A kind of compatible stealth anti-icing material and its preparation method and application

An anti-icing and patterning technology, applied in camouflage paint, induction heating, inductive current source, etc., can solve the problems of restricting the all-weather safe flight ability of stealth aircraft, strong reflection effect affecting stealth effect, and inability to realize anti-icing, etc. Achieve basic transmission simulation results, consistent transmission simulation results, and avoid heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

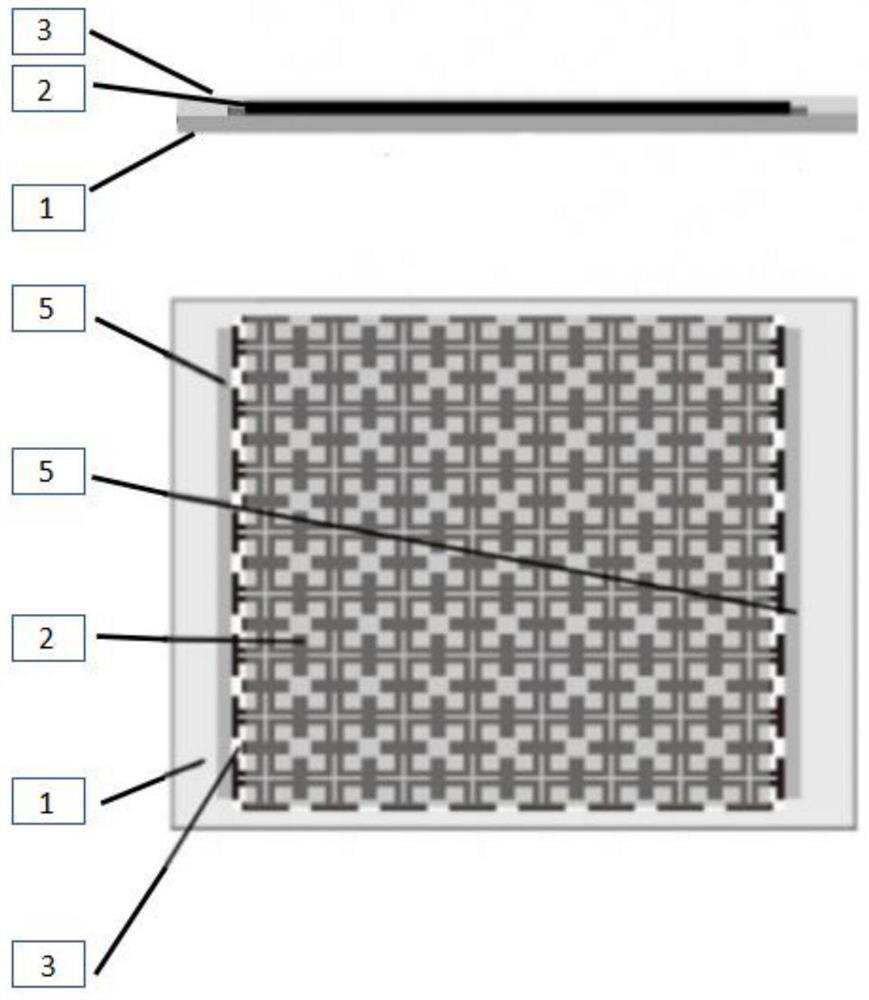

[0067] The present invention also provides the preparation method of the compatible stealth anti-icing material described in the above technical solution, comprising the following steps:

[0068] Provide insulation and thermal insulation;

