Pipe fitting stack mold

A technology of laminated molds and pipe fittings, which is applied to household appliances, tubular objects, and other household appliances, etc. It can solve the problems of not being able to improve production efficiency and not being able to make full use of injection characteristics, so as to improve the utilization rate of equipment, improve the utilization rate, and produce The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

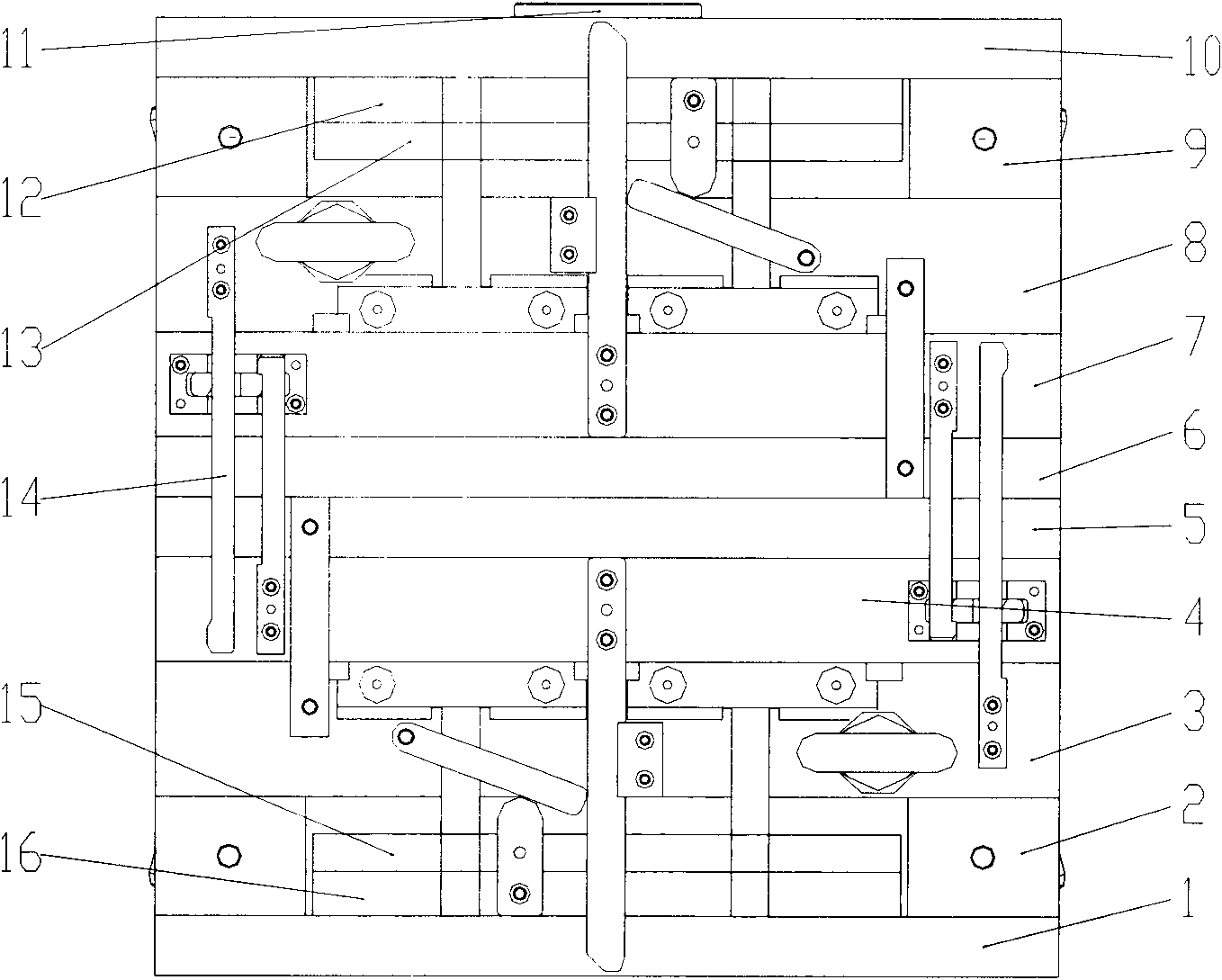

[0025] exist figure 1 In the process, under the control of the lock, the mold is opened by the injection molding machine. Under the control of the lock 14, the lower fixed template 3, the lower movable template 4, the upper fixed template 7, and the upper movable template 8 are opened to drive the upper push plate 12. The upper push rod fixing plate 13, the lower push rod fixing plate 15, and the lower pushing rod fixing plate 16 push out the product and the flow channel at the product; then push out the plate 5 from the flow channel, open the flow channel plate 6, and pull out the main flow channel; finally Push out the flow channel push-out plate 5, release the main flow channel, the base plate 1, the lower support block 2, the upper support block 9, the panel 10, and the positioning ring 11 are motionless. The injection molding machine closes the mold, the push rod is reset first, and the above process is repeated.

