Automatic numerical-control punching device

An automatic and punching technology, applied in the field of automatic numerical control punching equipment, can solve the problems of time-consuming and laborious, limited production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

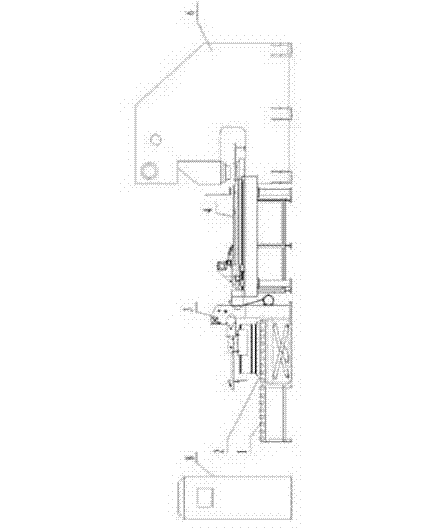

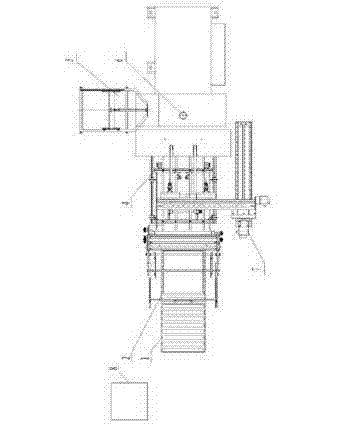

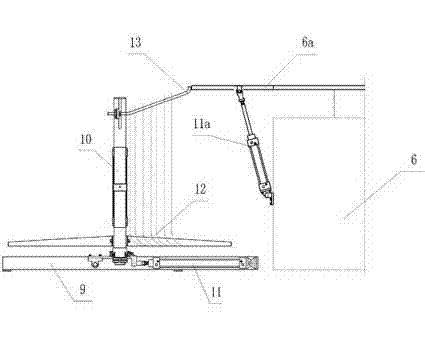

[0015] Automatic numerical control punching equipment, including a punch press 6 and a numerical control system 8, the rear of the punch press 6 is connected with a feeding device 4, and the feeding device 4 cooperates with the set right-angle feeder 7 for feeding, and the rear of the feeding device 4 is connected with a front-stage feeding device 3. A hydraulic lifting device 2 is installed under the front-stage feeding device 3, and the rear part of the hydraulic lifting device 2 is equipped with a roller transition frame 1. One side of the punch press 6 is equipped with an automatic waste collection device 5. The automatic waste collection device 5 includes a slide on the inside. The waste collection base 9 of the groove 9a and the waste collection support 10 provided with rollers 10a at the bottom, one end of the waste collection base 9 is fixedly connected to the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com