Low-temperature lithium-ion battery

A lithium-ion battery, low-temperature technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow lithium diffusion and charge transfer, poor wettability penetration, poor performance, etc., to achieve excellent power rate performance, convenient Structural design layout, the effect of improving mass energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

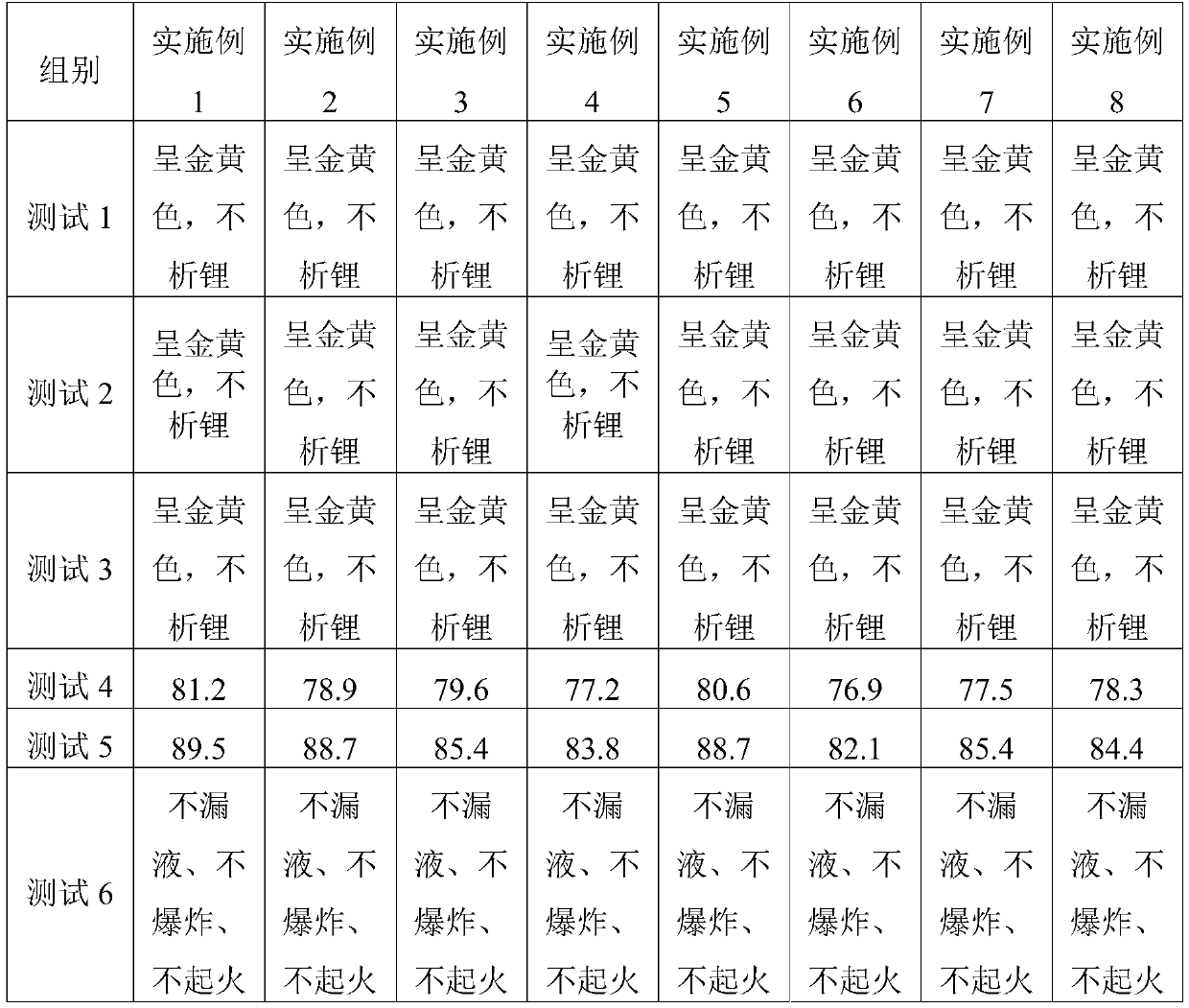

Examples

Embodiment 1

[0045] The low-temperature lithium-ion battery includes a positive electrode sheet, a separator, a negative electrode sheet and an electrolyte, specifically:

[0046] (1) Positive plate. The positive electrode sheet includes: ternary nickel cobalt lithium manganese oxide material, positive electrode conductive agent, and positive electrode binder. Among them, the ternary nickel cobalt lithium manganese oxide material is NCM811, which is a composite material of aggregate material and single crystal-like material. The median particle size of the aggregate is 4 μm, and the primary particle size of the aggregate is 550nm. The median particle size is 8μm, and the specific surface area of the composite is 0.5m 2 / g, the tap density of the composite material is 1.5g / cm 3 , the agglomerates account for 30% of the mass of the composite material, and the surface of the composite material is coated with a composite conductive polymer with a thickness of 2nm. The composite conductive ...

Embodiment 2

[0052] The low-temperature lithium-ion battery is the same as in Example 1, except that the composition of the positive electrode sheet, the negative electrode sheet and the electrolyte is as follows:

[0053](1) Positive plate. The positive electrode sheet includes: ternary nickel cobalt lithium manganese oxide material, positive electrode conductive agent, and positive electrode binder. Among them, the ternary nickel cobalt lithium manganese oxide material is NCM622, which is a composite material of aggregate material and single crystal-like material. The median particle size of the aggregate is 4 μm, and the primary particle size of the aggregate is 550nm. The median particle size is 8μm, and the specific surface area of the composite is 0.5m 2 / g, the tap density of the composite material is 1.5g / cm 3 , the agglomerates account for 30% of the mass of the composite material, and the surface of the composite material is coated with a composite conductive polymer with a t...

Embodiment 3

[0057] The low-temperature lithium-ion battery is the same as in Example 1, except that the composition of the positive electrode sheet, the negative electrode sheet and the electrolyte is as follows:

[0058] (1) Positive plate. The positive electrode sheet includes: ternary nickel cobalt lithium manganese oxide material, positive electrode conductive agent, and positive electrode binder. Among them, the ternary nickel cobalt lithium manganese oxide material is NCM811, which is a composite material of aggregate material and single crystal-like material. The median particle size of the aggregate is 4 μm, and the primary particle size of the aggregate is 550nm. The median particle size is 8μm, and the specific surface area of the composite is 0.5m 2 / g, the tap density of the composite material is 1.5g / cm 3 , the agglomerates account for 30% of the mass of the composite material, and the surface of the composite material is coated with a composite conductive polymer with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com