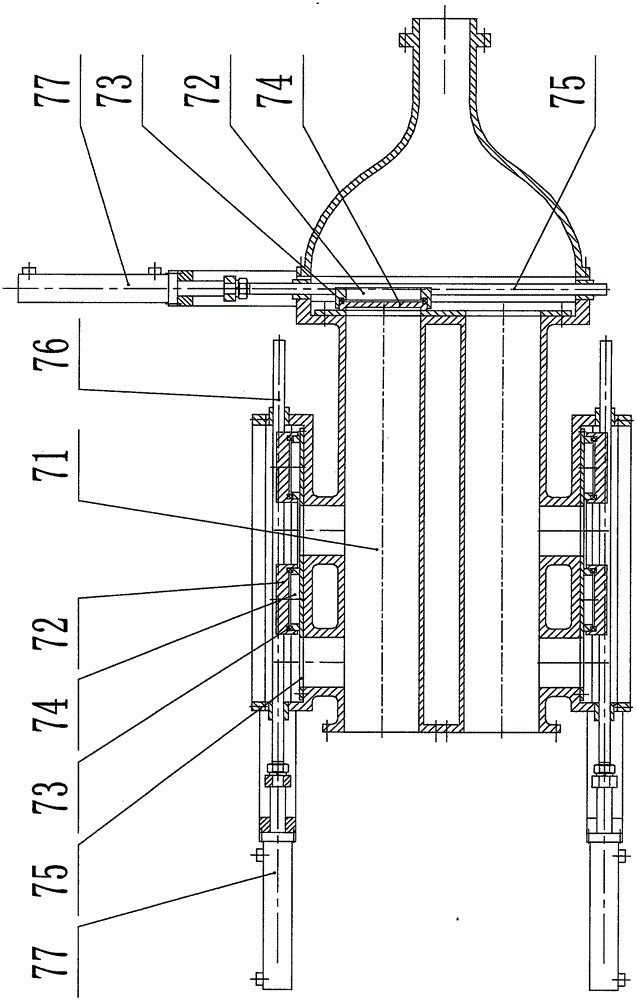

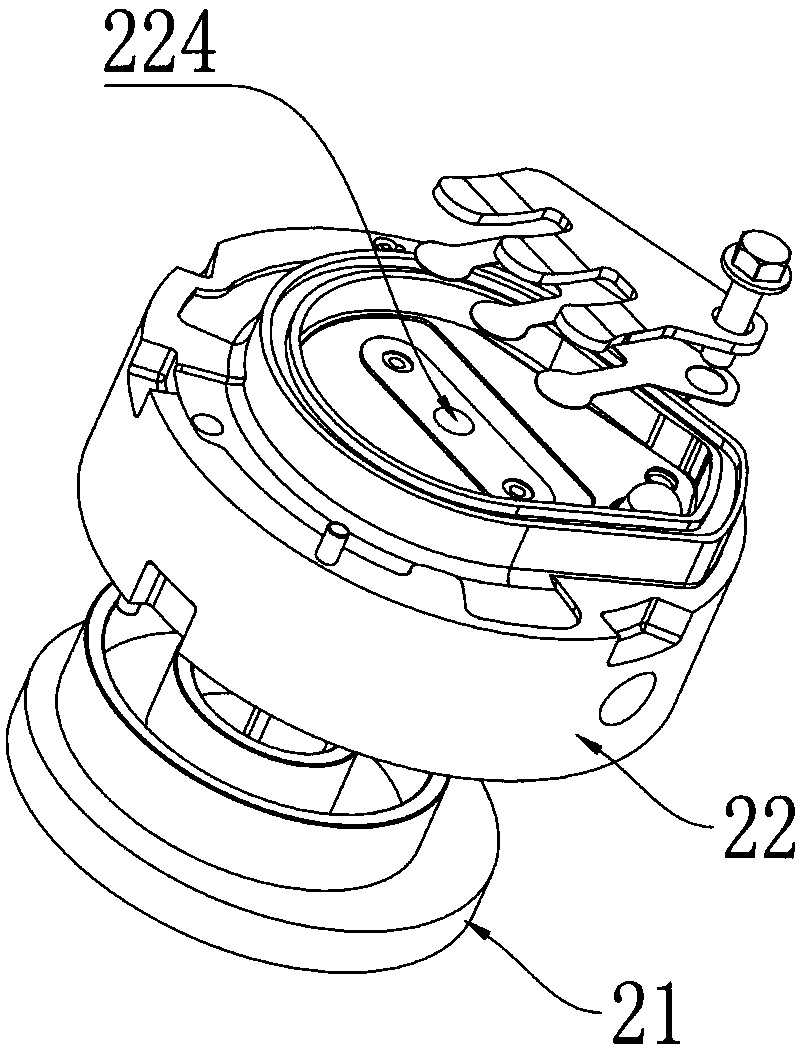

Distribution valve and conveying pump adopting same

ActiveCN106545493APrevent backflowImprove pumping efficiencyPositive displacement pump componentsPumpsVolumetric efficiencyCapacity efficiency

The invention discloses a distribution valve which comprises a distribution valve box, a slide body, an elastic sealing part, a slide sealing part, a friction plate, a guide rod and a drive device, wherein the drive device, the guide rod and the friction plate are mounted on the distribution valve box; the drive device is connected with the guide rod; the guide rod is connected with the slide body; the slide sealing part and the elastic sealing part are mounted on the slide body; the elastic sealing part is positioned between the slide sealing part and the slide body; the drive device drives the guide rod; and the guide rod, the slide body, the elastic sealing part and the slide sealing part move on the friction plate, so that opening-closing and reversing of a valve are realized. The distribution valve has the advantages of being reliable in sealing, great in conveying pressure, small in material absorbing resistance, high in capacity efficiency and the like. The invention further discloses a conveying pump adopting the distribution valve.

