Electric welding forming method for large-size amorphous alloys and bulk amorphous alloys

An amorphous alloy, welding forming technology, applied in non-electric welding equipment, welding equipment, laser welding equipment, etc., can solve problems affecting welding quality, uneven heat, slow welding speed, etc., to improve welding quality and welding efficiency, Guaranteed heating temperature and uniform heat production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A discharge welding forming method for large-size amorphous alloys disclosed in this embodiment includes the following steps:

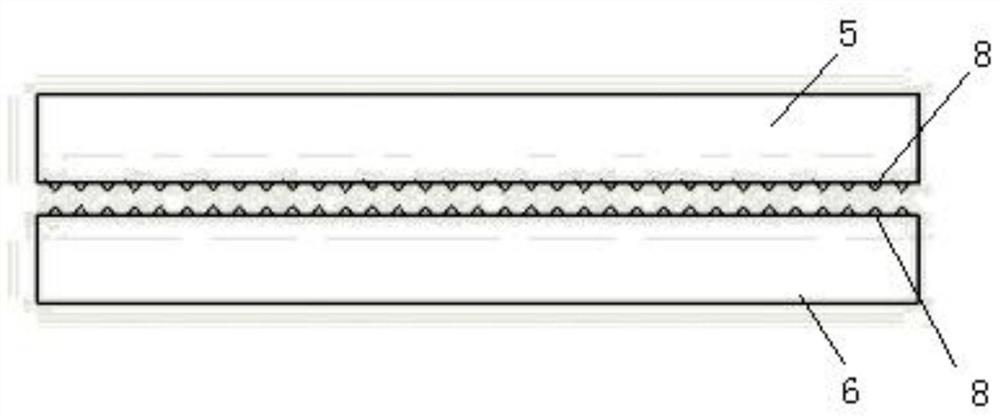

[0043] S1: Laser processing the surfaces of the first amorphous alloy 5 and the second amorphous alloy 6 to be welded as follows figure 2 The tapered microstructure 8 is shown. Wherein the composition of the first amorphous alloy 5 and the second amorphous alloy 6 is Zr 66 Al 18 Ni 26 , Tg is 398.85°C, Tx is 434.45°C, the processed amorphous alloy is placed in ethanol for ultrasonic cleaning for 5 minutes, and then dried in a drying oven for 15 minutes to ensure that the surface is free of pollutants.

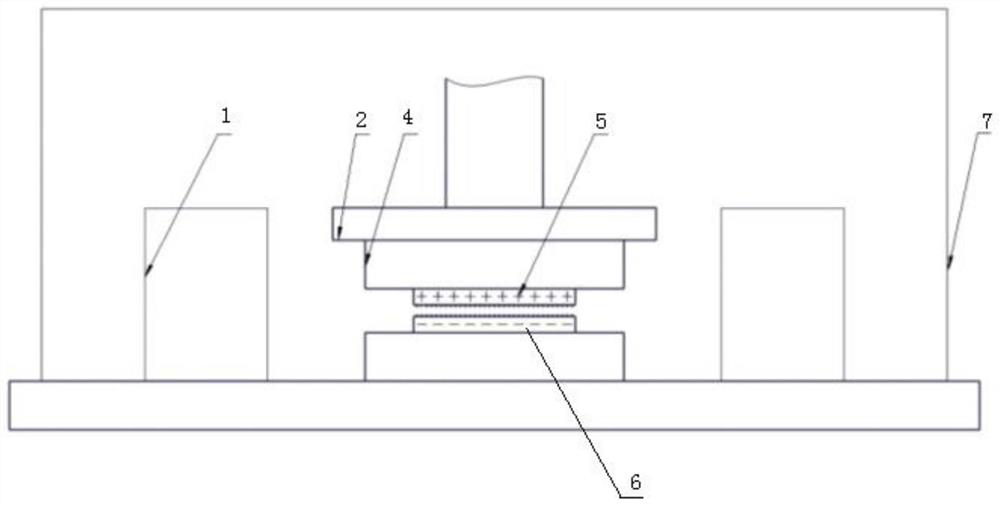

[0044] S2: install the processed first amorphous alloy 5 and the second amorphous alloy 6 on the figure 1 On the upper and lower clamps 4 of the shown precision mobile platform, then adjust the precision mobile platform so that the microstructure surfaces of the first amorphous alloy 5 and the second amorphous alloy 6 are opposite, and the ...

Embodiment 2

[0049] A discharge welding forming method for large-size amorphous alloys disclosed in this embodiment includes the following steps:

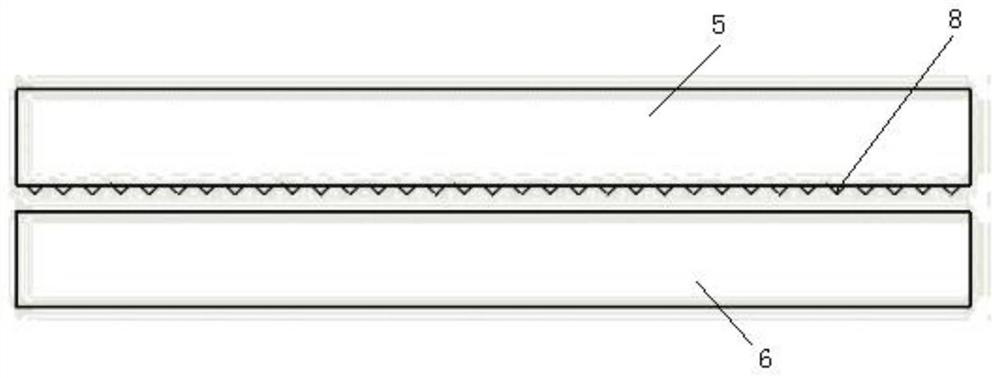

[0050] S1: the surface of the first amorphous alloy 5 to be welded and the surface of the second amorphous alloy 6 are processed by laser such as image 3 The shown tapered microstructures 8 and tapered hole microstructures 8 (not shown in the figure). Wherein the composition of the first amorphous alloy 5 is Cu 54 Zr 42.5 Al 3.5 , Tg is 443.85°C, and Tx is 491.85°C. The composition of the second amorphous alloy 6 is Zr 60 Al 13.3 co 26.7 , Tg is 444.85 ° C, Tx is 483.85 ° C, the processed amorphous alloy is placed in ethanol for ultrasonic cleaning for 5 minutes, and then dried in a drying oven for 15 minutes to ensure that the surface is free of pollutants.

[0051] S2: install the processed first amorphous alloy 5 and the second amorphous alloy 6 on the figure 1 On the upper and lower clamps 4 of the shown precision mobile platform, ...

Embodiment 3

[0056] A discharge welding forming method for large-size amorphous alloys disclosed in this embodiment includes the following steps:

[0057] S1: the surface of the first amorphous alloy 5 to be welded and the surface of the second amorphous alloy 6 are processed by laser such as Figure 4 As shown in the millimeter-scale microstructure 8, a nano-scale conical microstructure is further processed on the millimeter-scale microstructure 8, so that more discharge tips can be added. Wherein the composition of the first amorphous alloy 5 is Fe 67 co 10 Tb 3 B 20 , Tg is 521.85°C, and Tx is 557.85°C. The composition of the second amorphous alloy 6 is Zr 55 Al 20 co 25 , Tg is 490.85 ° C, Tx is 565.85 ° C, the processed amorphous alloy is placed in ethanol for ultrasonic cleaning for 5 minutes, and then dried in a drying oven for 15 minutes to ensure that the surface is free of pollutants.

[0058] S2: install the processed first amorphous alloy 5 and the second amorphous allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com