Multifunctional same-furnace multi-band bimetal strip saw blade heat treatment full-automatic production line and process thereof

A bimetal belt, multi-functional technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of saw blade deformation, high power consumption of bell furnace, uneven rewinding tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

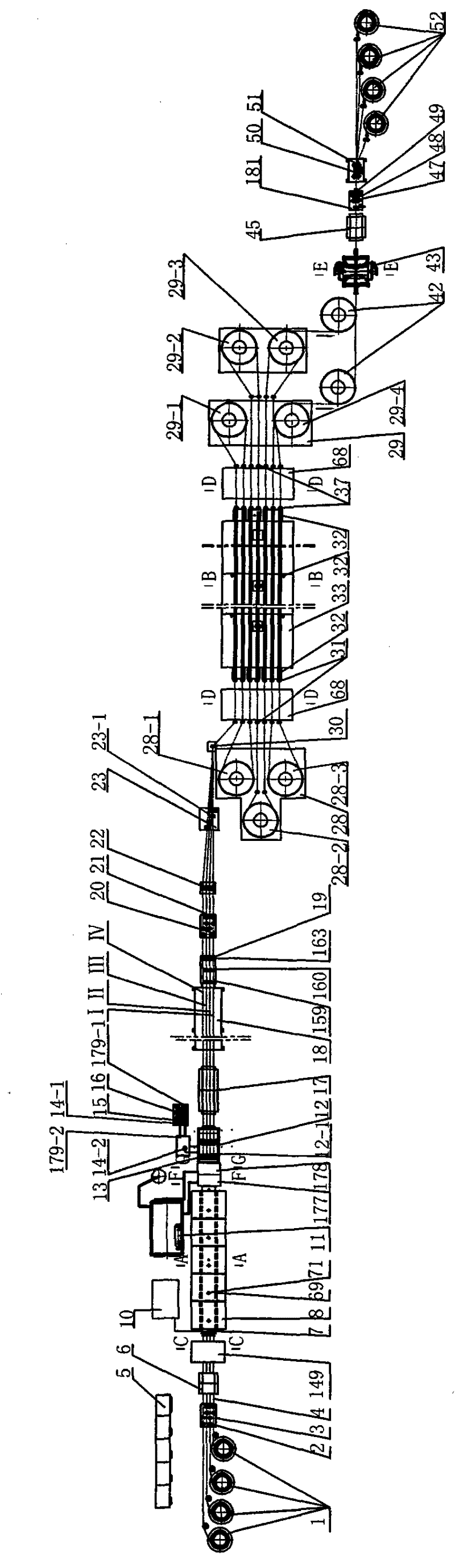

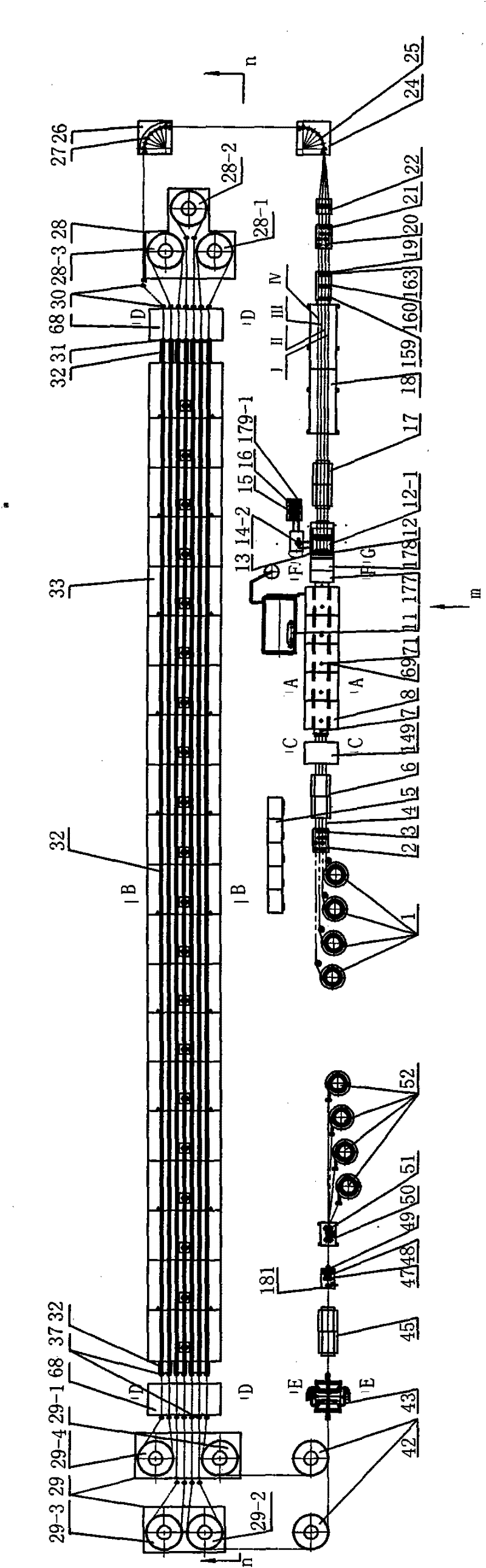

[0075] Specific implementation mode two: as figure 1 , Figure 12a with Figure 12b As shown, the production line in this embodiment also includes a pre-tempering thermal straightening heating furnace 18 and a saw blade back straightness detection and control device 19, the pre-tempering thermal straightening heating furnace 18, a saw blade back straightness detection and control device 19 According to the saw blade input to output direction, it is arranged between the oil cooling quenching device 12 and the traction device 20;

[0076] The pre-tempering heat straightening heating furnace 18 comprises a lifting seat 155, a ball screw 156, a shaft coupling 157, a servo motor 158, a first position sensor 159, a second position sensor 160, a third position sensor 163, and the output of the servo motor 158 The shaft is connected with the ball screw 156 through the coupling 157, and the lifting seat 155 moves up and down under the action of the ball screw 156; , the first sensor...

specific Embodiment approach 3

[0077] Specific implementation mode three: as figure 1 , Figure 11a with Figure 11b As shown, the dry sandblasting machine 43 in this embodiment consists of two vertical plates 142, a support plate 143, a plurality of spray guns 152, a plurality of adjustment devices, a first rotating shaft 147, a