Double-end spiral screw rod and double-screw pump and dry vacuum screw pump adopting screw rod

A double-headed screw and screw technology, which is applied to the parts of the pumping device for elastic fluid, the pump parts of the rotary piston type/oscillating piston type, and the rotary piston type pump, etc. Vibration and other problems, to achieve high volumetric efficiency, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

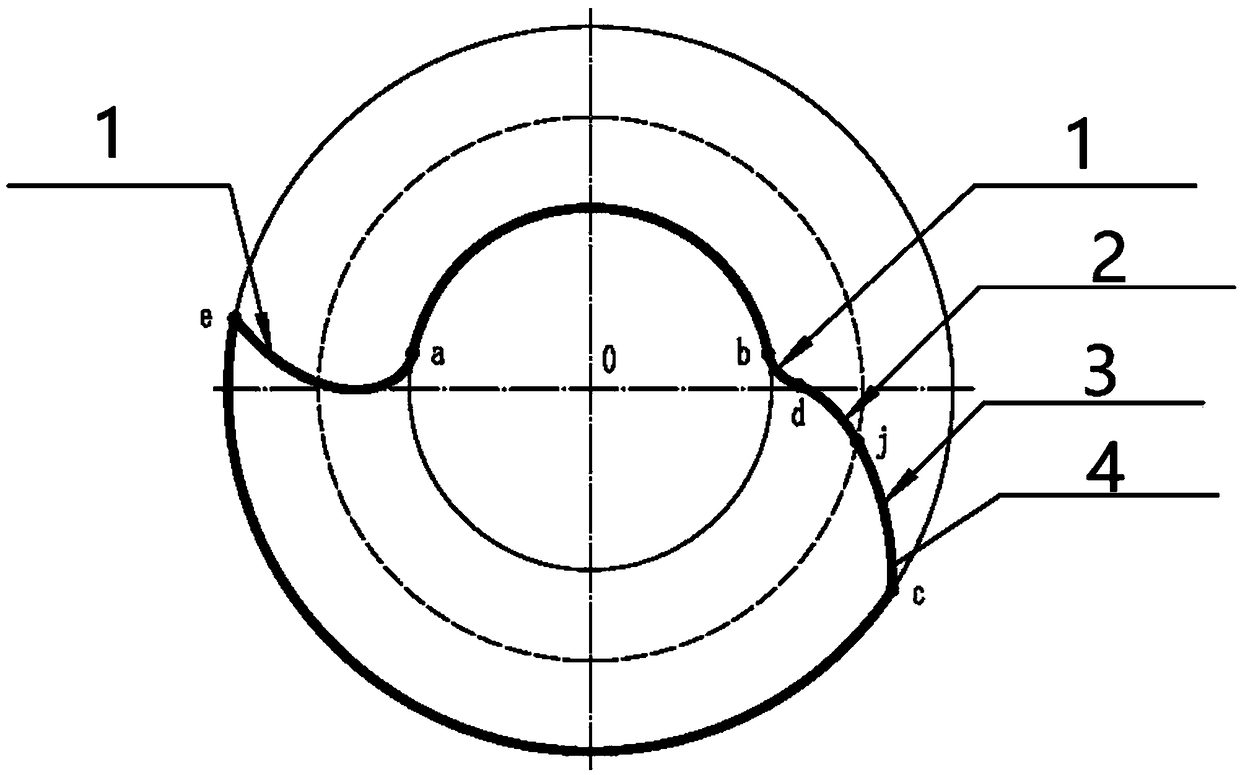

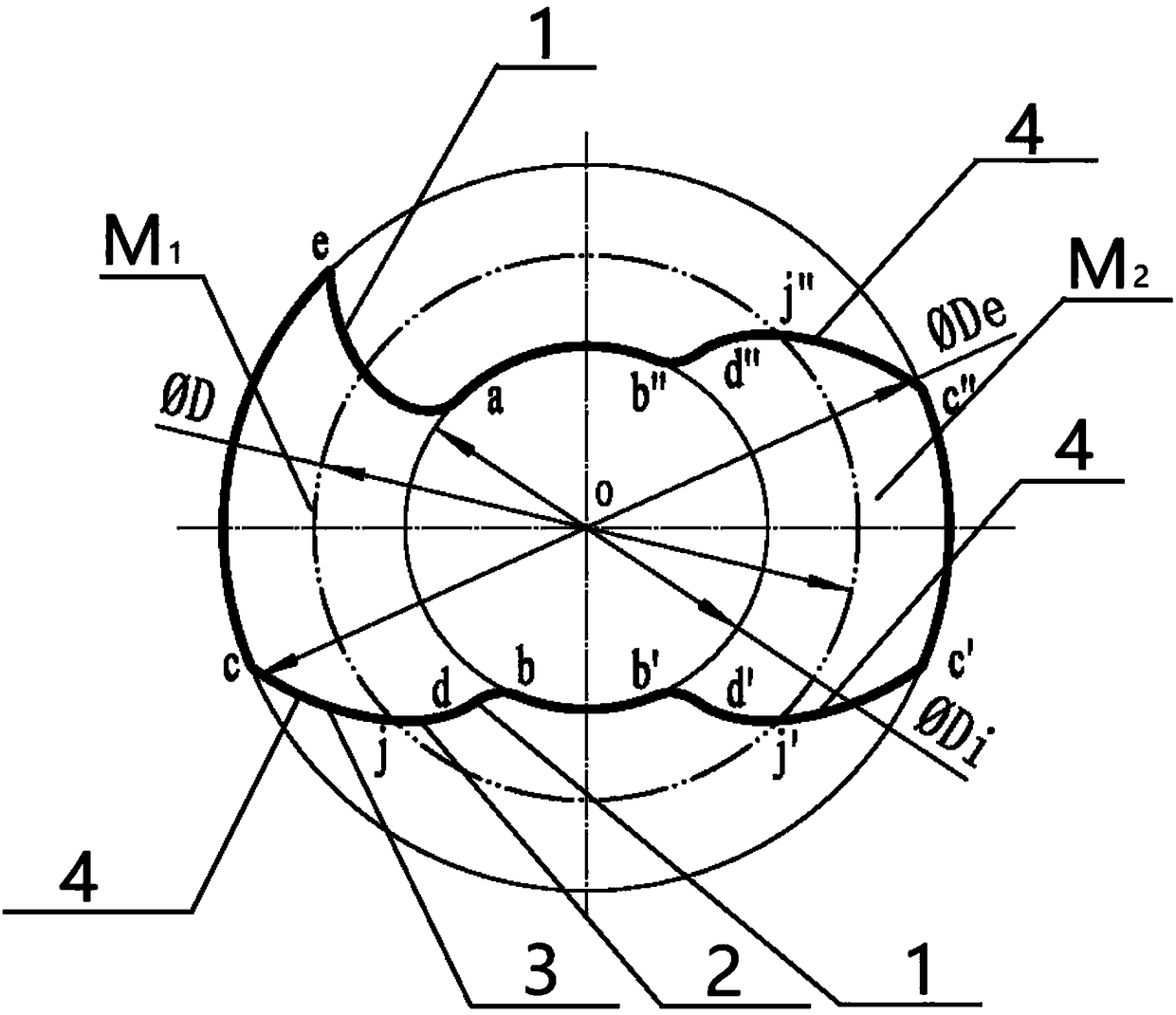

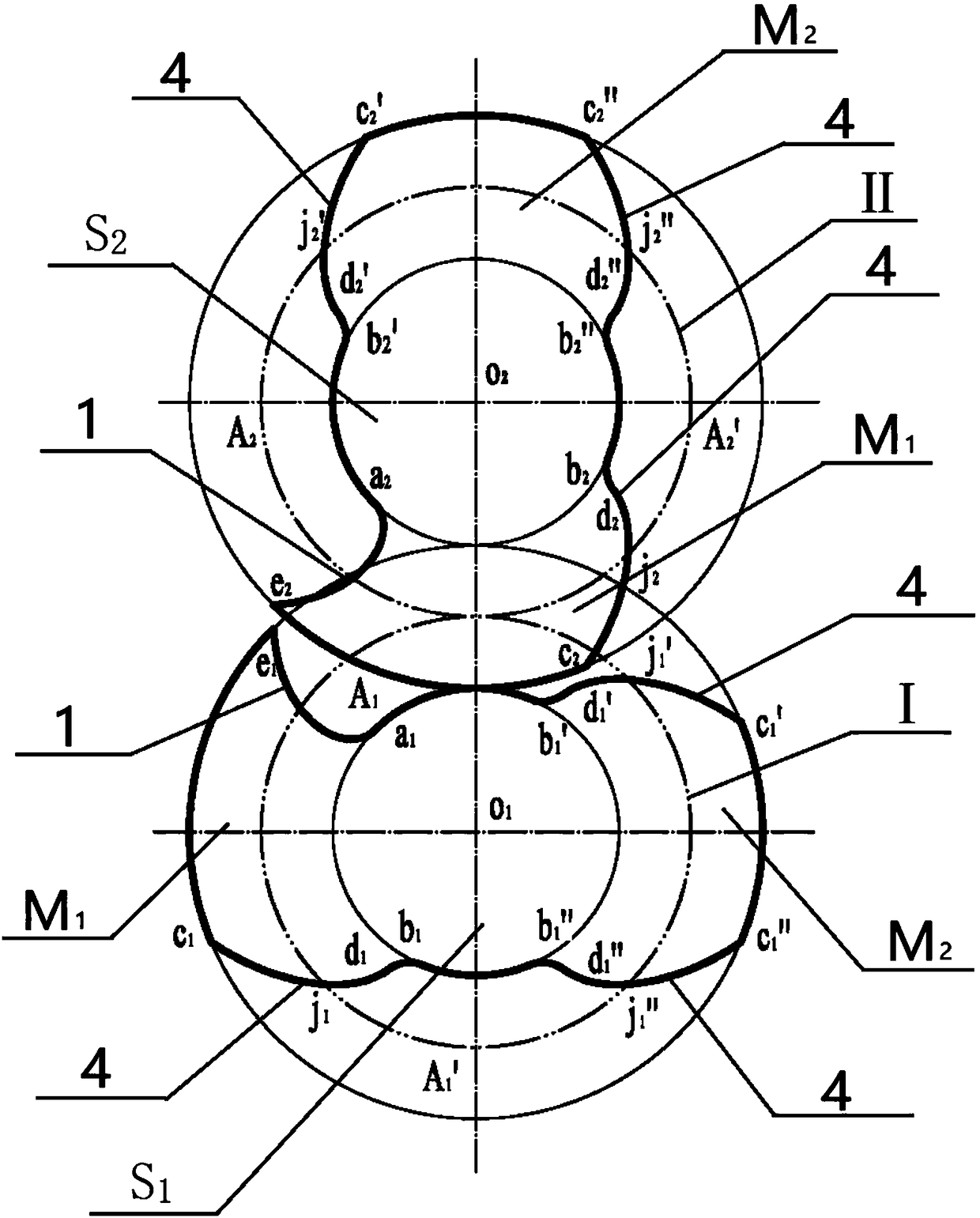

[0038] In this embodiment, there is provided a kind of asymmetrical double-headed helical screw which is used for twin-screw pump with strict seal and tooth shape of Aprocycloid 4 force transmission side, including active screw S 1 with driven screw S 2 . The helixes of the main and slave screws adopt