Device and method for diagnosing faults and testing performance of single-screw pump

A single-screw pump, fault diagnosis technology, applied in neural learning methods, pumps, pump components, etc., can solve problems such as increased pump failure rate, stator and rotor wear, and irregular installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

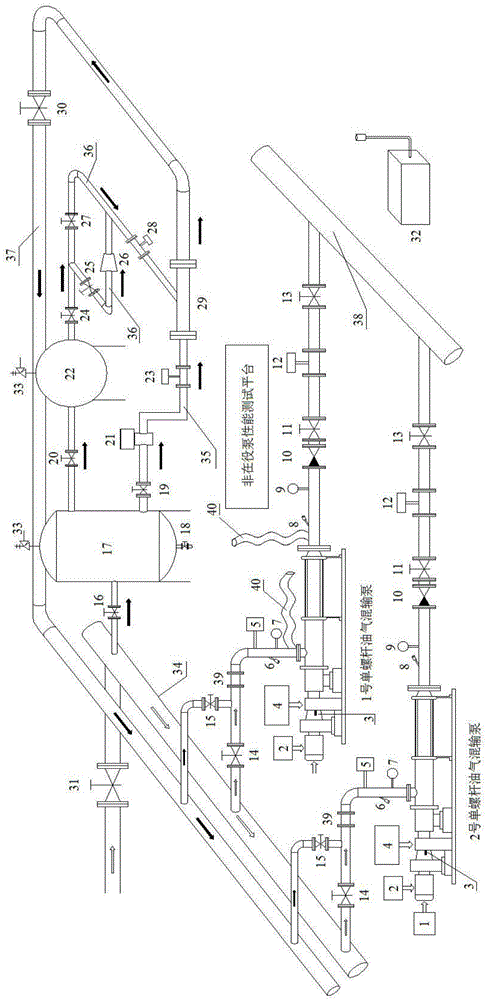

[0055] One of the purposes of the present invention is to design a set of single screw pump fault diagnosis and performance testing device, whose function is to remotely control the terminal equipment installed in the transfer station of the oil field ground gathering and transportation system through the monitoring center, so as to realize the operating conditions of the single screw pump Online monitoring, fault diagnosis and performance testing.

