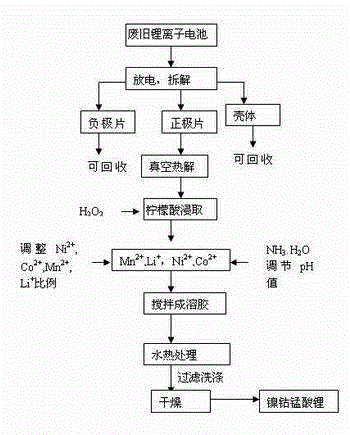

Method for preparing lithium nickelate cobaltate manganate cathode material by taking waste lithium ion batteries as raw material

A technology for nickel-cobalt lithium manganate and lithium ion batteries is applied in the field of preparing nickel-cobalt lithium manganate cathode materials, which can solve the problems of insufficient recovery of lithium, waste gas and waste water pollution, etc., so as to avoid high-temperature calcination, low cost, and energy efficiency. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) After the non-iron lithium-ion battery is discharged, disassemble the battery and separate the positive electrode sheet; (2) Put the positive electrode sheet obtained in step (1) into a vacuum furnace for high temperature treatment to decompose the binder; (3) Treatment High temperature pyrolysis of the positive electrode sheet, the positive electrode slurry is peeled off from the aluminum foil to obtain the positive electrode slurry; (4) the positive electrode slurry obtained in step (3) is dissolved in a citric acid solution with a molar concentration of 1.0mol / L, Among them, the ratio of the mass of positive electrode slurry to the volume of citric acid solution is 60g / L; (5) add reducing agent hydrogen peroxide solution, dissolve and filter; (6) measure the content of metal ions in the solution, use manganese nitrate, lithium nitrate , nickel nitrate and cobalt nitrate to adjust Li in the solution + , Mn 2+ 、Co 2+ and Ni 2+ The molar ratio is 3:1:1:1; (7) Use...

Embodiment 2

[0014] (1) After the non-iron lithium-ion battery is discharged, disassemble the battery and separate the positive electrode sheet; (2) Put the positive electrode sheet obtained in step (1) into a vacuum furnace for high temperature treatment to decompose the binder; (3) Treatment High temperature pyrolysis of the positive electrode sheet, the positive electrode slurry is peeled off from the aluminum foil to obtain the positive electrode slurry; (4) the positive electrode slurry obtained in step (3) is dissolved in a citric acid solution with a molar concentration of 0.75mol / L, Among them, the ratio of the quality of the positive electrode slurry to the volume of the citric acid solution is 45g / L; (5) add the reducing agent hydrogen peroxide solution, dissolve and filter; (6) measure the content of metal ions in the solution, use manganese acetate, lithium acetate , nickel acetate and cobalt acetate to adjust Li in the solution + , Mn 3+ 、Co 3+ and Ni 3+ The molar ratio is ...

Embodiment 3

[0016] (1) After the non-iron lithium-ion battery is discharged, disassemble the battery and separate the positive electrode sheet; (2) Put the positive electrode sheet obtained in step (1) into a vacuum furnace for high temperature treatment to decompose the binder; (3) Treatment High temperature pyrolysis of the positive electrode sheet, the positive electrode slurry is peeled off from the aluminum foil to obtain the positive electrode slurry; (4) the positive electrode slurry obtained in step (3) is dissolved in a citric acid solution with a molar concentration of 1.25mol / L, The ratio of the mass of positive electrode slurry to the volume of citric acid solution is 75g / L; (5) add reducing agent hydrogen peroxide solution, dissolve and filter; (6) measure the content of metal ions in the solution, use manganese sulfate, lithium sulfate , nickel sulfate and cobalt sulfate to adjust Li in the solution + , Mn 2+ 、Co 2+ and Ni 2+ The molar ratio is 3:1:1:1; (7) Use ammonia wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com