Owner:山东瀚纶环保机械有限公司

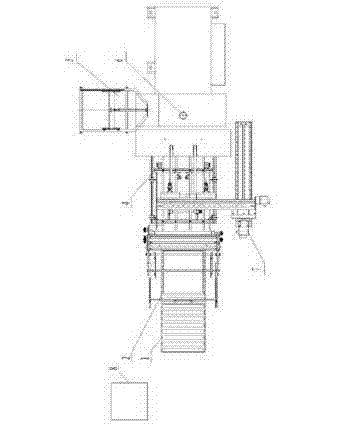

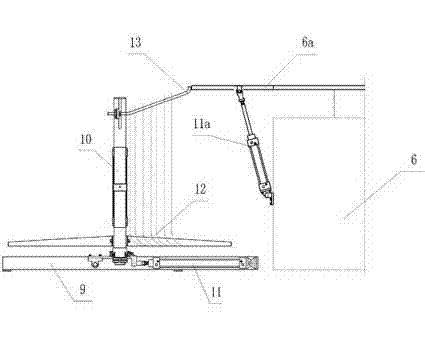

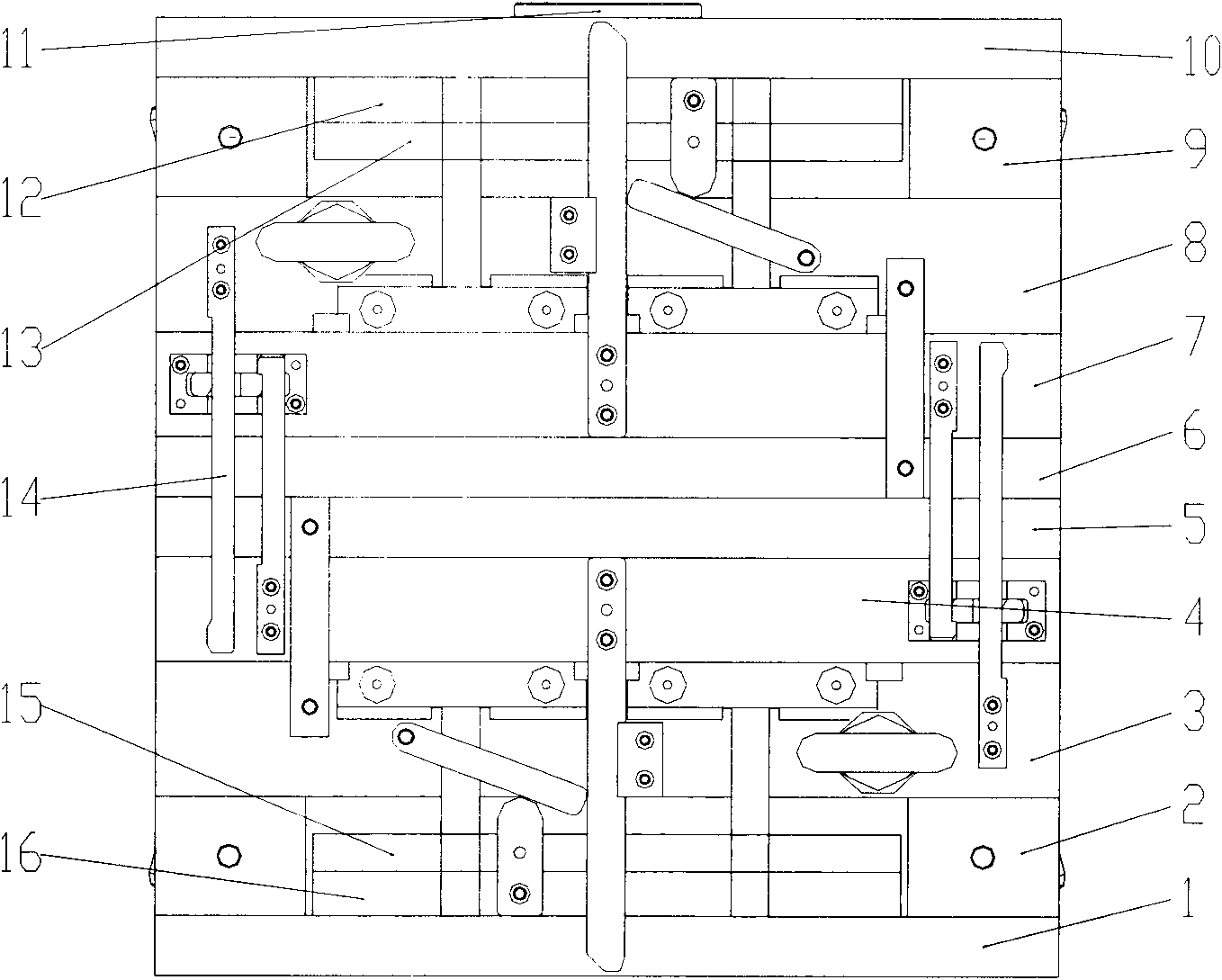

Automatic numerical-control punching device

InactiveCN102896199AAutomatic waste hasWith automatic suctionMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention belongs to the technical field of punching equipment, and particularly relates to a full-automatic numerical-control punching device. The full-automatic numerical-control punching device comprises a punch press and a numerical-control system, and is characterized in that a feeding device is arranged on the rear portion of the punch press in a connection manner, a preceding-stage feeding device is arranged on the rear portion of the feeding device in a connection manner, a hydraulic lifting device is arranged below the preceding-stage feeding device, and the punch press, the feeding device, the preceding-stage feeding device, the hydraulic lifting device and the numerical control are electrically connected. On the original basis, the automatic numerical control punching device is improved in technological design, an automatic feeding function system and an automatic waste discharging mechanism are added, and the automatic numerical control punching device has functions of automatic sucking, automatic feeding, automatic punching, automatic waste discharging and the like to plates, manual labor is lowered, capacity efficiency is greatly improved, and the full-automatic numerical-control punching device is significant in wide popularization.

Owner:台州市通益机械设备有限公司

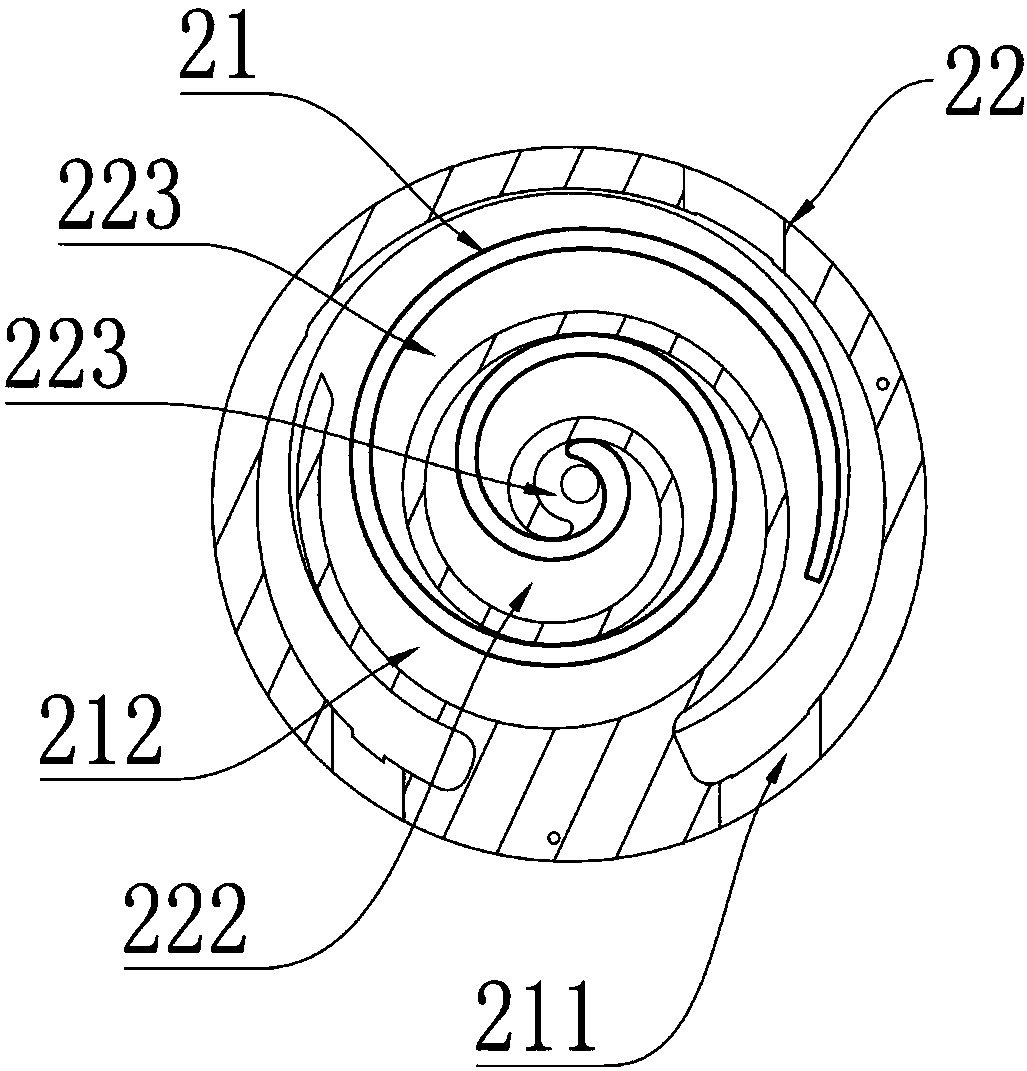

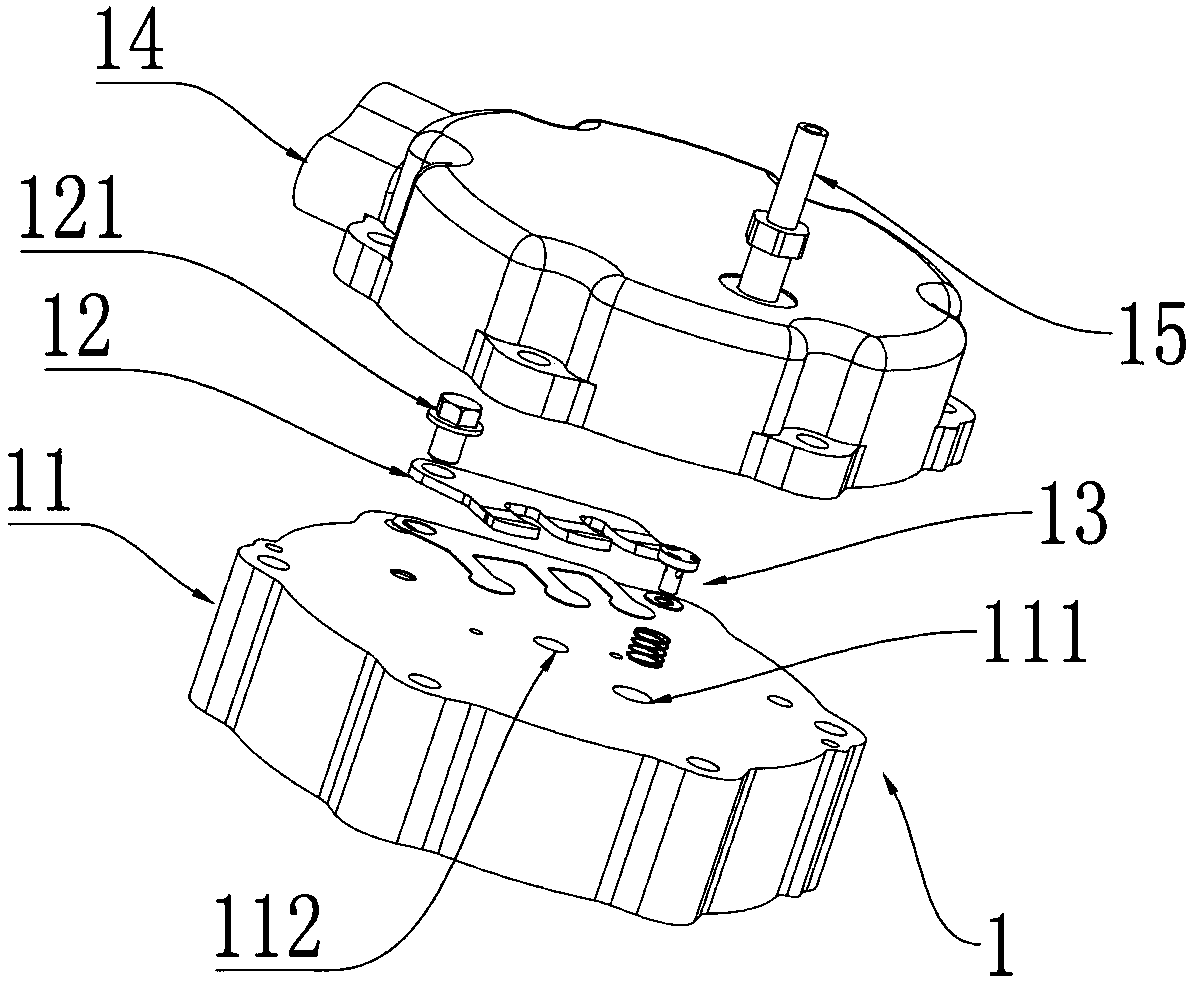

Enthalpy increasing structure of compressor and scroll compressor

ActiveCN108035879AIncrease heating capacityImprove performanceRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

The invention provides an enthalpy increasing structure of a compressor. The enthalpy increasing structure of the compressor comprises a fixed scroll disc, an exhaust valve, a pressure valve module, atop cover and an enthalpy increasing pipe, wherein the fixed scroll disc is provided with a valve base mounting hole, and an exhaust hole positioned on one side of the valve base mounting hole; the exhaust valve is arranged on the fixed scroll disc, and is corresponding to the exhaust hole; the pressure valve module is arranged on the valve base mounting hole; the top cover is tightly connected with the fixed scroll disc, and is provided with an exhaust cavity and a pressure cavity; the exhaust cavity is corresponding to the exhaust valve; the pressure cavity is corresponding to the pressurevalve module; and one end of the enthalpy increasing pipe penetrates through the top cover and communicates with the pressure cavity. The invention provides the enthalpy increasing structure of the compressor, and a scroll compressor with the enthalpy increasing structure of the compressor; the heating quantity of the scroll compressor under low-temperature heating condition is improved; meanwhile, the performance of the compressor is improved; the enthalpy increasing structure can effectively reduce the clearance volume influence of the scroll compressor; the capacity efficiency and the performance of the scroll compressor are improved; and a pressure valve module is simple in design, high in reliability and easy to assemble.

