Piston dynamic seal apparatus used for Calor fluid machine

A technology of fluid machinery and dynamic sealing, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids. It can solve problems such as leakage in the fit gap, achieve the effects of reducing leakage and improving the efficiency of adiabatic indication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

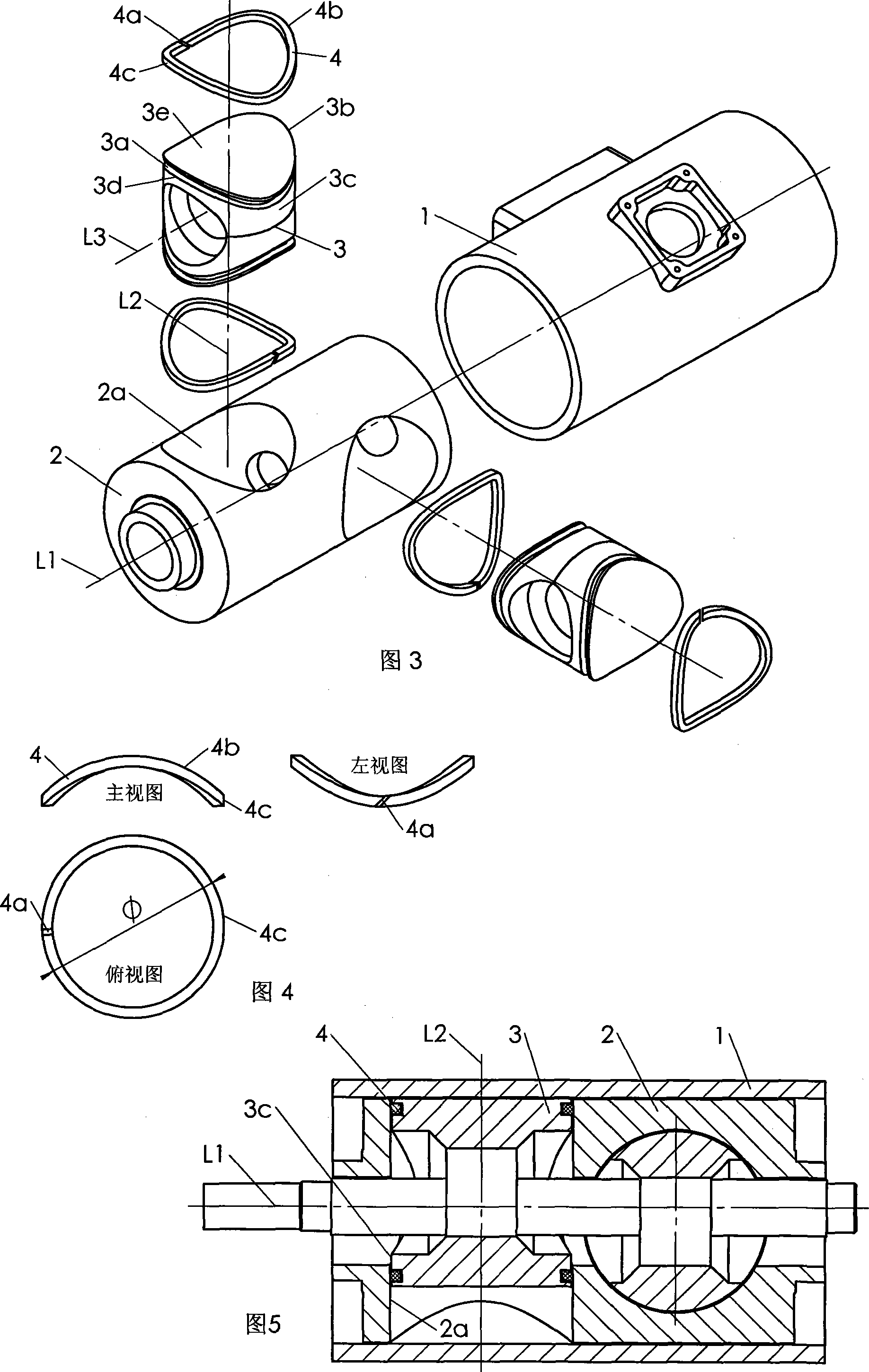

[0026] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

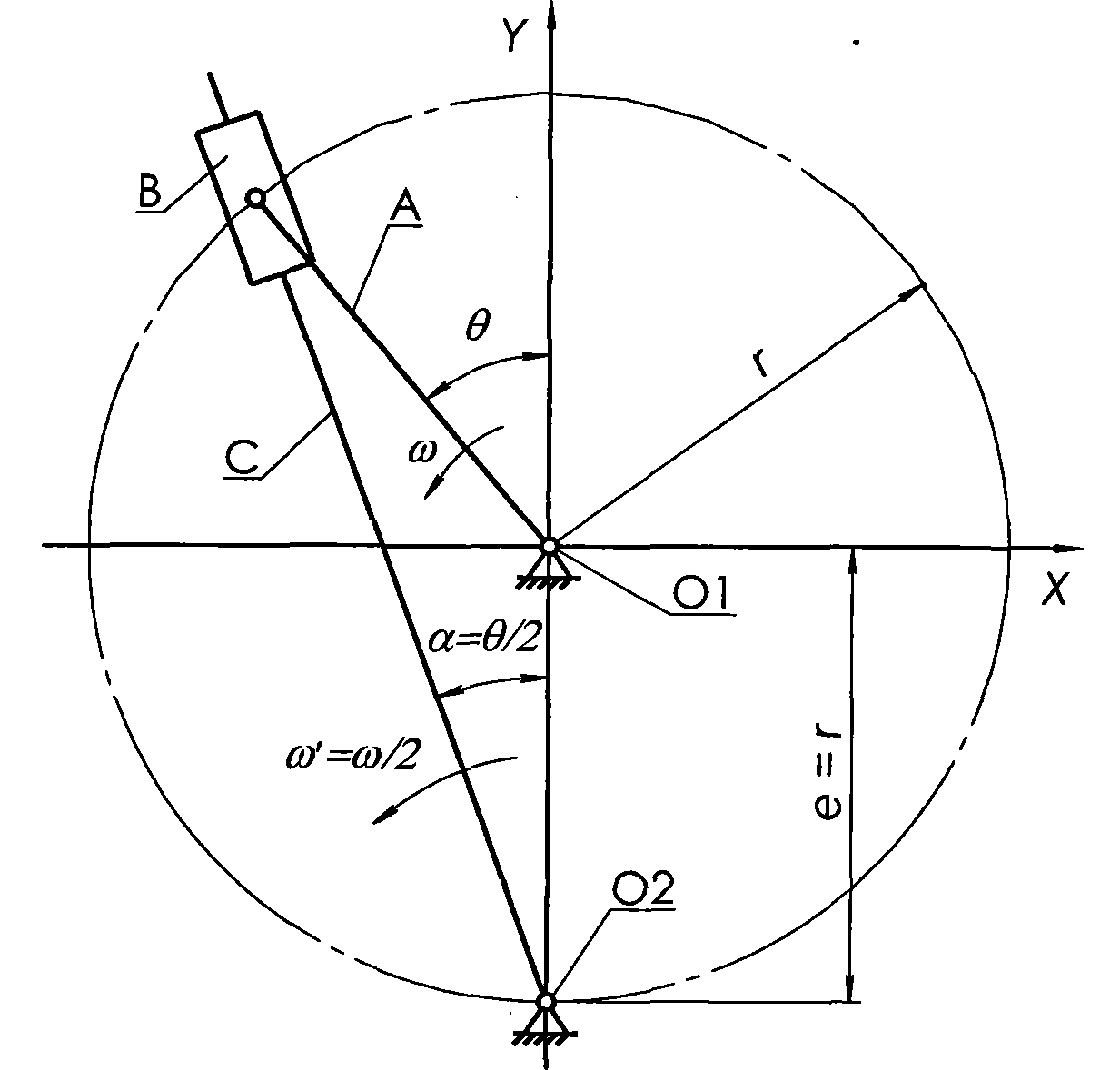

[0027] figure 1 It is a principle diagram of the mechanism motion transformation relation of the Carroll fluid machine targeted by the present invention. The slider in the figure is equivalent to the piston, the guide rod is equivalent to the cylinder hole, and the distance e between the cylinder body (ie the guide rod) and the center of the main shaft (ie the crank) is just equal to the crank radius r. When the crank drives the slider to rotate, the slider slides along the guide rod, and drives the guide rod to rotate at a half-synchronous rotation speed of the crank. Every time the crank rotates one revolution, the slider travels 4r along the guide rod. In the mechanism with only one slider and guide rod, when the crank angle is 180°, there is uncertainty in the direction of rotation of the guide rod.

