Composite negative electrode sheet with rapid heating function, and cell and battery using same

A negative pole piece and negative pole piece technology, which is applied in the field of composite negative pole piece with rapid heating function, rapid heating of batteries and batteries, and can solve problems such as poor heat production rate and temperature uniformity, limited application scenarios, and poor user experience, etc. problems, to achieve the effect of uniform heat production, fast heat conduction, and small production changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

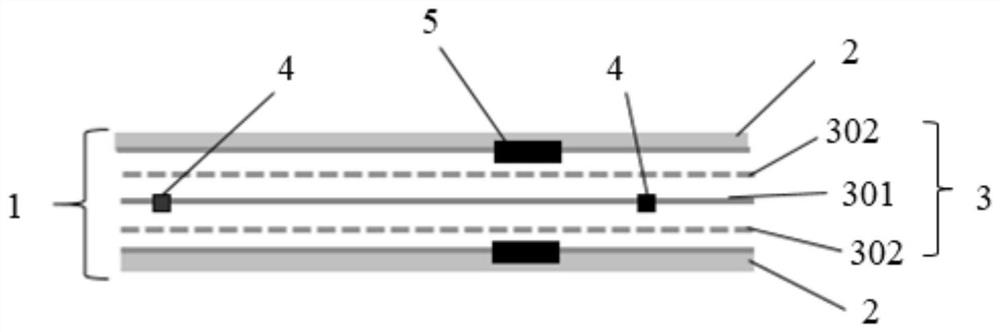

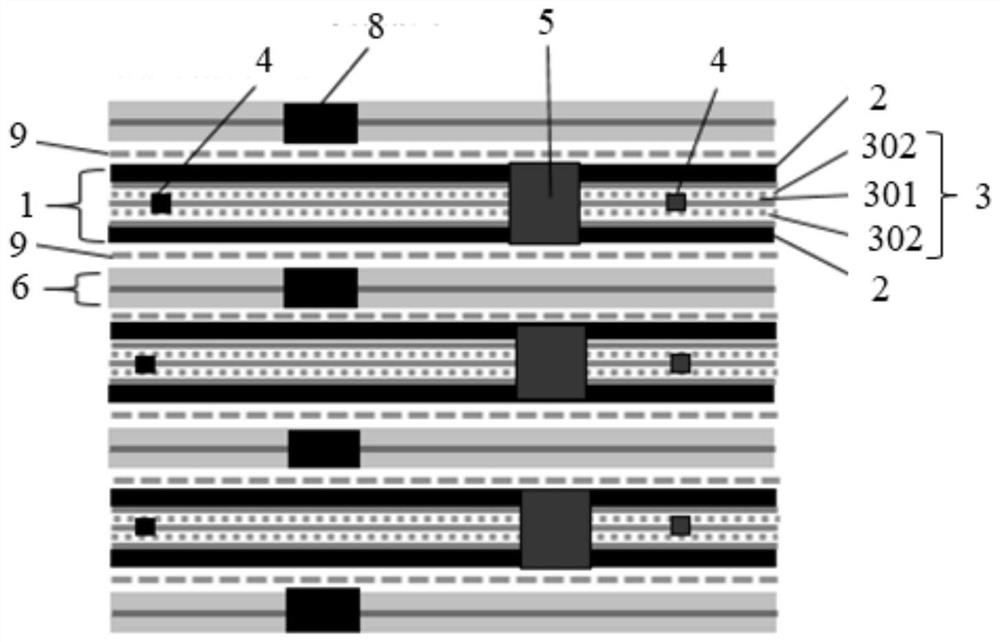

[0062] This embodiment provides a composite negative electrode plate 1 including two negative electrode sheet 2, and two negative electrode sheets 2 are provided with a thermal resistance sandwich structure 3, the thermal resistance sandwich structure 3 contains two The layer diaphragm 302 and a layer of heat resistance sheet 301 disposed intermediate in the two-layer diaphragm 302 are provided with two thermal resistant sheets 4 having a certain spacing on the thermal resistance sheet 301. Among them, the negative pole sheet 2 is a single-sided negative electrode sheet, and the slurry layer of the single-sided negative electrode sheet is toward the inside of the composite negative electrode plate 1.

[0063] It can be seen from the above structure that is spaced from the diaphragm 302 between the heat resistance sheets 301 and the two negative electrode sheets 2.

[0064] The composite negative electrode sheet of the present embodiment is connected by a built-in power source or a...

Embodiment 2

[0068] The other structure is the same as in Example 1 in addition to the double-sided negative electrode sheet.

[0069] The composite negative electrode sheet of the present embodiment is connected by a built-in power source or an external power source and a thermal resistant sheet, which can be energized after power is energized, and the purpose of rapid heating from the pole level level.

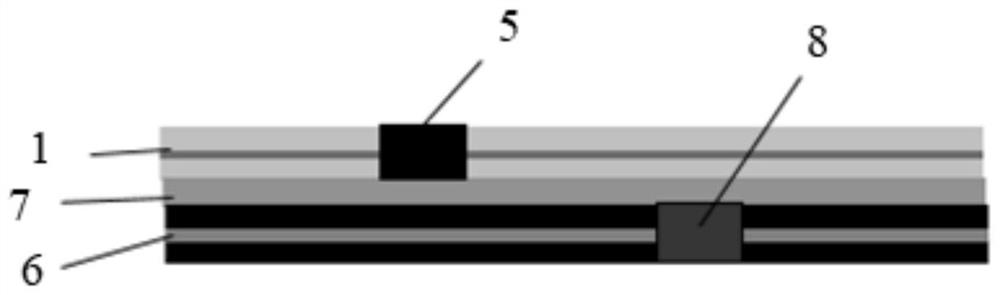

Embodiment 3

[0071] The present invention provides a battery, including a positive electrode, a diaphragm, and an negative electrode, and the positive electrode and the negative electrode are located on both sides of the diaphragm, and the negative electrode is the composite negative electrode plate, the assembly mode of the battery is: according to ... positive , The sequence of the diaphragm, the composite negative electrode, the diaphragm, the positive electrode, the diaphragm, the composite negative electrode plate, the diaphragm, the positive electrode, and then wound, and the bare core is obtained.

[0072] At the positive electrode and the negative electrode, the positive electrode pole and the negative electrode ear are provided, and the positive electrode ears and the negative electrode ears are connected to the top cover, and the heat resistance ear is cut into the outside of the cell, and the heating, sealing through the external circuit control strategy. After the electrolyte is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com