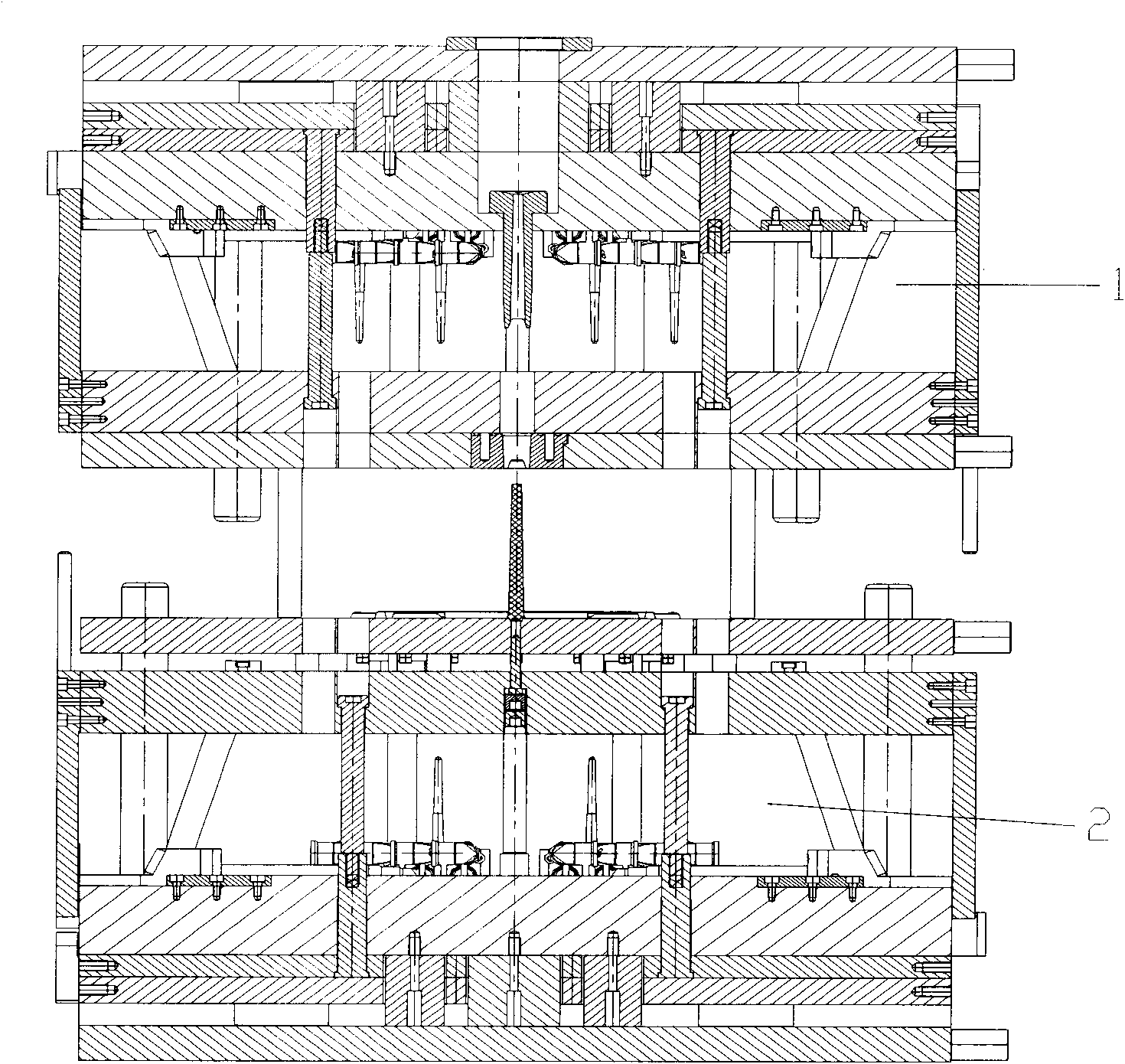

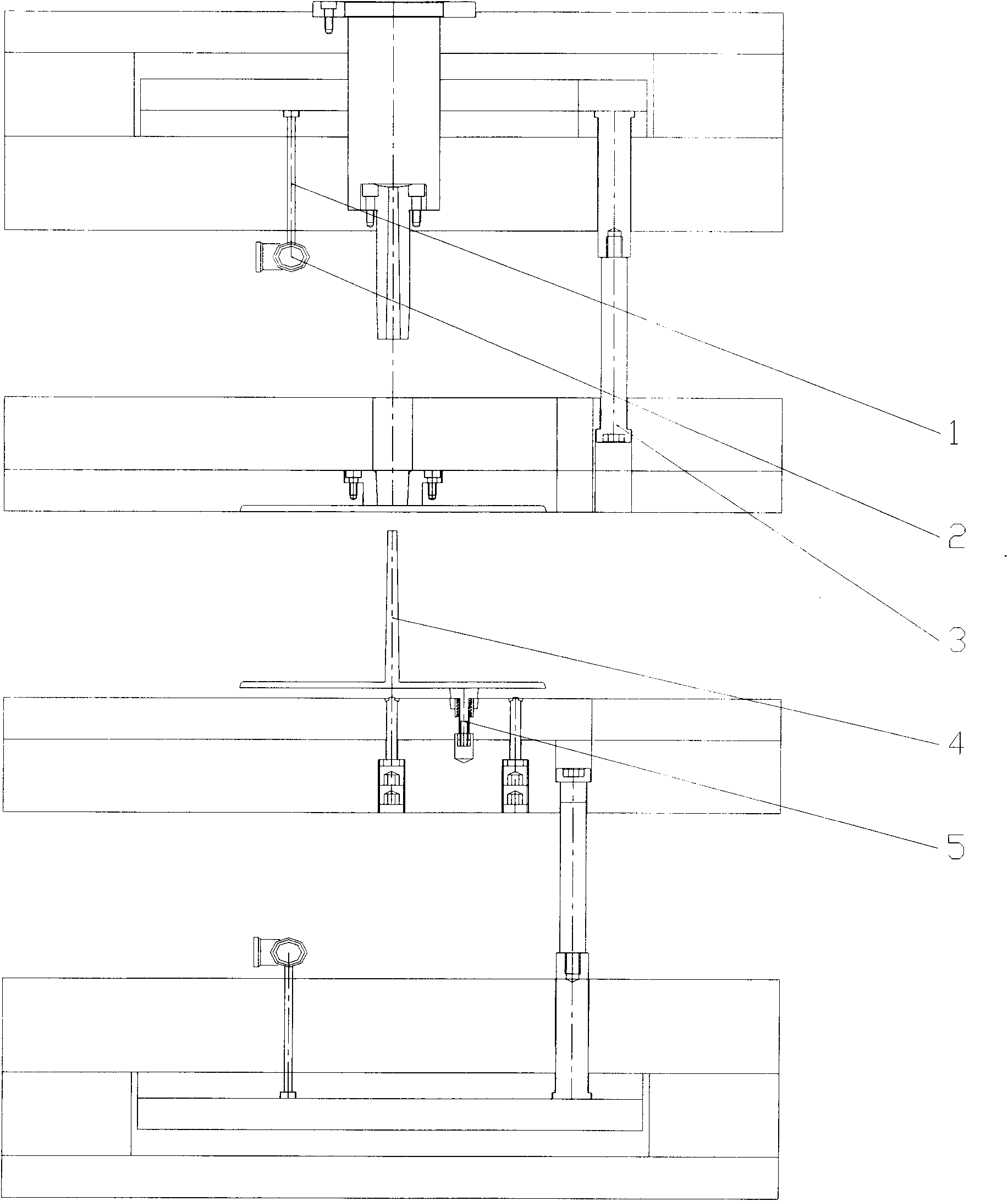

[0026] exist image 3 In the process, the injection mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com