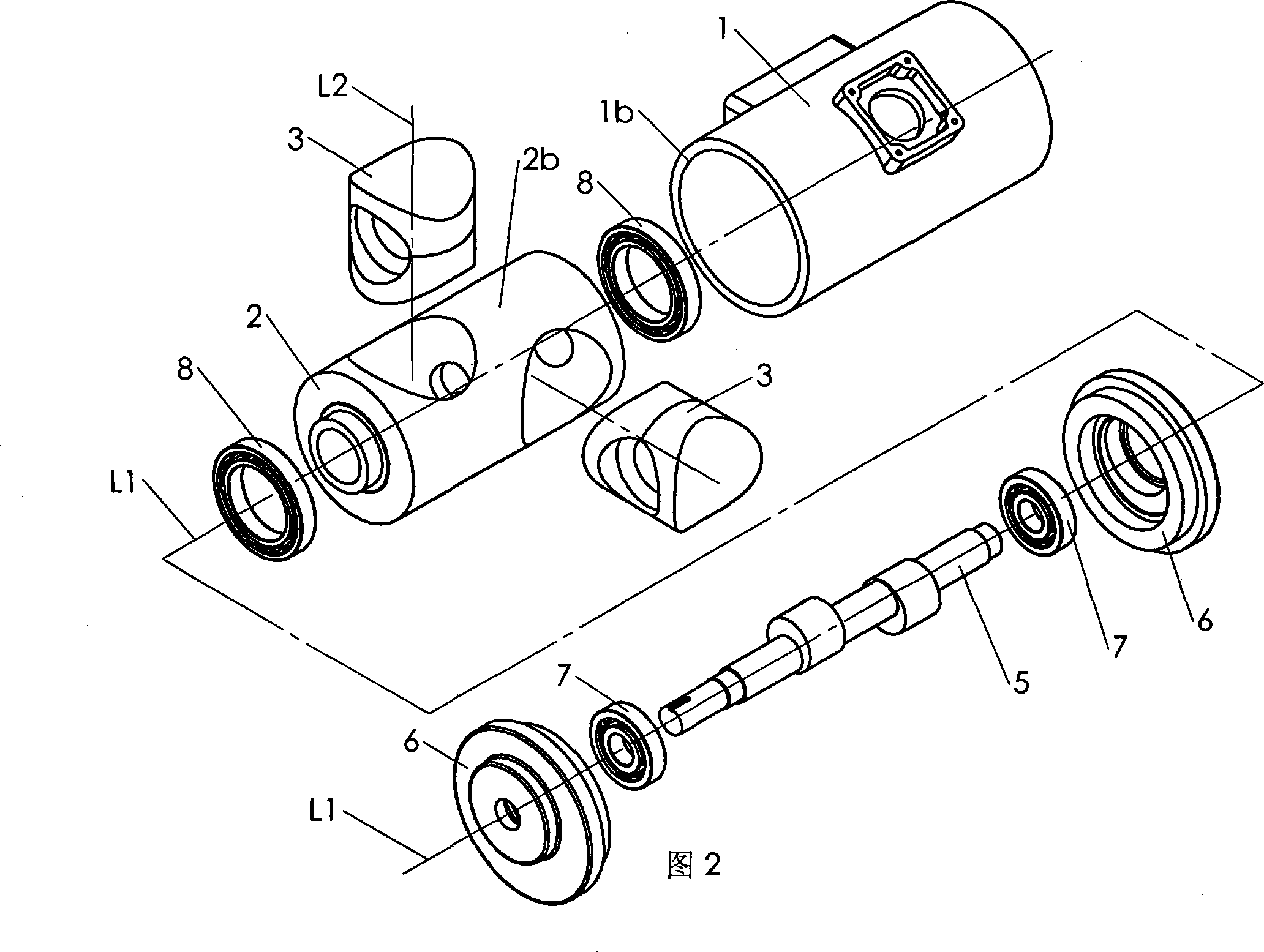

[0028] figure 2 It is a schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com