Owner:广东兴泽尔新能源科技有限公司

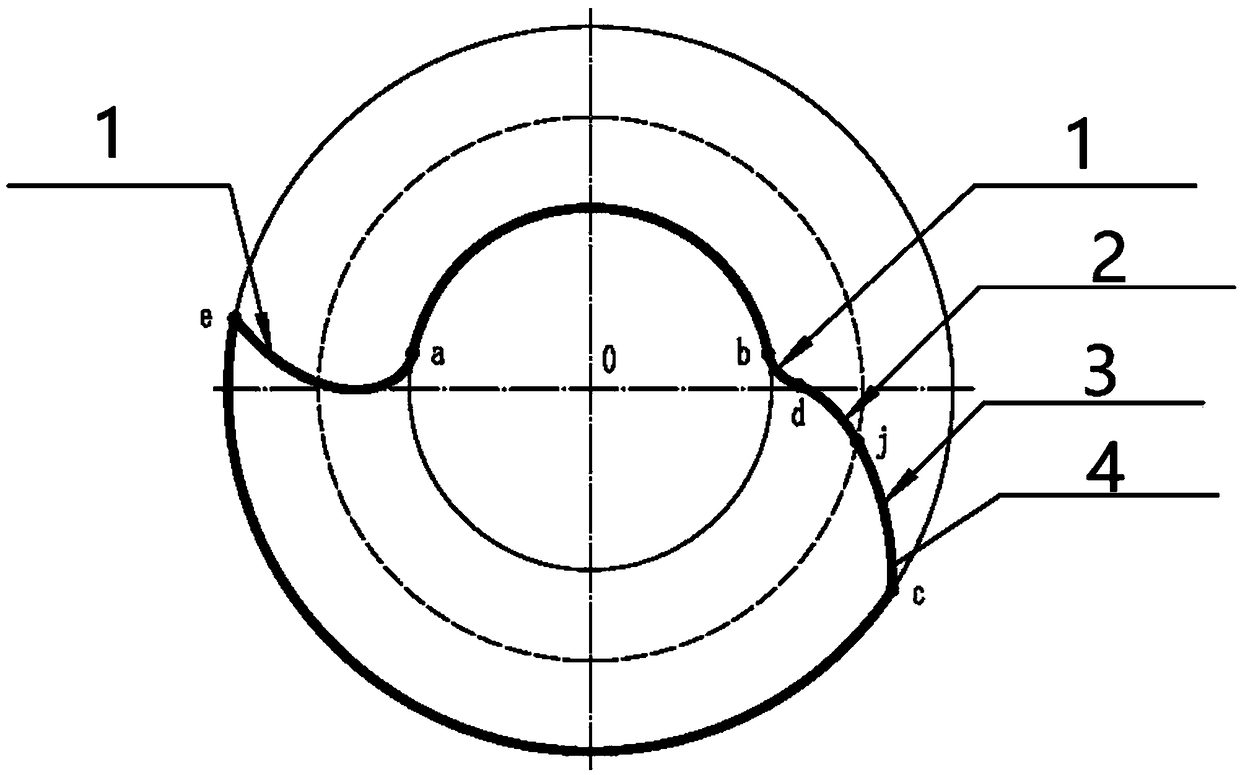

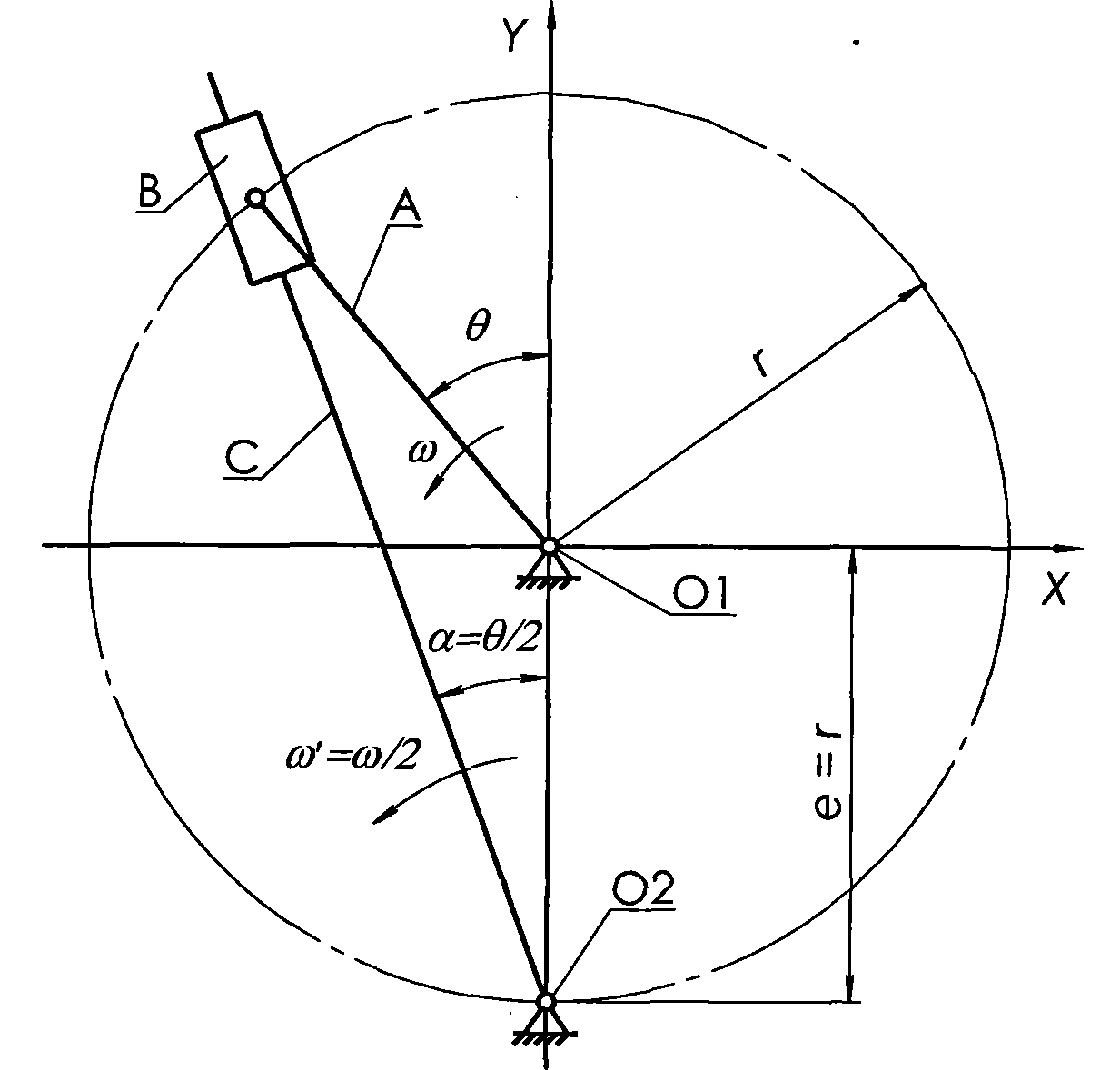

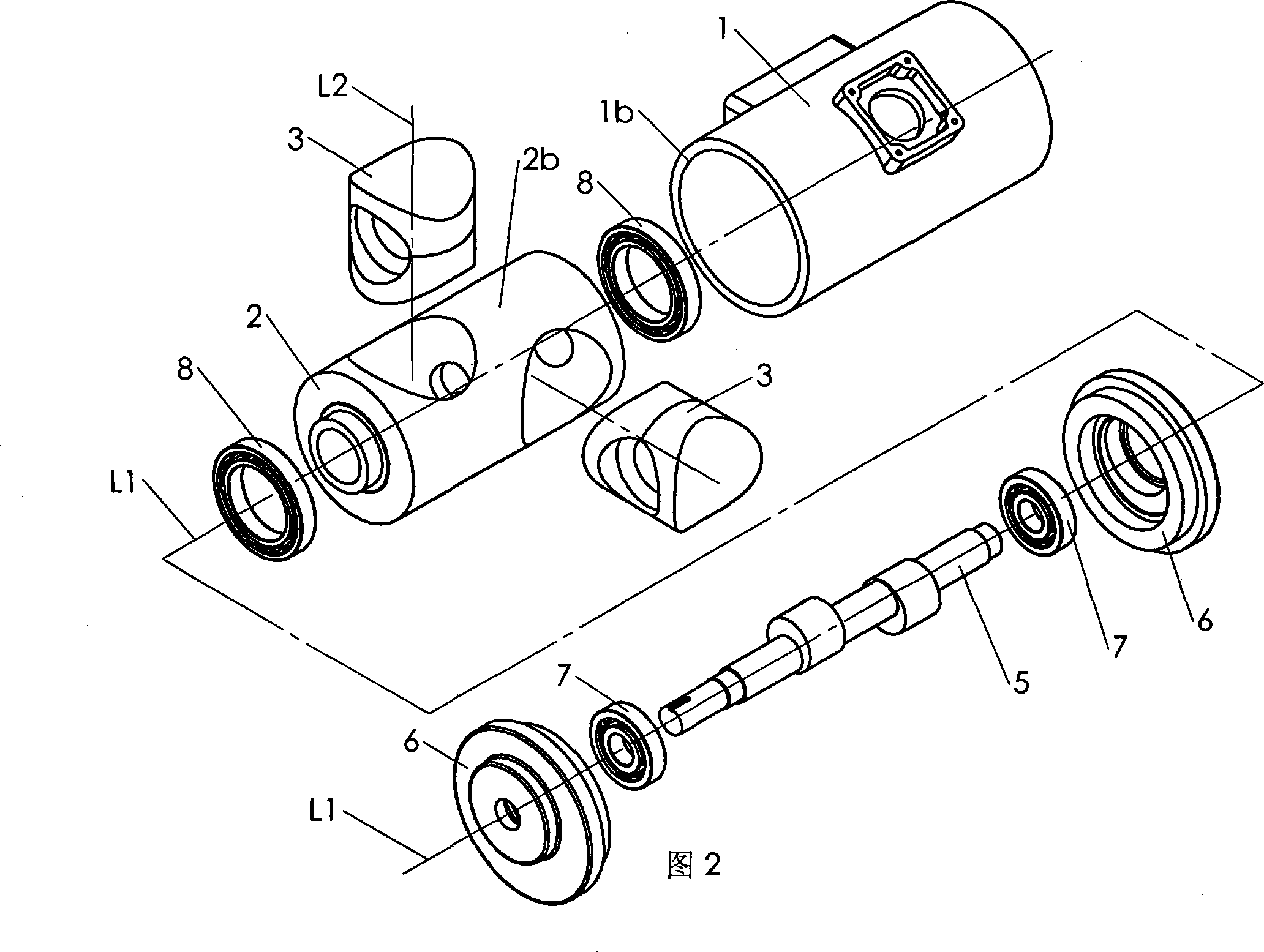

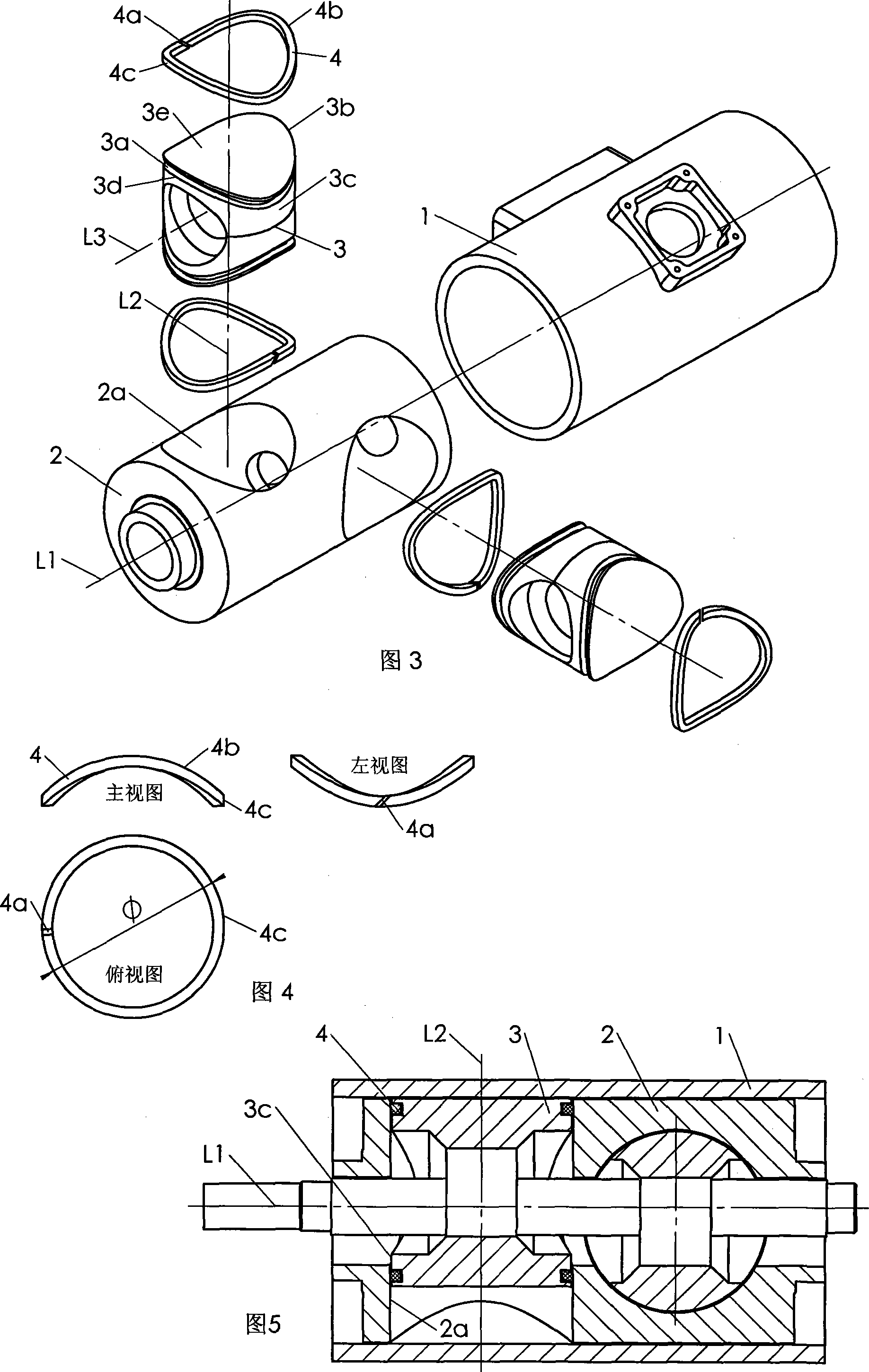

Cylinder dynamic seal apparatus used for Calor fluid machine

