Wide-angle double-material product gate type secondary injection mold

A large-angle double-material and secondary injection molding technology, which is applied in the field of double-material product injection molds, can solve problems such as failure to seal normally, product distortion, etc., and achieve low cost of single-piece injection molding, short molding cycle, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0026] What needs to be explained here is that the orientation words up, down, top and bottom in the text are based on figure 1 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

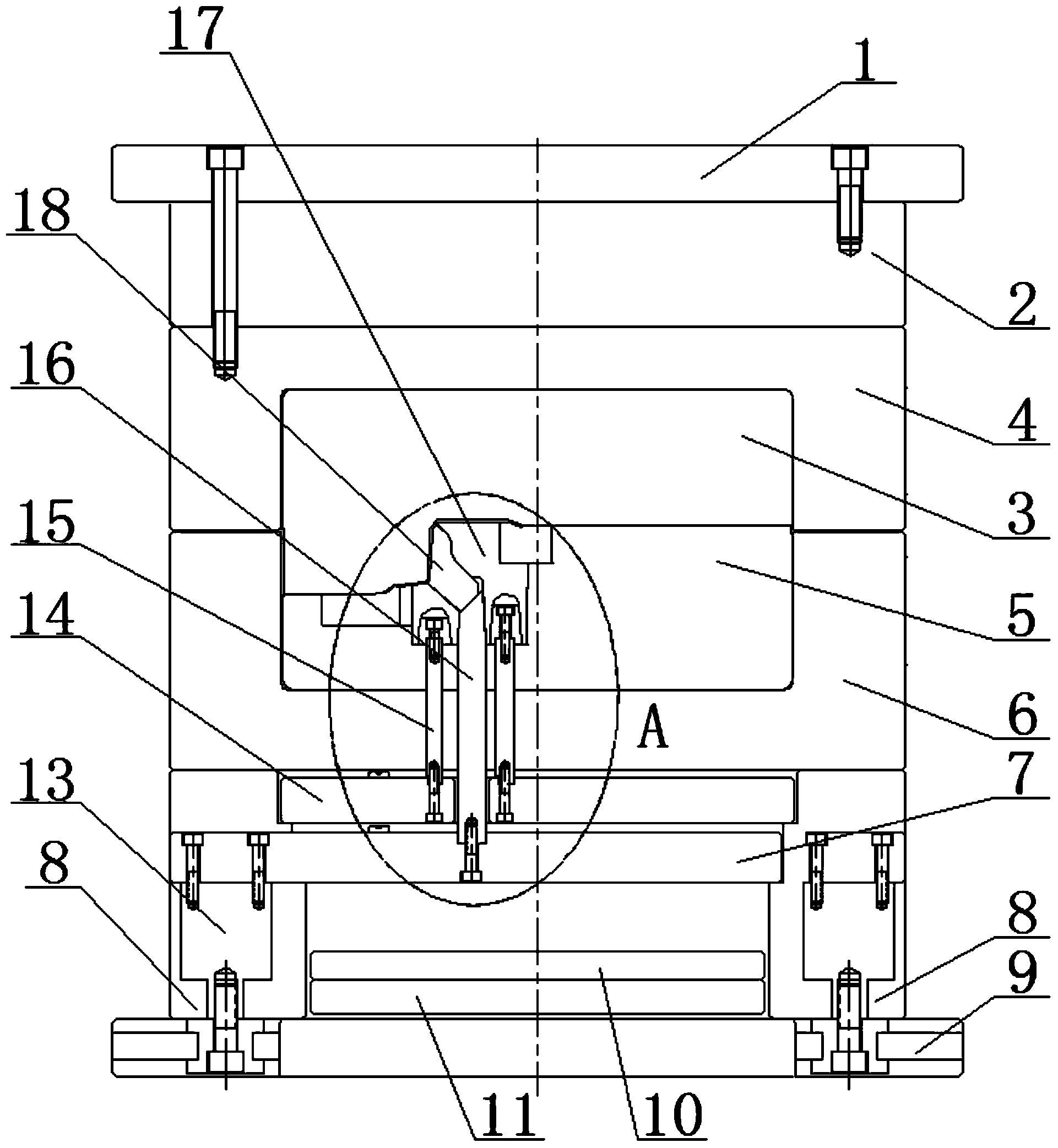

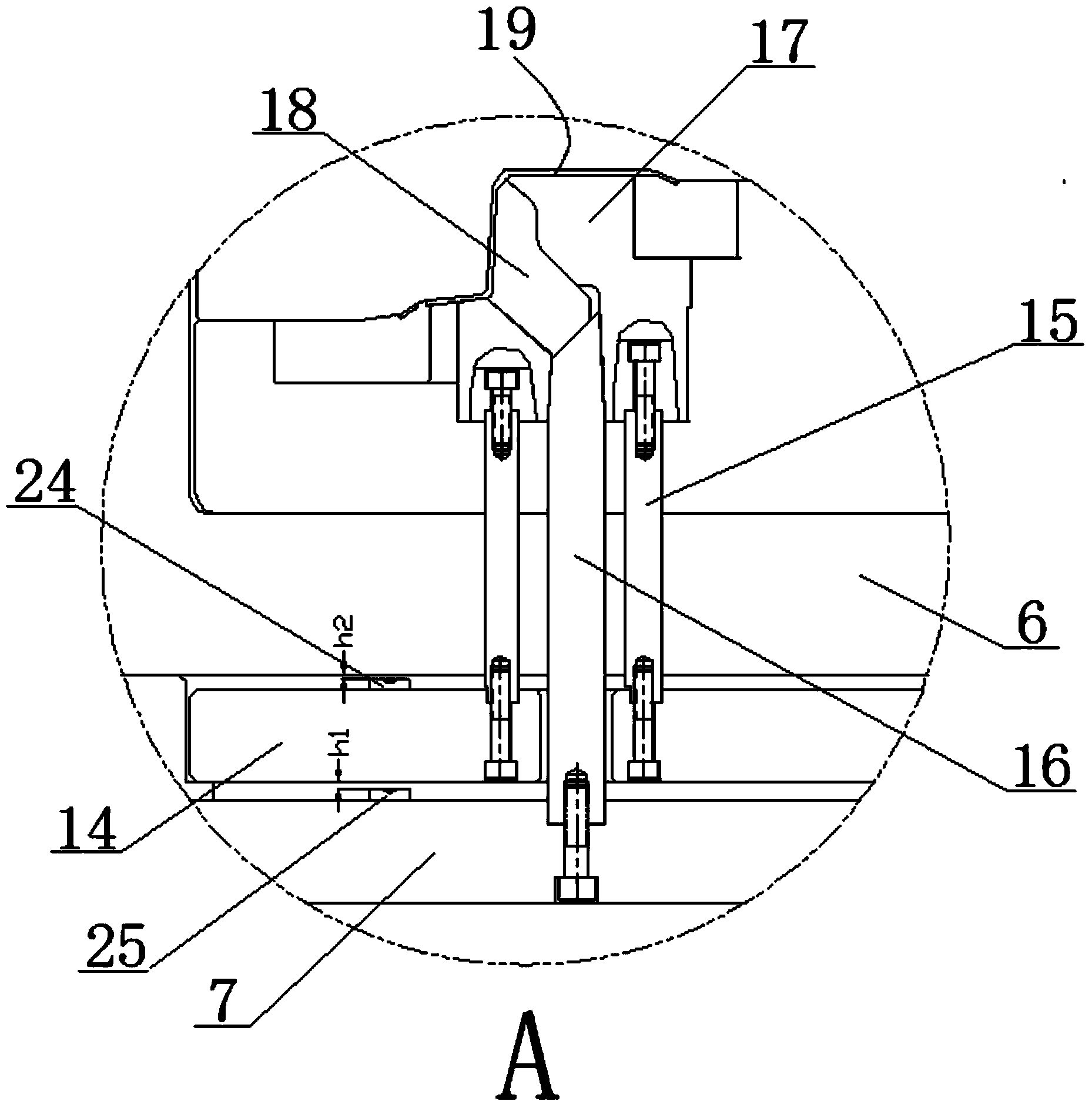

[0027] Such as figure 1 and figure 2 As shown, a large-angle double-material product gate-type secondary injection mold in this embodiment includes: a panel 1, a hot runner plate 2, a front mold main insert 3, a front template 4, a rear mold main insert 5 and a rear mold main insert 5. Template 6 is characterized in that it also includes:

