Two-screw multiphase pump device suitable for working condition with high air void

A technology of twin-screw and mixed pumps, which is applied to rotary piston/oscillating piston pump components, pumps, pump components, etc., can solve the problems of unfavorable service life and reliability of mixed pumps, reduced efficiency of mixed pumps, rotor heat Increased deformation and other issues to achieve the effect of lowering temperature, improving efficiency and reliability, and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

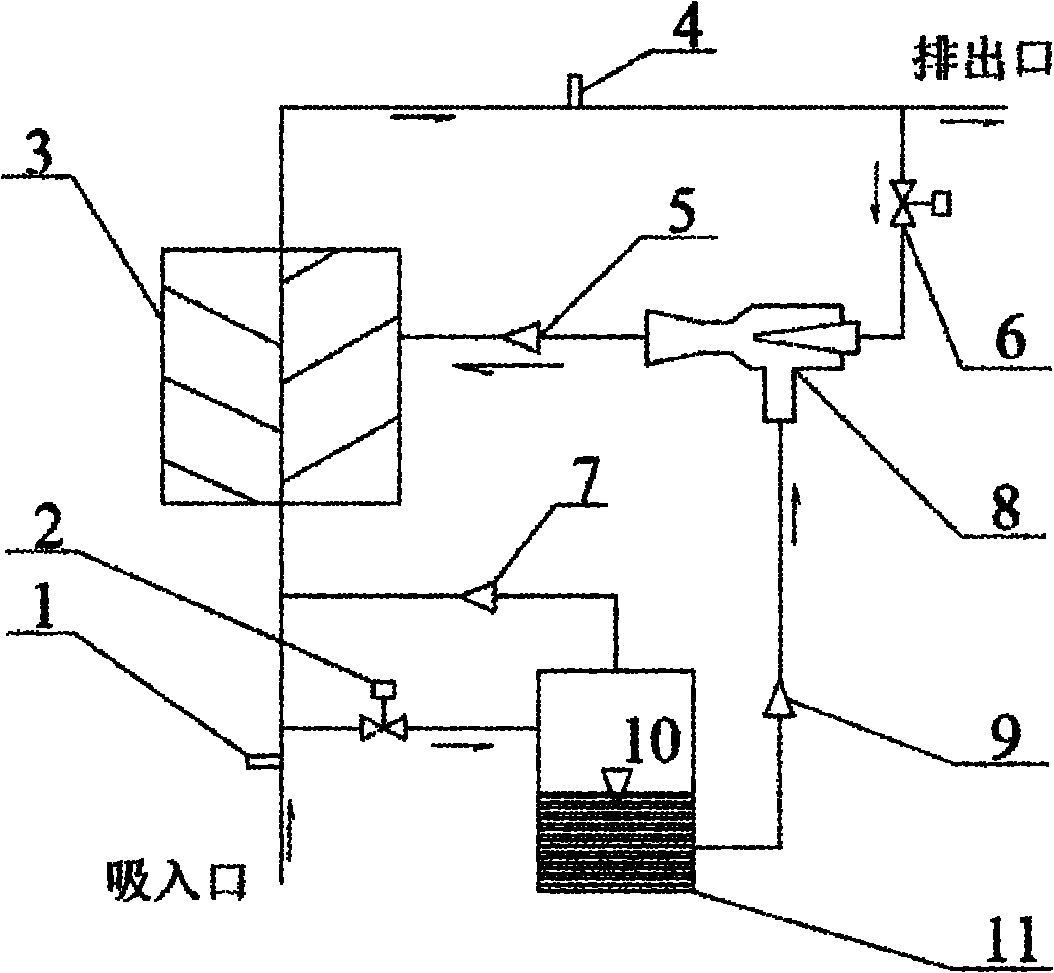

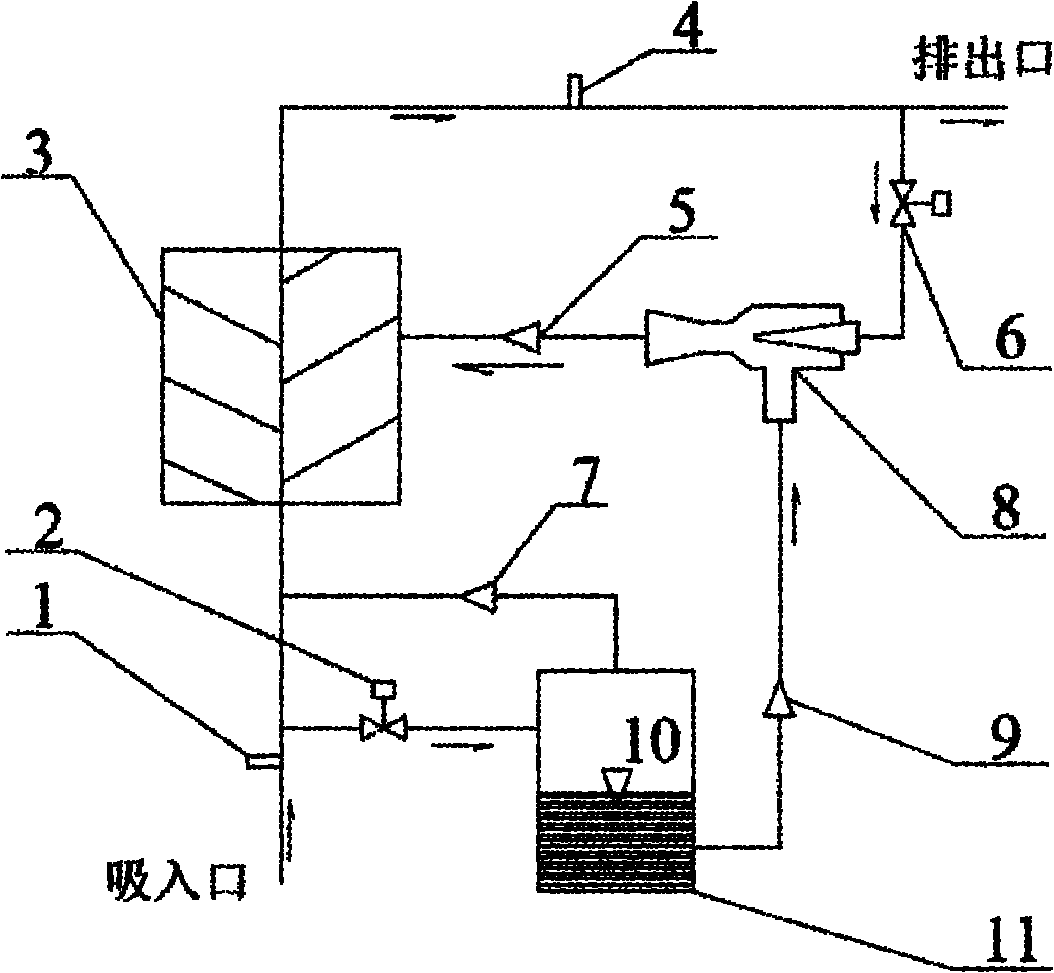

[0011] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are described in further detail

[0012] see figure 1 , the present invention comprises a twin-screw mixed delivery pump 3, an inlet temperature sensor 1 is installed on the inlet pipeline of the twin-screw mixed delivery pump 3, and the inlet pipeline of the twin-screw mixed delivery pump 3 is also connected with the gas-liquid separation and liquid storage device 11, Between the inlet of the gas-liquid separation and liquid reservoir 11 and the inlet pipeline of the twin-screw mixed pump 3, a liquid reservoir inlet solenoid valve 2 and a valve for controlling the gas-liquid separation and the entry of liquid in the liquid reservoir and the liquid level are installed. Liquid level switch 10, gas-liquid separation and between the outlet of liquid reservoir 11 and the inlet pipe of twin-screw mixed transport pump 3, there is a liquid storage outlet check va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com