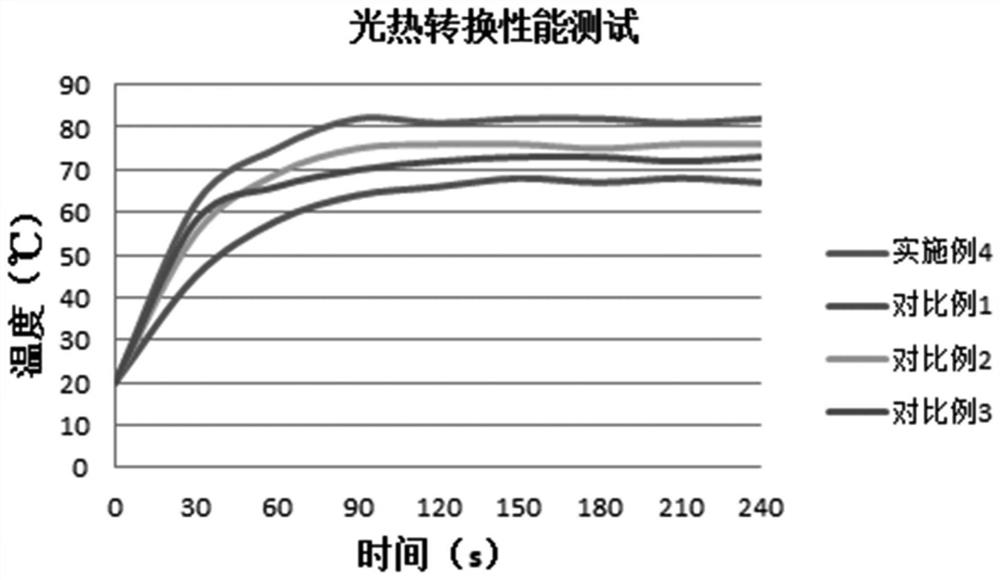

Non-layered molybdenum nanosheet/graphene-based fiber membrane and preparation method thereof

A technology of olefin-based fibers and nanosheets, which is applied in the chemical characteristics of fibers, non-woven fabrics, rayon manufacturing, etc., can solve the problems of easy stacking of graphene scales, low electrical conductivity, poor dispersion effect, etc., and achieves high mechanical properties. , good flexibility, uniform heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of non-layered molybdenum nanosheet / graphene-based fiber membrane, comprising the following steps:

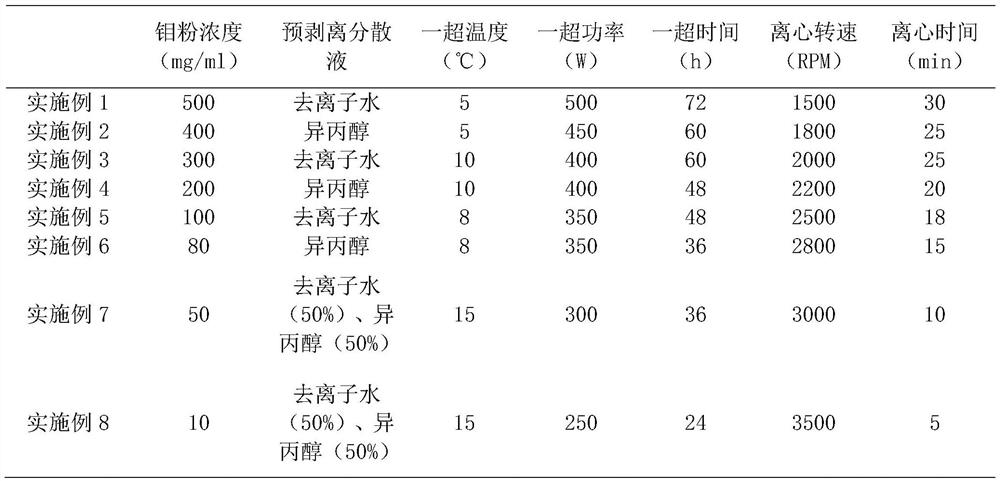

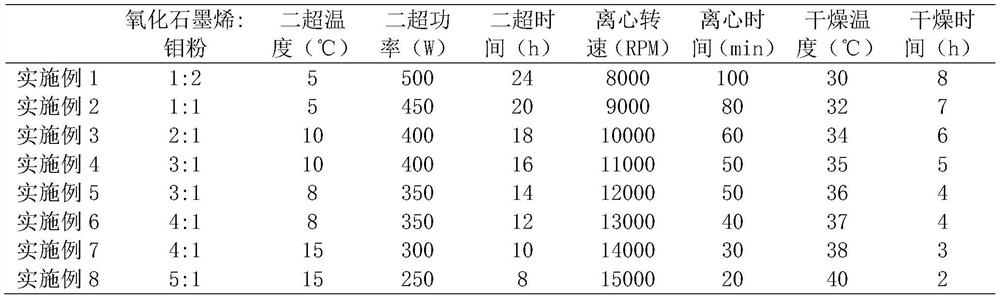

[0037] Prepare the pre-stripping dispersion liquid of molybdenum powder: provide molybdenum powder and add in the pre-stripping dispersion liquid, the kind of pre-stripping dispersion liquid (the pre-stripping dispersion liquid in embodiment 7 and embodiment 8 is the mixture of deionized water and Virahol The mass ratio is 1:1 mixed pre-stripping dispersion) and the concentration of molybdenum powder in the pre-stripping dispersion is shown in Table 1. The pre-stripping dispersion liquid that is added with molybdenum powder is subjected to first-level water bath ultrasonic, wherein the temperature of first-level water bath ultrasonic (the first-level water bath ultrasonic is referred to as "one super", the temperature here is the temperature value set by the water bath, the actual The temperature of the water bath will fluctuate to a certain extent),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com