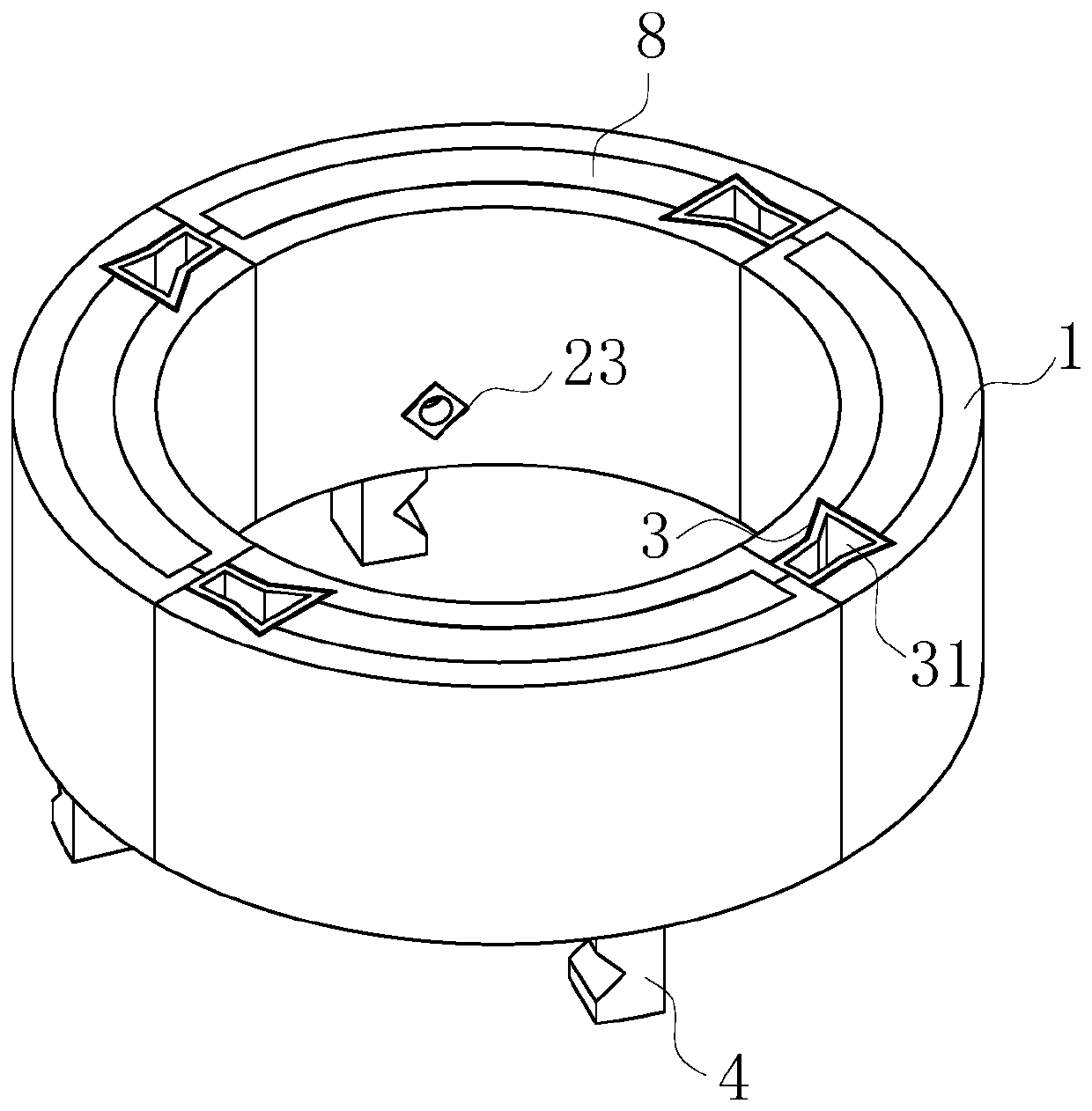

Prefabricated part of blast furnace throat

A technology of blast furnace throat and prefabricated parts, which is applied to blast furnace parts, blast furnace, blast furnace details, etc., can solve problems affecting the safety and efficiency of blast furnace smelting, poor integrity and cushioning of the furnace throat, and the falling off of the furnace throat. Achieve the effect of improving the stable installation effect, facilitating quick disassembly and replacement, and reducing the welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

