Method for turning over subsections and overall section

A technology of turning over and total section, applied in the directions of load hanging components, transportation and packaging, can solve the problems of heavy grinding and repairing workload, difficult installation of D-shaped lifting rings, and high production cost of lifting rings, so as to reduce welding workload and reduce lifting rings. Cut off the sanding workload and avoid the effect of repairing the sanding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The method for turning over of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention cannot be limited by this.

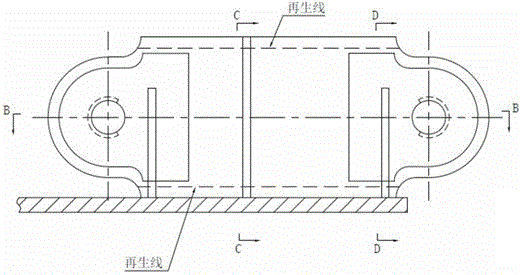

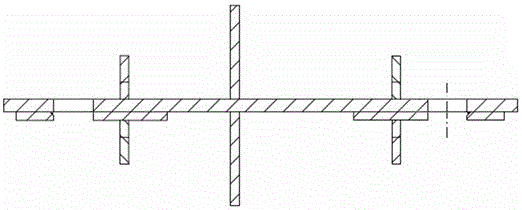

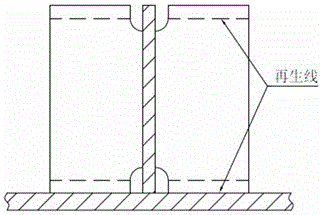

[0041] like Figure 5-Figure 15 As shown, the present embodiment is used for the method of subsection and total section turning over, and the method of turning over comprises the following steps:

[0042] S1, according to the weight of the small section A is 113t, and the B-type lifting ring is used as the main hook, four B-40T lifting rings are needed. Determine the type and number of Type B lifting rings, and then obtain the installation diagram of Type B lifting rings according to the hull structure. According to the distribution of the center of gravity, Type B lifting rings should be placed on FR197, FR201, FR211, and FR215 ribs According to the structural characteristics of the turning tool, the fixed bottom plate must...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com