Universal automatic feeding device for punch press

An automatic feeding and universal technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of small application range, troublesome production, affecting the widespread use of automatic feeding of punching machines, etc., and achieve the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

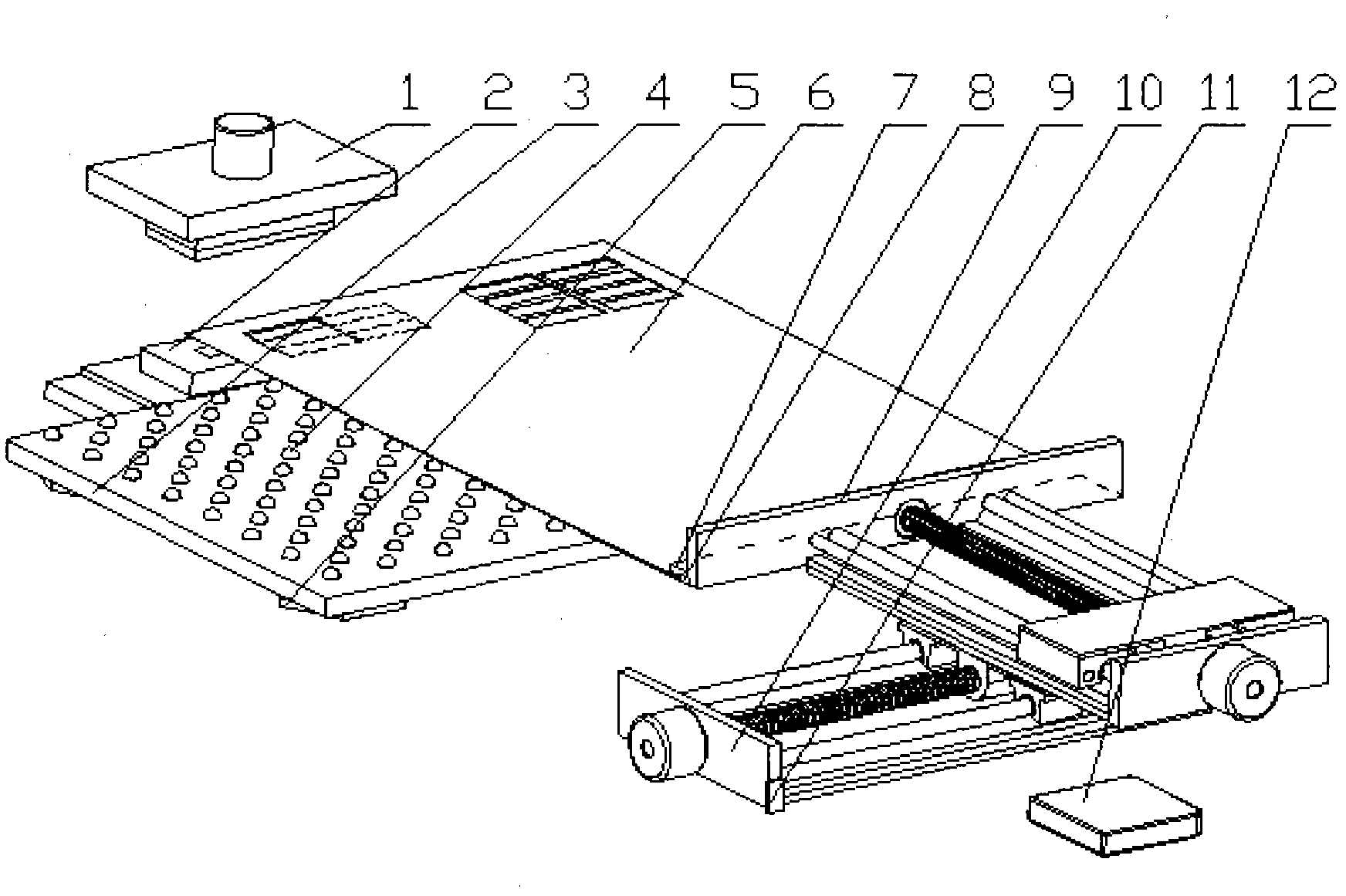

[0014] exist figure 1 In the middle, after the upper mold assembly (1) and the lower mold assembly (2) are normally clamped on the punch press, the ball backing plate (3) is connected to the punch table, and there are 4 under the ball backing plate (3) that can be adjusted The height adjustment nut (5) of the ball backing plate is used to adjust the height of the ball backing plate (3) through the adjusting nut (5), so that the balls (4) embedded in the backing plate are coplanar with the upper plane of the lower mold assembly (2), The magnetic suction plate (7) sucks the metal plate (6), and the computer (12) controls the rotation of the servo motor (I) and the servo motor (II) to drive the metal plate (6) to translate back and forth, left and right on the ball backing plate (3) , to achieve automatic feeding.