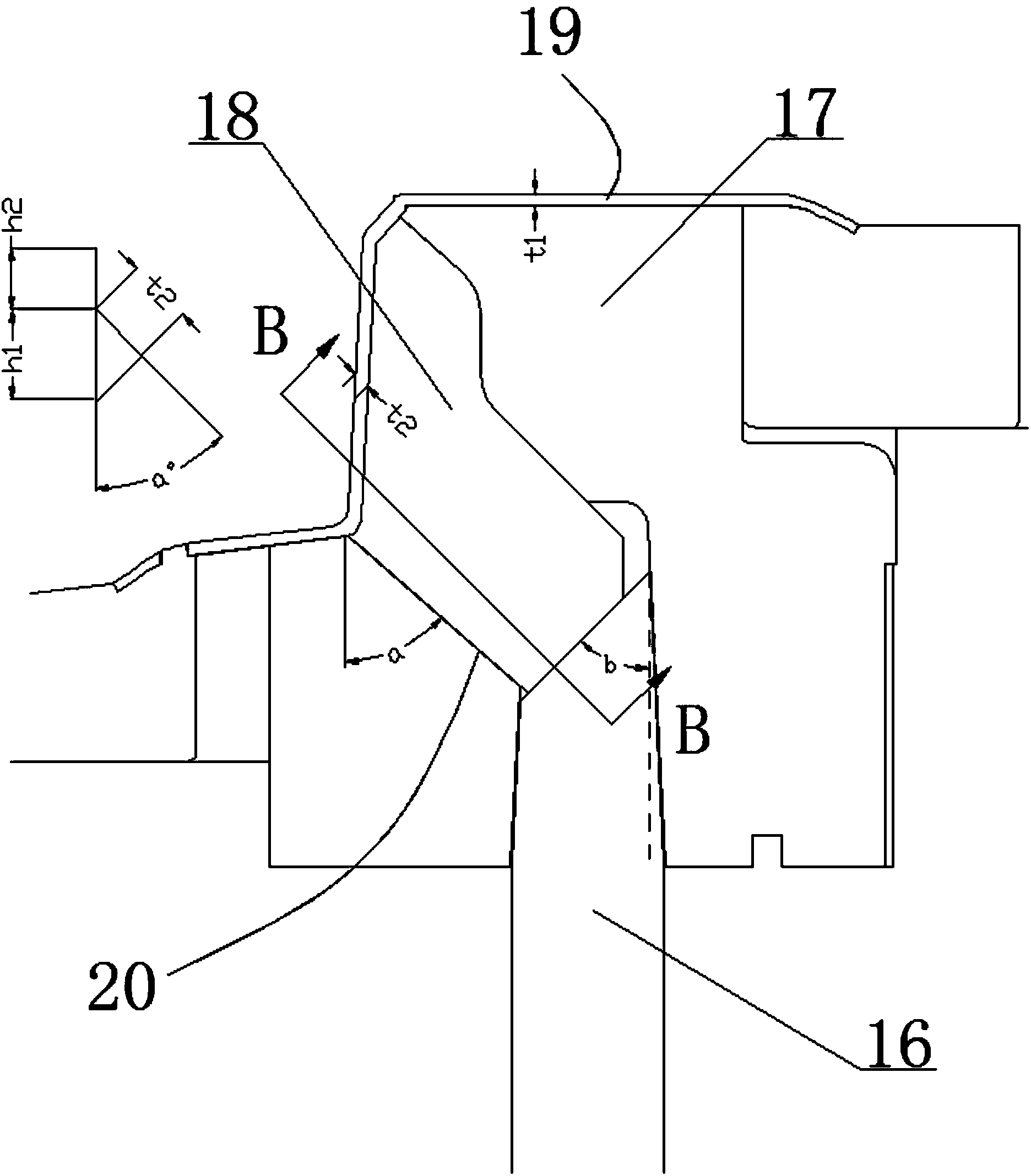

[0028] The first knife 17 has a first chute 20 on it, the length direction of the first chute 20 (the sliding direction of the second knife 18) and the vertical direction are at an angle a, and the setting of the angle a It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com