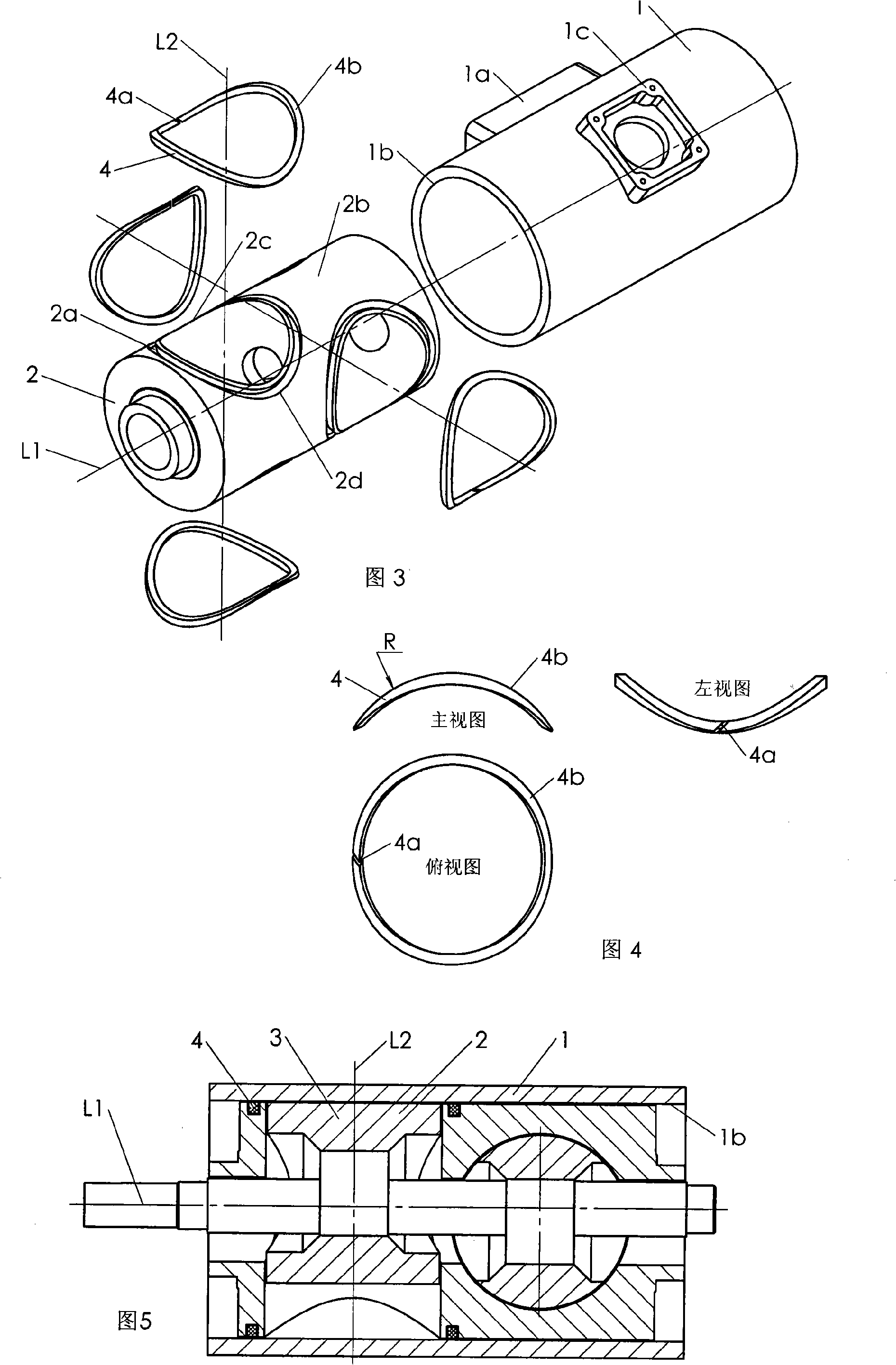

InactiveCN101280775AImprove volumetric efficiencyImprove the efficiency of adiabatic indicationPositive displacement pump componentsMulti-stage pumpsEngineeringDepth direction