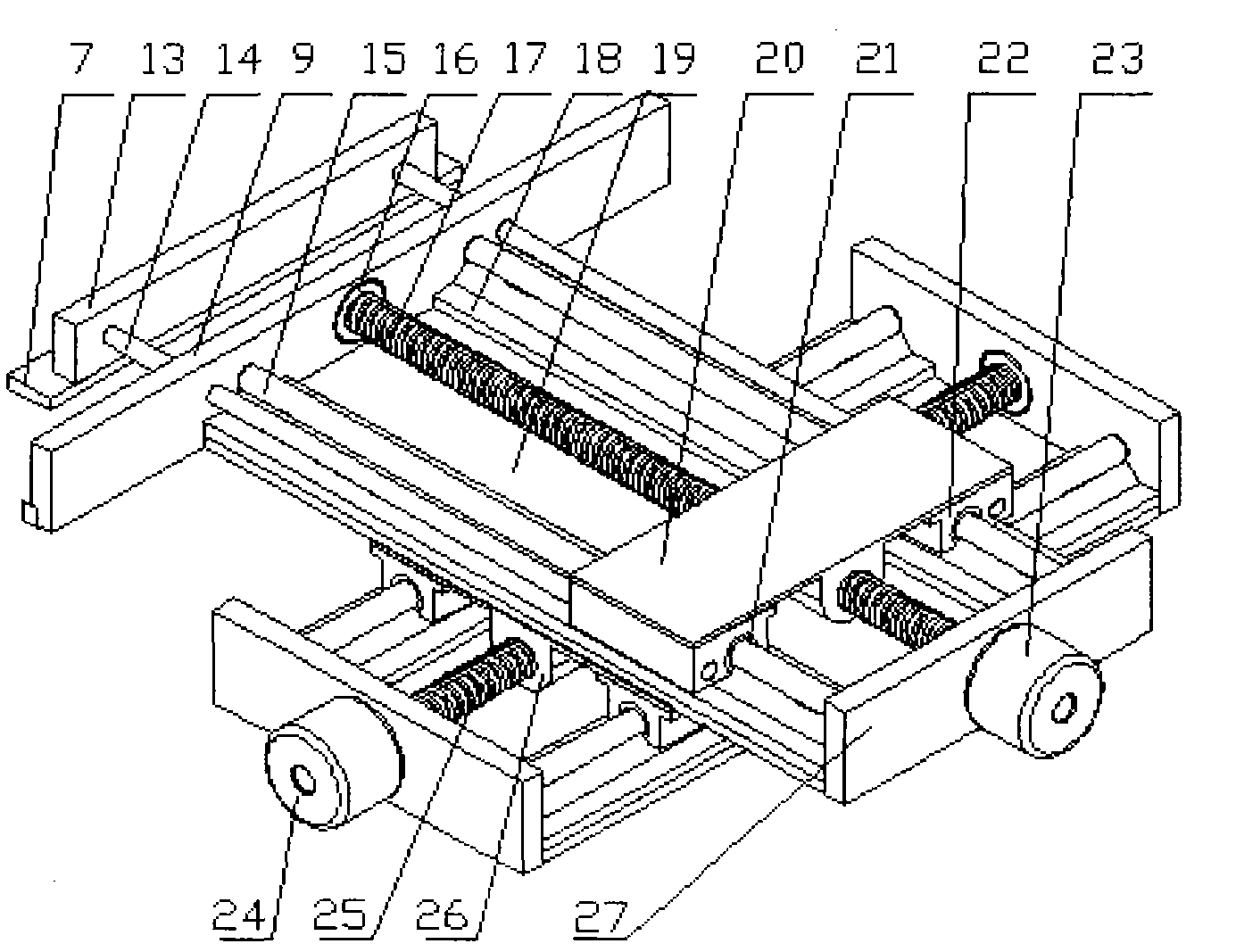

[0015] exist figure 2 It can be seen that two double-deck light rails connected by a cross (the upper light rail and the lower light rail are connected in a cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com