Desulphurization absorbing tower having flow-guiding bodies on tower wall

The technology of desulfurization absorption tower and guide fluid is applied in the field of flue gas purification equipment, which can solve the problem of high energy consumption and achieve the effect of low pressure energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

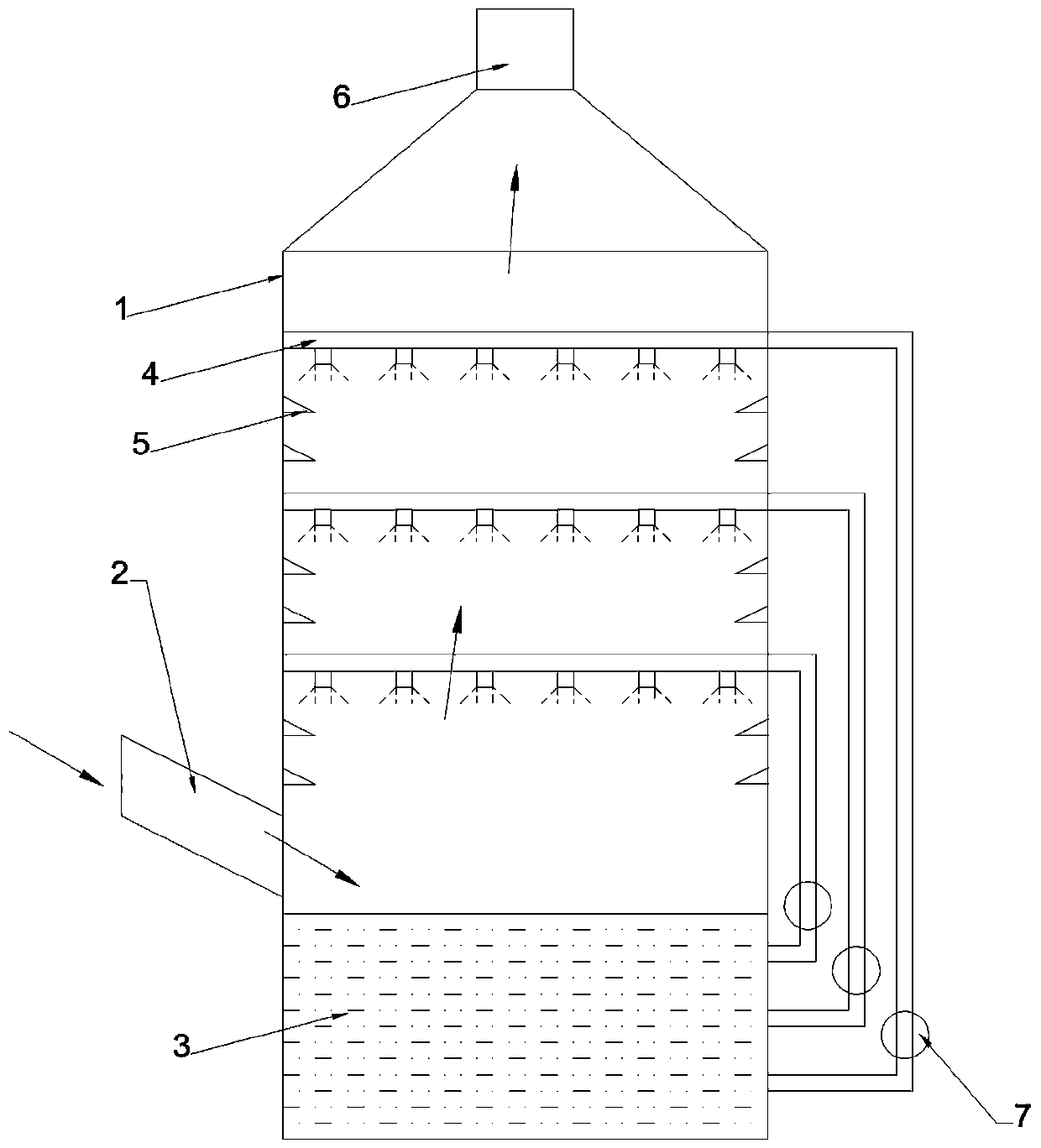

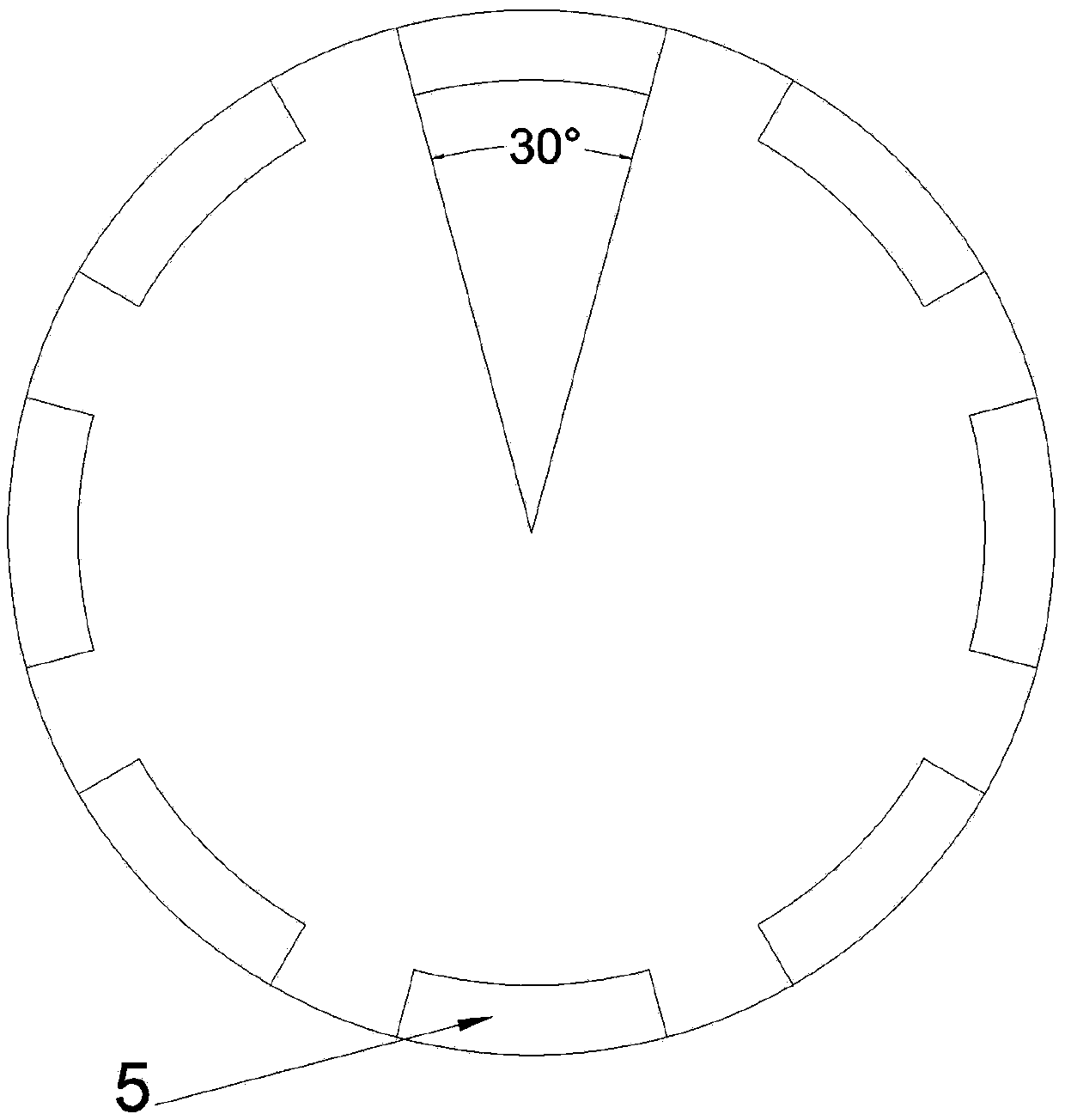

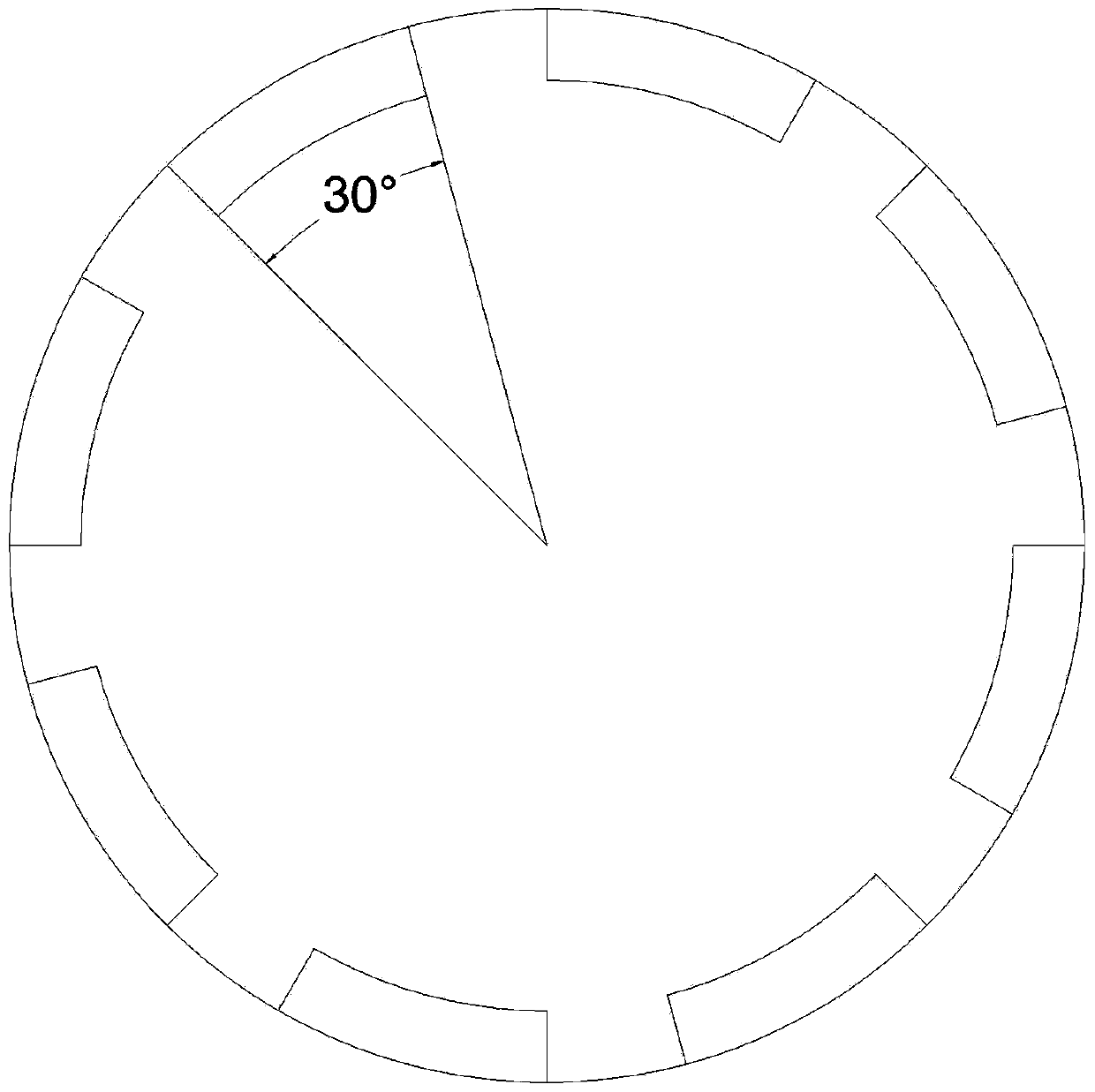

[0030] Such as figure 1 As shown, the present embodiment is a desulfurization absorption tower with a tower wall diverter, wherein the lower side of the tower body 1 is provided with a flue gas input pipe 2, the bottom of the tower body 1 is provided with a slurry pool 3, and the middle part of the tower body 1 is provided with There are 3 spray layers 4, a