Vacuum drying oven

A vacuum oven and drying oven technology, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of shortening the service life of the vacuum oven and uneven drying, so as to facilitate uniform internal temperature distribution, reduce dead angles, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below in conjunction with specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

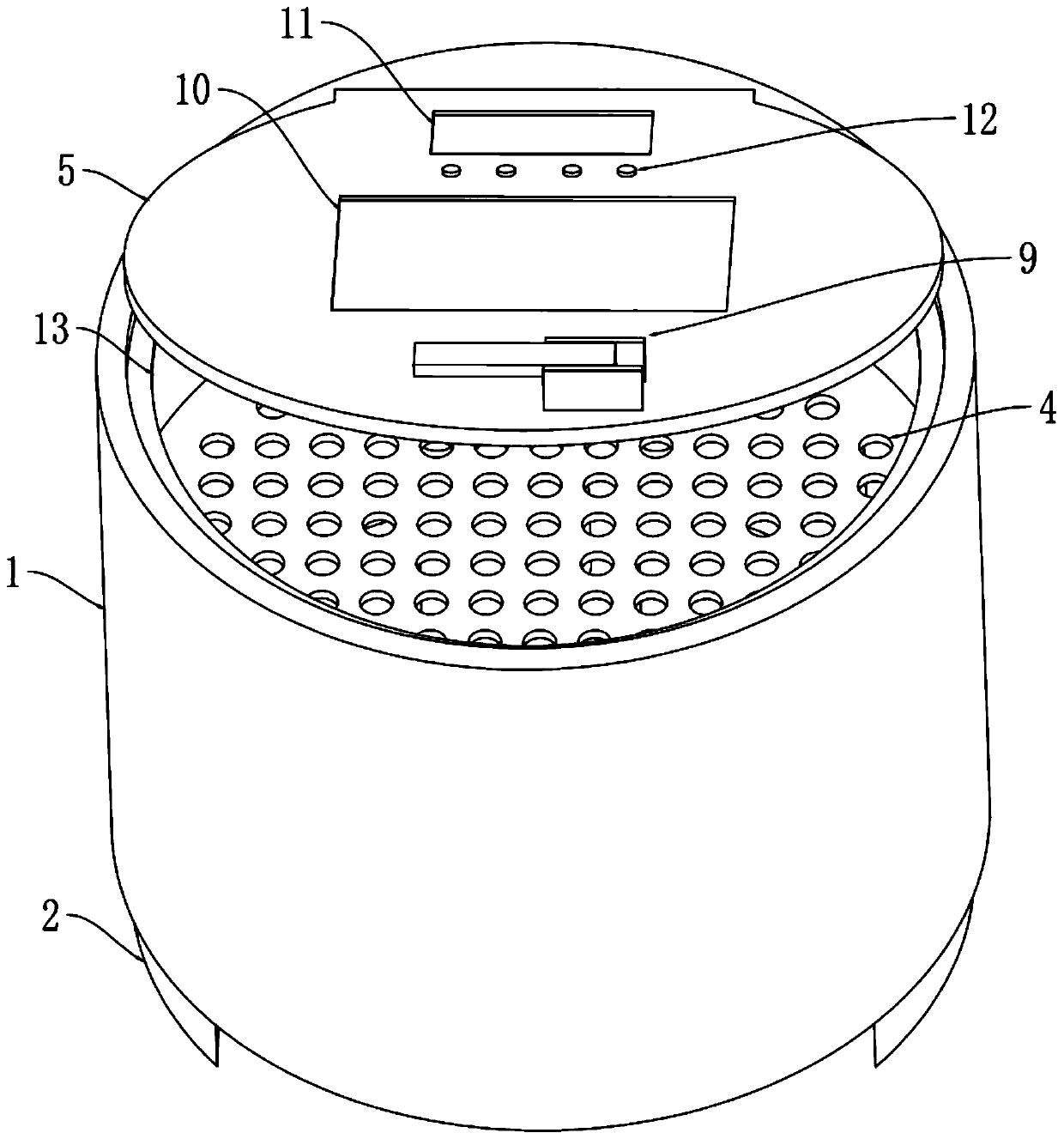

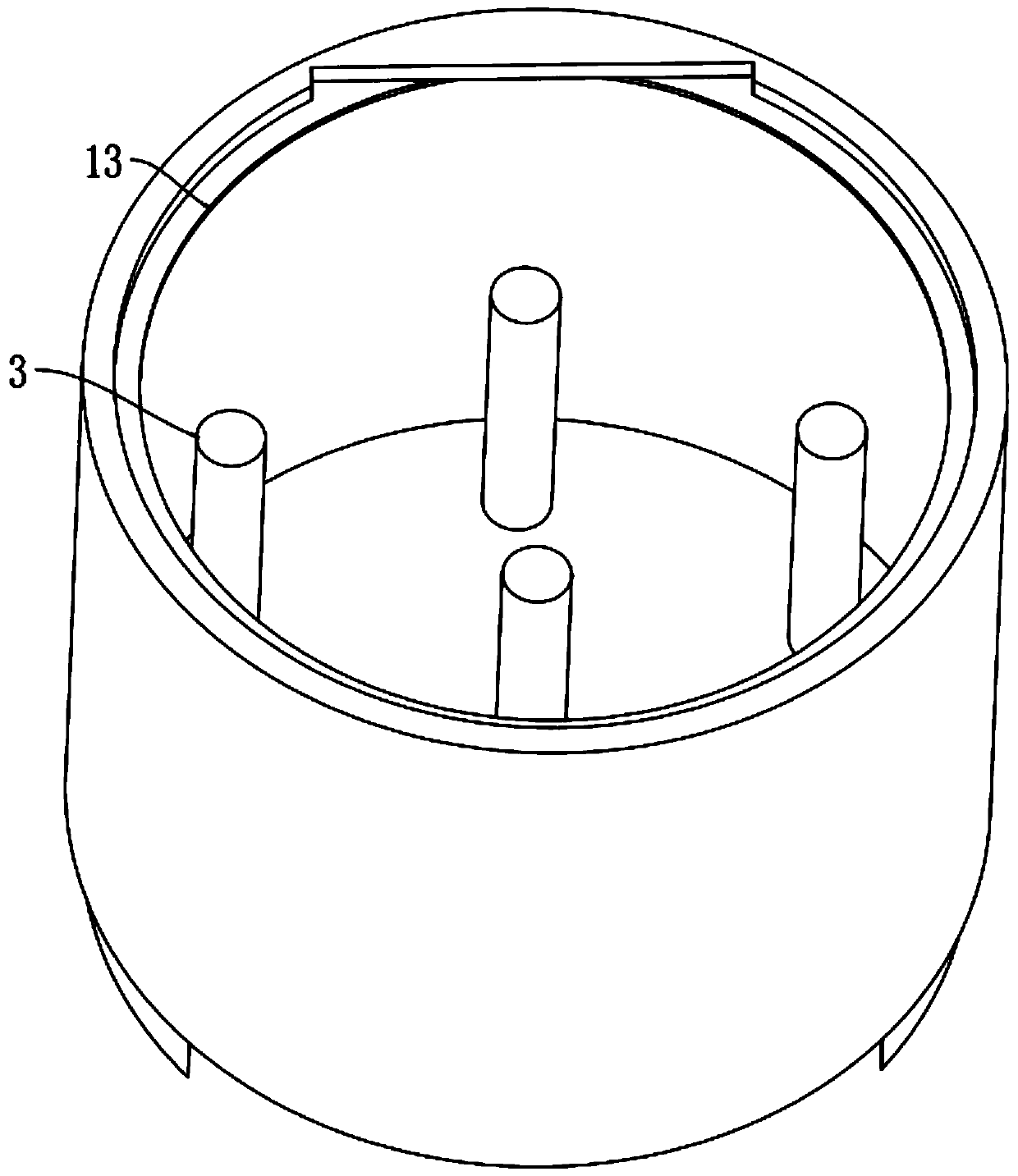

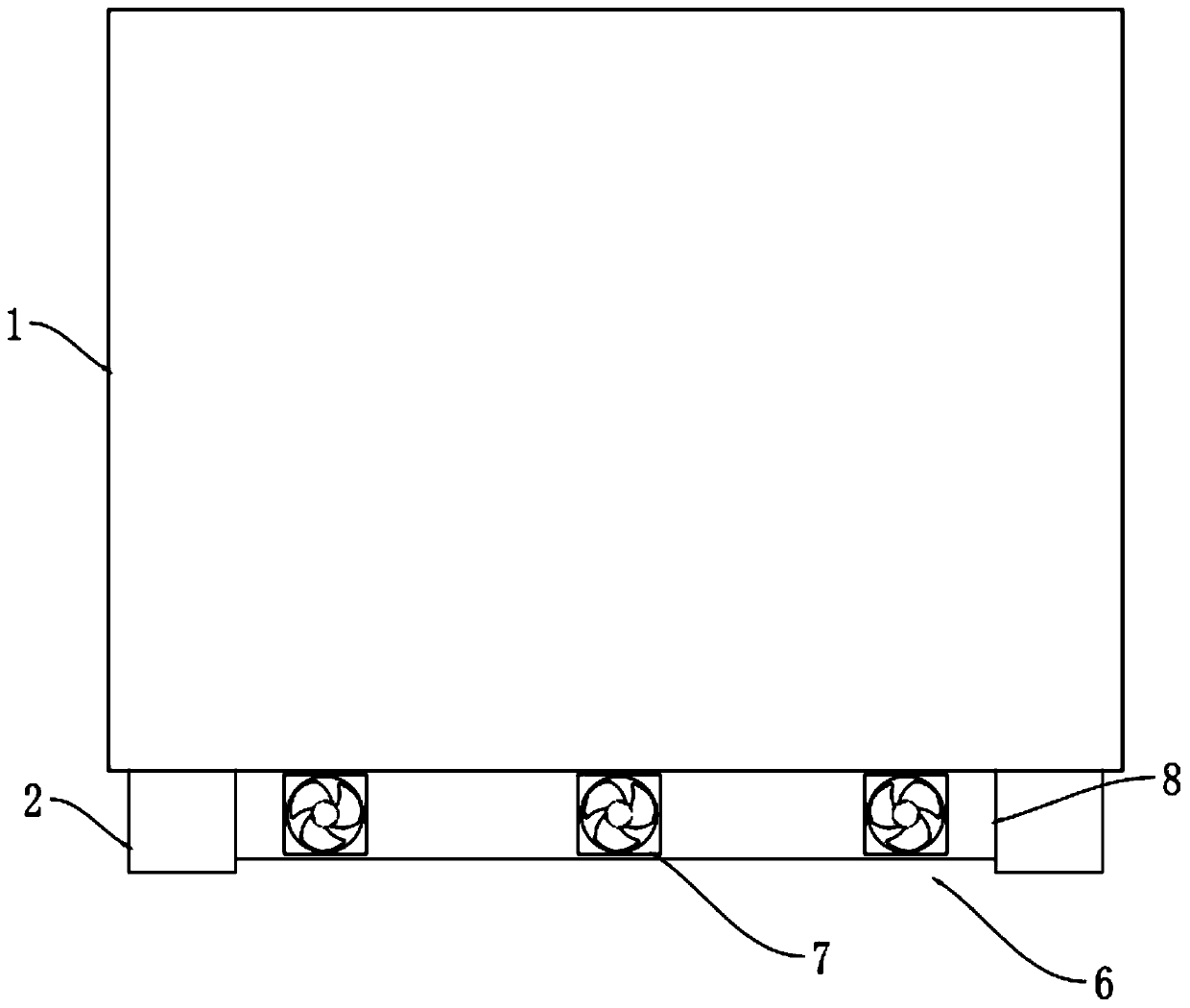

[0020] like Figure 1-4 As described above, a vacuum oven of the present invention includes an oven body 1, a base 2, an electric heating rod 3, a support frame 4, a sealing cover 5 and an anti-heat accumulation member 6, and the oven body 1 is a cylindrical hollow cavity with an open upper end Structural setting, the base 2 is symmetrically arranged on the bottom of the oven body 1, the electric heating rod 3 is arranged on the inner bottom wall of the oven body 1, the support frame 4 is arranged in the oven body 1 and covered on the electric heating rod 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com