Sheet medium conveying mechanism

A transmission mechanism and medium technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of damage, short service life, low transmission speed, etc. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

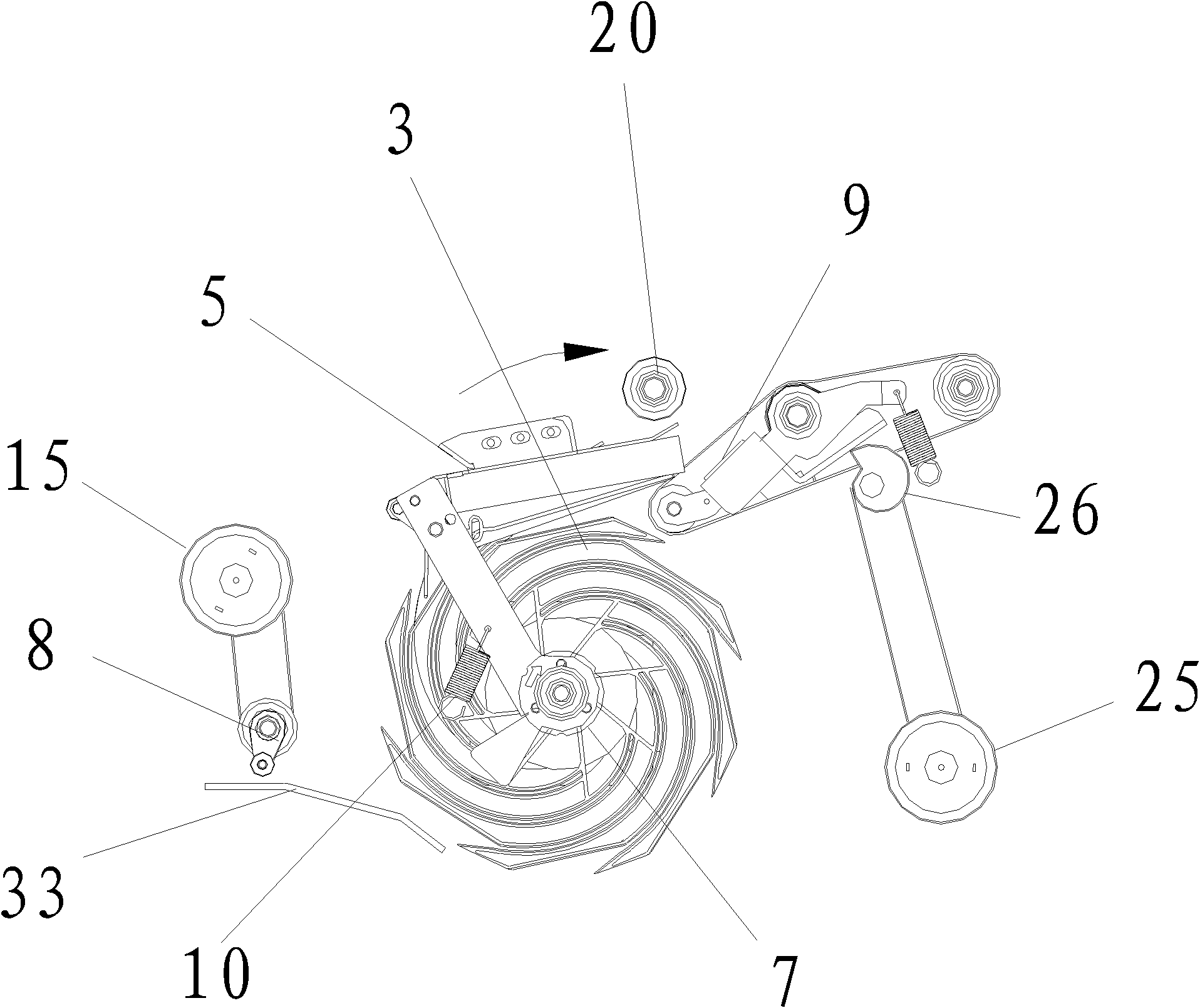

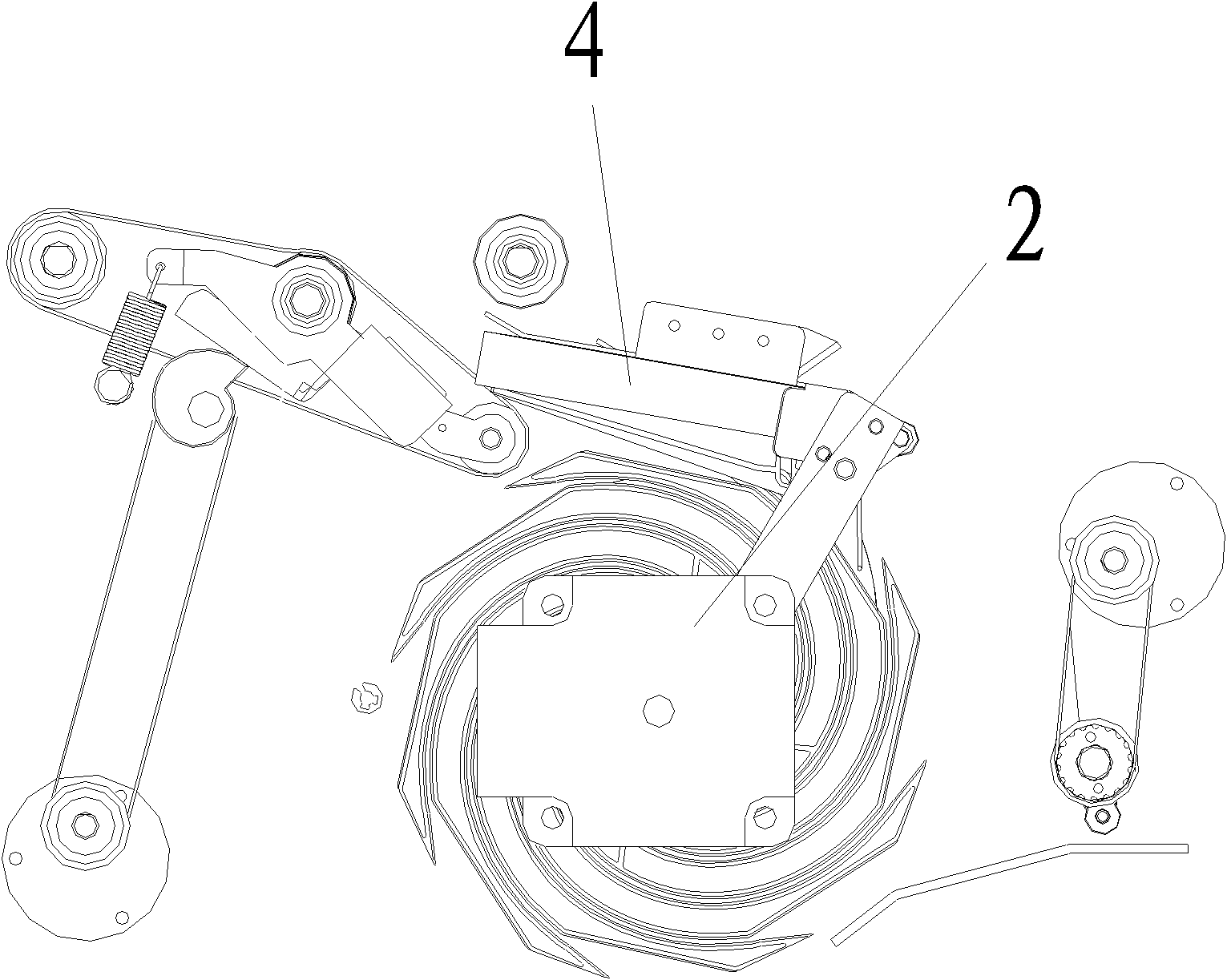

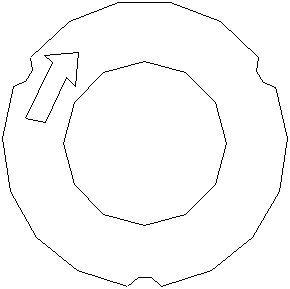

[0023] refer to Figure 1 to Figure 12 , the sheet medium transmission mechanism of the embodiment of the present invention mainly includes: a power source 2 with a central shaft 1, and a stacked sheet 3 that is screwed out on the central shaft 1 and has a sheet medium receiving groove, wherein the power source 2 is controlled Under the control of the system, the power is output to the central shaft 1 to drive it to rotate clockwise or counterclockwise; the transfer mechanism 5 is set on one side of the stack sheet 3 to receive and stack the sheet medium 4 conveyed by the stack sheet 3, and the transfer mechanism 5 passes through a rotating bracket 6 The one-way bearing 7 arranged at the front end is rotatably fixed on the central shaft 1; the locking mechanism 8 provided near the first position where the transfer mechanism 5 rotates is used to positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com