set of diversion bodies 5 are arranged on the tower wall below each spray layer 4, and a flue gas outlet 6 is arranged on the top of the tower body 1.

[0031] Among them, the tower body 1 is 26 meters high, the middle and lower parts are cylindrical, the inner wall diameter is 5.3 meters, and the top is a truncated cone. The flue gas outlet 6 is located on the top of the truncated cone with a diameter of 2.6 meters.

[0032] The relative pressure of the flue gas at the flue gas input pipe 2 is 1260Pa, and the relative pressure at the flue gas outlet 6 is 60Pa, both of which are positive pressure relative to the atmospheric...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment is a desulfurization absorption tower with a tower wall diversion body. The side of the lower part of the tower body 1 is provided with a flue gas input pipe 2, the bottom of the tower body 1 is provided with a slurry pool 3, and the middle part of the tower body 1 is provided with There are 3 spray layers 4 , a set of diversion bodies 5 are arranged on the tower wall below each spray layer 4 , and a flue gas outlet 6 is arranged on the top of the tower body 1 .

[0040] Among them, the tower body 1 is 37 meters high, the middle and lower parts are cylindrical, the inner wall diameter is 20 meters, and the top is in the shape of a truncated cone. The flue gas outlet 6 is located on the top of the truncated cone with a diameter of 9.5 meters.

[0041] The relative pressure of the flue gas at the flue gas input pipe 2 is 1190Pa, and the relative pressure at the flue gas outlet 6 is 70Pa, both of which are positive pressure relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com