The invention relates to Carroll fluid machinery, in particular discloses a cylinder dynamic sealing device used in Carroll fluid machinery. The cylinder dynamic sealing device comprises a ring groove (2a) arranged on an outer cylindrical surface (2b) of a rotating cylinder block body (2) matched with the inner hole (1b) of a shell (1) and a sealing ring (4) arranged in the ring groove (2a), and is characterized in that: the ring groove (2a) is arranged closely around the outer periphery of the opening of the cylinder; a special contour line (2d) formed by the intersection of the ring groove (2a) and the outer cylindrical surface (2b) of the rotating cylinder block body (2) and an intersection line (2c) of the outer cylindrical surface (2b) of the rotating cylinder block body (2) of the corresponding cylinder opening have similar special shapes; the sealing ring (4) and the ring groove (2a) have the same special shapes and are sliding-fit along the depth direction of the ring groove (2a). Compared with the traditional Carroll fluid machinery, the invention can substantially reduce circumferential leakage of the medium transmitted in a working cavity at the cylinder opening through the matched gap between the rotating cylinder block and the shell, thereby improving the capacity efficiency and thermal efficiency of the fluid machinery.

Owner:XI AN JIAOTONG UNIV

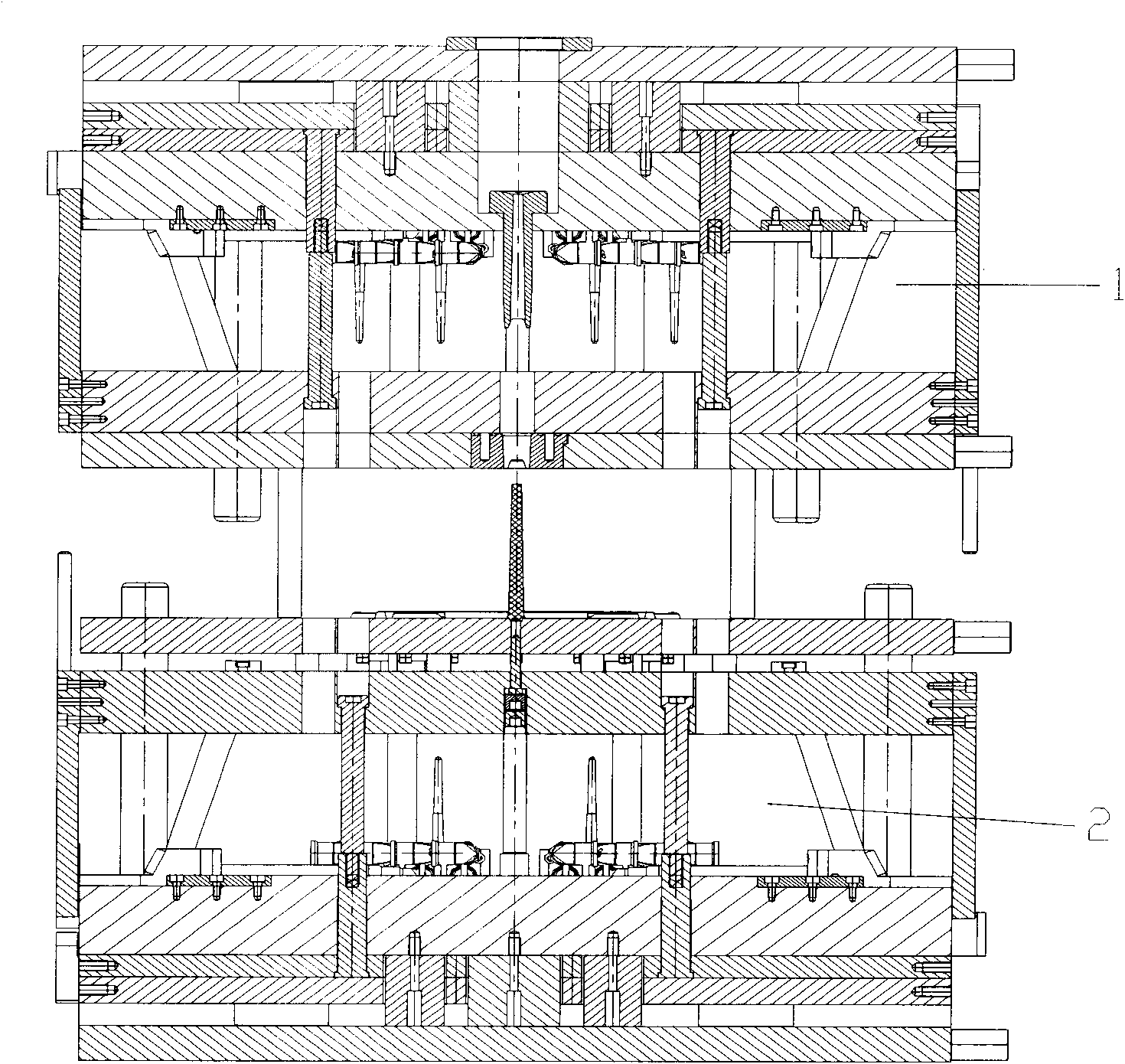

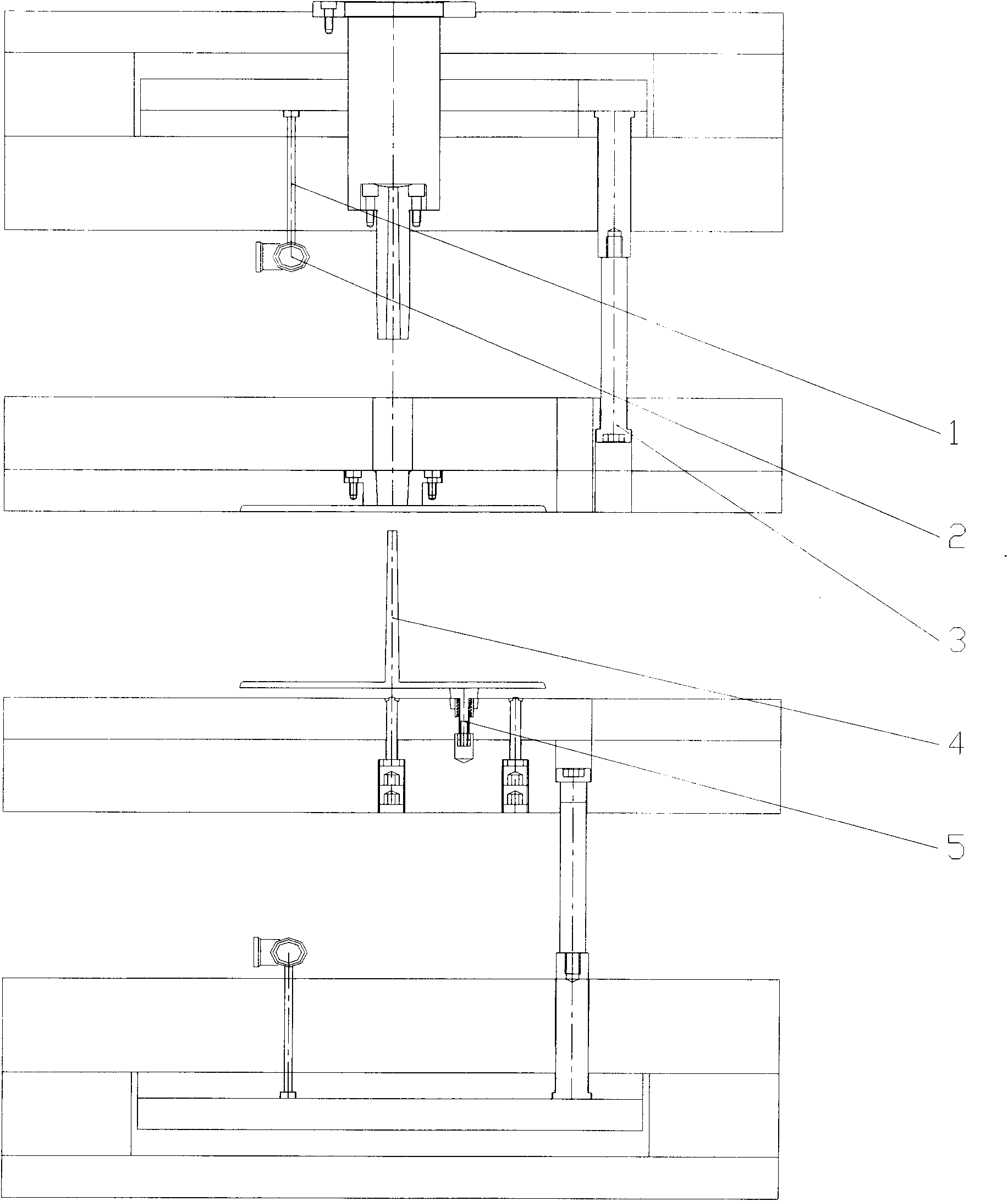

Pipe fitting stack mold

The invention relates to a pipe fitting stack mold, which is mainly used for mass and efficient production of small plastics products. The actual injection quantity of the conventional single layer cavity mold is only 20 to 40 percent of the maximum injection quantity of an injection molding machine because of mold capacity limitation of the injection molding machine, so the conventional single layer cavity mold cannot make full use of the injection characteristics thereof and cannot improve production efficiency. The pipe fitting stack mold adopts a multi-layer cavity, does not need to improve any equipment, and only most effectively uses an axial space of the injection molding machine. The technical key comprises the qualifying of products, the design of a flow channel, sequence controlof separating and opening the mold and the design of a resetting mechanism. The pipe fitting stack mold adopts a prolonged nozzle to reduce the length of the main flow channel; the pipe fitting stackmold has grouped qualifying with consistent type of the end faces of the products and a pre-reset structure; and the aggregation and ejection of the products and the flow channel are completed by moldopening linkage of injection molding machine. The pipe fitting stack mold is novel in structure, makes full use of the mold capacity space of the injection molding machine, improves capacity efficiency and doubles production efficiency.

