Filter screen of fuel oil pump

A technology for fuel pumps and filter screens, applied in the field of filter screens, can solve the problems of increasing the number of molds and fixtures, reducing production efficiency, and poor fixing reliability, and achieves the effects of eliminating assembly processes, improving work efficiency, and reducing injection molding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The fuel pump filter screen of the present invention will be further described in detail with reference to the accompanying drawings.

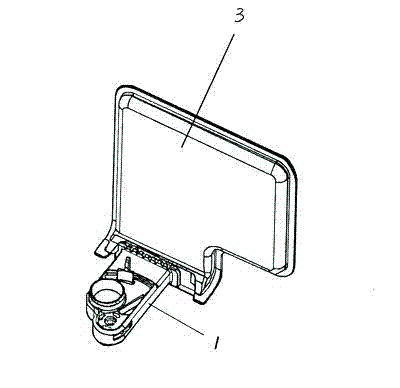

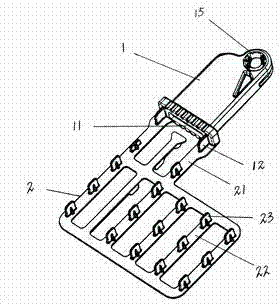

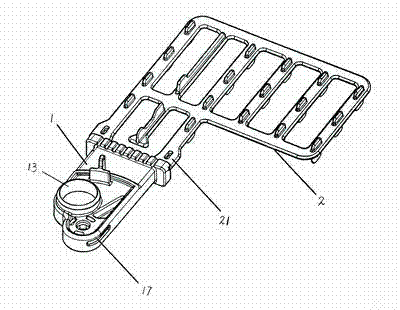

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , The fuel pump filter screen of the invention includes a connector 1, a mesh skeleton 2 and a mesh 3.

[0022] The connector 1 is a flat cavity in the shape of an inverted "U", and an oil inlet 11 is provided at the lower end of the connector 1 of the flat cavity in the shape of an inverted "U". The lower end surfaces of the two ends of the oil port 11 respectively extend downwards with a longitudinal and arc-shaped stop piece 12, and the upper end of the connector 1 of the flat hollow body in the shape of an inverted "U" A circular oil outlet is provided at the left end of the lower end surface of the upper part, and a ring-shaped oil outlet joint 13 extends downwards from the end surface of the circular oil ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com