bracket 148, a second rotating shaft 149 and compressed air. Air intake pipe 150, two vertical plates 142 are arranged in parallel and connected together by a support plate 143 arranged horizontally between the two, and a plurality of spray guns 152 are divided into two groups and arranged on both sides above the support plate 143, and the two spray guns 152 of the group The nozzles 153 are arranged oppositely, and each spray gun 152 is provided with a sand inlet hole 151, and each spray gun 152 is installed on the bracket 148 through the first rotating shaft 147, and each spray gun 152 is connected with one end of the adjusting rod 146 of the adjustment device through the second ...

specific Embodiment approach 9

[0085] Embodiment 9: The difference between this embodiment and Embodiment 1 is that the air-cooling quenching device 177, the cryogenic quenching device 178 and the oil-cooling quenching device 12 described in Embodiment 1 are replaced by air Cold quenching device 177, or replaced by cryogenic quenching device 178, or replaced by oil-cooled quenching device 12, or replaced by air-cooled quenching device 177 and cryogenic quenching device 178, or replaced by cryogenic quenching device 178 and oil-cooled quenching device 12, or an air-cooled quenching device 177 and an oil-cooled quenching device 12 instead. Other components and connections are the same as those in the first embodiment.

[0086] Specific implementation mode ten: as Figure 3-5 As shown, the quenching process described in this embodiment adopts three methods of air-cooling quenching, cryogenic quenching and oil quenching to sequentially perform composite quenching on the saw blade 4; the quenching medium of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com