Owner:亿美特装备(武汉)有限公司

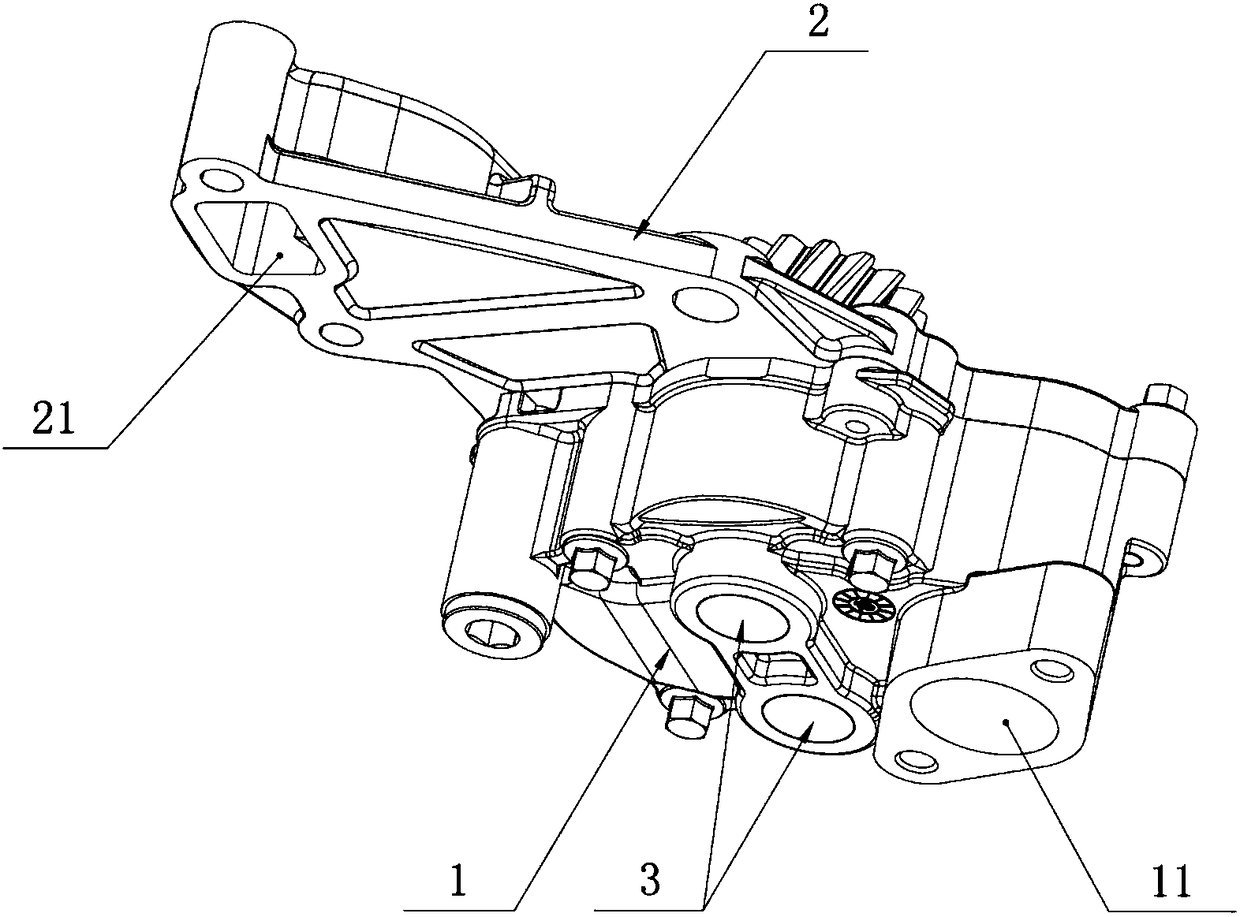

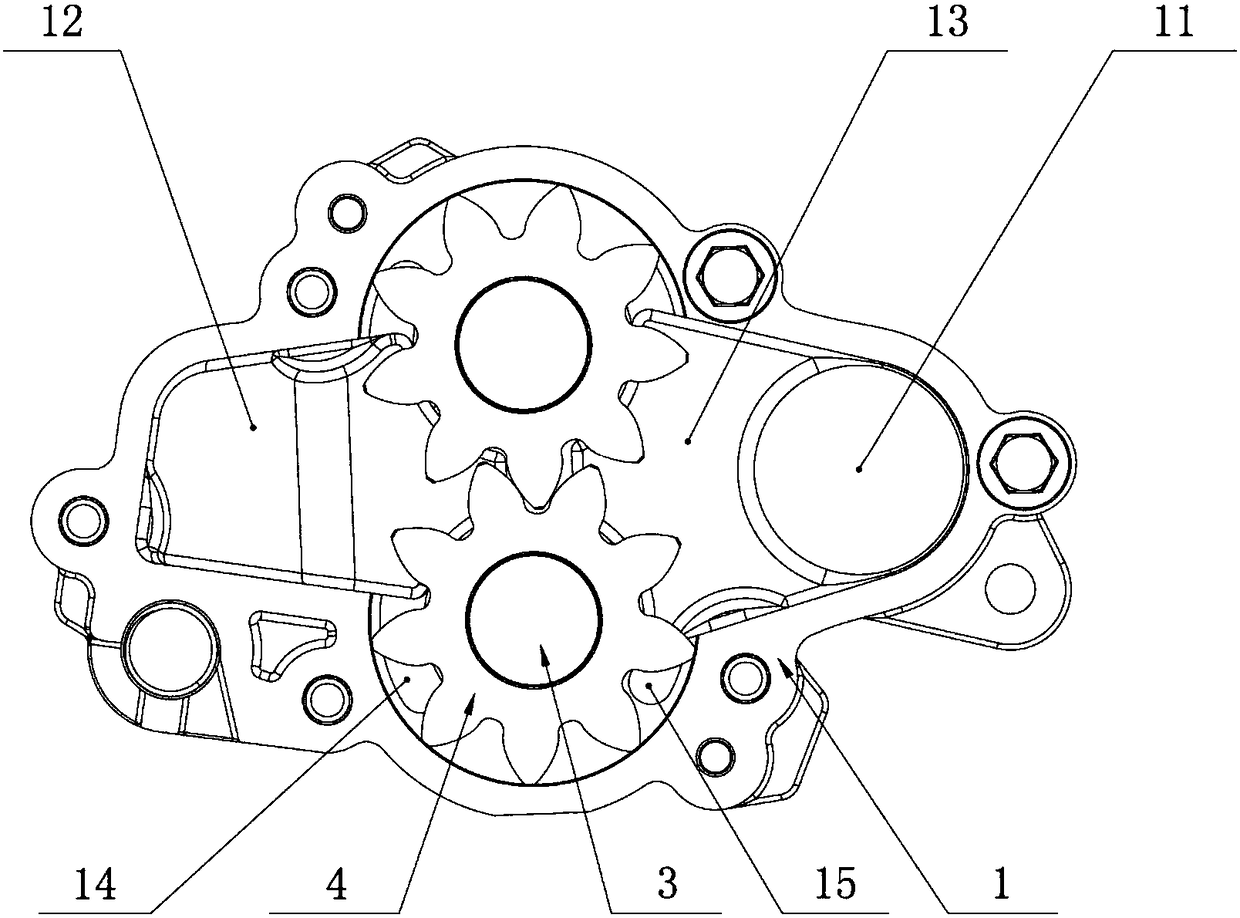

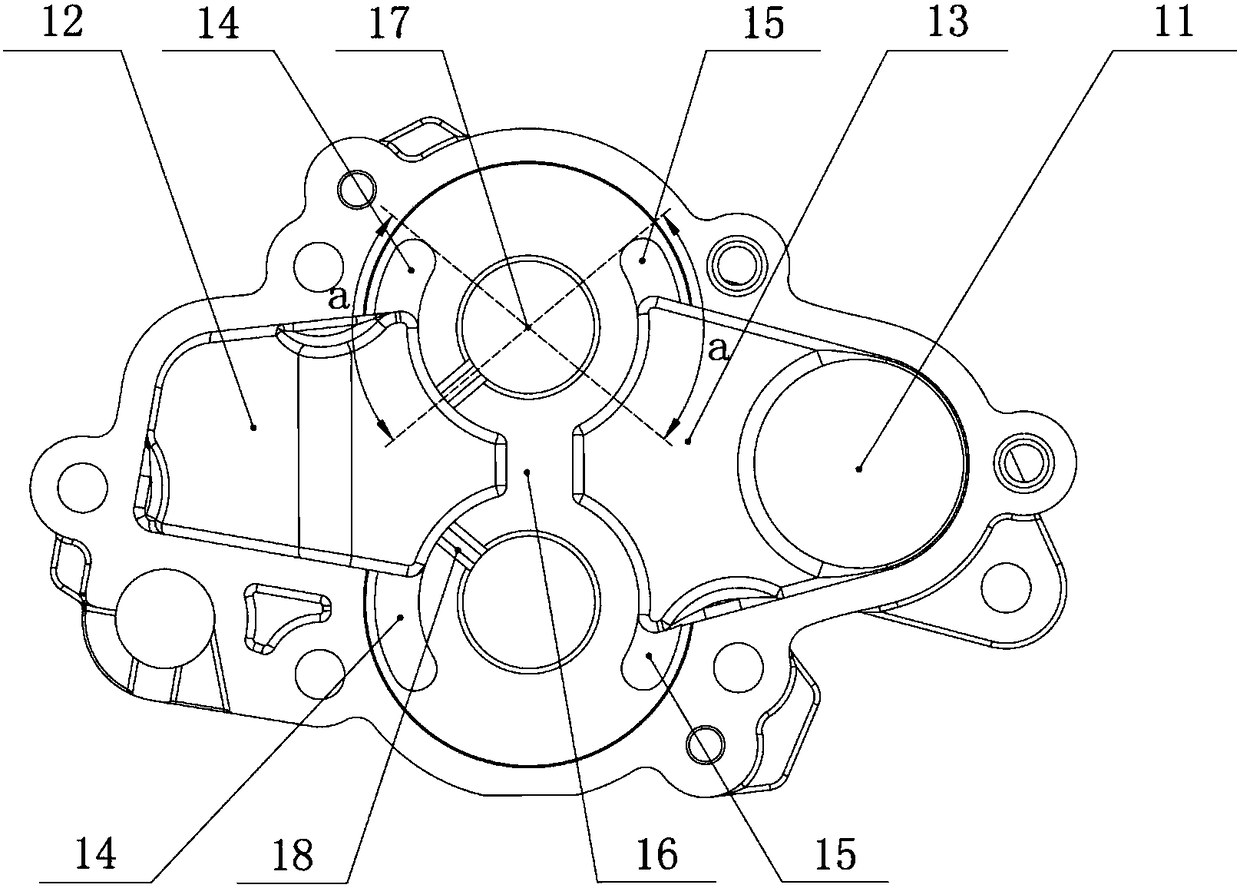

Machine oil pump and engine

ActiveCN108167180AReduce the phenomenon of "pumping out"Reduce or even avoid the phenomenon of "pumping out"Rotary piston pumpsRotary piston liquid enginesWork performanceDrive shaft

The invention belongs to the field of engine fittings, and discloses a machine oil pump and an engine. The machine oil pump comprises a pump body and a pump cover connected with each other, and two transmission shafts mounted on the pump body and the pump cover; the pump body is provided with an oil inlet; and the pump cover is provided with an oil outlet. The machine oil pump is characterized inthat the pump body comprises a first high-pressure groove communicating to the oil outlet and a first low-pressure groove communicating to the oil inlet; the two sides of the first high-pressure groove communicate with first oil unloading grooves; the two sides of the first low-pressure groove communicate with first oil supplementing grooves; and the first oil unloading grooves and the first oil supplementing grooves both can cover at least one part of areas between gear roots and gear tops of gears relative to projections of the gears on the transmission shafts. Through arrangement of the first oil supplementing grooves and the first oil unloading grooves, the phenomenon of oil trapping and evacuation can be effectively reduced or even prevented, the working performance of the machine oilpump can be improved, the service life of the machine oil pump is prolonged, the noise is reduced, and the capacity efficiency is improved.