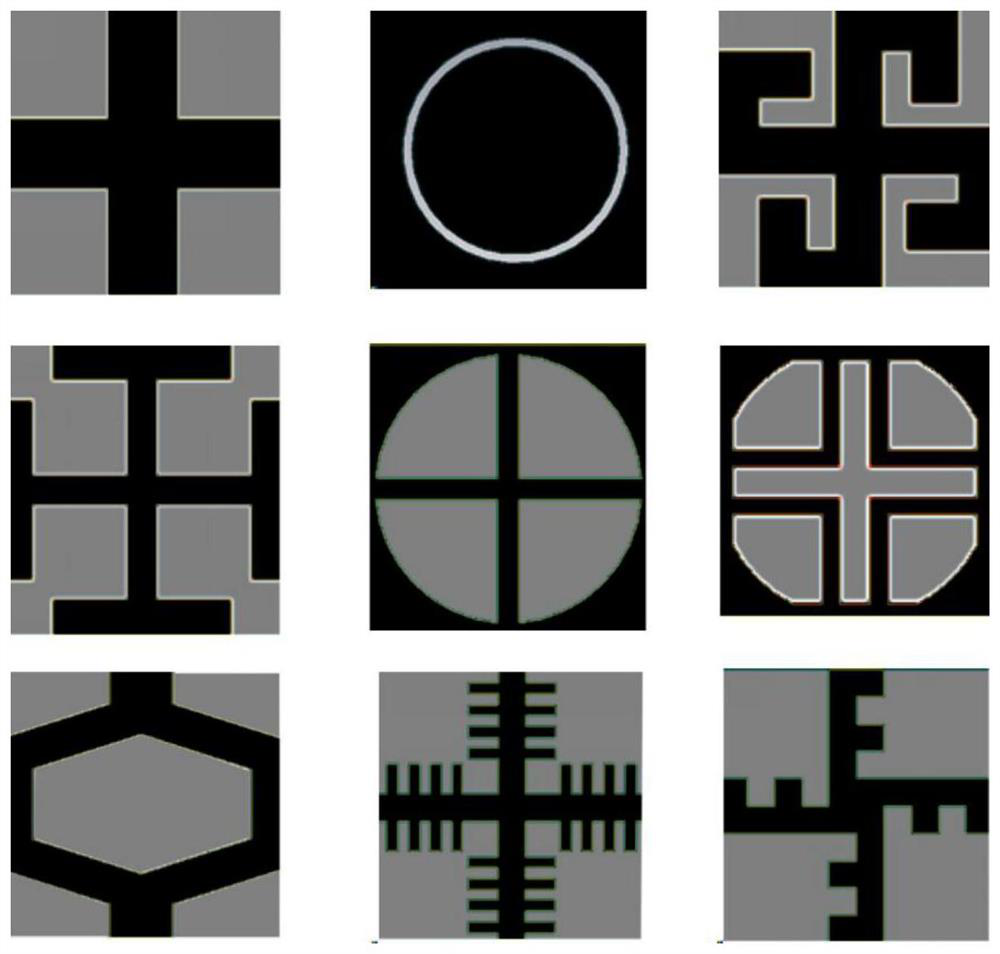

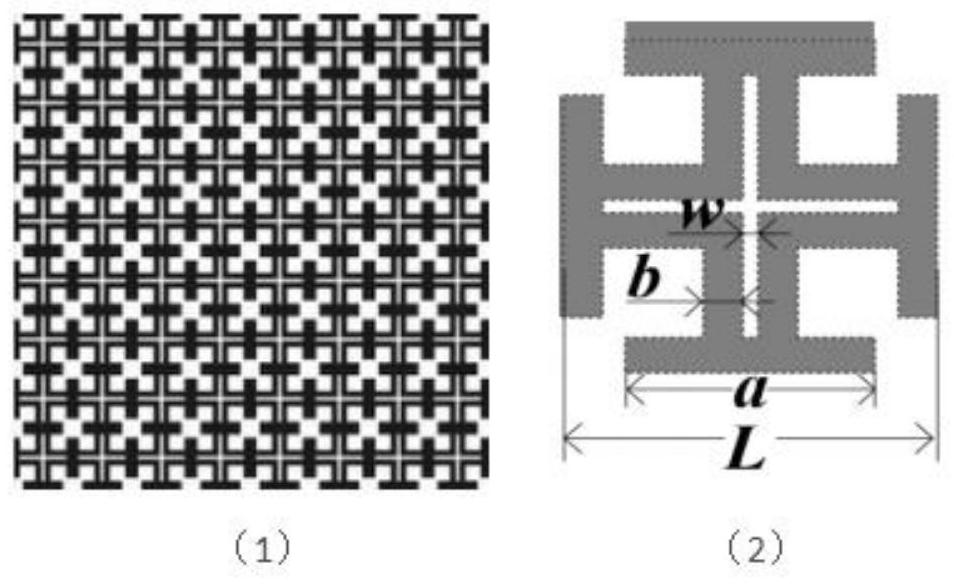

[0069] Prepare a patterned heating layer on the surface of the insulating and heat insulating layer;

[0070] preparing an insulating and thermally conductive layer on the surface of the patterned heating layer;

[0071] A hydrophobic layer is prepared on the surface of the insulating and heat-conducting layer to obtain the compatible stealth anti-icing material.

[0072] The present invention provides an insulating and heat insulating layer.

[0073] The present invention does not specifically limit the preparation method of the insulating and heat-insulating layer, as long as the material and thickness of the insulating and heat-insulating layer can be ensured. In the present invention, the material of the insulating and heat-insulatin...

Embodiment 1

[0119] The silicone rubber, hollow glass microspheres and toluene are mixed in a mass ratio of 4:1:5 to obtain an insulating and heat-insulating layer slurry. The obtained insulating and heat-insulating layer slurry is sprayed on the surface of the epoxy resin matrix, and after drying, a thickness of 50 μm is obtained. insulation layer;

[0120] After the non-electrode area is covered and protected by the tape, copper is magnetron sputtered in the electrode area at both ends of the insulating and heat insulating layer, and the tape is removed to obtain the insulating and heat insulating layer system containing electrodes;

[0121] Polyurethane, conductive carbon black and toluene are ultrasonically dispersed and mixed in a mass ratio of 4:1:5 to obtain a heating layer slurry; the area that does not need to prepare a heating insulation layer is covered with a mask, and the obtained heating layer slurry is sprayed on the insulation and heat insulation layer. The surface of the l...

Embodiment 2

[0130] The silicone rubber, hollow glass microspheres and toluene are mixed in a mass ratio of 4:1:5 to obtain an insulating and heat-insulating layer slurry. The obtained insulating and heat-insulating layer slurry is sprayed on the surface of the epoxy resin matrix, and after drying, a thickness of 100 μm is obtained. insulation layer;

[0131] After the non-electrode area is covered and protected by the tape, copper foil is pasted on the electrode regions at both ends of the insulating and heat-insulating layer, and the tape is removed to obtain an insulating and heat-insulating layer system containing electrodes;

[0132] The styrene-butadiene rubber, nano-graphite powder and toluene are dispersed and mixed ultrasonically according to the mass ratio of 4:1:5 to obtain the heating layer slurry; the area that does not need to prepare the heating insulating layer is covered with a mask, and the obtained heating layer slurry is sprayed on the insulating layer. On the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com