Balanced high-heat type aluminum hot-welding agent

A kind of thermite flux and high heat technology, applied in the direction of aluminotherm welding equipment, welding equipment, welding medium, etc., can solve the problems of difference in welding effect, difficulty in heat control, etc., and achieve the effect of uniform heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

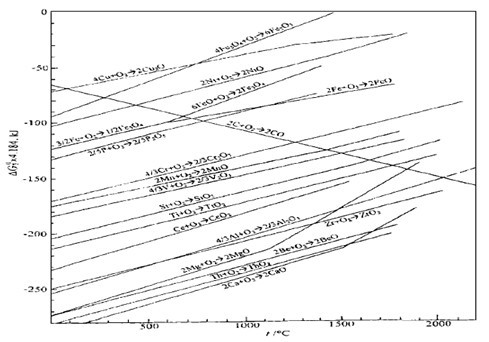

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example is a low-dose thermite flux composition ratio, and the equivalent weight (the sum of the mass of all components) is 85 grams. The composition and quality are shown in Table 1.

[0042] Table 1. Equivalent 85# thermite composition ratio table

[0043]

[0044] MgO is relatively stable at low temperature, does not participate in the reaction, and is equivalent to an inert additive, so adding too much will hinder the reaction. Adding too little can not play a role in adjusting the thermal peak. The mass content of MgO in this example is about 9%.

[0045] CuO particles with stepped distribution are used because particles with uniform particle size have the same combustion velocity and combustion peak, so the heat generated by the superposition of uniform particle size powder is in a normal distribution; the heat production in the initial stage and the end stage of combustion is less than that of external The heat dissipated, and the heat generated in the m...

Embodiment 2

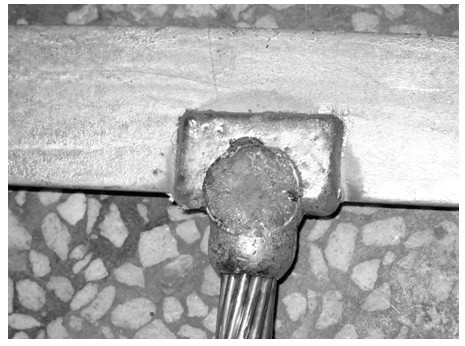

[0054] This example is the composition ratio of medium dose thermite flux, and the equivalent weight (sum of all components) is 115 grams. The composition and quality are shown in Table 2. The mass content of MgO in this example is about 8%. The preparation and welding process of the solder powder is the same as in Example 1. The combustion reaction process of the solder powder is smooth, the mouth is round and the shape is full.

[0055] image 3 95mm welded by 115# flux 2 19-core steel strand with 4×40mm 2 Galvanized sheet T joint. Figure 4 Three sections of joint specimens are shown: section of copper-clad galvanized sheet, section of copper-clad stranded wire, and overlap of galvanized sheet and steel stranded wire. The section was observed after grinding, mechanical polishing, and tissue erosion. From the macroscopic section of the sample, it can be seen that the welding interface is well bonded, and there are no continuous pores, cracks, incomplete fusion, inclusio...

Embodiment 3

[0062] This example is a high-dose thermite flux component ratio, and the equivalent weight (sum of all components) is 150 grams. The composition and quality are shown in Table 3.

[0063] Table 3. Equivalent 150# thermite composition ratio table

[0064]

[0065] The mass content of MgO in this example is about 7%. The preparation of solder powder and the welding process are the same as Example 1 and Example 2. The combustion reaction process of the solder powder is smooth, the mouth is round, and the shape is full. Figure 7 4×40mm welded by 150# flux 2 Galvanized sheet T joint. Figure 8 It is the microstructure of the welded joint of the galvanized sheet. Figure a shows the structure near the fusion line between the galvanized sheet and copper. The grains of the base metal galvanized sheet are in a semi-melted state, and there is a transition between the galvanized sheet and copper. layer (iron, copper, zinc solid solution); Figure b shows the microstructure of mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com