Application of microwave technology in control on disease and insect damage to tobacco

A technology for pests and diseases, tobacco, applied in the field of tobacco pest control, application of microwave technology to control tobacco pests and diseases, can solve practical application difficulties, no use value, no penetration and other problems, achieve fast disinfection speed, working environment and occupation. The effect of small land area and light damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Application of Microwave Technology in the Prevention and Control of Tobacco Diseases and Insects in Tobacco Seedling Cultivation

[0019] ① Use all-water foamed polyurethane (cost about 28,000 yuan / ton), and use a temperature resistance above 160°C as a seedling tray (specification: about 160 plants per tray), and the recycling cycle is 3-6 years.

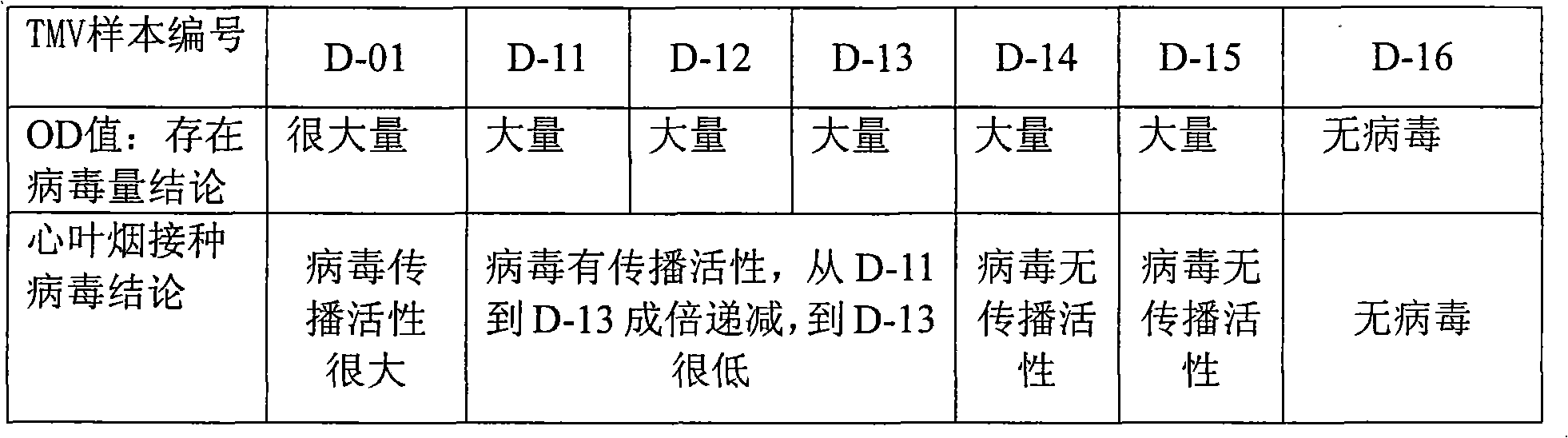

[0020] ② Disinfect and kill the seedling trays: Tobacco growers use the seedling trays to clean, and then use microwave assembly line equipment with a frequency of 900-2500MHz and an output power of 220V900-2500W to irradiate and disinfect the seedling trays for 5-10 minutes. Tobacco mosaic virus can be inactivated by disinfection for 5 minutes. The sterilized seedling trays are directly used for seedling cultivation.

[0021] ③ Disinfection and elimination of leaf shears, leaf pinchers, and root cutters: use engineering plastics that can withstand high temperatures above 200°C and have good physical properties ...

Embodiment 2

[0023] Example 2: Application of Microwave Technology in the Prevention and Control of Tobacco Pests and Diseases in Tobacco Planting

[0024] Use a backpack-type mobile microwave device with a microwave frequency of 500-1500MHz and an output power of 200-1000W. Add an ultraviolet device with a wavelength of 254nm and a power of 30-100W to irradiate the tobacco plants for 5-20 seconds, which can effectively inactivate, reduce and inhibit the diseases on the surface of the tobacco plants, especially for the control of pests such as budworms. Reduce the transmission of tobacco mosaic virus through the mouthparts of pests.

Embodiment 3

[0025] Example 3: Application of microwave technology in preventing and controlling tobacco diseases and insect pests in tobacco curing and conditioning

[0026] The use of microwaves has the characteristics of internal heating and high heating efficiency. It is used to transform existing curing rooms or build new curing rooms. While curing tobacco leaves, it can kill tobacco viruses and reduce the subsequent spread of tobacco viruses. According to the area of the barn, microwave devices are generally configured at 915MHz and 500-1000W per cubic meter. Use a microwave device with a frequency of 900-2500MHz and an output power of 900-2500W. The microwave irradiation disinfection time is determined according to the yellowing stage, color fixing stage and gluten drying stage of the current baking process, and is determined according to the quality and variety of tobacco leaves. The baking and tempering method is energy-saving, environmentally friendly and non-toxic, and can ina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com