Electric heating die

A technology of electric heating and electric heating device, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of affecting the molding quality, difficult processing, complex flow channel structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

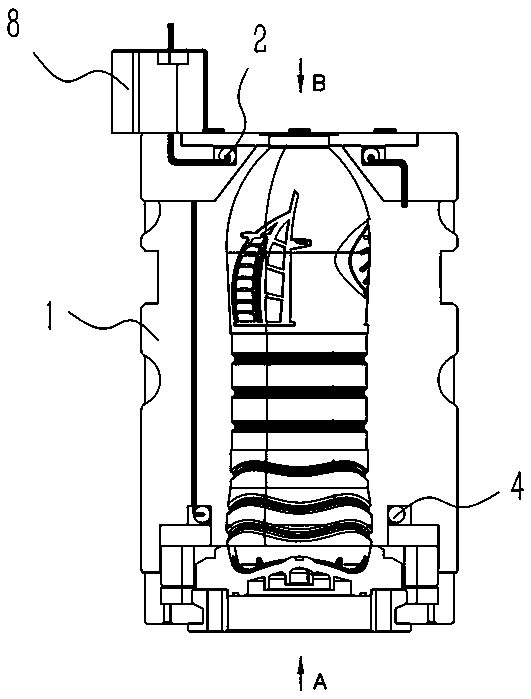

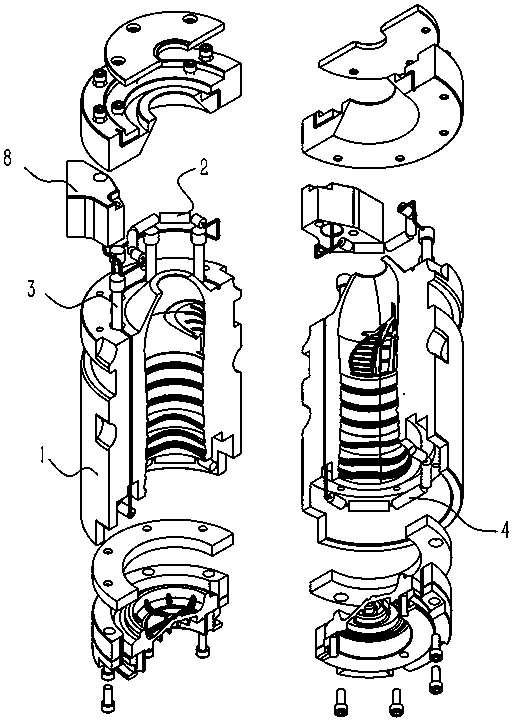

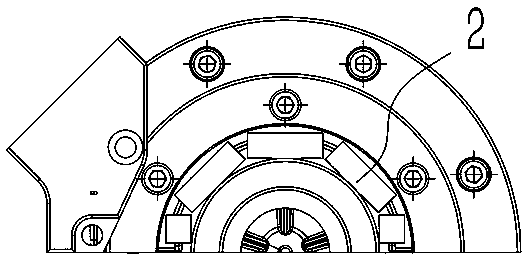

[0013] An electric heating mold, such as Figure 1 to Figure 8 As shown, it includes the mold shell 1 and the electric heating device in the mold shell 1. The electric heating device includes the upper ring heating resistance element group 2 for heating around the bottle neck, and the middle ring in-line heating element group for heating around the bottle body. The columnar heating resistance element group 3 and the lower annular heating resistance element group 4 for heating around the bottom of the bottle.

[0014] The mold shell includes a left mold shell 1 and a right mold shell 2; the upper annular heating resistance element group 2 includes a left semi-annular upper heating resistance element group 3 and a right semi-annular upper heating resistance element group, which are respectively arranged on On the left mold shell and the right mold shell; the middle annular in-line cylindrical heating resistance element group 3 includes a left semi-annular middle in-line cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com