Distribution valve and conveying pump adopting same

A technology of distributing valves and conveying pumps, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as difficult suction, low volumetric efficiency, and low pumping pressure, and meet the requirements of high lift and long-distance pipeline transportation, improve volumetric efficiency, and prevent material backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

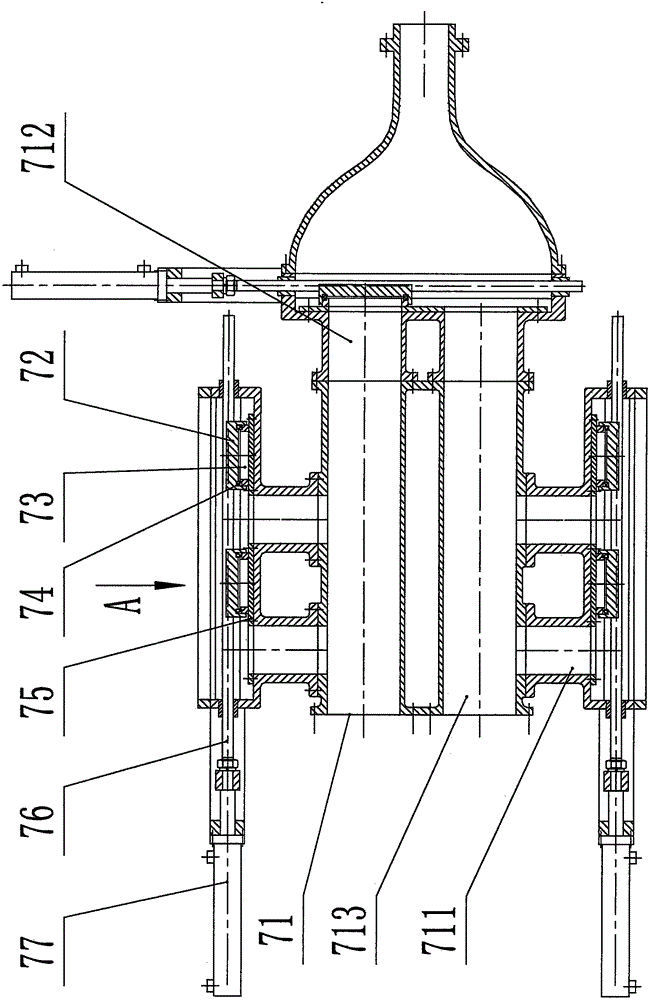

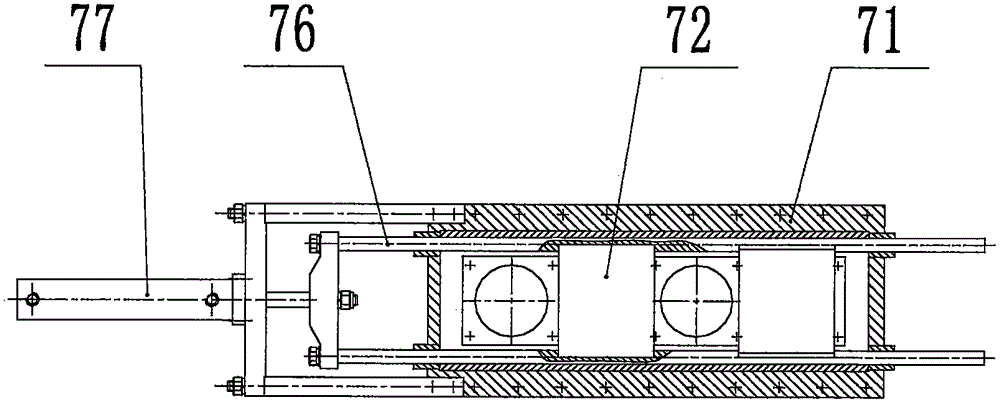

[0044] see figure 1 and figure 2 , which shows a schematic diagram of a dispensing valve according to a preferred embodiment of the present invention. The distribution valve includes: distribution valve box 71, sliding body 72, elastic seal 73, sliding seal 74, friction plate 75, guide rod 76, driving device 77, distribution valve body 1 711, distribution valve body 2 712, distribution valve Body III 713.

