Port resonator high-frequency welding fixture

A high-frequency welding and resonator technology, applied in the direction of high-frequency current welding equipment, welding equipment, welding equipment, etc., can solve the problems of increasing labor costs, material costs, waste of resources, etc., and achieve the effect of improving quality and reducing welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

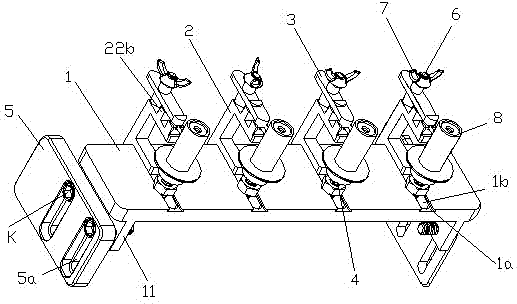

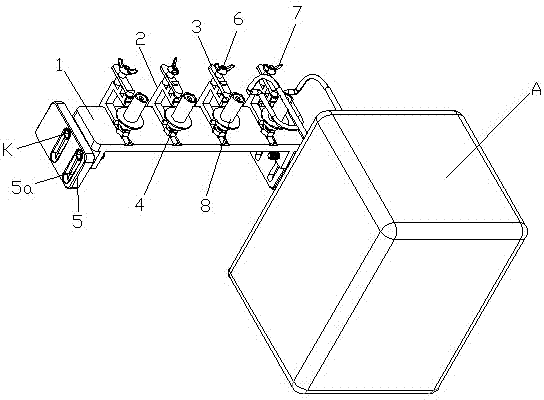

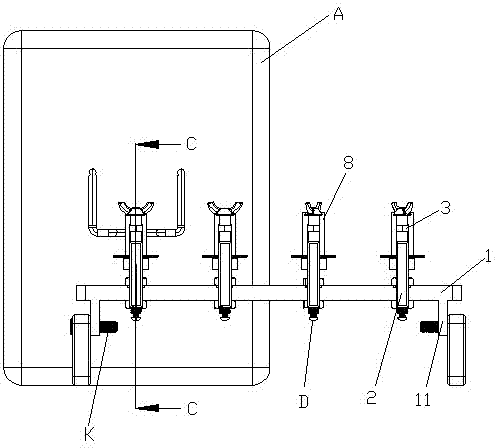

[0029] Figure 1 to Figure 12 Shown is the structure and working state schematic diagram of the present invention.

[0030] The reference signs are: high-frequency welding machine A, positioning screw D, platen adjustment bolt K, tooling platen 1, guide channel 1a, guide slot hole 1b, support frame plate 11, connecting threaded hole 11a, tooling slide Block 2, clamping groove cavity 2a, longitudinal plate 21, wire loading hole 21a, upper horizontal plate 22, front positioning protrusion 22a, rear positioning protrusion 22b, front station arc groove 22c, rear station arc groove 22d, front Station through hole 22e, rear station through hole 22f, middle horizontal plate 23, lower horizontal plate 24, positioning screw hole 24a, tooling pressure plate 3, front pressure plate protrusion 3a, rear pressure plate protrusion 3b, pressure plate sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com