Balance weighing structure and balance weighing method for horizontal rotating construction of box girder bridge

A construction method and technology of box girders, which are applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems that can only be installed on the top of bridge piers, increase jacking force, and concrete crushing, so as to ensure normal operation and erection. The effect of small jacking force and reduced running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

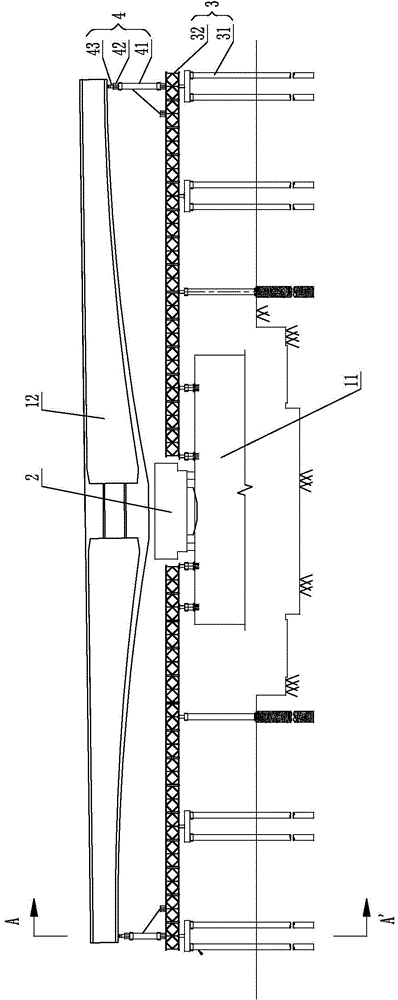

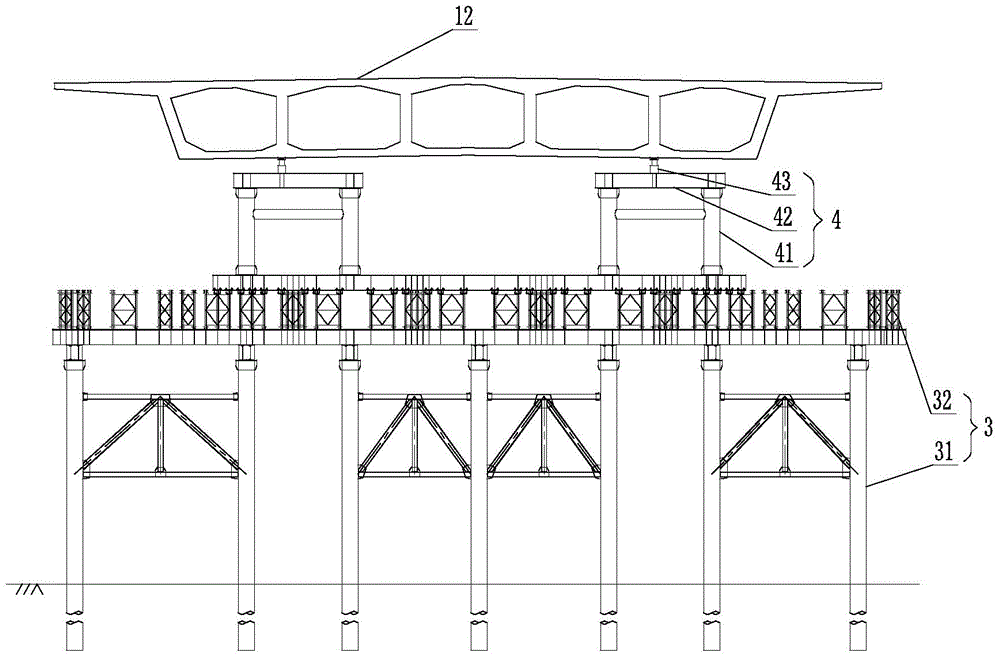

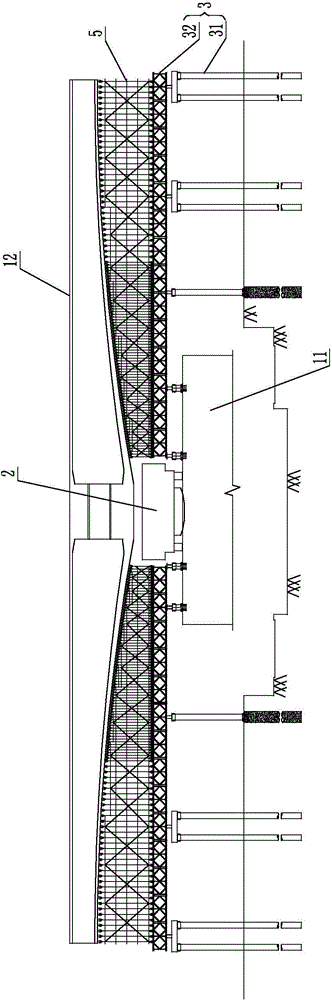

[0029] like figure 1 and figure 2 As shown, a balance weighing structure for the horizontal swivel construction of a box girder bridge is arranged on the T structure of the box girder bridge before the swivel body. The T structure of the box girder bridge includes a pier 11 and a main girder 12, and the pier 11 is M-shaped or door Form frame type, the pier 11 is arranged vertically on the ground, and the main girder 12 is arranged above the pier 11 horizontally. The balance weighing structure includes a turntable 2, two sets of lower brackets 3 and two sets of auxiliary weighing systems 4, the turntable 2 is arranged on the top surface of the bridge pier 11, and is located at the center of the bottom surface of the main girder 12, and the two sets of lower brackets 3 and Two sets of auxiliary weighing systems 4 are respectively symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com