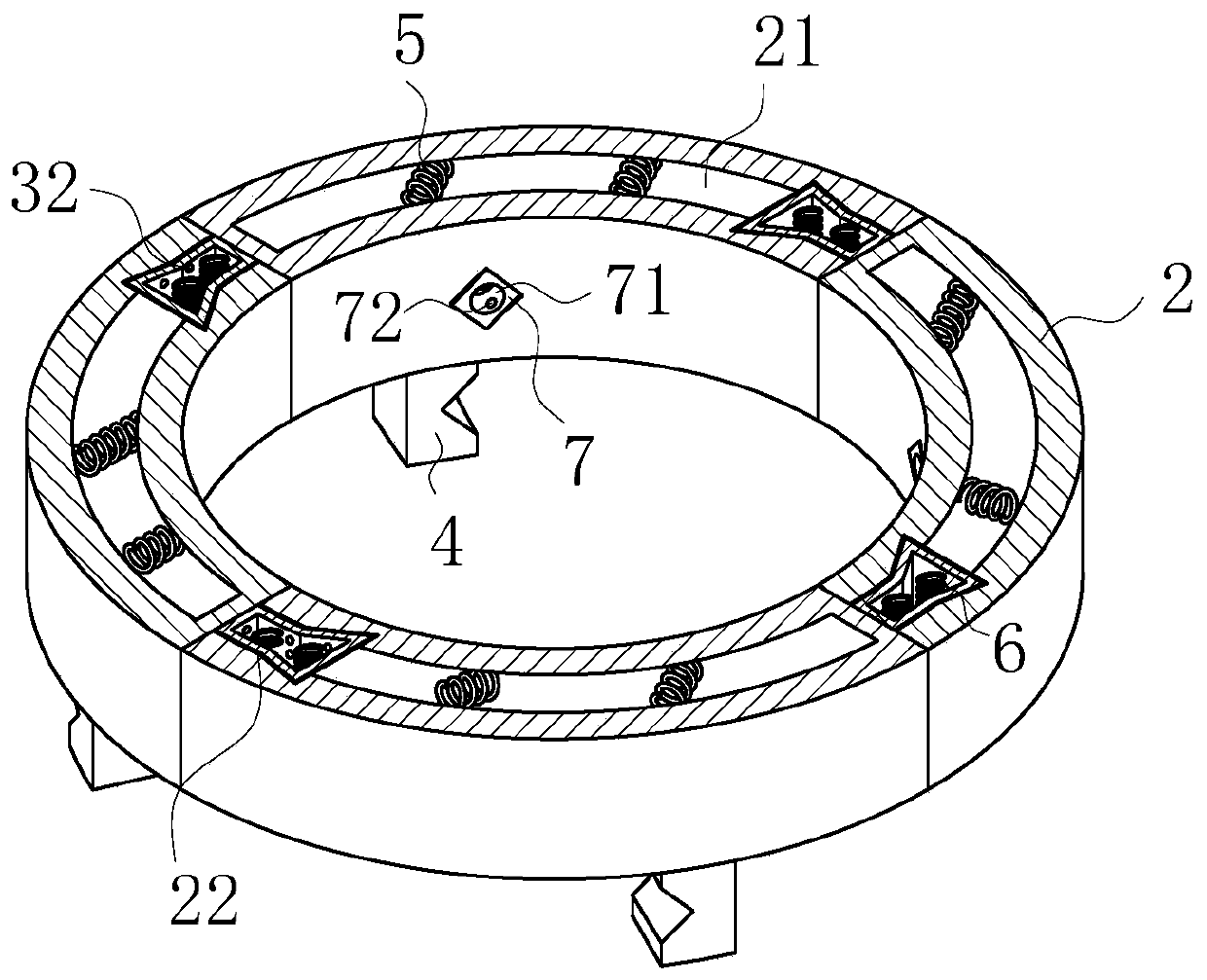

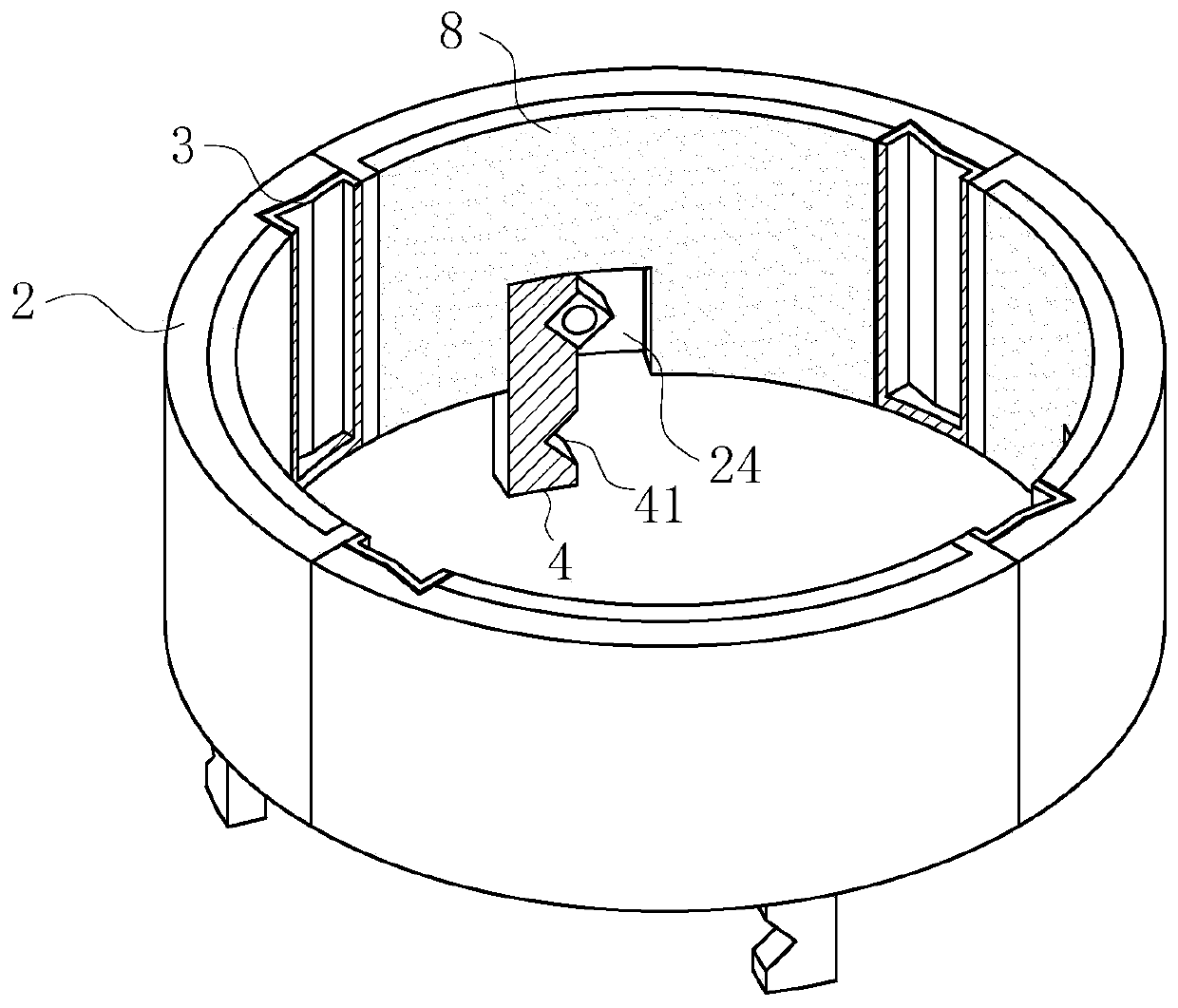

[0023] As an embodiment of the present invention, the dovetail socket block 3 is provided with a prefabricated cavity 31, and the spiral elastic skeleton 6 is inserted into the prefabricated cavity 31; the outer wall of the prefabricated cavity 31 is provided with an overflow hole 32, and the overflow The orifice 32 communicates with the dovetail slot 22; during operation, when clay slurry is injected into the filling cavity 21, excess clay slurry will enter the prefabricated cavity 31 through the overflow hole 32, so that the spiral in the prefabricated cavity 31 The elastic skeleton 6 is combined with the clay slurry, and at the same time, the clay slurry in the filling cavity 21 can form a nodular protrusion in the prefabricated cavity 31 of the dovetail socket block 3, thereby increasing the size of the dovetail socket block 3 and the filling cavity. 21 close fitting effect, and at the same time increase the stable connection between the spliced prefabricated panels 2; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com