Owner:WEICHAI POWER CO LTD

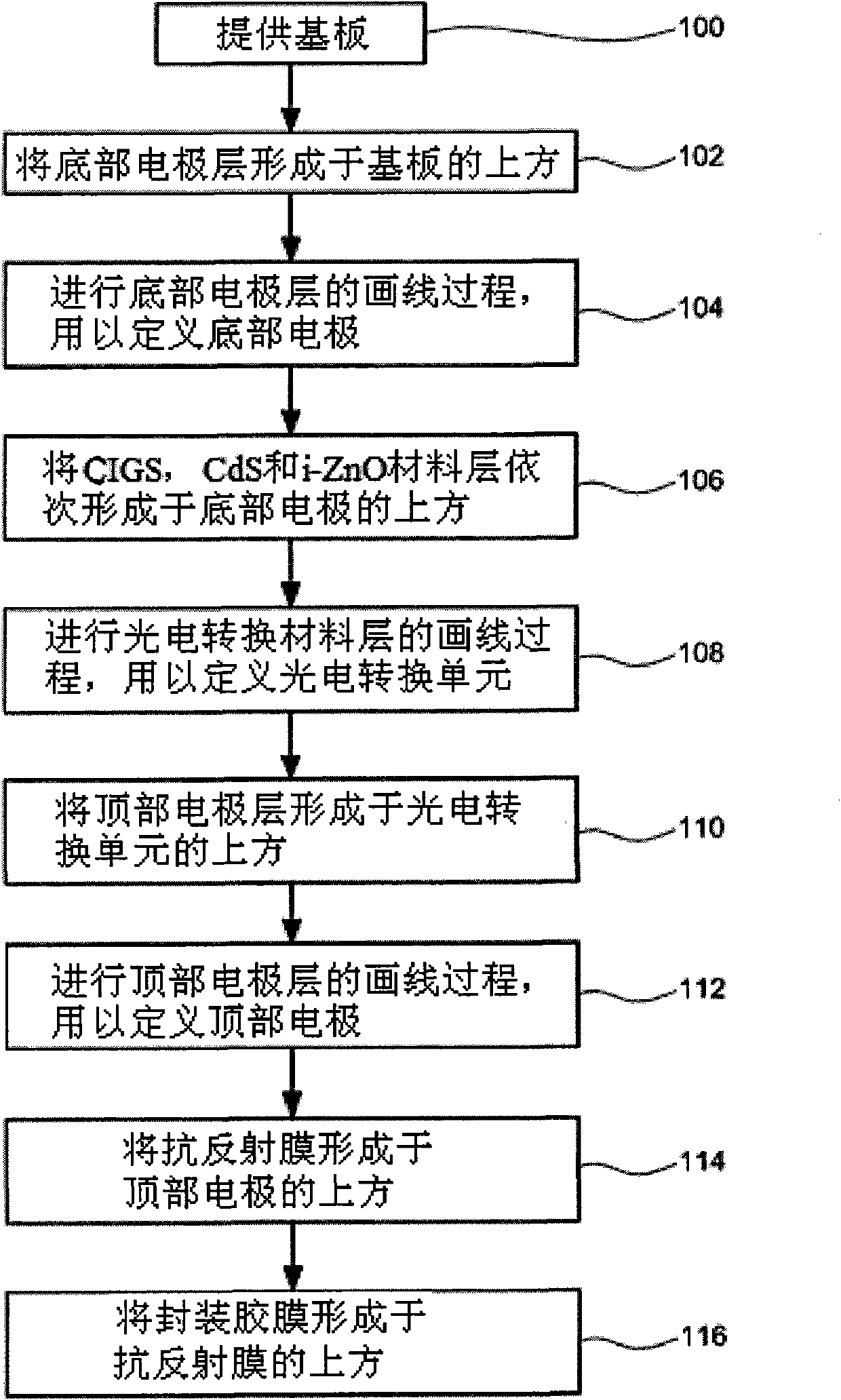

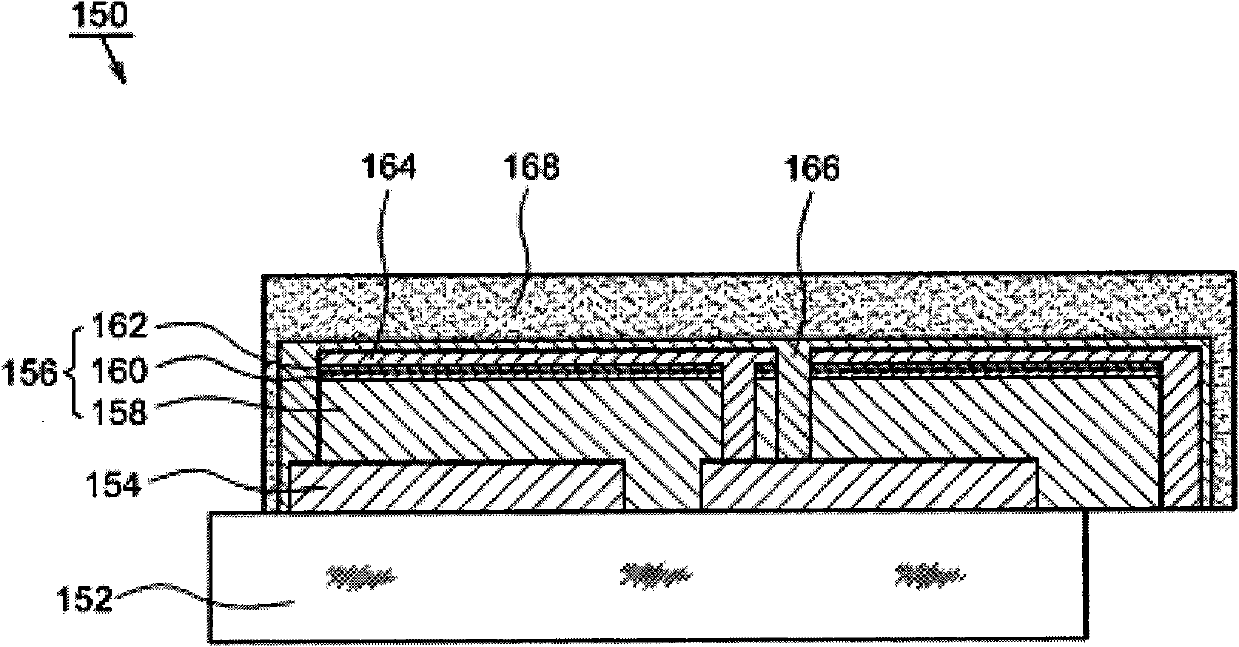

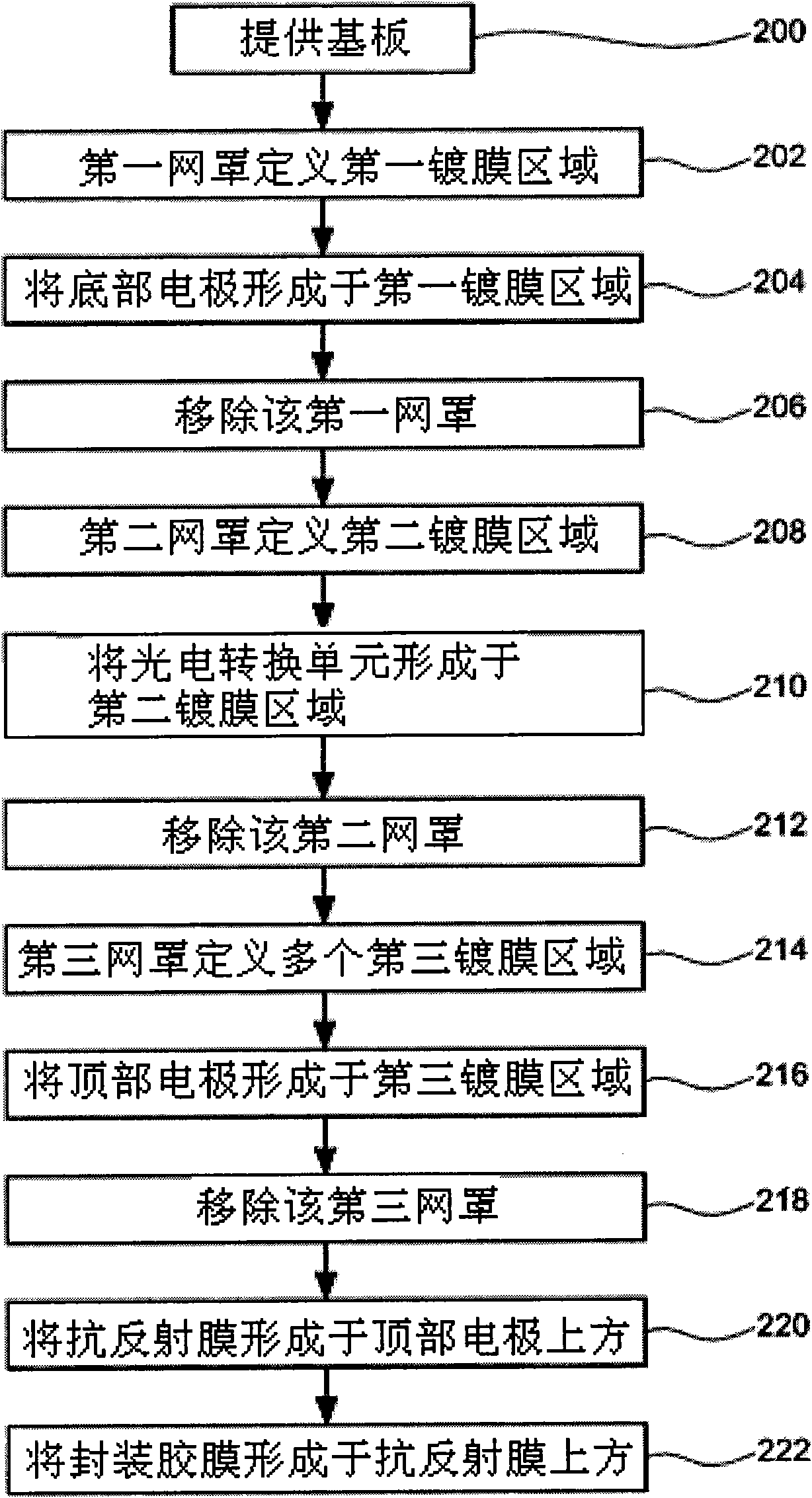

Method for manufacturing solar module

InactiveCN102024864AAvoid exposureIncrease production capacityFinal product manufactureVacuum evaporation coatingIndiumElectrical battery

The invention relates to a method for manufacturing a solar module. In the manufacturing method, an effective coating area is defined by a mesh cover; by using the mesh cover, each layer of film of the solar module can be directly and continuously formed under a vacuum environment, and the effective area of the solar module is not needed to be defined by a laser scraper, a mechanical scraper and other equipment. Therefore, the equipment cost and scraping process of the laser scraper and the mechanical scraper can be saved. The manufacturing method is particularly applied to a solar cell with a copper indium gallium selenium compound semiconductor film, and procedures in the production process can be reduced; therefore, the capacity efficiency can be improved.

Owner:吴静怡 +1

Piston dynamic seal apparatus used for Calor fluid machine

InactiveCN101280776BImprove volumetric efficiencyImprove the efficiency of adiabatic indicationPositive displacement pump componentsLiquid fuel engine componentsEngineeringMechanical engineering

The invention relates to Carroll fluid machinery and discloses a piston dynamic sealing device used in Carroll fluid machinery. The piston dynamic sealing device comprises a ring groove (3a) arranged on an outer cylindrical surface (3c) of a piston (3) matched with a cylinder hole (2a) and a sealing ring (4) arranged in the ring groove (3a), and is characterized in that: the ring groove (3a) is arranged in a way that is close to the end of the piston (3); a special contour line (3d) formed by the intersection of the ring groove (3a) and the outer cylindrical surface (3c) of the piston (3) is the same as an periphery special contour line (3b) of a working end face of the piston (3); the sealing ring (4) and the ring groove (3a) have the same special shapes and are sliding-fit along the radial direction. Compared with the traditional Carroll fluid machinery, the invention can substantially reduce leakage of the medium transmitted in a working cavity through the ring-shaped matched gap between the piston and the cylinder hole, thereby improving the capacity efficiency and thermal efficiency of the fluid machinery.

Owner:XI AN JIAOTONG UNIV

Device and method for fault diagnosis and performance test of single screw pump

InactiveCN105649978BRealize online monitoringImplement fault diagnosisPump componentsRotary piston pumpsEngineeringStrategy making

