Double-layer-structure mould pressing multi-core-group ceramic capacitor and production method thereof

A ceramic capacitor, double-layer structure technology, applied in the direction of multilayer capacitors, fixed capacitor dielectrics, fixed capacitor terminals, etc., can solve the problems of limited number of product chips, unable to meet customer needs, single type, etc., to achieve mechanical and The effect of strong environmental usability, convenient welding planning and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

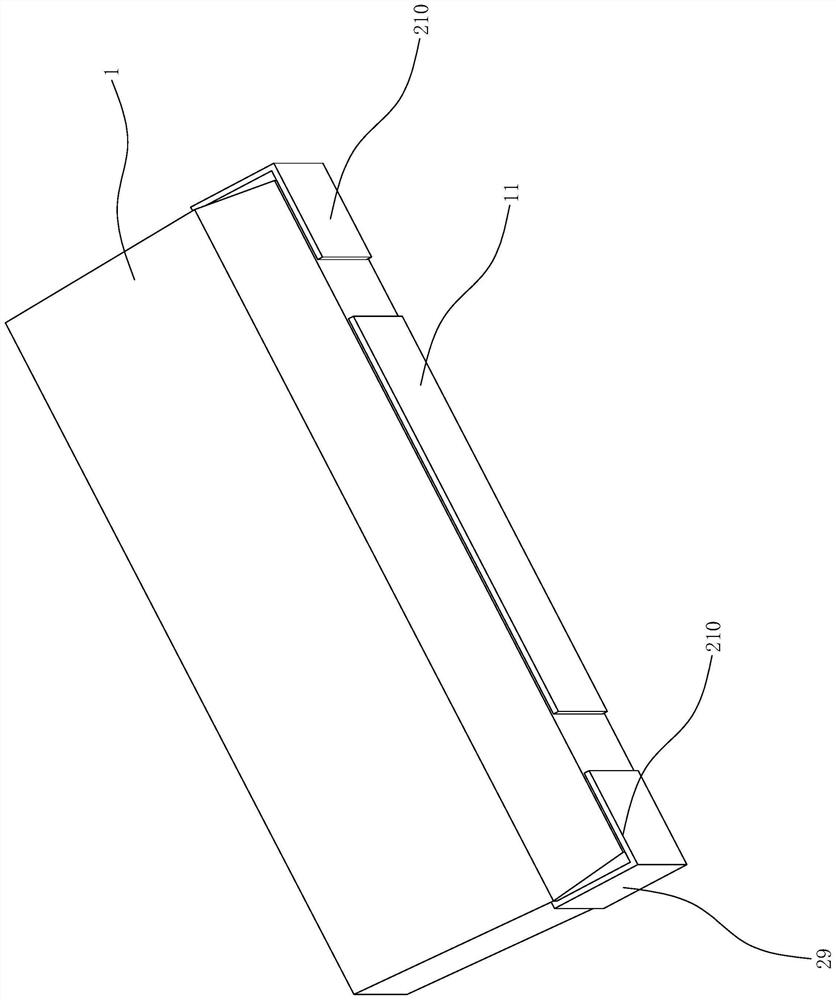

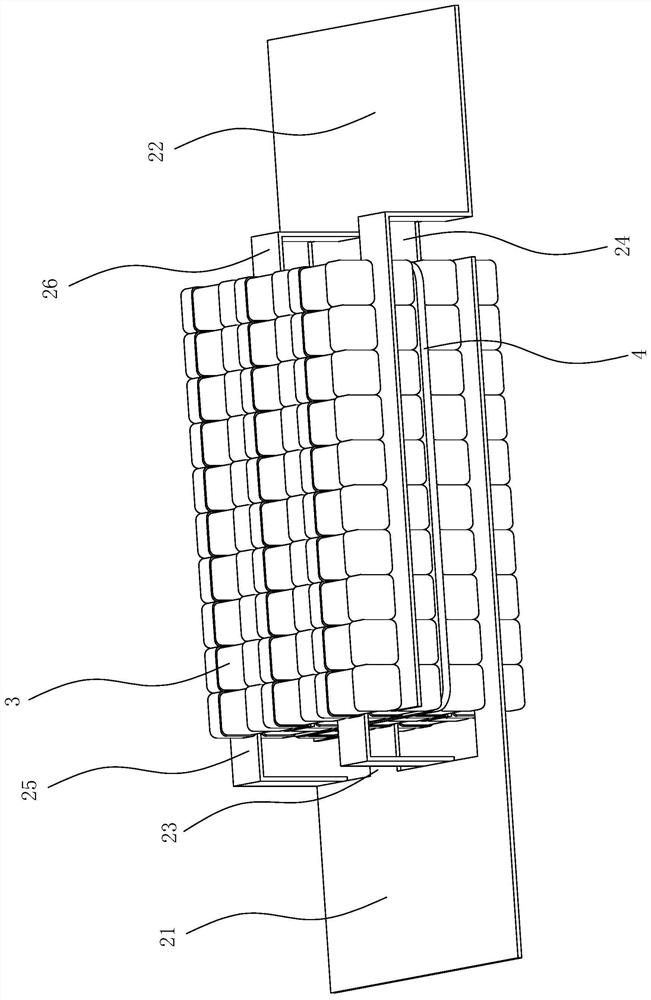

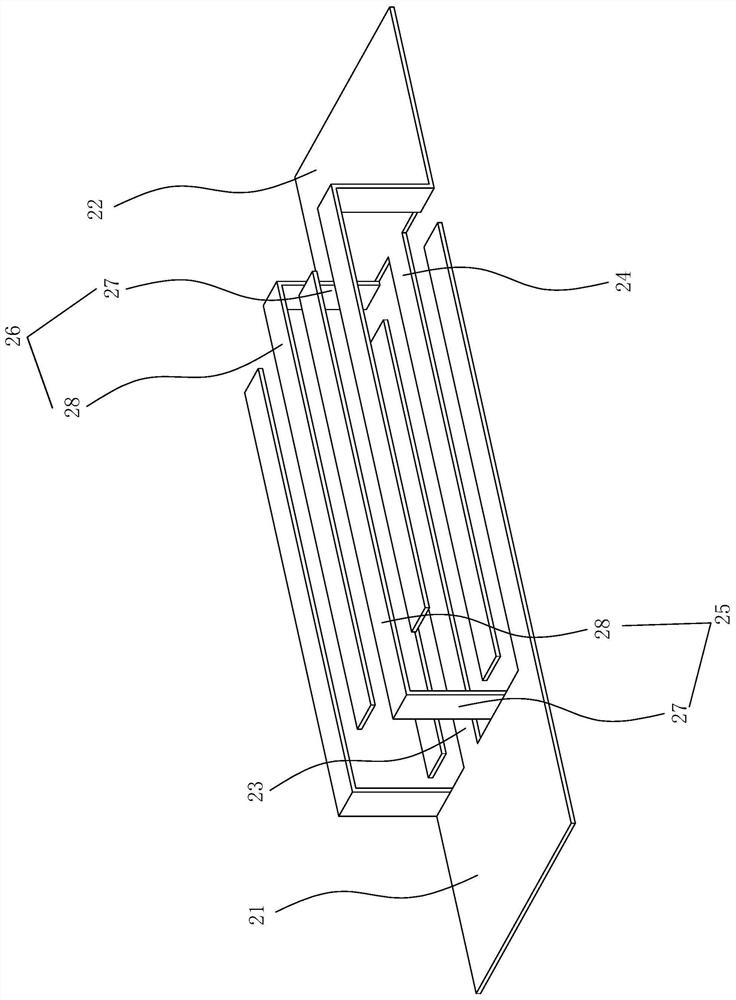

[0033] like Figure 1 to Figure 3 As shown, the double-layer structure molded multi-core group ceramic capacitor includes a plastic package 1, a frame arranged in the plastic package 1, four capacitor chip modules and an insulating gasket 4, and the frame includes a first lead-out 21, a second lead-out 22. The lower welding layer and the upper welding layer, the first lead-out end 21 and the second lead-out end 22 are arranged at intervals relative to each other, the lower welding layer includes two first welding strips 23 and two second welding strips 24 arranged in a staggered manner and extending horizontally, the two The first welding strip 23 is arranged at intervals on the first lead-out end 21, and the two second welding strips 24 are arranged at intervals on the second lead-out end 22. Two third welding strips 25 and two fourth welding strips 26 are arranged alternately, and all have vertical Section 27 and the horizontal section 28 that is arranged on the vertical sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com