[0045] Distribution valve box 71 is a split structure composed of multiple parts, including distribution valve body 1 711, distribution valve body 2 712, distribution valve body 3 713, distribution valve body 1 711, distribution valve body 2 712 and distribution valve body Three 713 are fixedly connected together.

[0046] The distributing valve includes two feed valves and a discharge valve, both of which are slide valve structures, and each feed valve includes two valve plate units and two feed ports, so The discharge valve described above includes a valve plate unit...

Embodiment 2

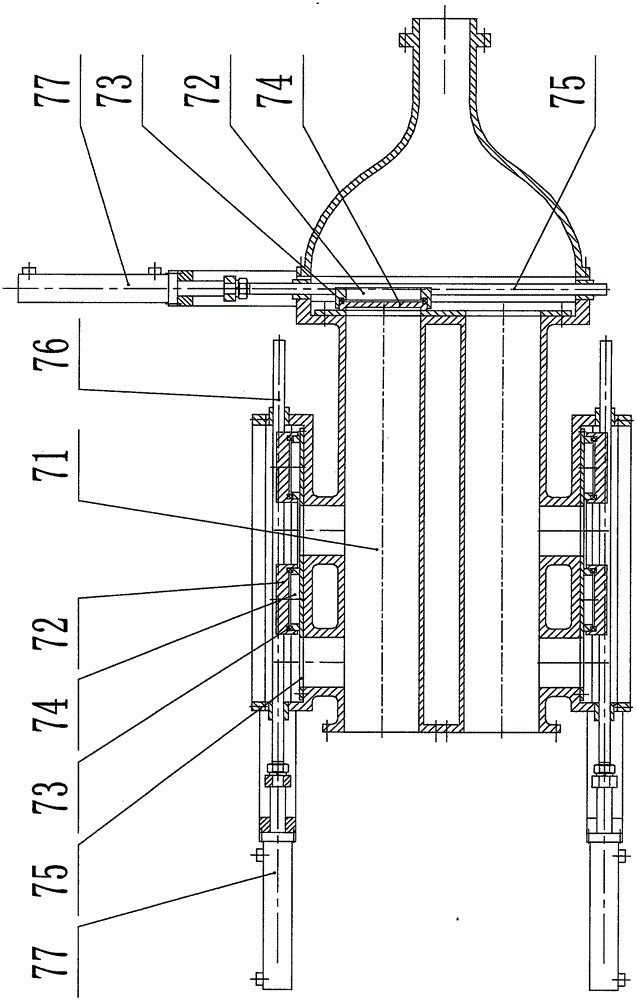

[0051] see image 3, which shows a schematic diagram of a dispensing valve according to another preferred embodiment of the present invention. The distribution valve includes: a distribution valve box 71 , a sliding body 72 , an elastic seal 73 , a sliding seal 74 , a friction plate 75 , a guide rod 76 , and a driving device 77 .

[0052] The driving device 77, the guide rod 76 and the friction plate 75 are installed on the distribution valve box 71, the power output end of the driving device 77 is connected with the guide rod 76, and the guide rod 76 is connected with the sliding body 72 again, and the sliding seal 74 and the elastic The sealing member 73 is installed on the sliding body 72, and the elastic sealing member 73 is located between the sliding body 72 and the sliding sealing member 74, the friction plate 75 is located between the distribution valve box 71 and the sliding sealing member 74, the elastic force of the elastic sealing member 73 Under action, the slidi...

Embodiment 3

[0056] see Figure 4 , which shows a schematic diagram of a dispensing valve according to another preferred embodiment of the present invention. The distributing valve includes: a distributing valve box 71 , a sliding body 72 , an elastic seal 73 , a sliding seal 74 , a driving device 77 , and a seat valve head 78 .

[0057] The distribution valve is a mixed structure of a slide valve and a seat valve, and the distribution valve includes two inlet valves and two outlet valves. The feed valve is a slide valve structure, wherein the driving device 77 is connected with the sliding body 72, the sliding seal 74 and the elastic seal 73 are installed on the distribution valve box 71, and the elastic seal 73 is located between the sliding seal 74 and the distribution valve box Between 71, there are through holes on the sliding body 72 and the sliding sealing member 74, and the sliding sealing member 74 can be compressed on the sliding body 72 under the action of the elastic sealing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com