The invention provides a device and method for diagnosing faults and testing performance of a single-screw pump. The operation condition of the single-screw pump can be subjected to online monitoring, fault diagnosis and performance testing. Two work modes, namely, a normal production monitoring mode and a performance online testing mode are provided in the device. In the normal production monitoring mode, based on real-time monitoring on running parameters of the pump in the normal production process, the online monitoring of the operation condition of the pump is achieved; and online diagnosis of common faults of the pump can be completed by means of online detected data, and a maintaining strategy is made on the basis. In the pump performance testing mode, pump performance testing of an in-service single-screw pump / an out-of-service single-screw pump under a common operating condition / extreme operating condition can be achieved, the pump capacity efficiency, the shaft power, the lift, the overall efficiency and other performance parameters can be calculated under different operating conditions, and a performance curve is drawn and stored on the basis.

Owner:SOUTHWEST PETROLEUM UNIV

Multifunctional same-furnace multi-band bimetal strip saw blade heat treatment full-automatic production line and process thereof

ActiveCN101956056BIncrease work intensityImprove working environmentFurnace typesHeat treatment furnacesMulti bandQuenching

The invention discloses a multifunctional same-furnace multi-band bimetal strip saw blade heat treatment full-automatic production line and a process thereof, relating to a bimetal strip saw blade production line and a compound quenching process and solving the problems of difficult control of equipment and process parameters, difficult guarantee of product quality, incapability of producing multiple saw blades in various specifications at the same time, low equipment capacity efficiency, high production cost and energy wastes of water, power and gas at present. In the invention, equipment inall working procedures are integrated into one production line, all the working procedures of quenching, tempering, sand blasting, cleaning, baking, marking, oil coating, straightening and the like are completed on the same production line, the production of multiple saw blades in various specifications can be completed at the same time, and after the invention is applied, the total capacity can be improved by 5-8 times, the service life of the product can be improved by around 50%, and the production cost can be reduced by more than 40%. An on-ling dynamic rapid-tempering novel technology isadopted for tempering equipment and process, thus the saw blades travels faster on the production line to complete the whole process of tempering so that high capacity can be achieved for the saw blades.

Owner:曹玉贵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com