Nodular cast iron pipe for jacking construction

A ductile iron pipe jacking technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problem of improving the productivity and cost of ductile iron pipe jacking, limiting the use of socket-type ductile iron pipe jacking, Ribs and flanges are not easy to be automatically welded, etc., to reduce the welding area, reduce production costs, and save material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

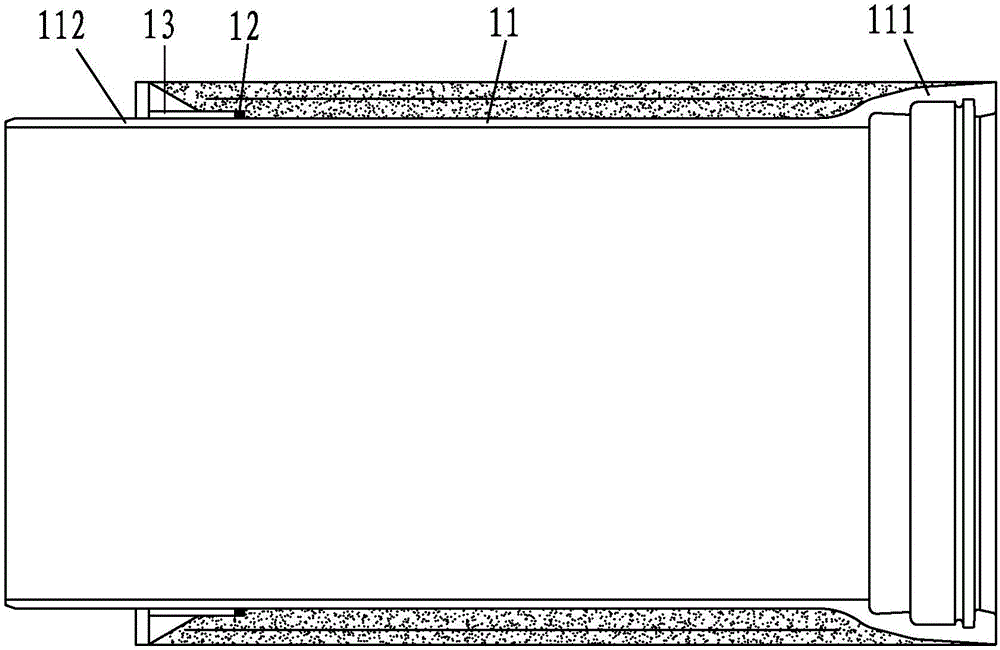

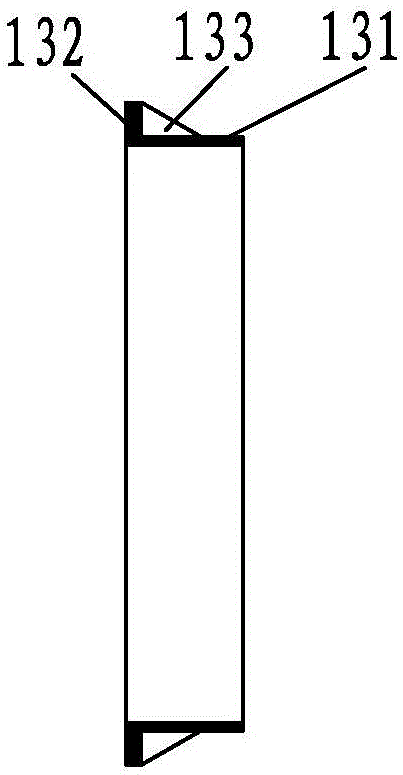

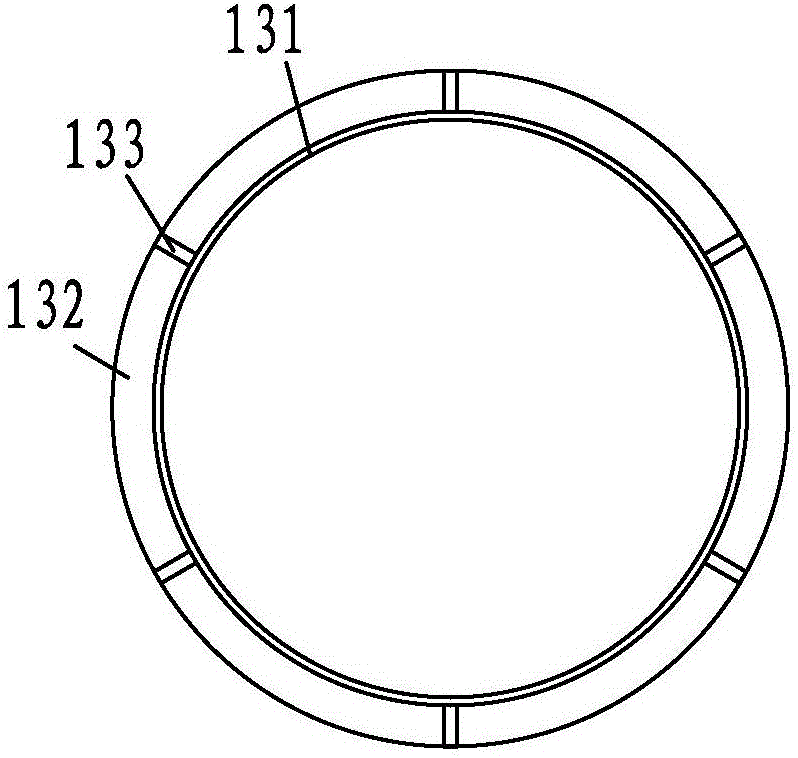

[0017] Such as figure 1 As shown, the ductile iron pipe used for jacking construction in the present invention includes a ductile iron pipe body 11, one end of the ductile iron pipe body 11 is a socket 111, and the other end is a socket 112, and the outer wall of the end of the ductile iron pipe body 11 close to the socket 112 Fixed with backstop ring 12 and push mechanism 13, such as figure 2 , 3 As shown, the pushing mechanism 13 includes a cylinder body 131 and a pushing flange 132, and the pushing flange 132, cylinder body 131, and backstop ring 12 are sequentially arranged from the outside to the inside, and the cylinder body 131 and the backstop ring 12 are closely attached.

[0018] The pushing mechanism 13 also includes at least three ribs 133. The cylinder 131 and the pushing flange 132 constituting the pushing mechanism 13 can be split. On the body 11, the two halves of the cylinder are butt welded to each other, and then welded together with the push flange 132. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com