Frame type enamel block corrosion-resistant chimney and mounting method thereof

An installation method and frame-type technology, applied in the field of chimneys, can solve problems such as difficult construction quality assurance, volatile scale paint, and harsh construction environment, and achieve the effects of avoiding inability to weld, low installation difficulty, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

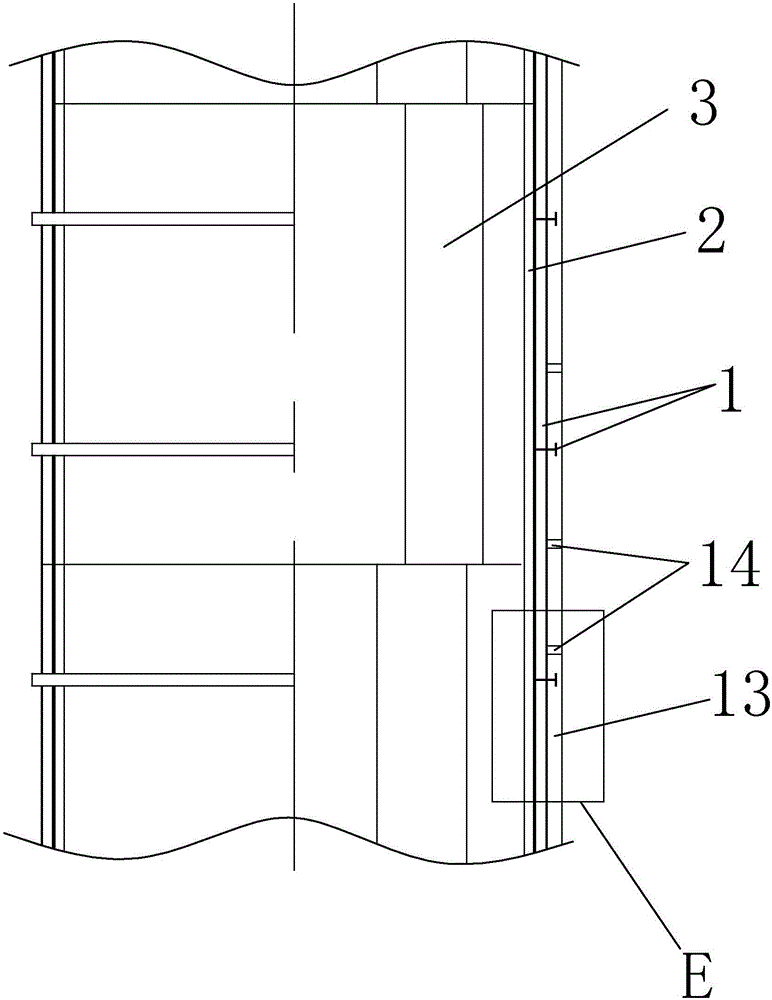

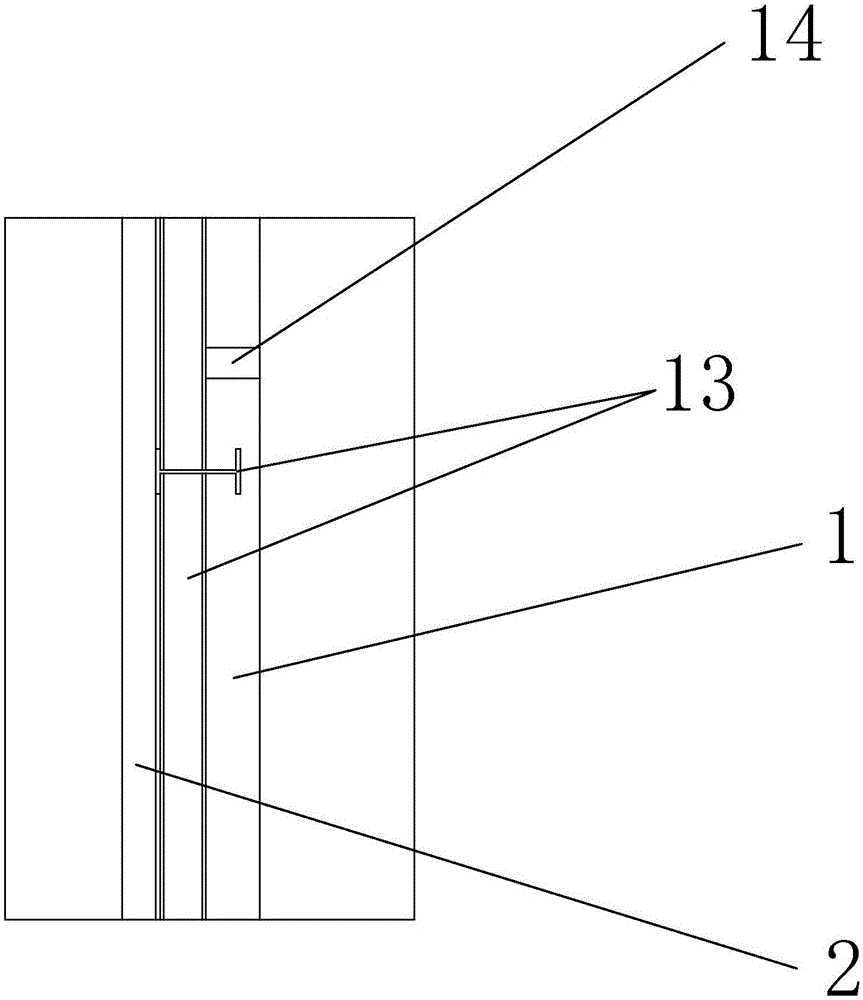

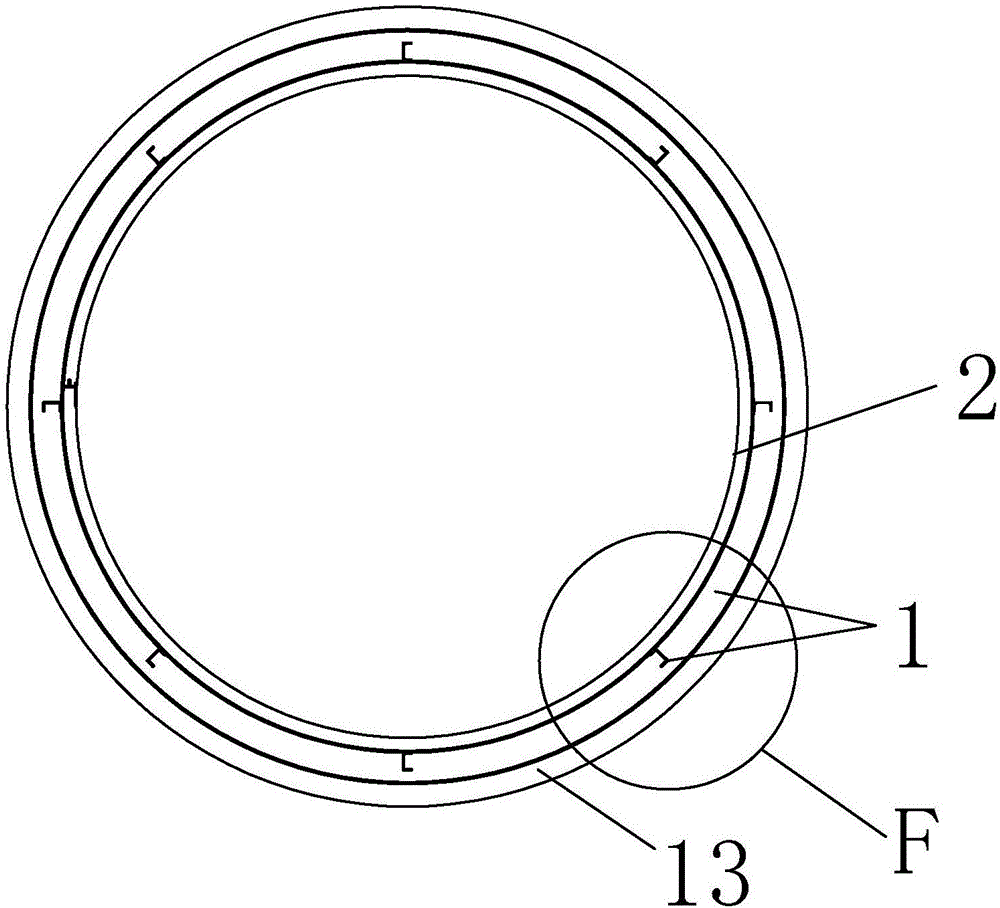

[0036] Such as Figure 1-5As shown, a frame-type enamel plate anti-corrosion chimney includes a steel frame 1 and an inner cylinder 2, the inner cylinder 2 is spliced by a plurality of enamel plates 3 connected to each other around, and the enamel plate 3 includes a base steel plate 4, The base steel plate 4 is provided with folds 5 that are bent toward the outside of the base steel plate 4, wherein at least one fold 5 is fixedly connected with a fixing plate 6 extending toward the inside of the fold 5, and the fixation plate 6 is arranged on the fold 5, the inner and outer edges, and the fixed plate 6 are welded to the steel frame 1 to connect, the base steel plate 4, the folded edge 5, and the fixed plate 6 are integral structures, and the folded edge 5 and the fixed plate 6 are formed by bending the base steel plate 4. The inner surface of the base steel plate 4 and the outer surface of the folded edge 5 are compounded with an enamel layer 7, and a high-temperature resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com