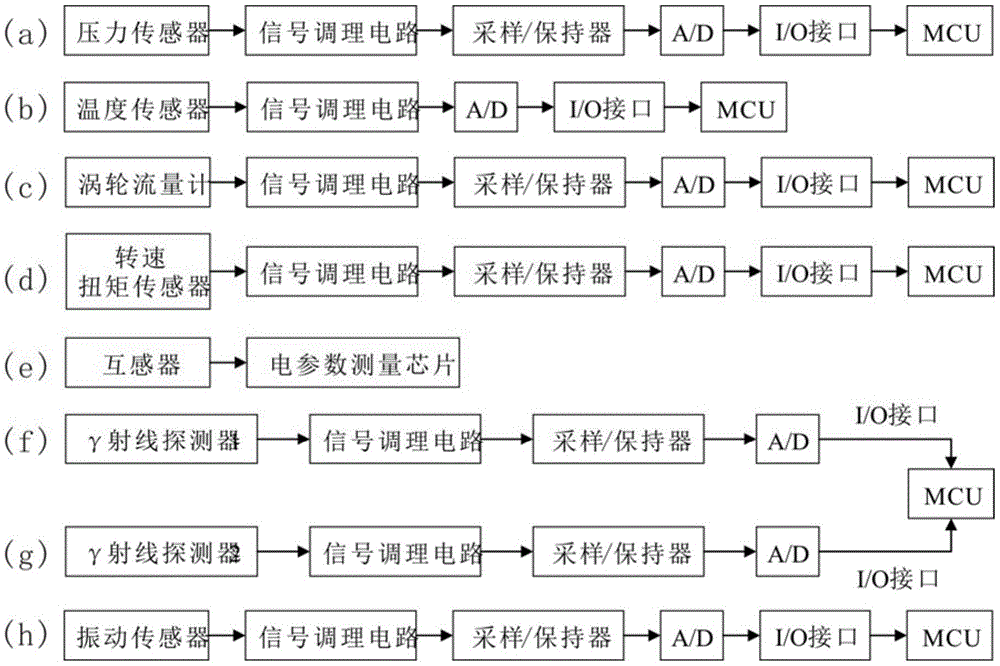

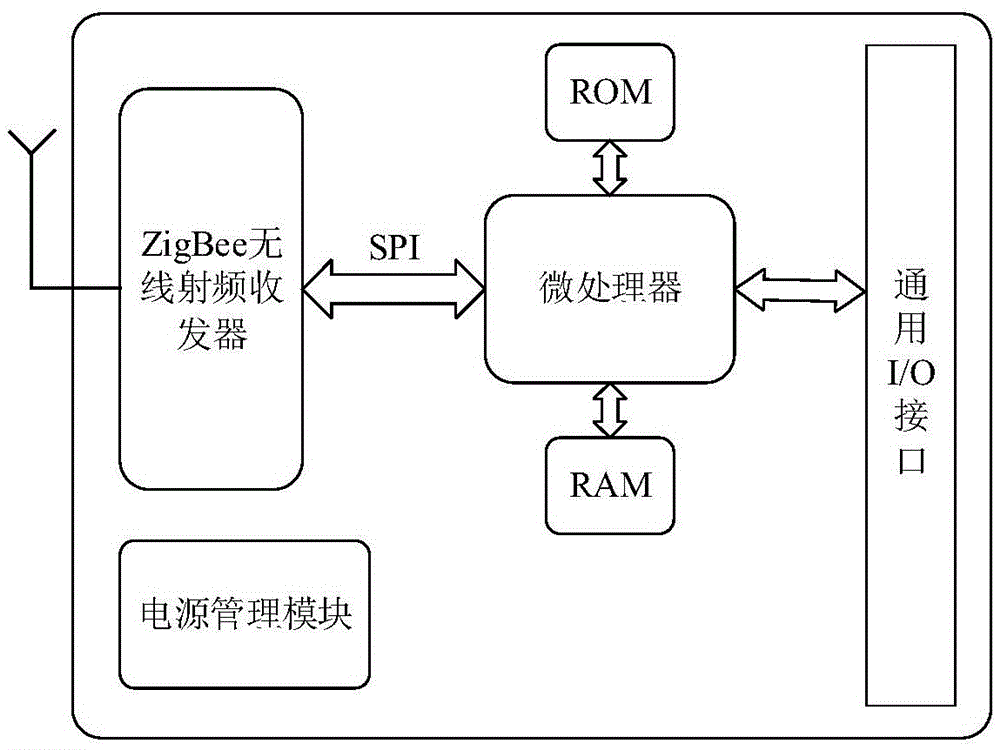

[0056] In order to achieve the above purpose, the single screw pump fault diagnosis and performance testing device provided by the present invention generally mainly includes terminal equipment and a monitoring center arranged in the transfer station of the oil field ground gathering and transportation system; the terminal equipment switches the working mode according to the control command , Collection of operating parameters and adjustment of operating conditions; the monitoring center realizes the monitoring of operating conditi...

Embodiment 2

[0116] This embodiment provides a method for diagnosing the fault of a single screw pump in normal production monitoring mode by using the device provided in Embodiment 1.

[0117] Normal production monitoring mode such as figure 1 indicated by the white arrow. During normal production, the electric control valves (15, 16, 19, 24) are closed by remote control, the performance test pipeline is in a deactivated state, the electric control valves (11, 14) are opened, and the wellhead produced fluid passes through the An oil collecting manifold 34 enters each booster pipeline, and after being pressurized by each single screw pump, enters the oil collecting main line through the second oil collecting manifold 38 to complete the boosting process. During this process, each wireless sensor node collects the operating state parameters of the single screw pump, and transmits the collected parameters to the monitoring center through the ZigBee / GPRS network to realize online real-time mo...

Embodiment 3

[0178] Performance testing, realize the detection of performance parameters such as displacement, volumetric efficiency, power and total efficiency of single screw pump under different working conditions, and complete the drawing of performance curves such as flow rate-lift, efficiency-lift, shaft power-lift, etc. To grasp the current performance status of the single screw oil-gas mixed pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com