exactly the same tooth profile, and the tooth profile of this embodiment is as follows: figure 2 shown, and are double-ended helices.

[0039] The tooth shape on both sides of the helix of one of the double-ended spirals adopts two asymmetrical tooth shape curves. The force transmission side (bc section) on one side adopts a cycloid 4 tooth shape curve, and the other The sealing edge (section ae) on the side adopts the tooth profile curve of elongated epicycloid 1; the tooth profile b′c′, b″ on both sides of the spiral (force transmission side and sealing side) of the other head of the double-ended spiral c " all adopt the cycloid 4 as the tooth profile curve.

[0040] Adopt...

Embodiment 2

[0052] On the basis of Example 1, the design of the extended epicycloid 1 addendum chamfer correction is usually adopted in the engineering practice of the sealing surface profile line, such as Figure 10 As shown, the tooth top section of the elongated epicycloid 1 adopts ff' chamfering, and the tooth shape of the sealing edge is composed of two sections: the elongated epicycloid section 1 (af section) and the elongated epicycloid 1 (ff' section). The main purpose of using ff′ chamfer to correct the tooth shape ae of the sealing edge is to improve the wear resistance of the sealing edge and cause a gap of the sealing line on the tooth top of the sealing edge helicoid.

[0053] Such as Figure 11 , 12 , 13, 14, and 15, whether it is the active screw S 1 A 1 , A' 1 Slot or follower screw S 2 A 2 , A' 2 The sealing lines on the helical surfaces on both sides of the grooves are continuous within the entire helical surface from the root circle to the addendum circle, withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com